Protection for wind power station

a protection technology for wind power stations, applied in the direction of motors, single-network parallel feeding arrangements, reactive power adjustment/elimination/compensation, etc., can solve the problems of no use of ups systems for power stations and impact on transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

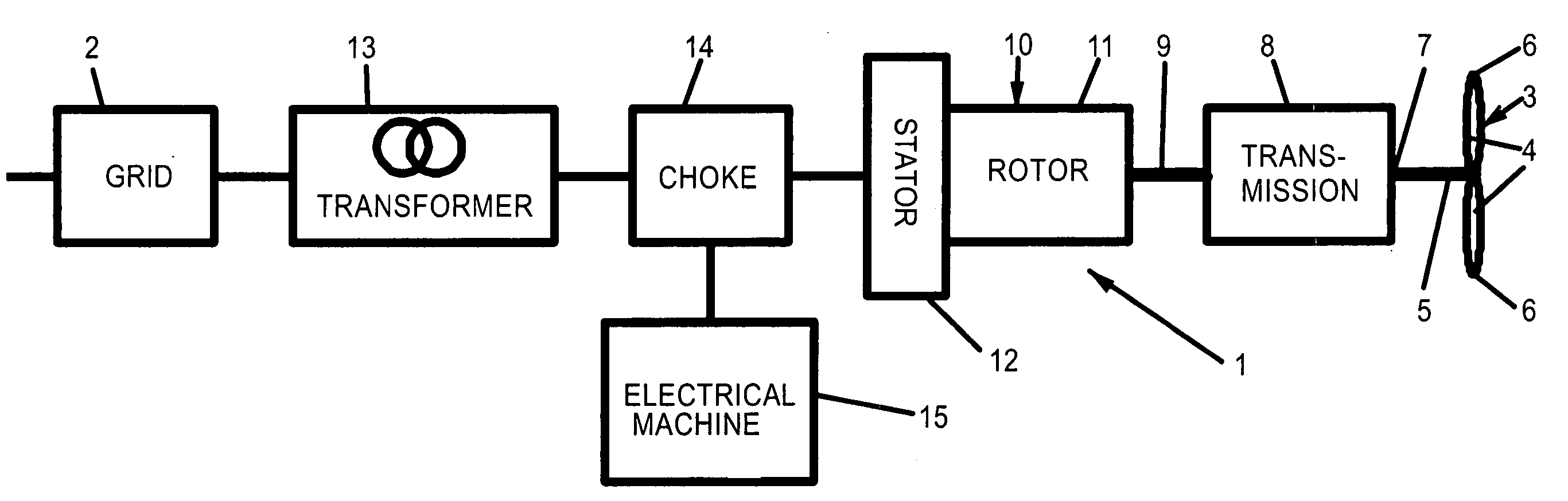

[0023] Referring now in greater detail to the drawings, FIG. 1 illustrates a wind power station 1 connected to a power grid 2. The wind power station 1 includes a wind rotor 3 having at least one, typically 2 or 3 blades 4, each of which being connected to a rotatable shaft 5. Generally, the rotatable shaft 5 is oriented horizontally at a distance to the ground which is in the order of the diameter of the wind rotor 3. Thus, the tips 6 of the blades 4 keep a distance to the ground of about half of the diameter of the wind rotor 3. The rotatable shaft 5 of the wind rotor 3 is mechanically coupled to an input shaft 7 of a transmission 8. The transmission 8 is a fixed ratio transmission increasing the rotational speed of its input shaft7 into a higher output speed of its output shaft 9. In this way the rotational speed of the wind rotor 3 is raised into an operation range of a generator 10, a rotor 11 of which is mechanically coupled to the output shaft 9 of the transmission for rotation

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap