Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Blade accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

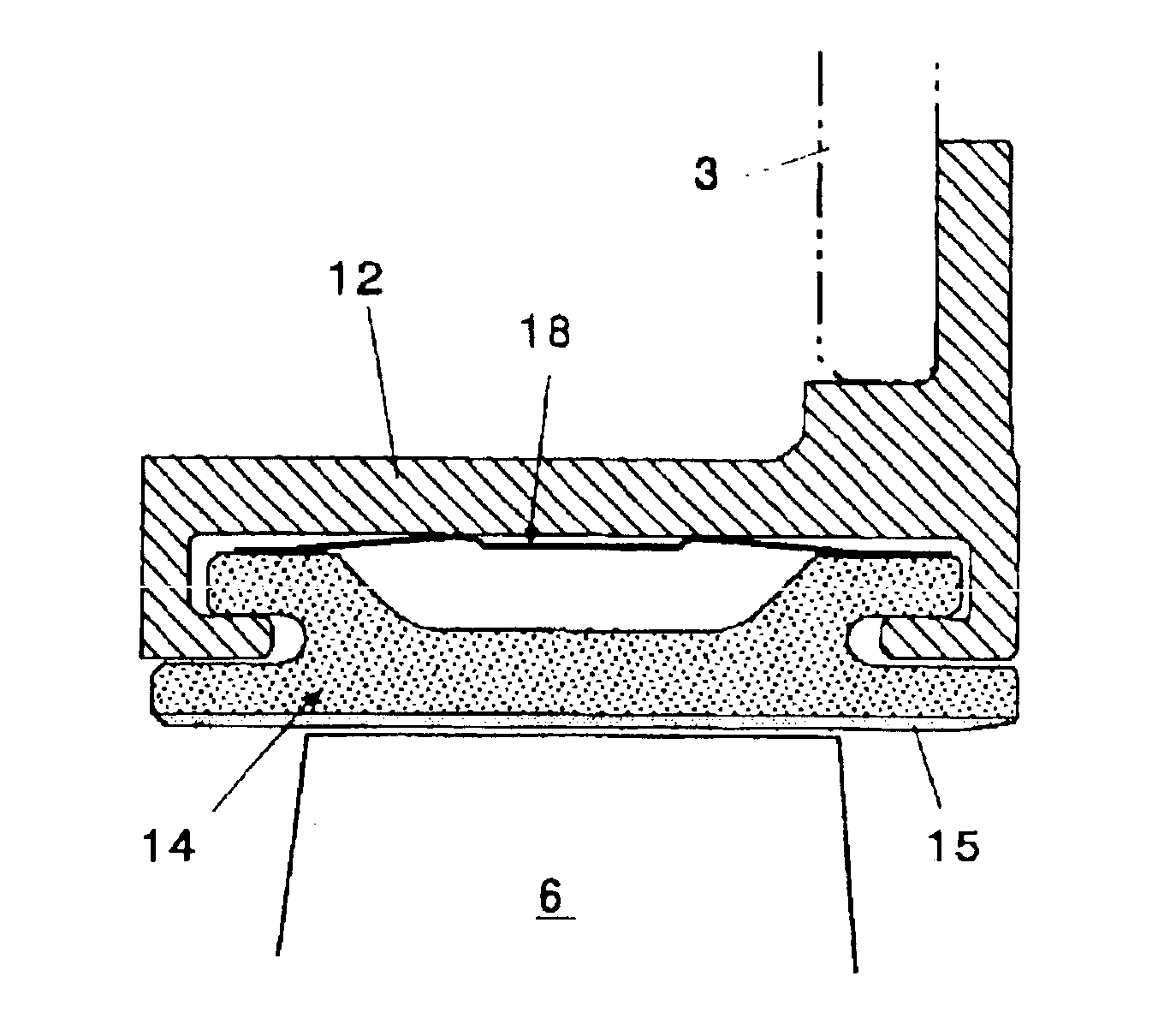

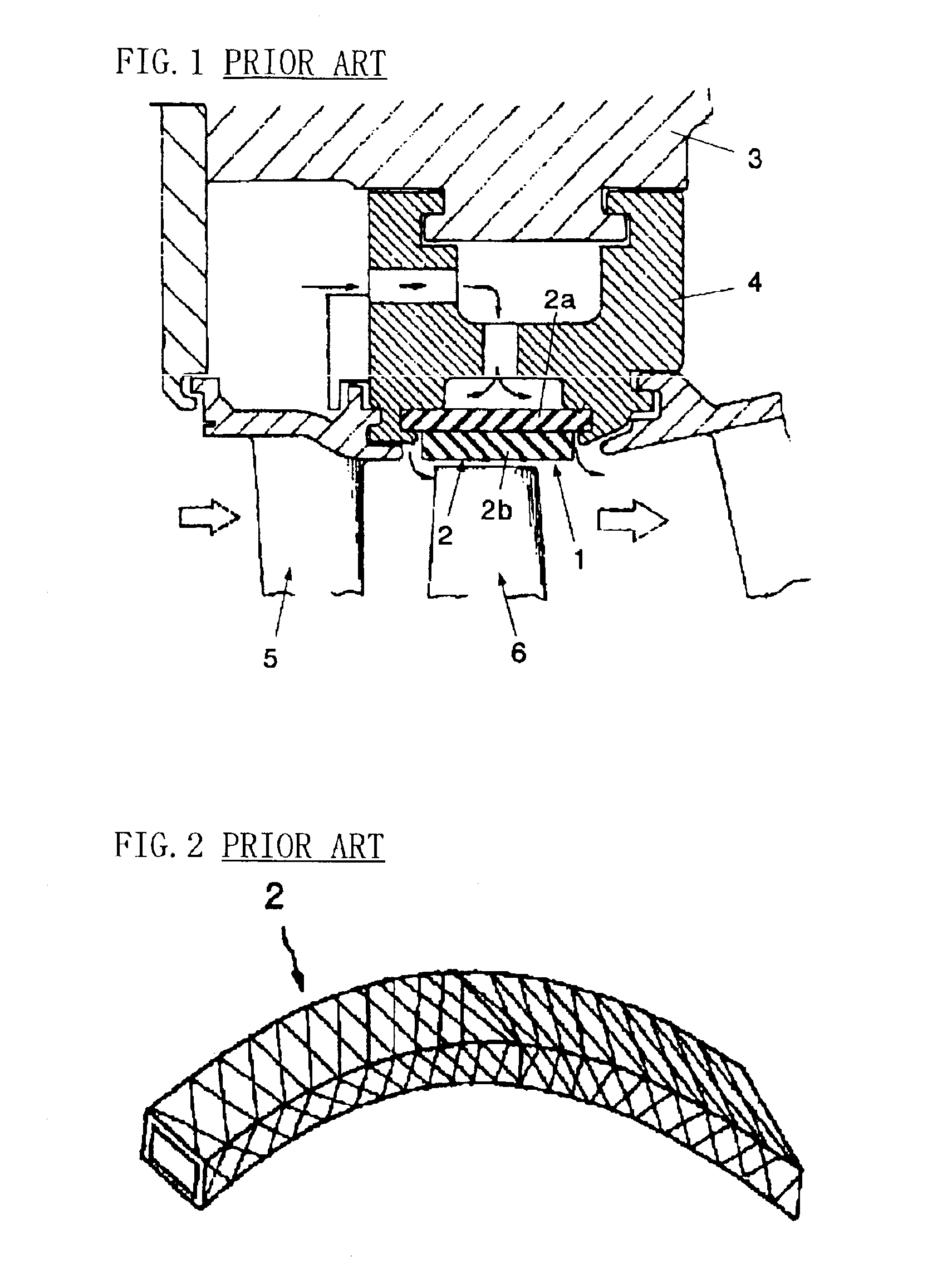

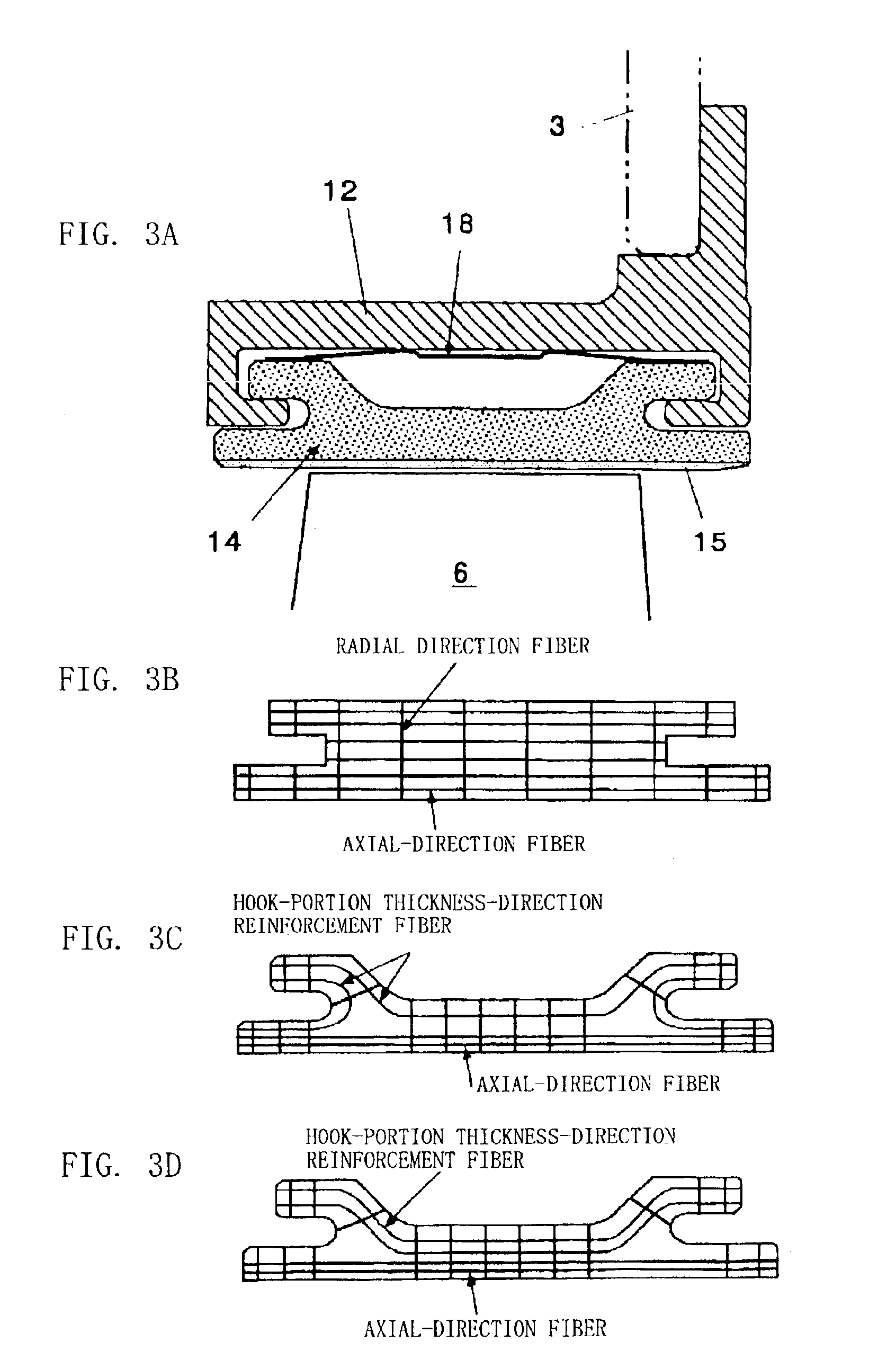

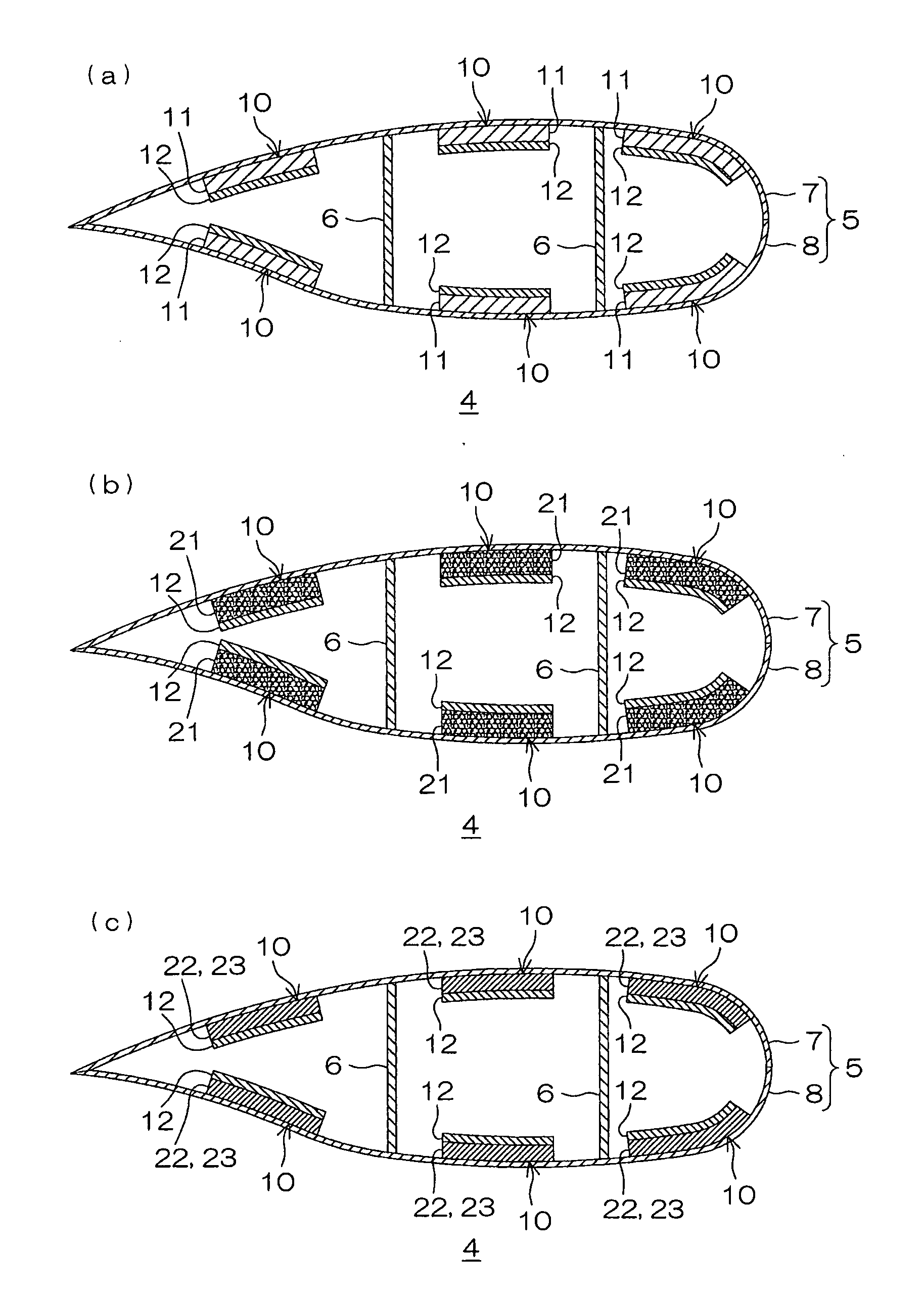

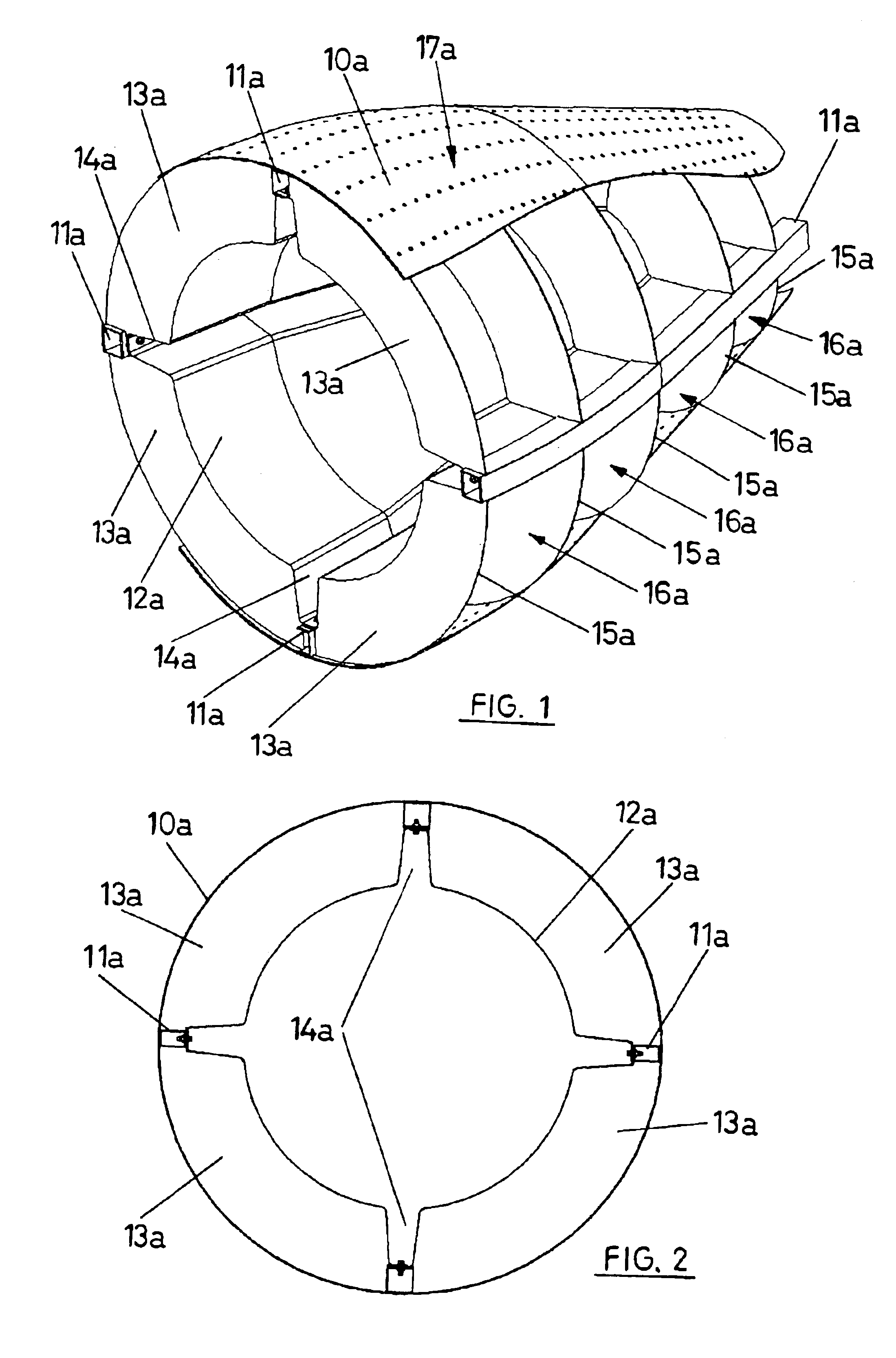

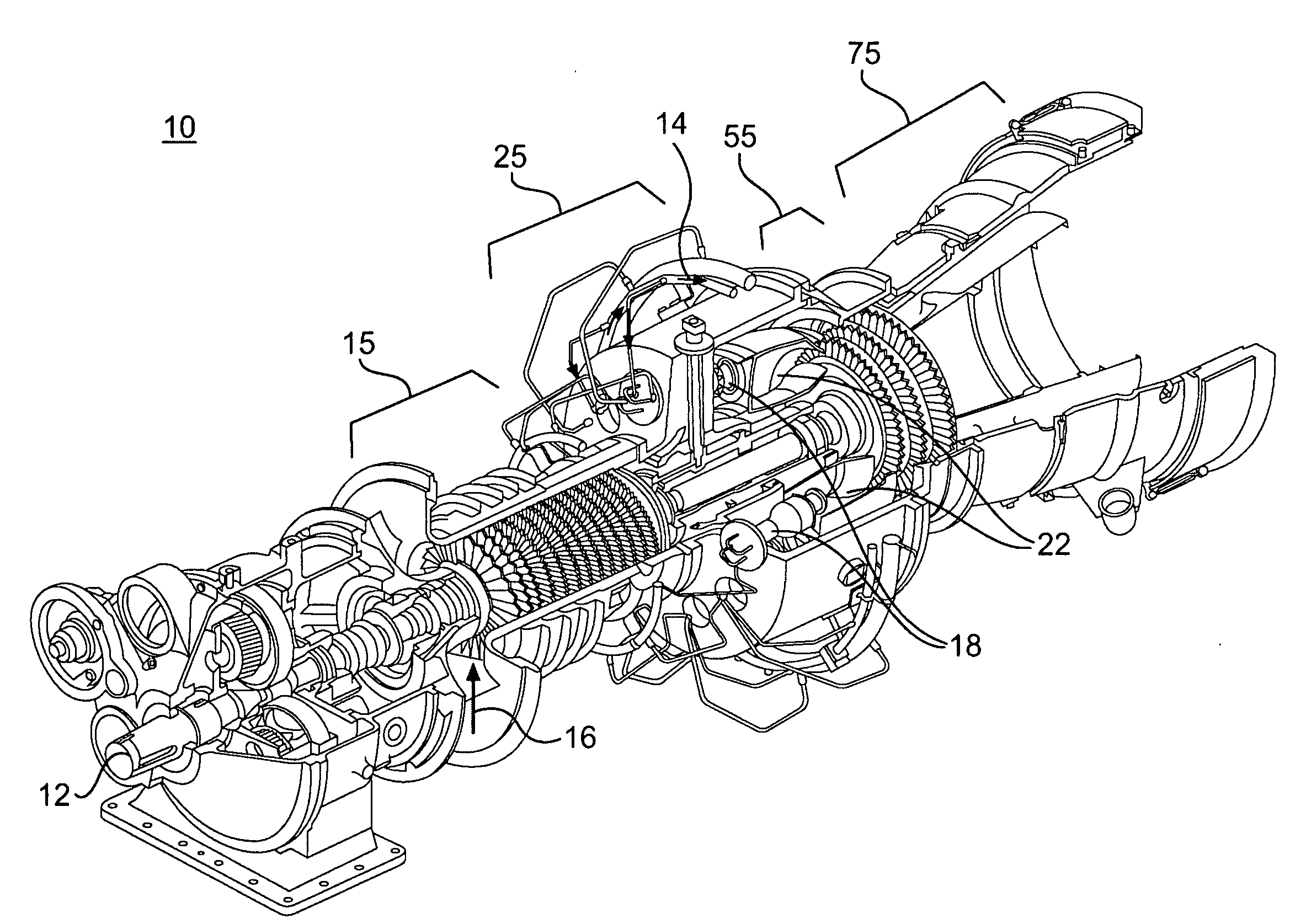

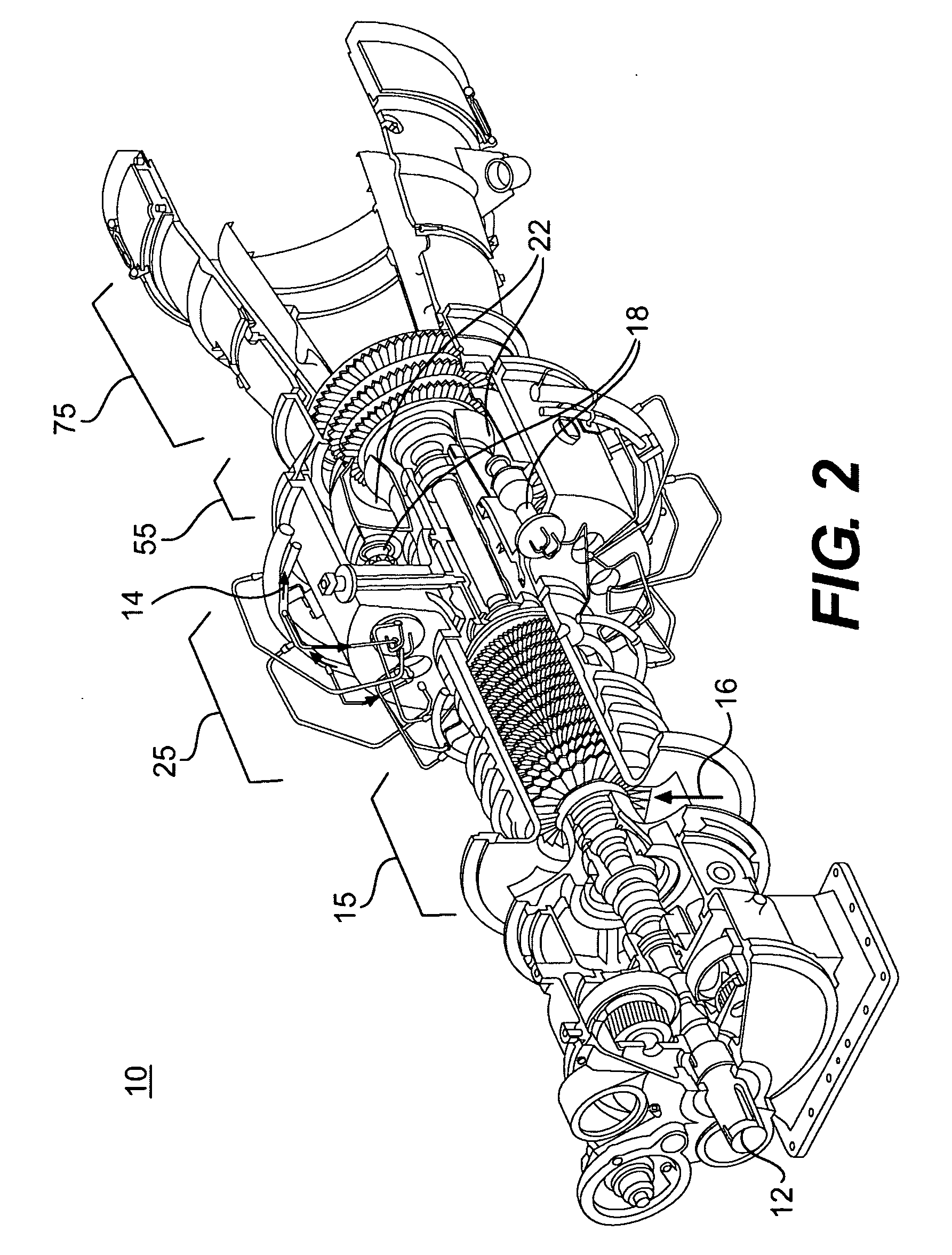

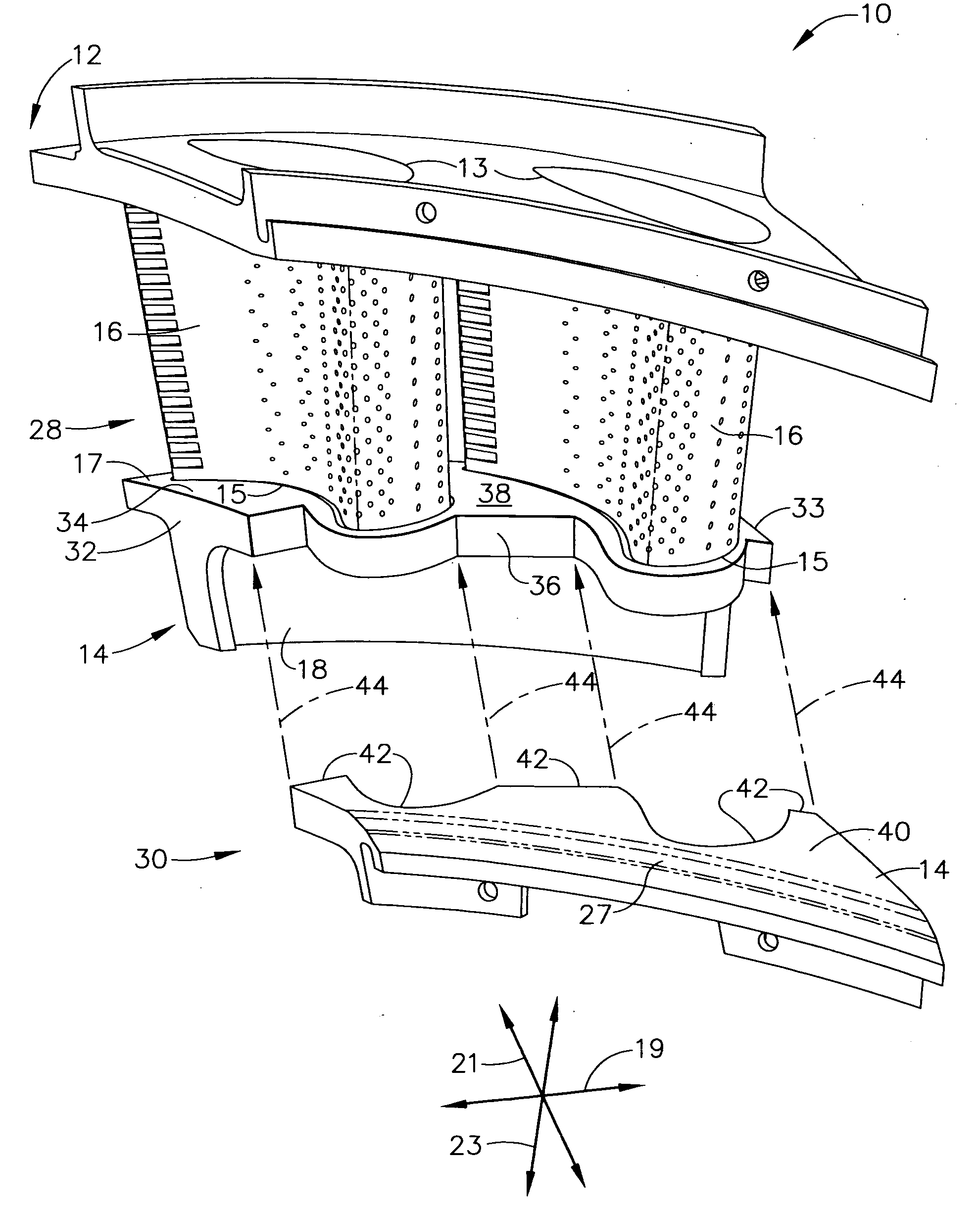

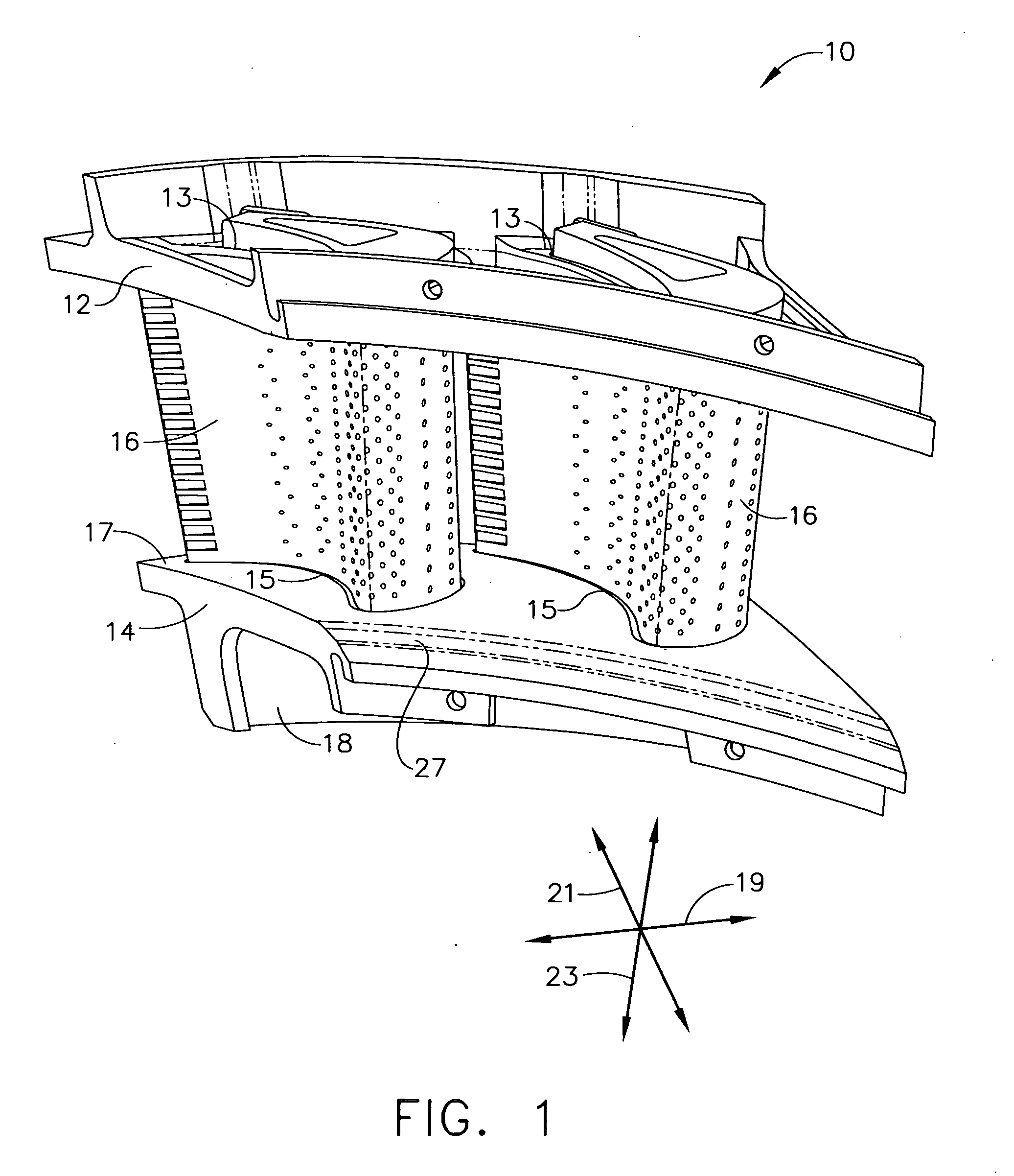

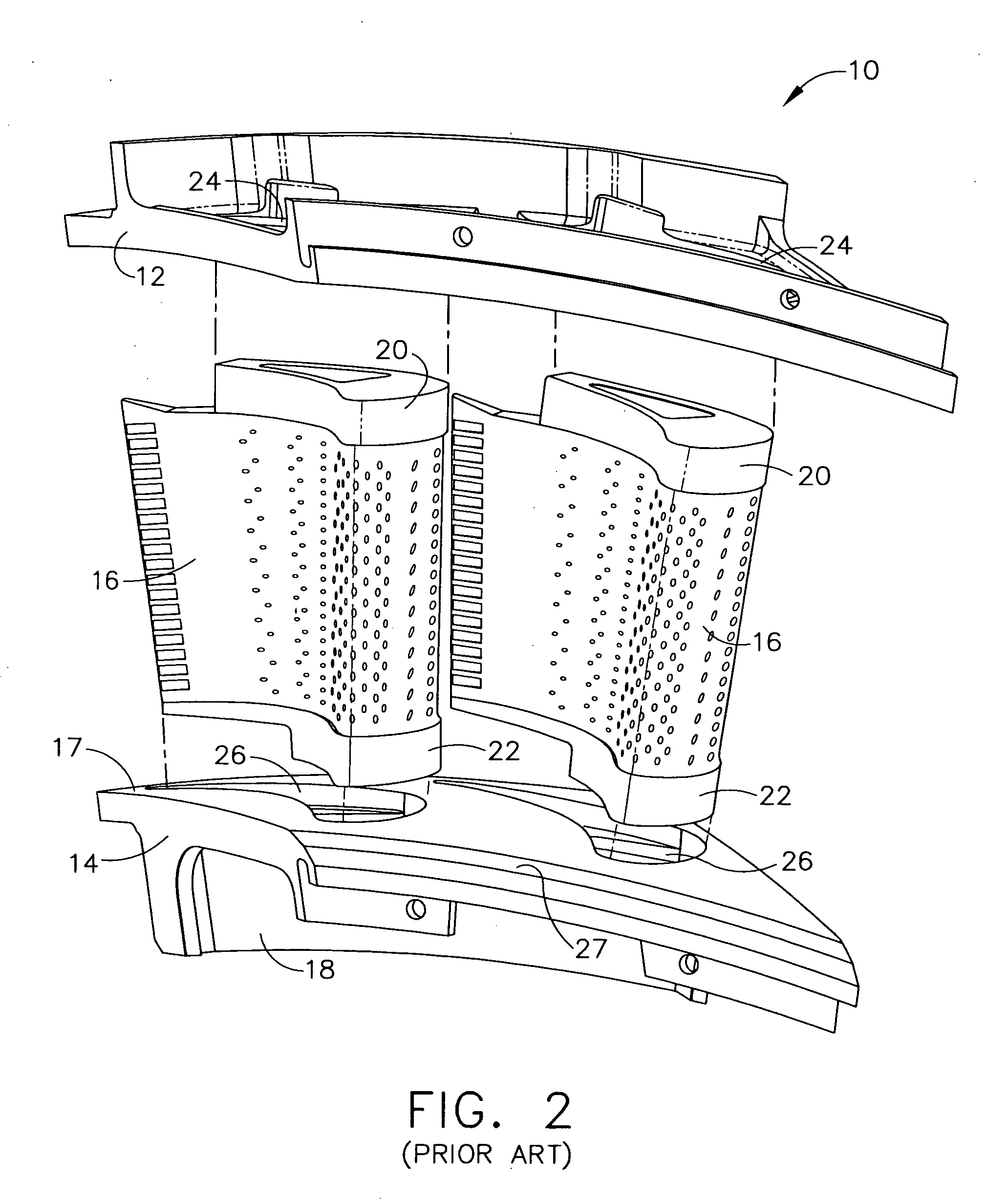

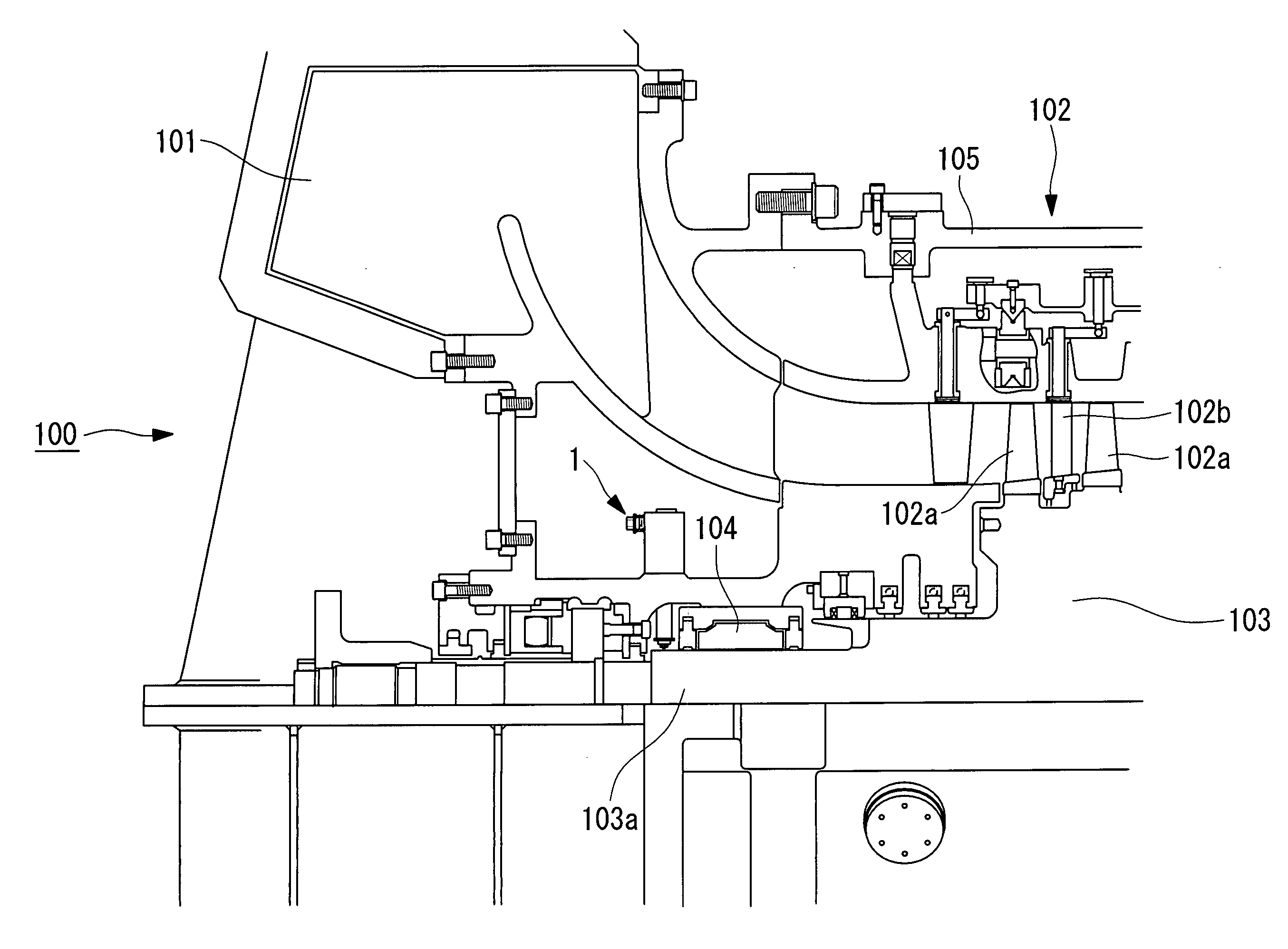

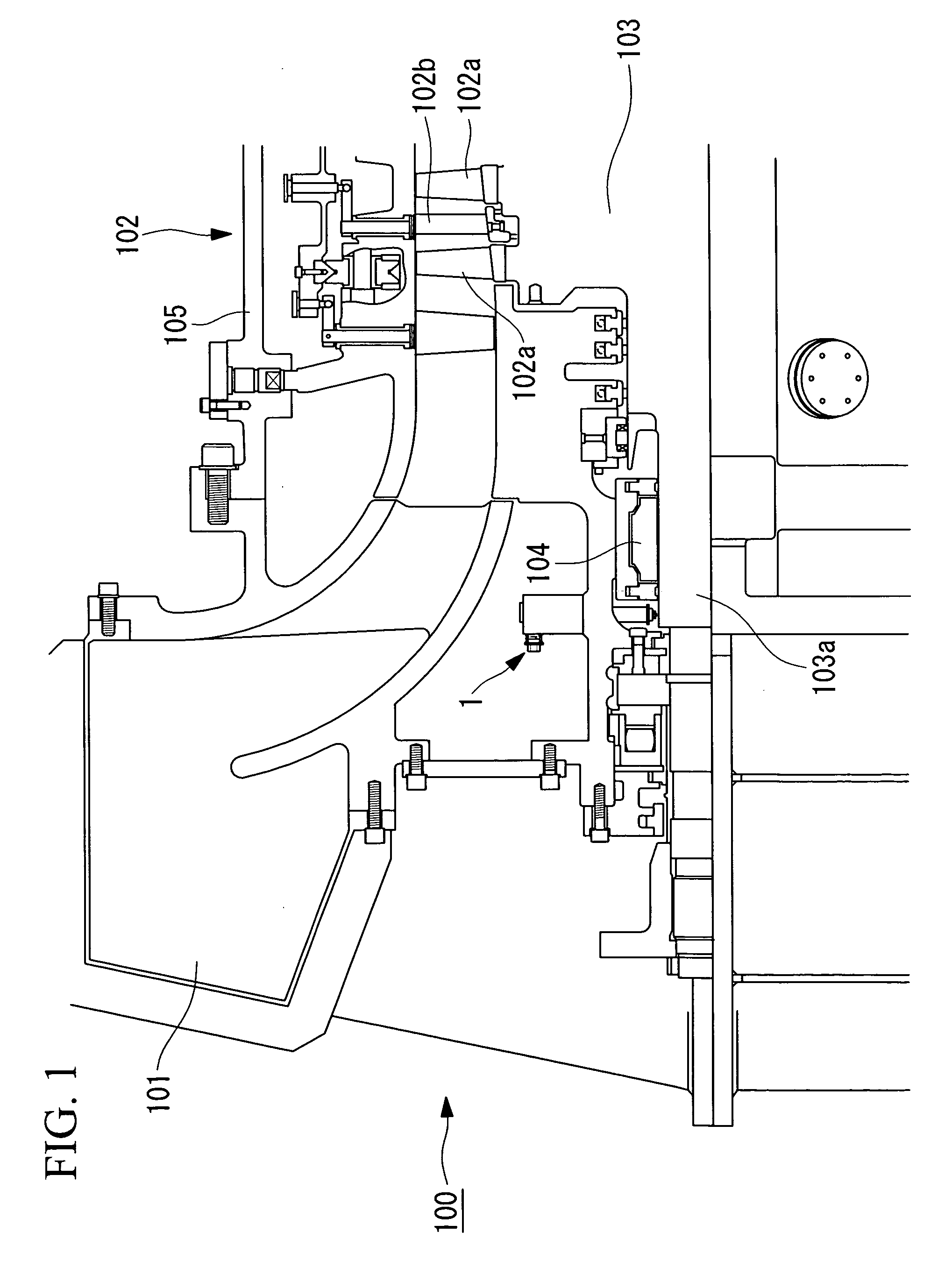

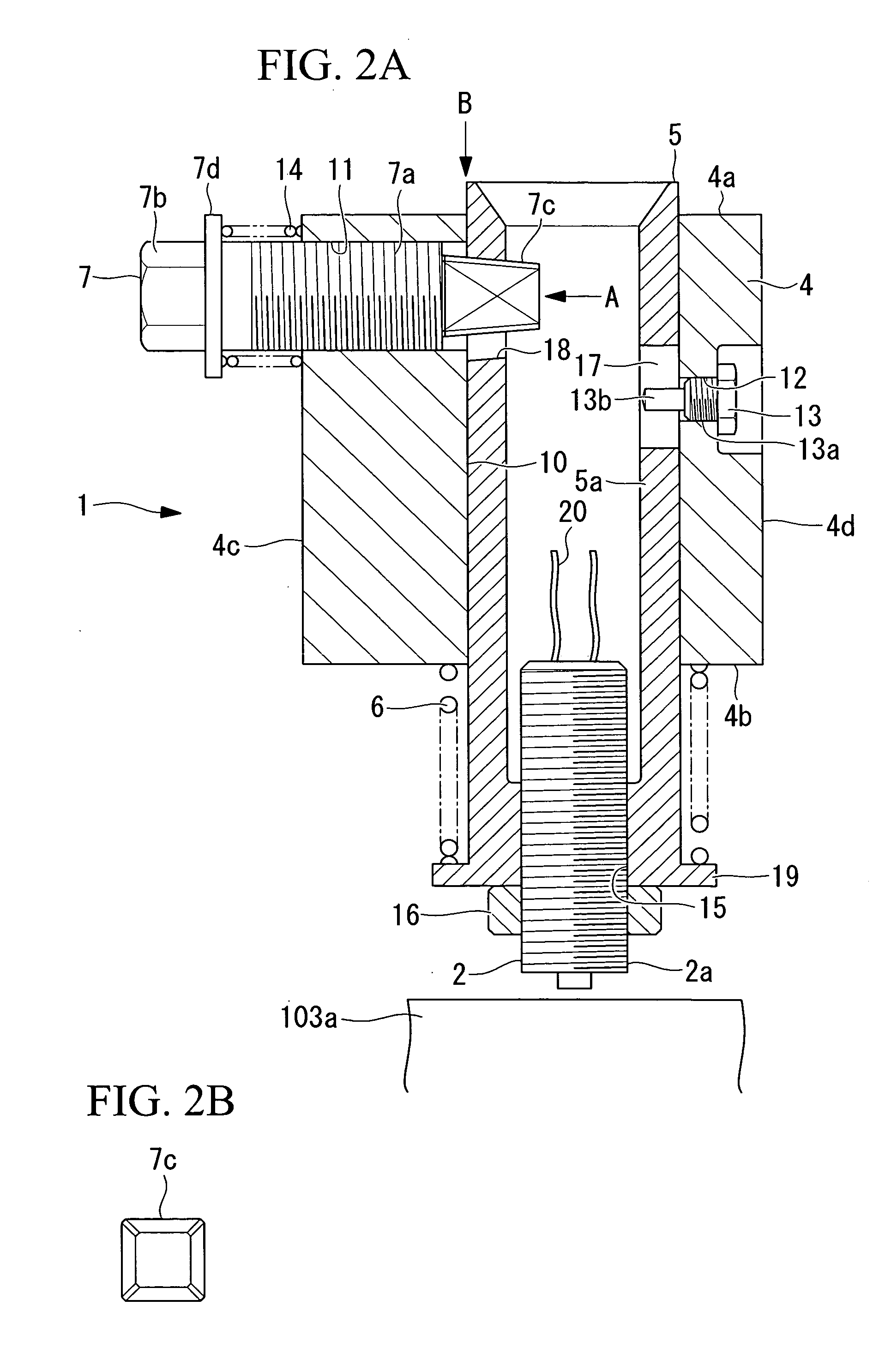

Gas turbine shroud structure

InactiveUS6932566B2Prevent generation of high thermal stressEnhance gas turbine capabilityPump componentsBlade accessoriesCeramic compositeEngineering

Owner:IHI CORP

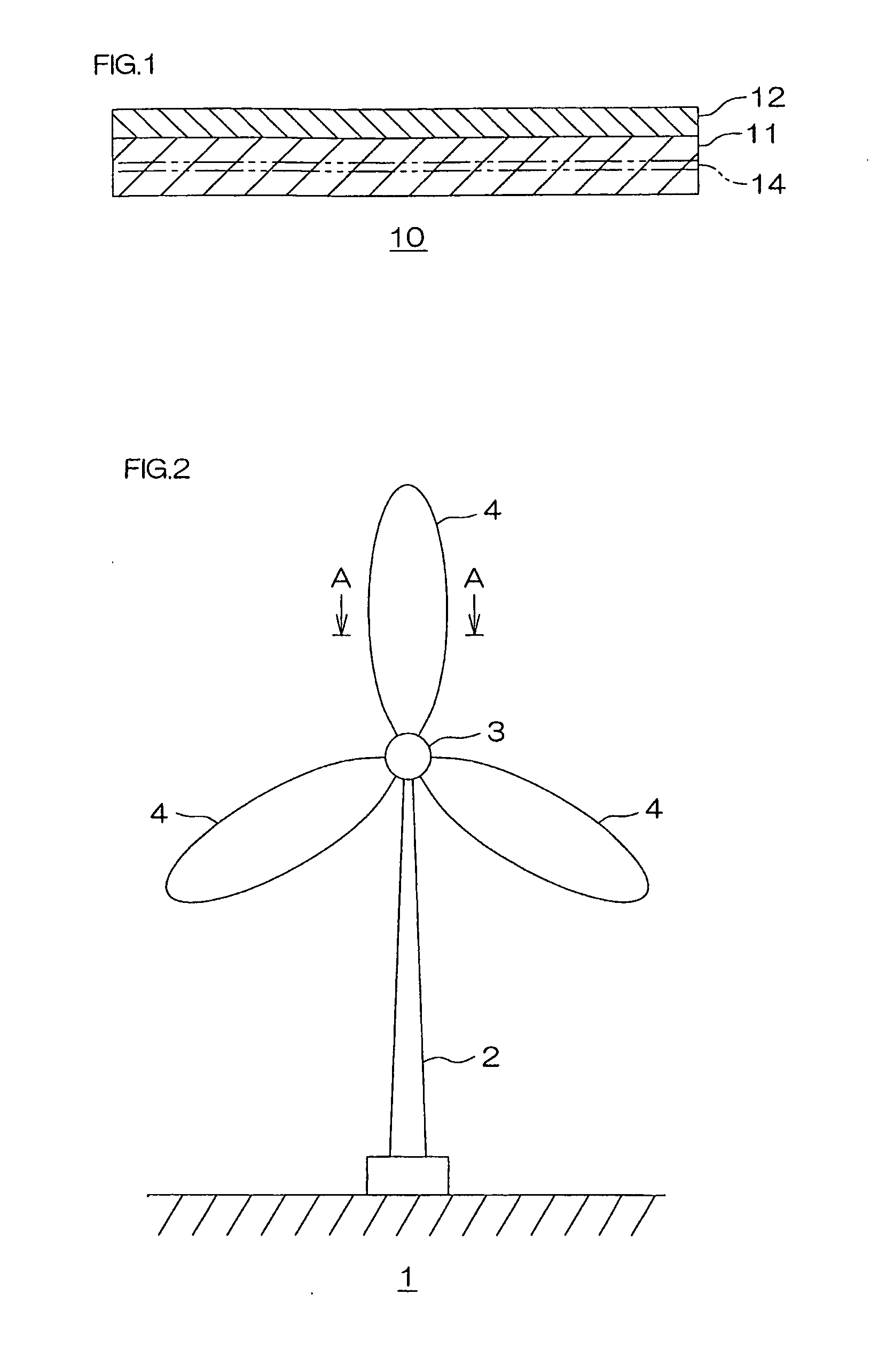

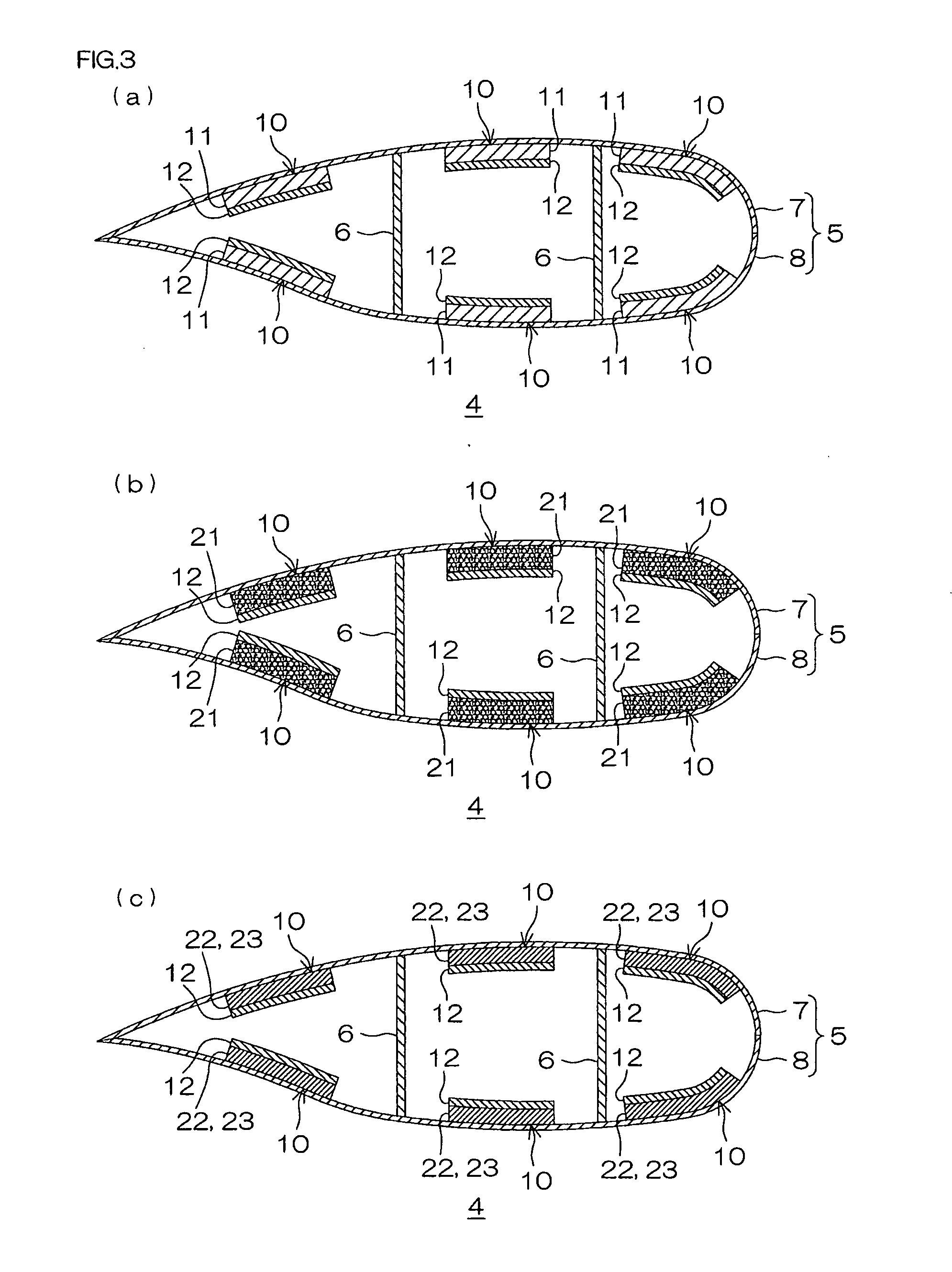

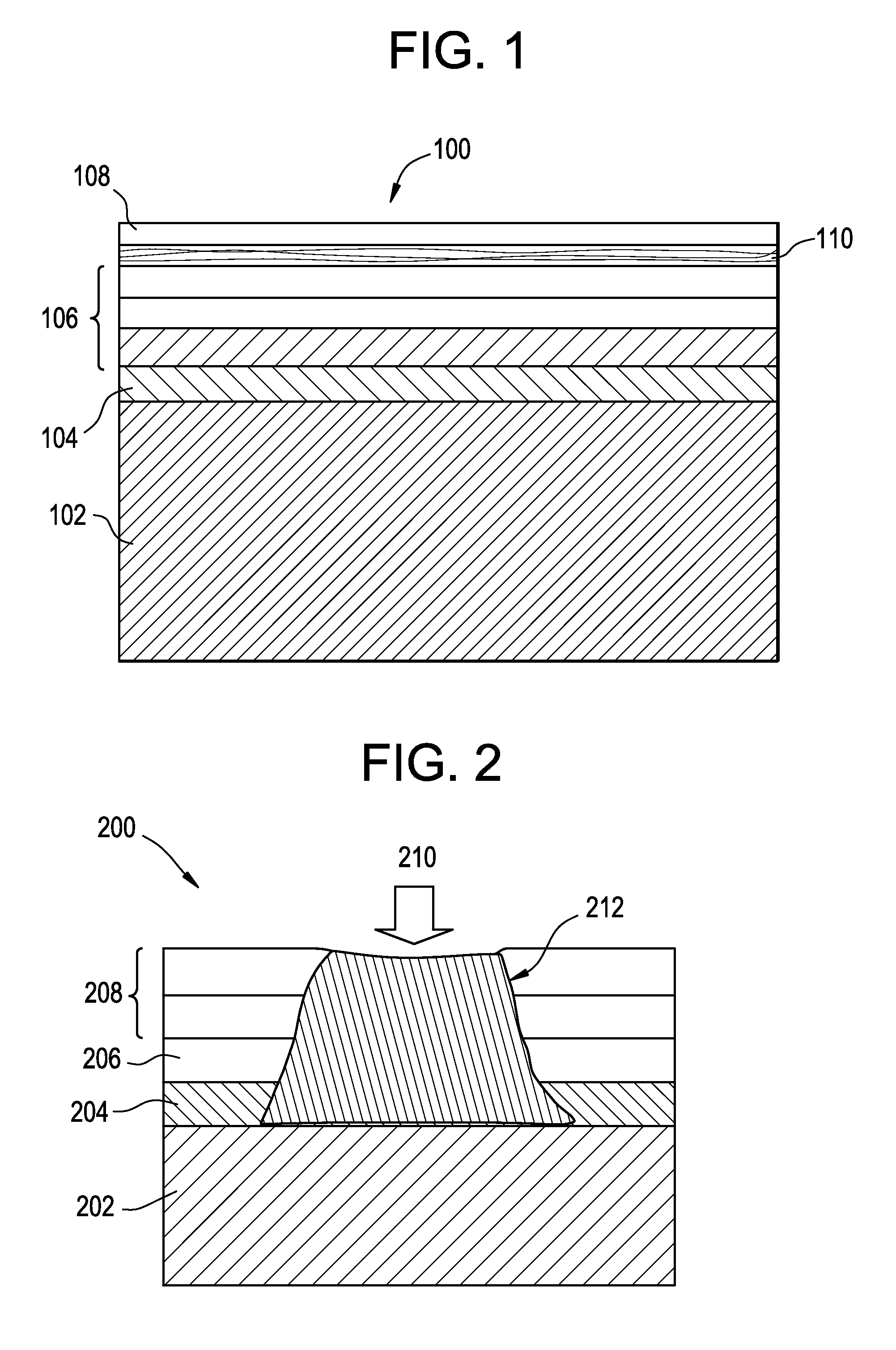

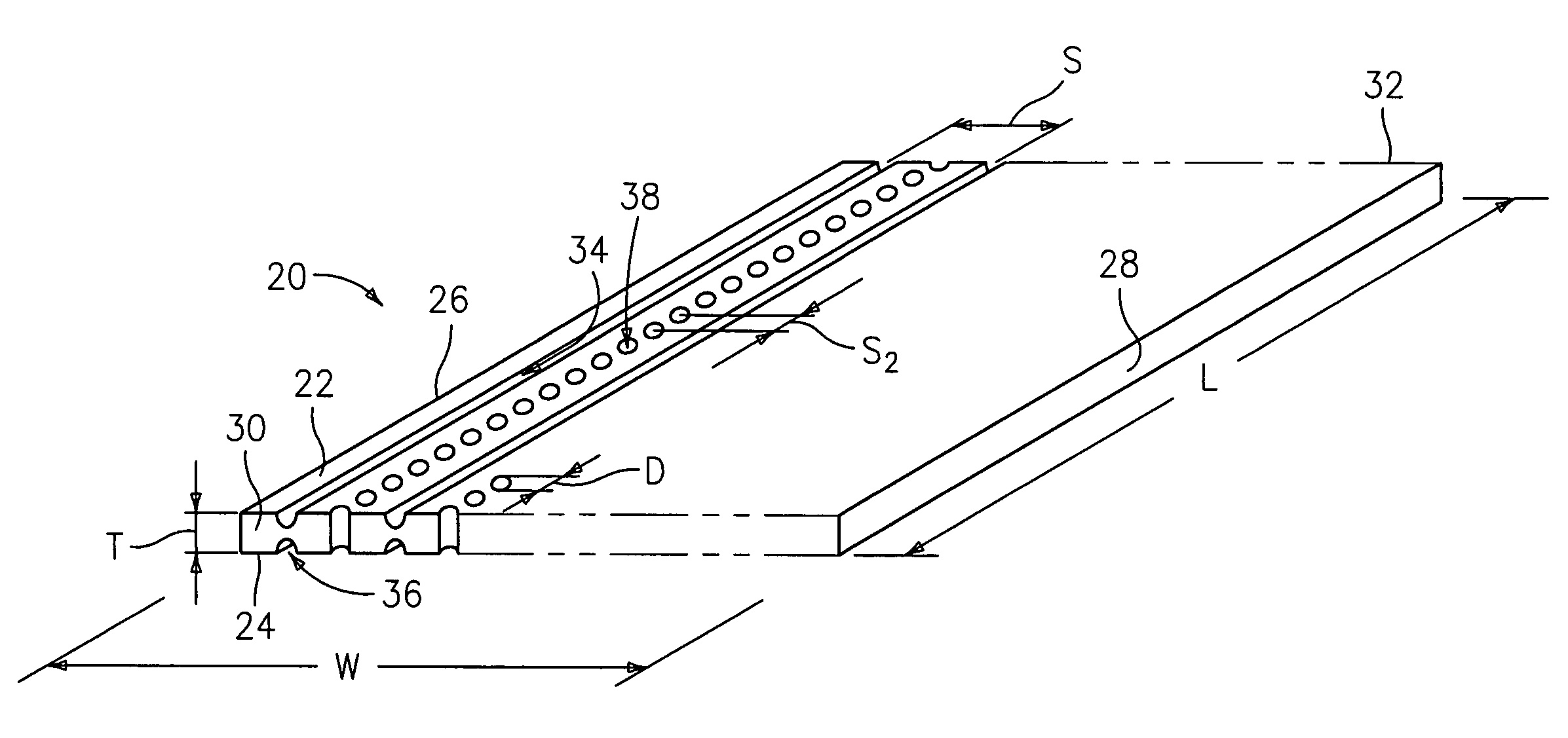

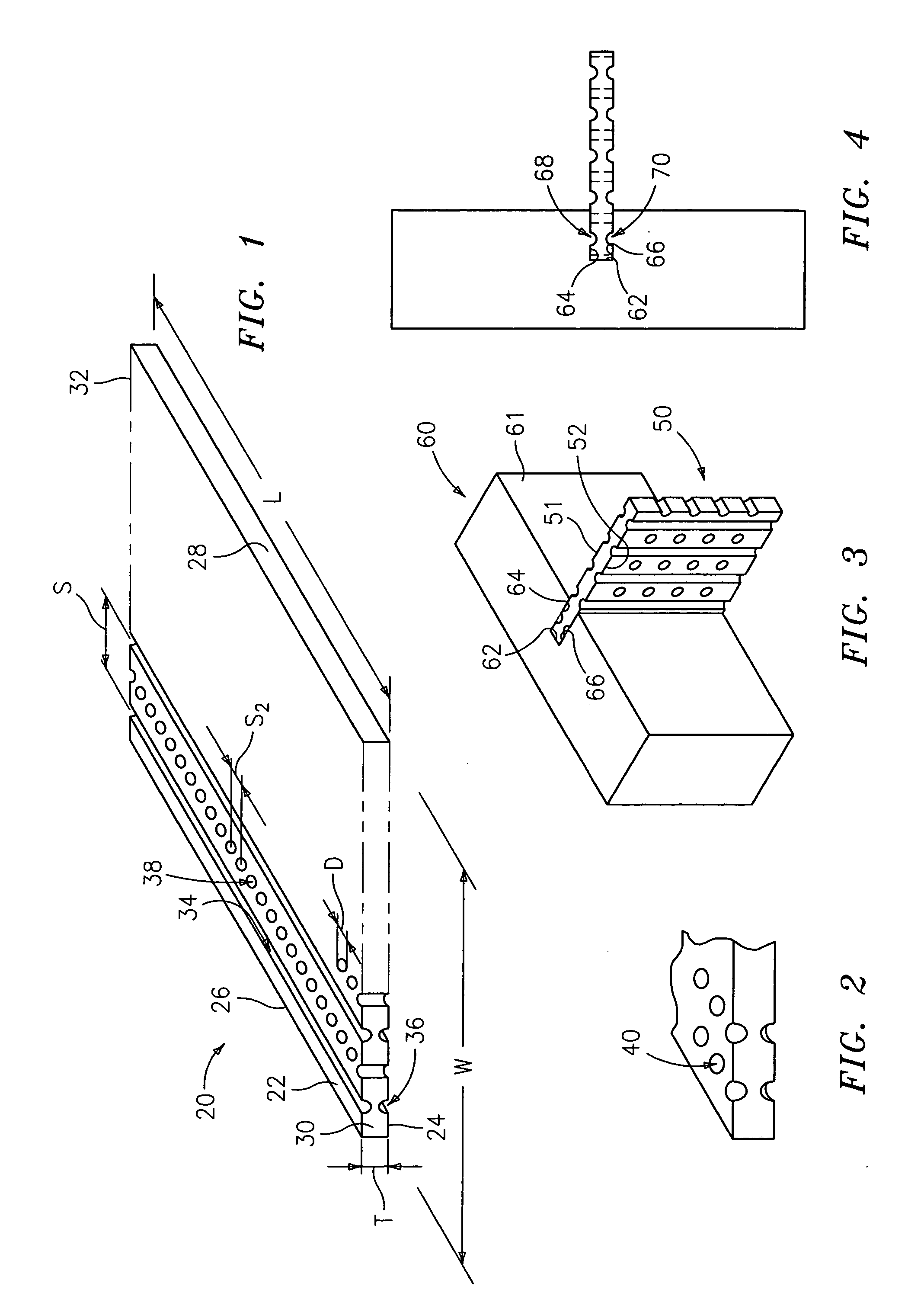

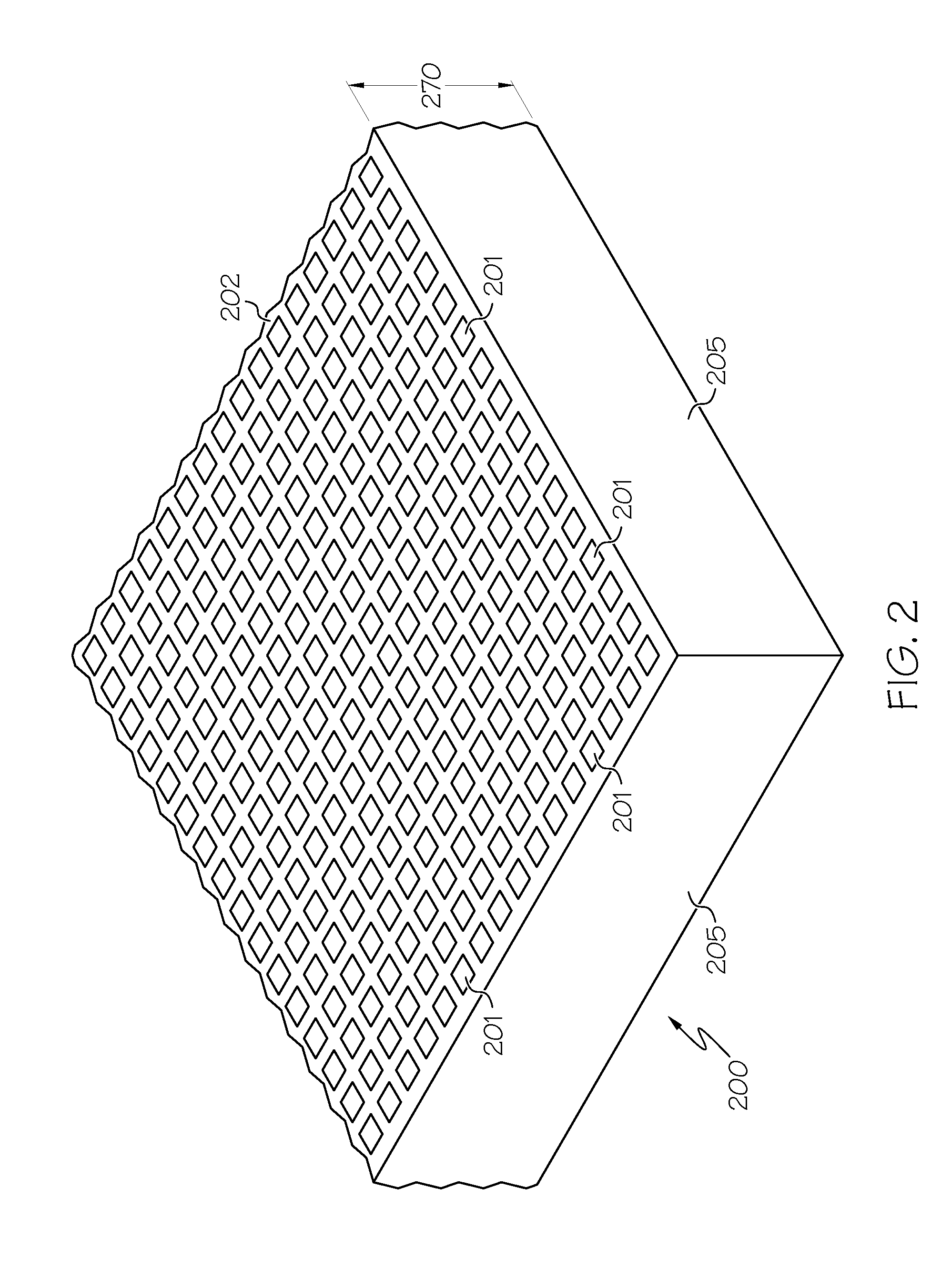

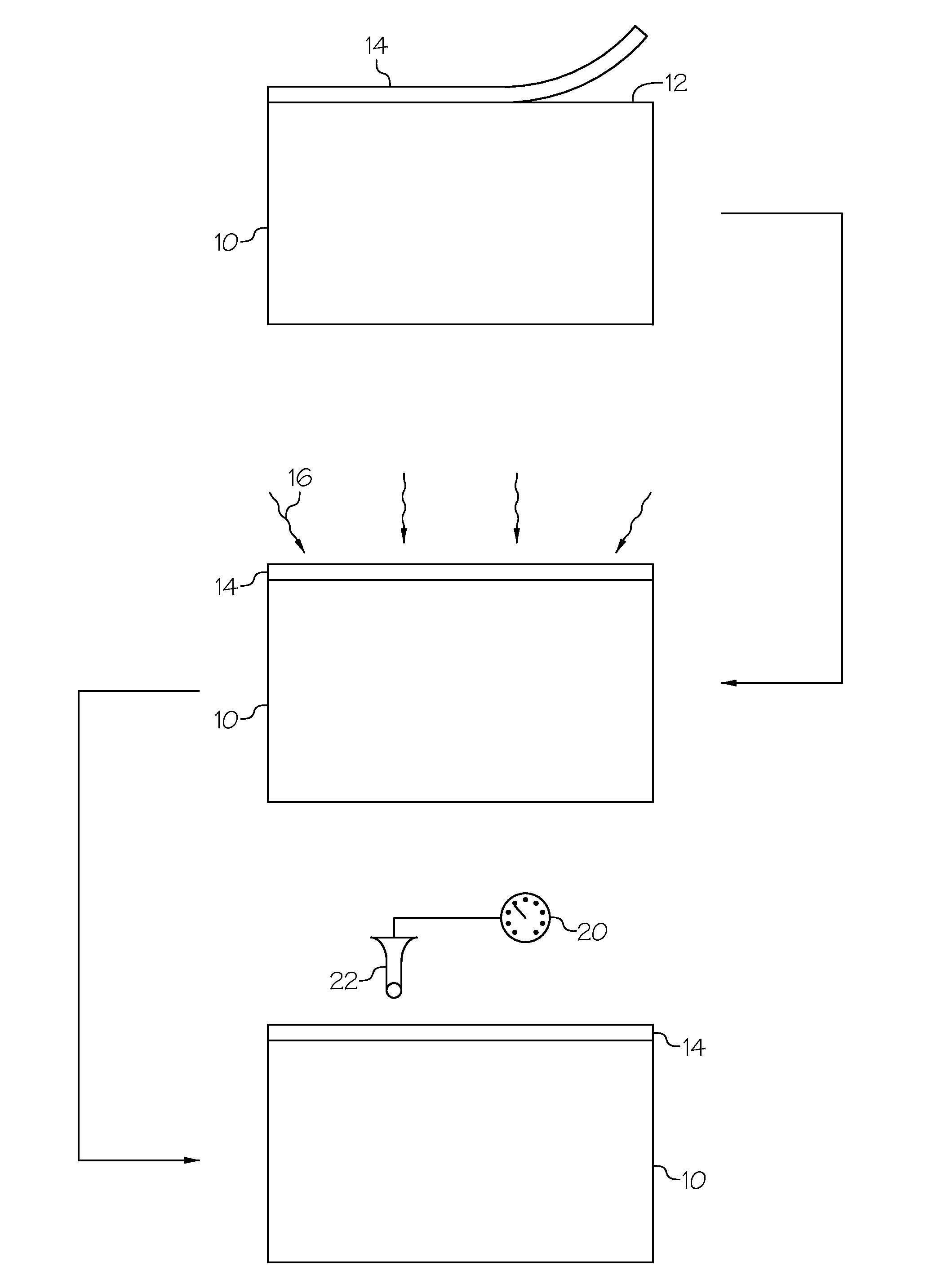

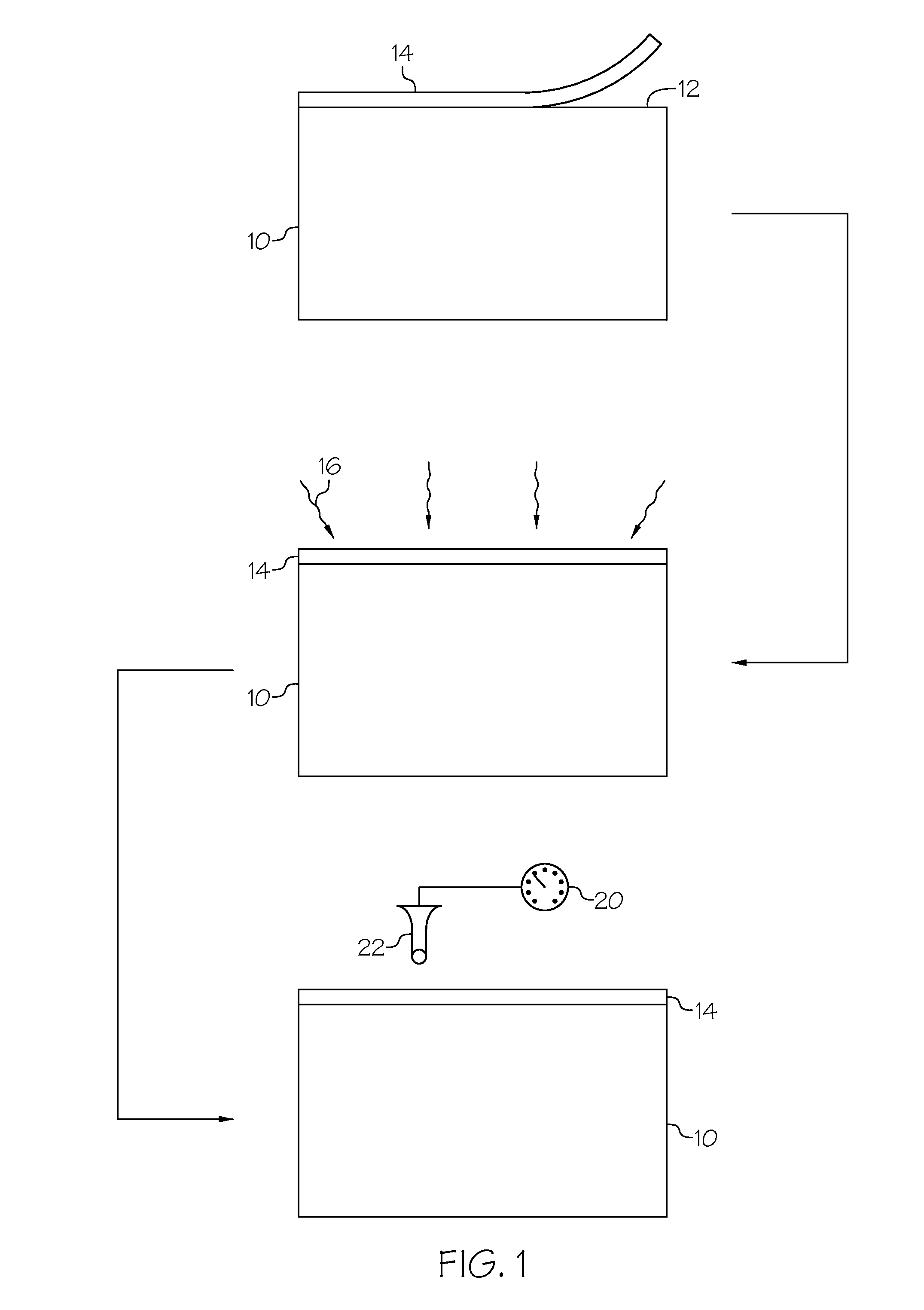

Reinforcing sheet for wind power generator blades, reinforcing structure of wind power generator blade, wind power generator, method for reinforcing the wind power generator blade

InactiveUS20110031758A1Easily and sufficiently reinforceRigidity can be easily and reliablyPropellersReaction enginesWind forceElectric generator

Owner:NITTO DENKO CORP

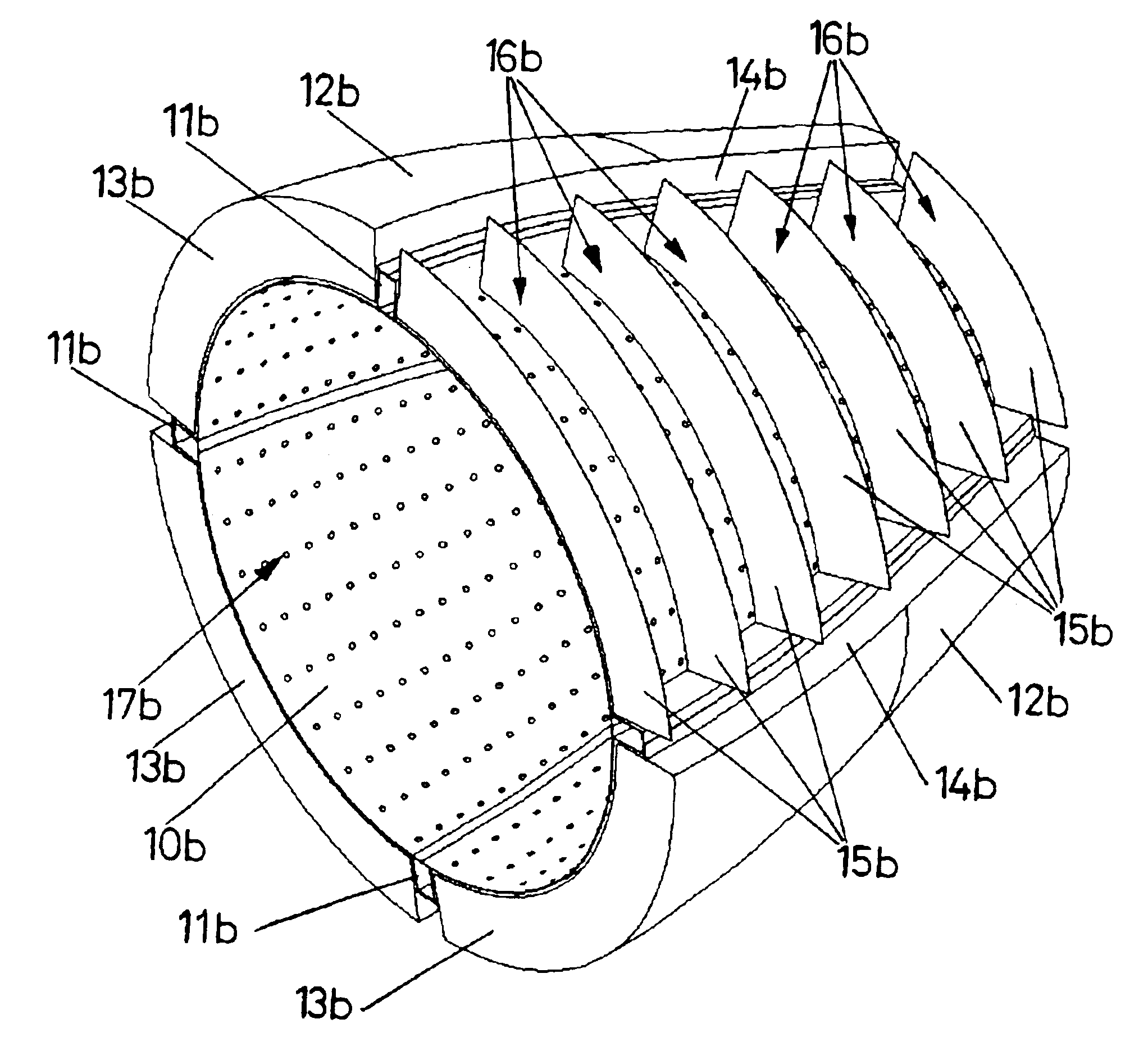

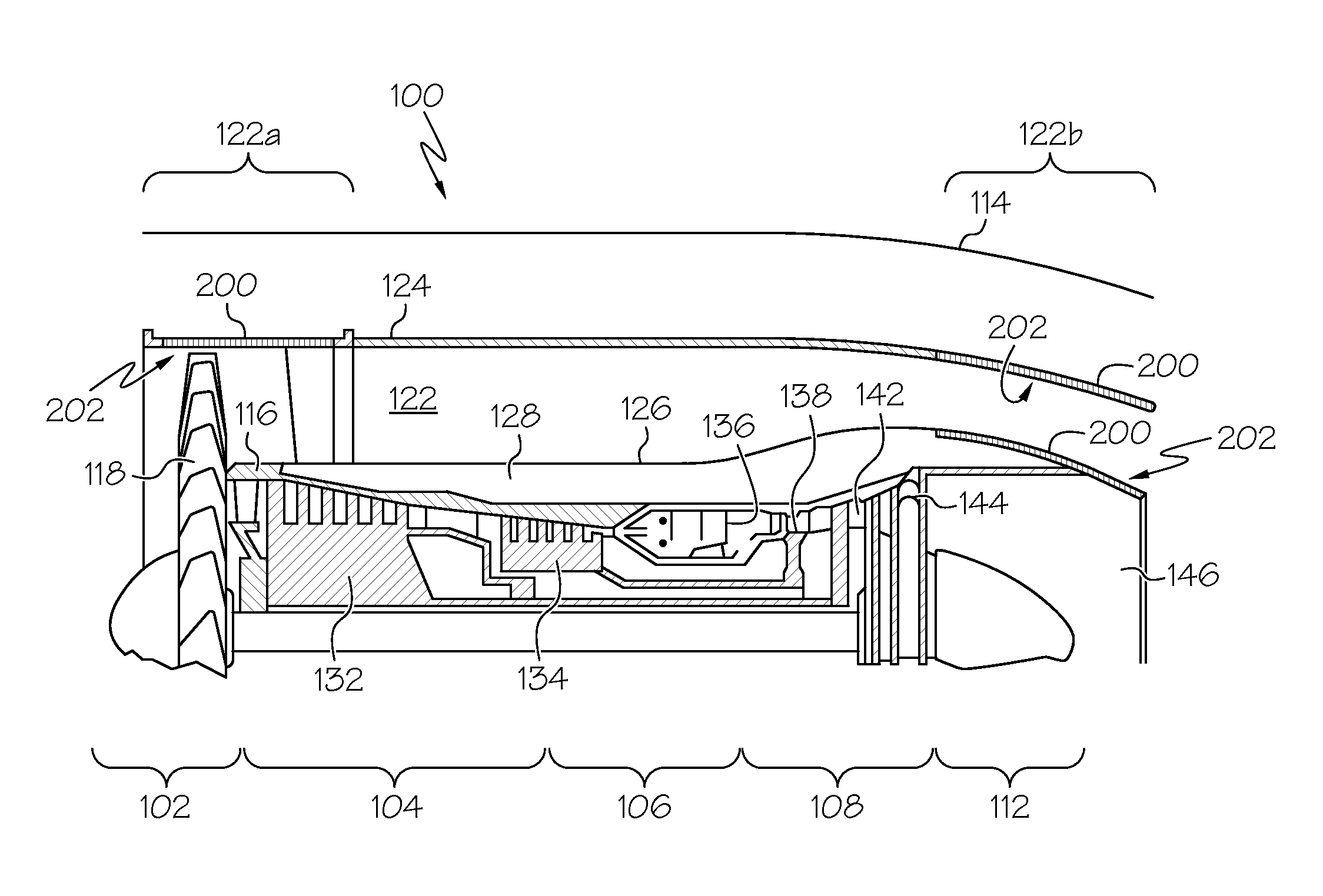

Noise reduction conduit for static components in aircraft engines

InactiveUS6935834B2Light structural solutionReduce thicknessPump componentsBlade accessoriesNoise reductionGas turbines

Owner:SENER ING Y SISTEMAS

Gas turbine airfoil trailing edge corner

Owner:SIEMENS ENERGY INC

Surface-aided melt infiltration for producing a ceramic matrix composite

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

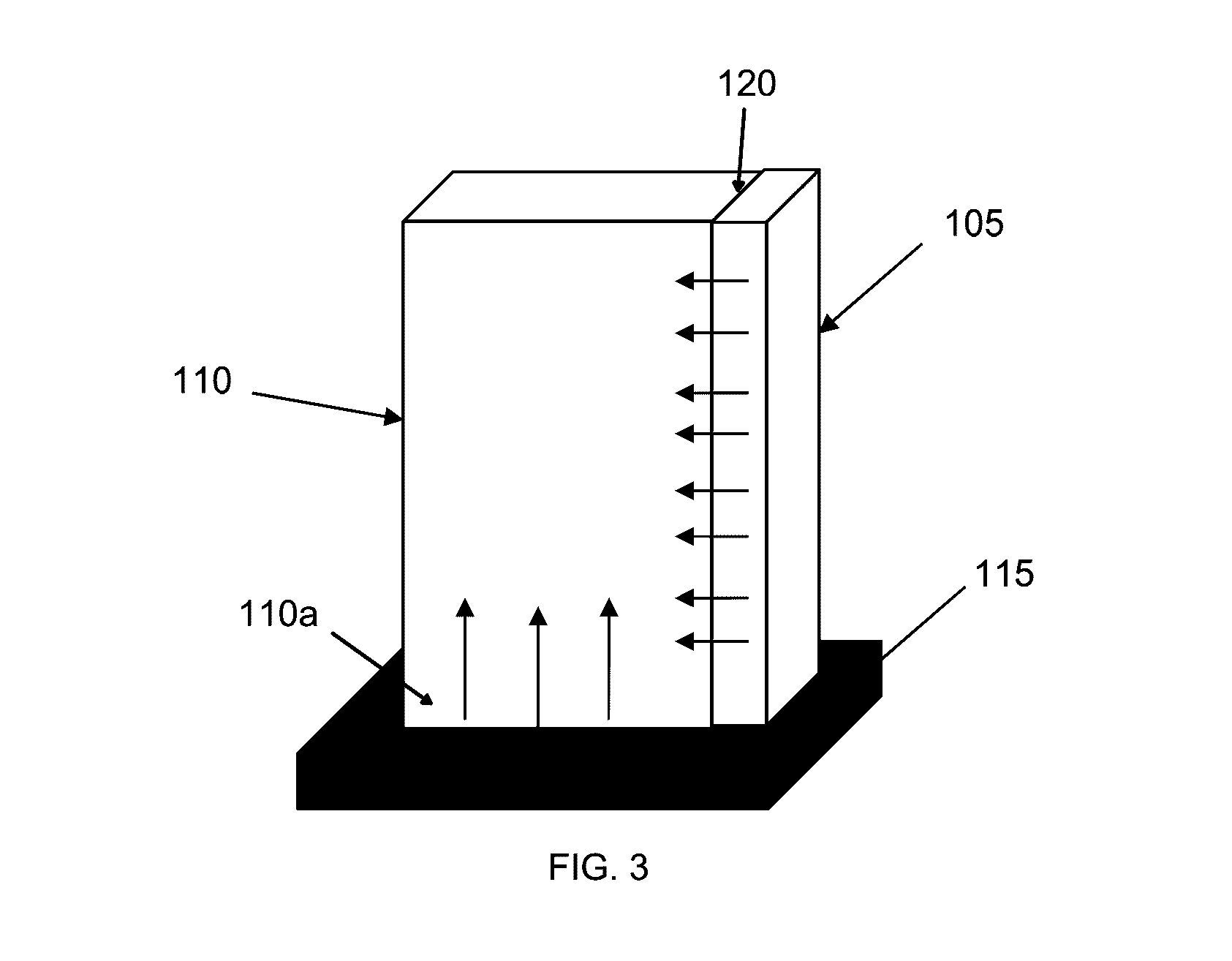

Coating system for clearance control in rotating machinery

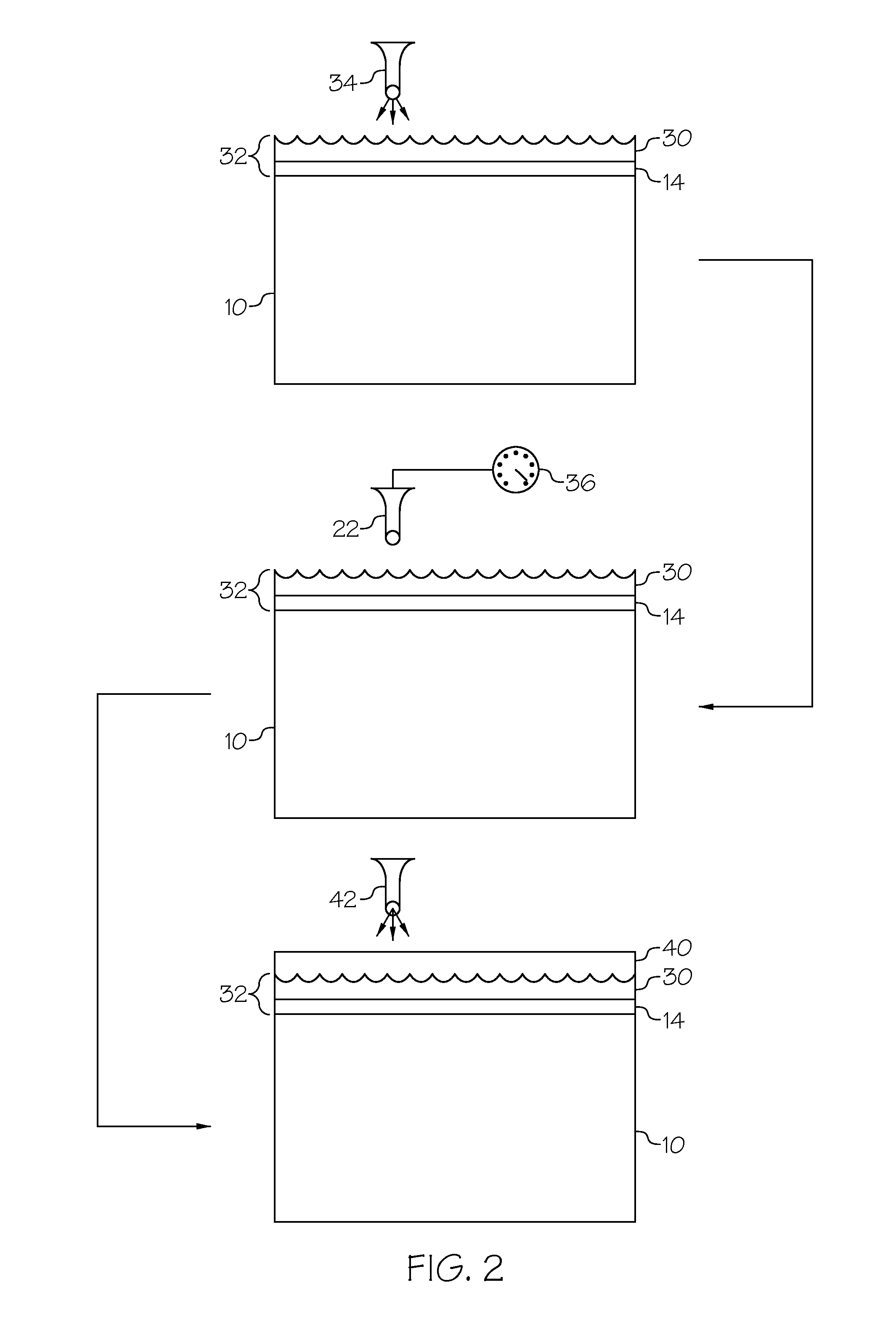

InactiveUS20110164963A1Minimizes blade tip lossLow costMolten spray coatingPump componentsEngine efficiencyCoating system

Owner:PRAXAIR ST TECH INC

Alternator fan

InactiveUS20050106024A1High mechanical strengthImprove homogeneityPropellersPump componentsMobile vehicleAlternator

The invention is a fan for an alternator adapted to be coupled in rotation to the alternator rotor, and being of the type comprising a wheel part and a plurality of fan blades (47, 48) extending from the latter, the fan being moulded in a plastics material on an insert (50) which is preferably of metal and which constitutes the wheel part of the fan and is arranged to provide fastening of the fan on the rotor, being configured so as to constitute a means for increasing the mechanical strenght of the fan; the insert (50, 65) includes at least a portion of a blade (48, 69) of the fan. The invention is useful in the manufacture of a high power cooling fan for a motor vehicle alternator.

Owner:VALEO EQUIP ELECTRIC MOTEUR

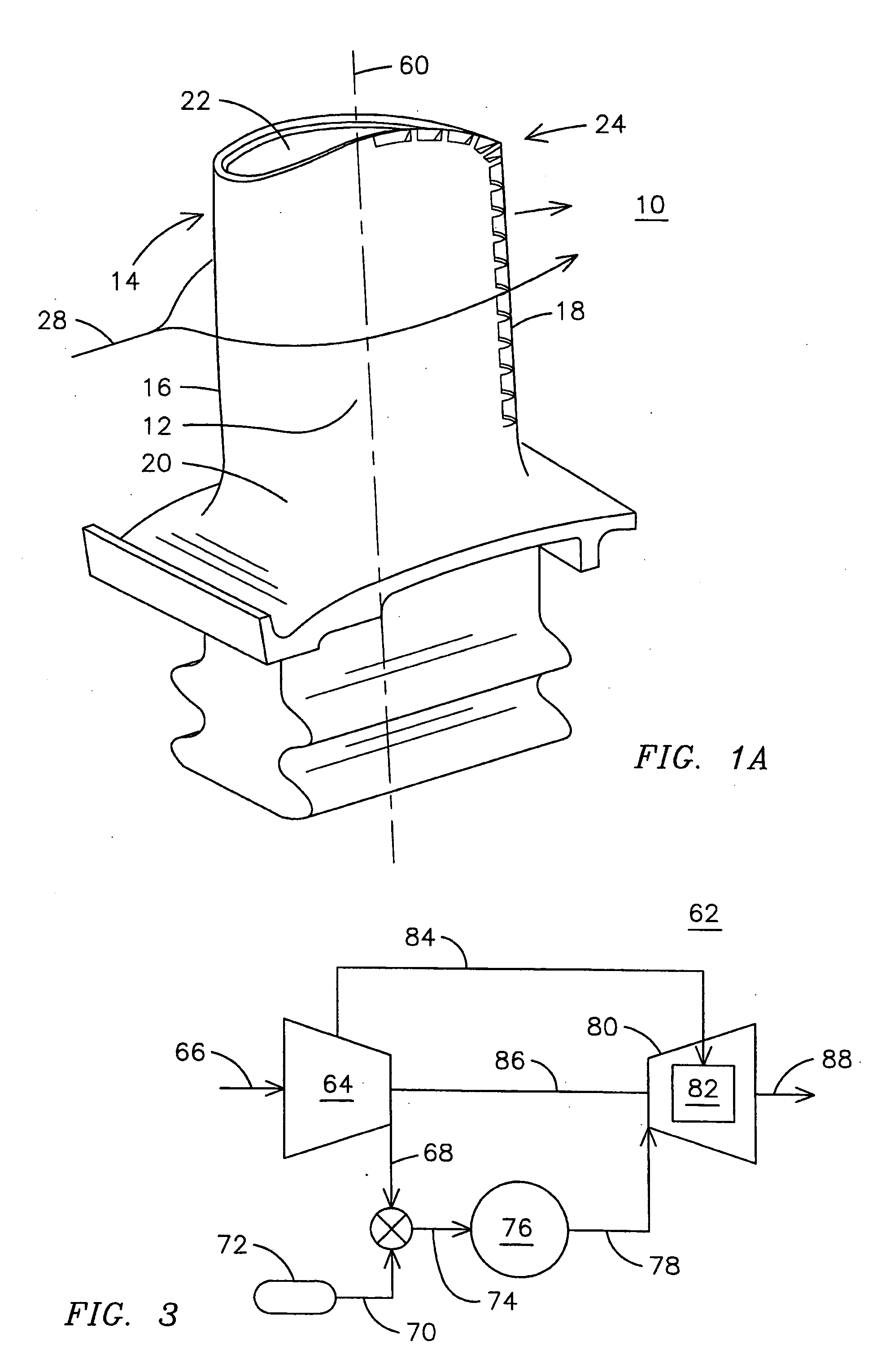

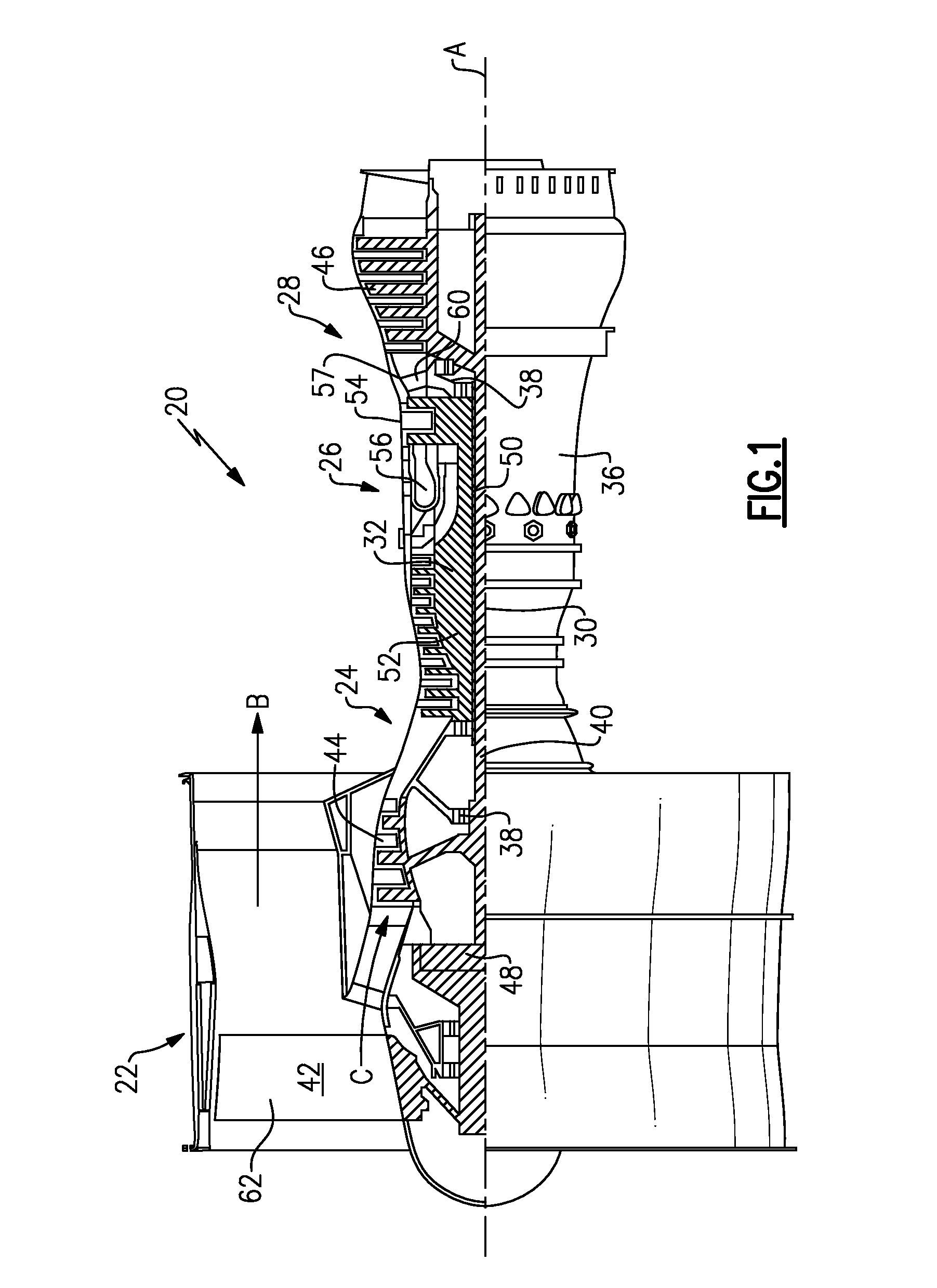

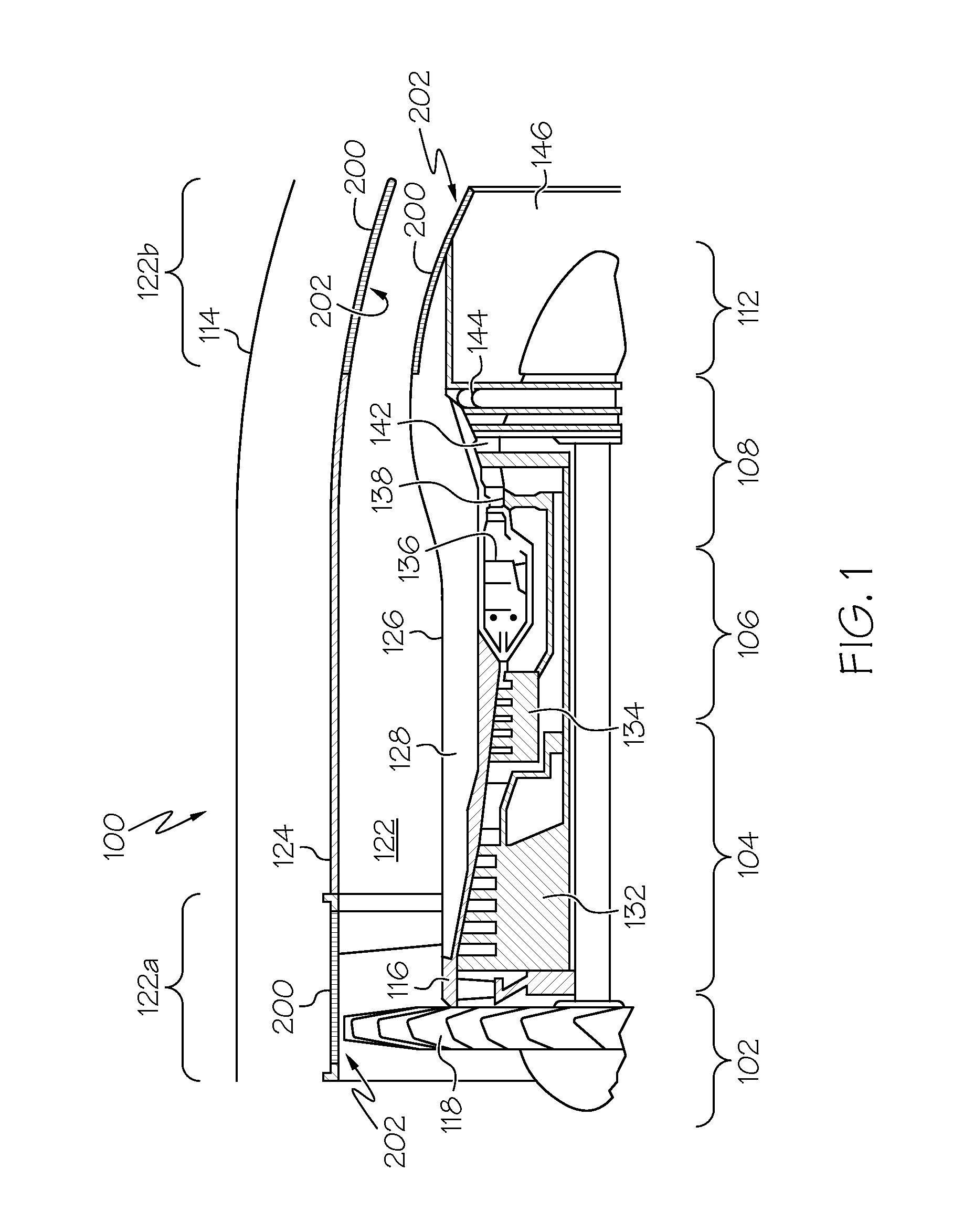

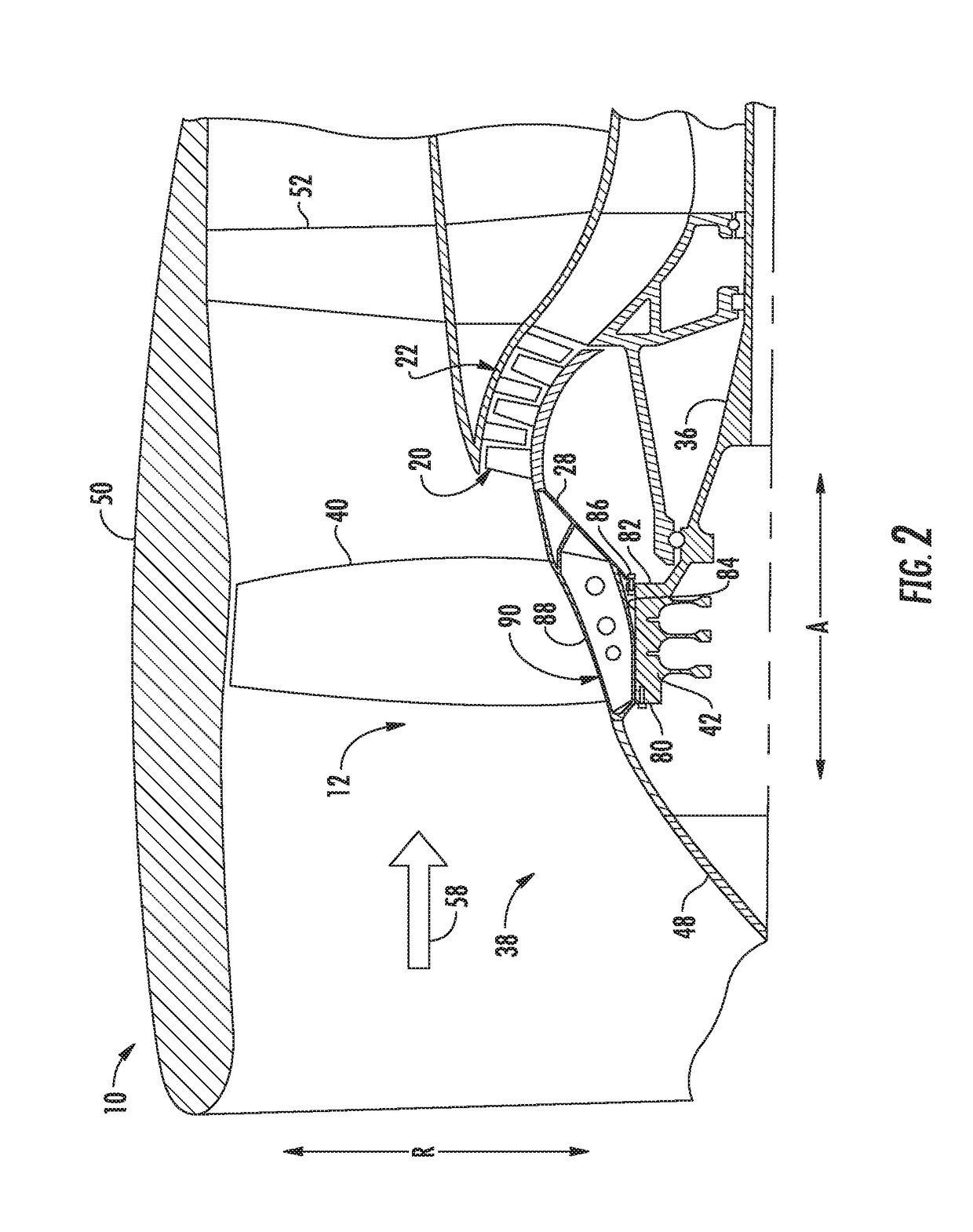

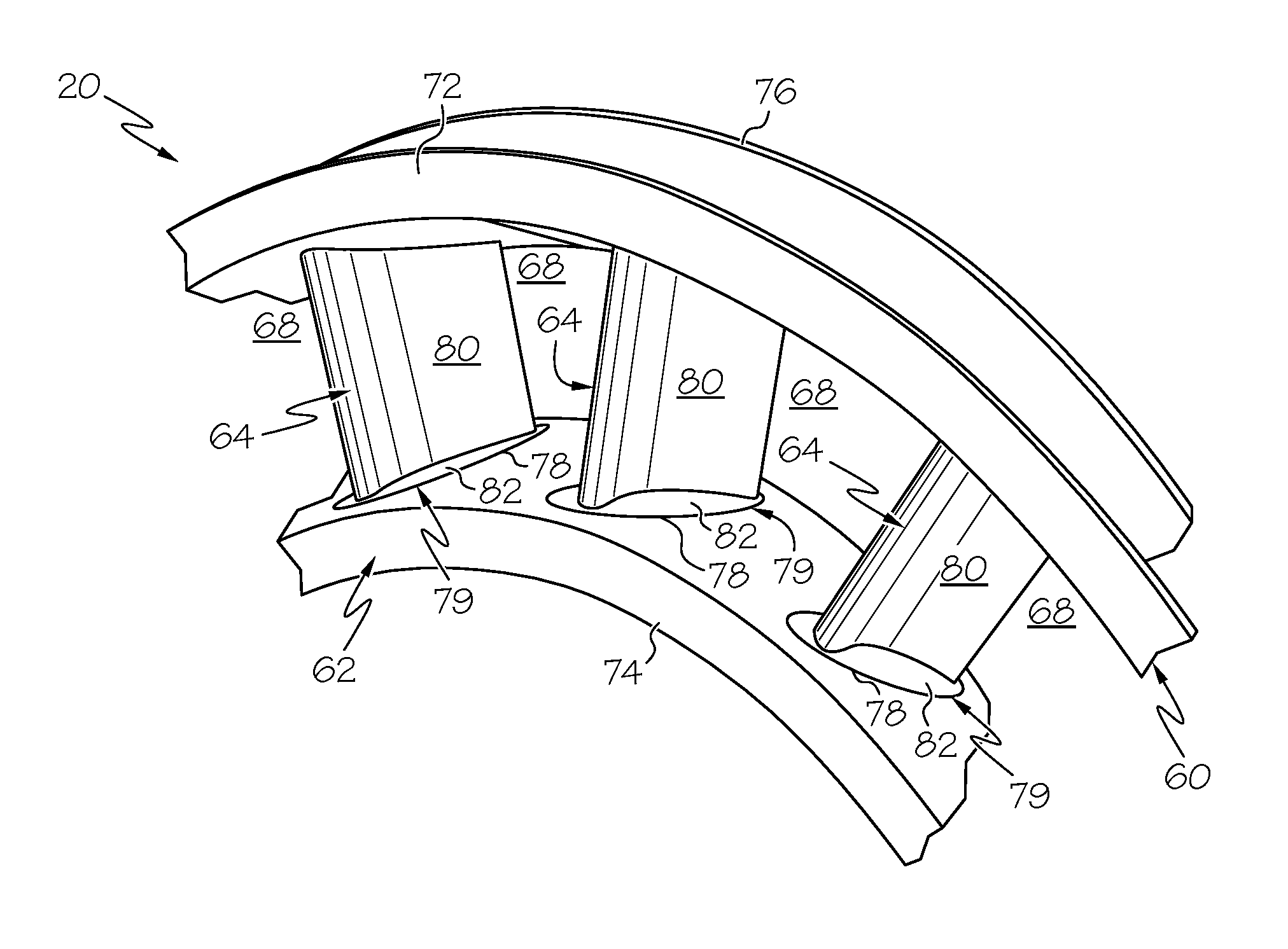

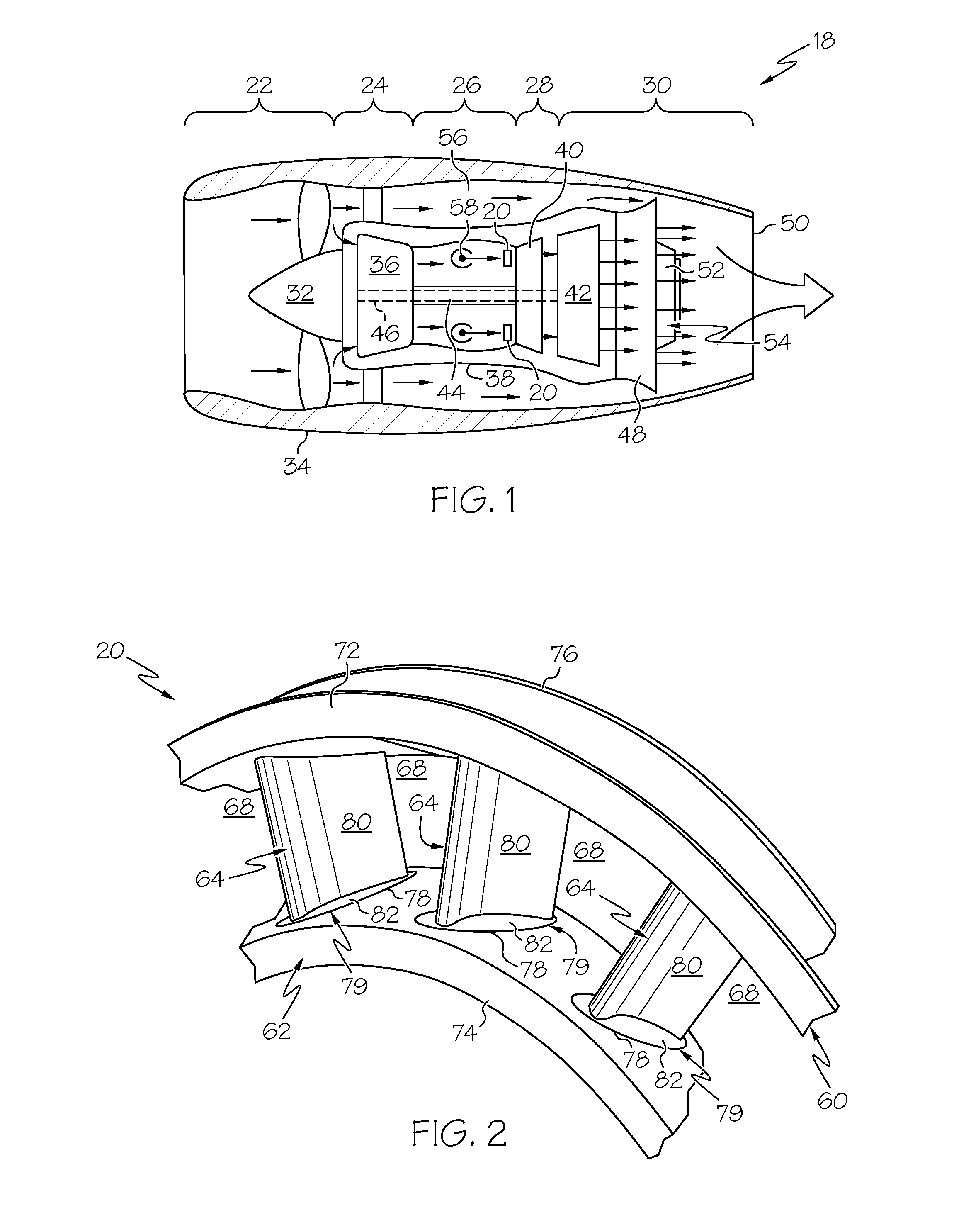

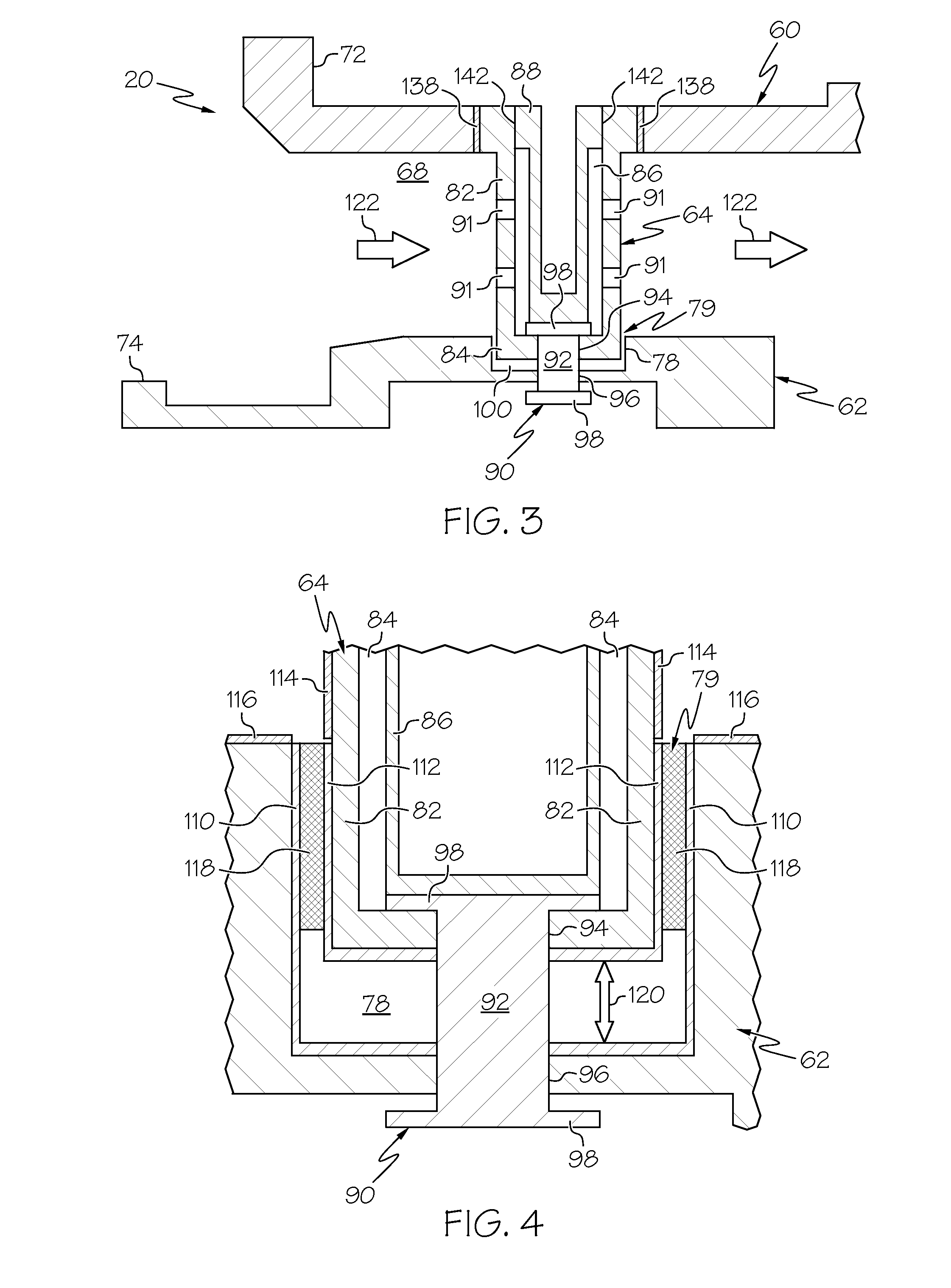

Apparatus and method for cooling a turbine airfoil arrangement in a gas turbine engine

A turbine airfoil arrangement for a gas turbine engine includes an airfoil having an inlet and an exit, the inlet configured to receive a cooling gas flow operable to cool at least part of an other airfoil; and a passage disposed in the airfoil and fluidly coupled to the inlet and the exit, the exit being configured to pass at least some of the cooling gas flow to the other airfoil.

Owner:ROLLS ROYCE CORP

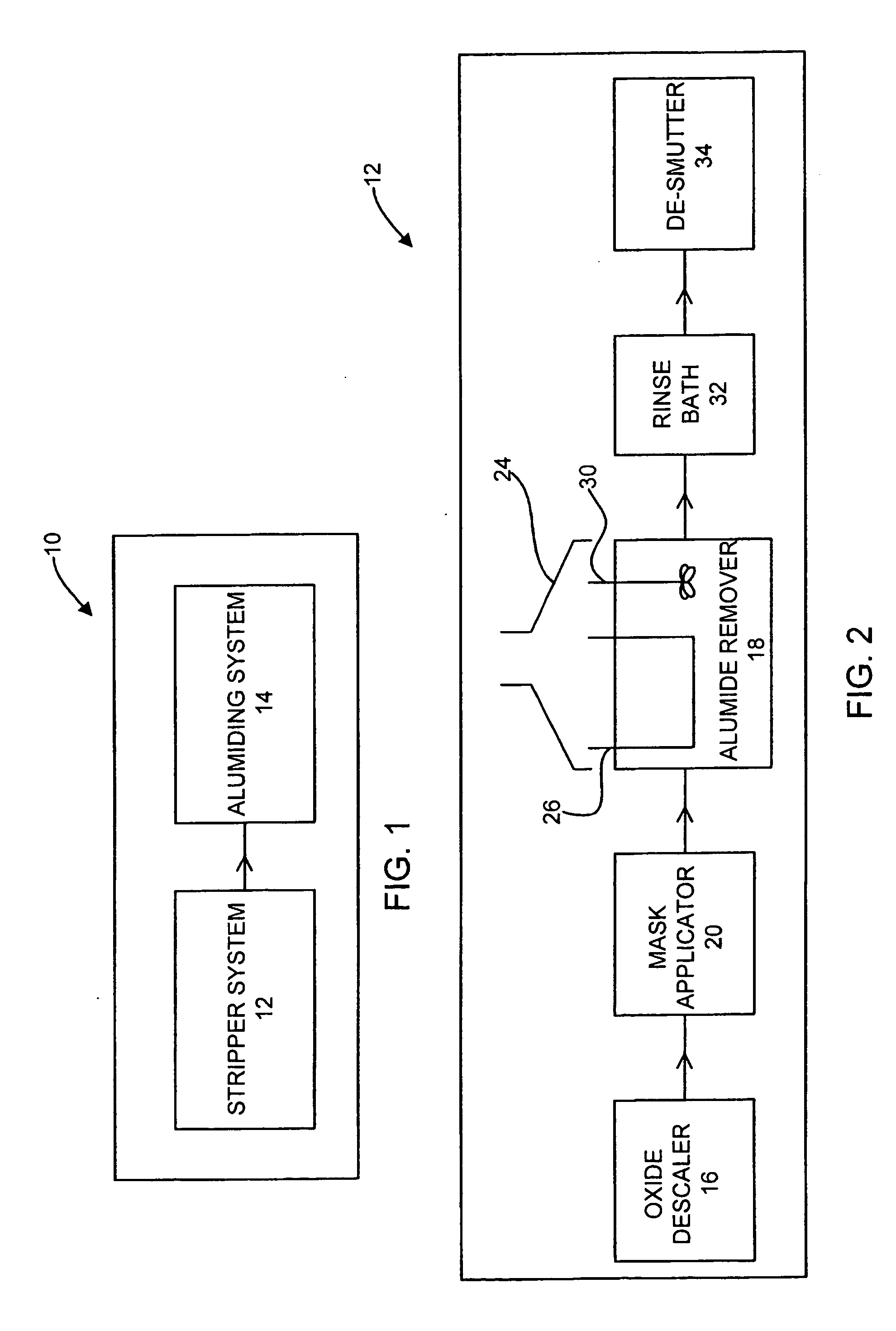

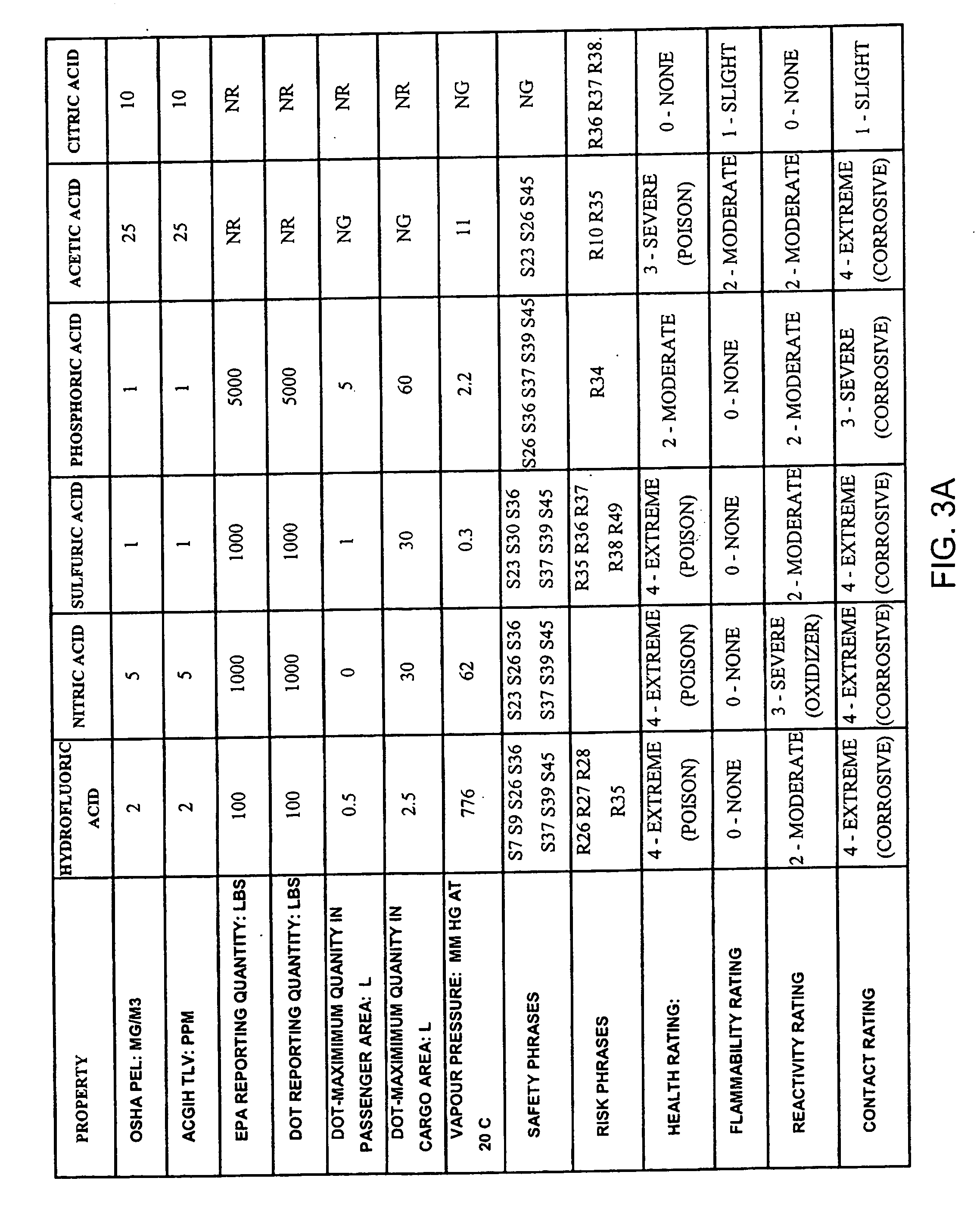

Airfoil refurbishment method

InactiveUS20070023142A1Environment safetyBlade accessoriesEfficient propulsion technologiesAluminideCoating

Owner:LAGRAFF JOHN ROBERT +5

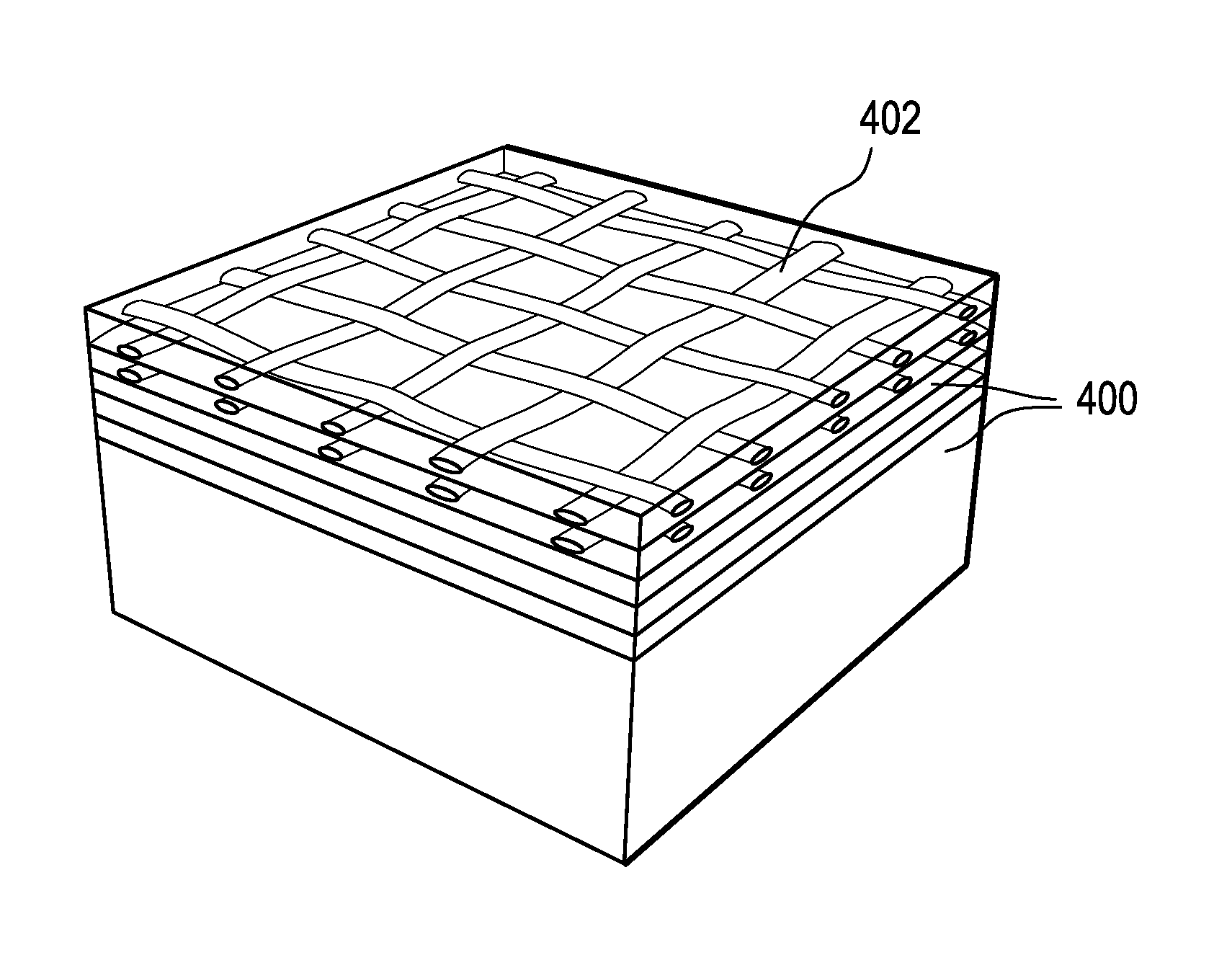

Reinforced coatings and methods of making the same

Owner:GENERAL ELECTRIC CO

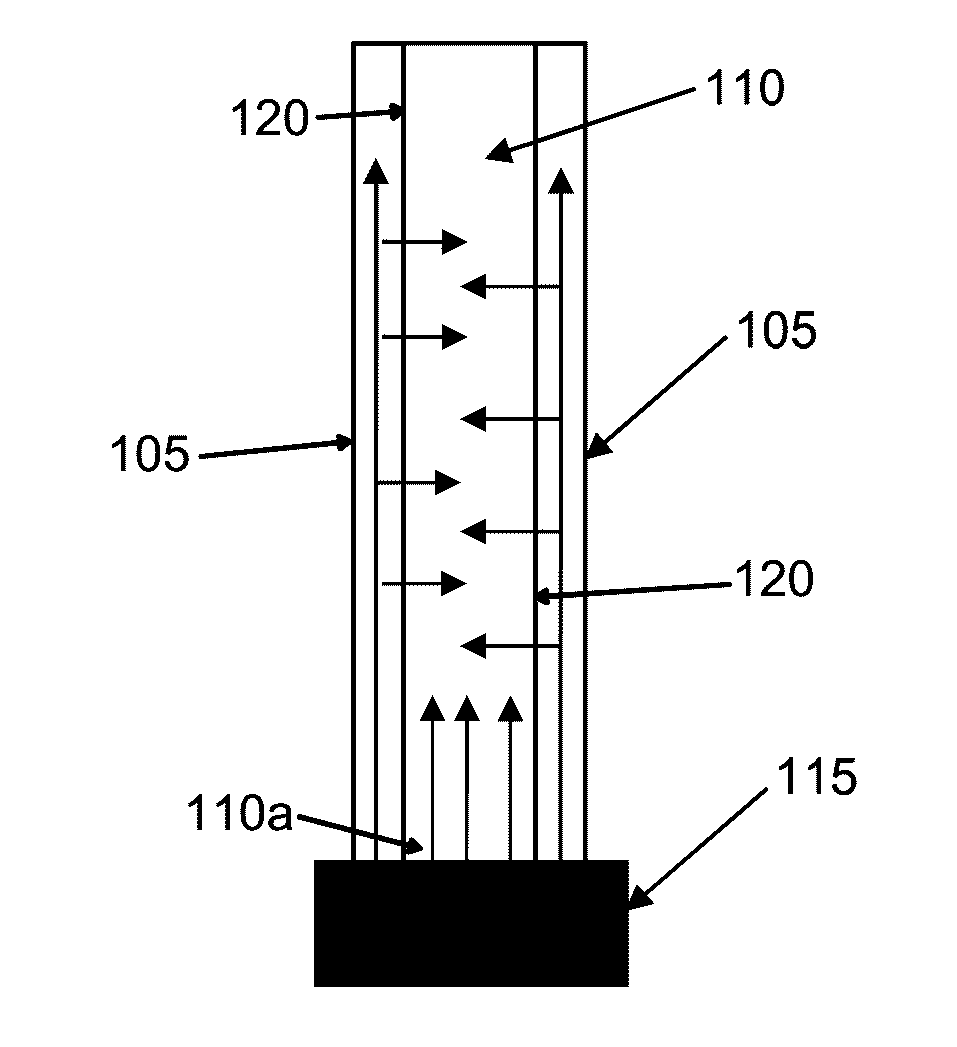

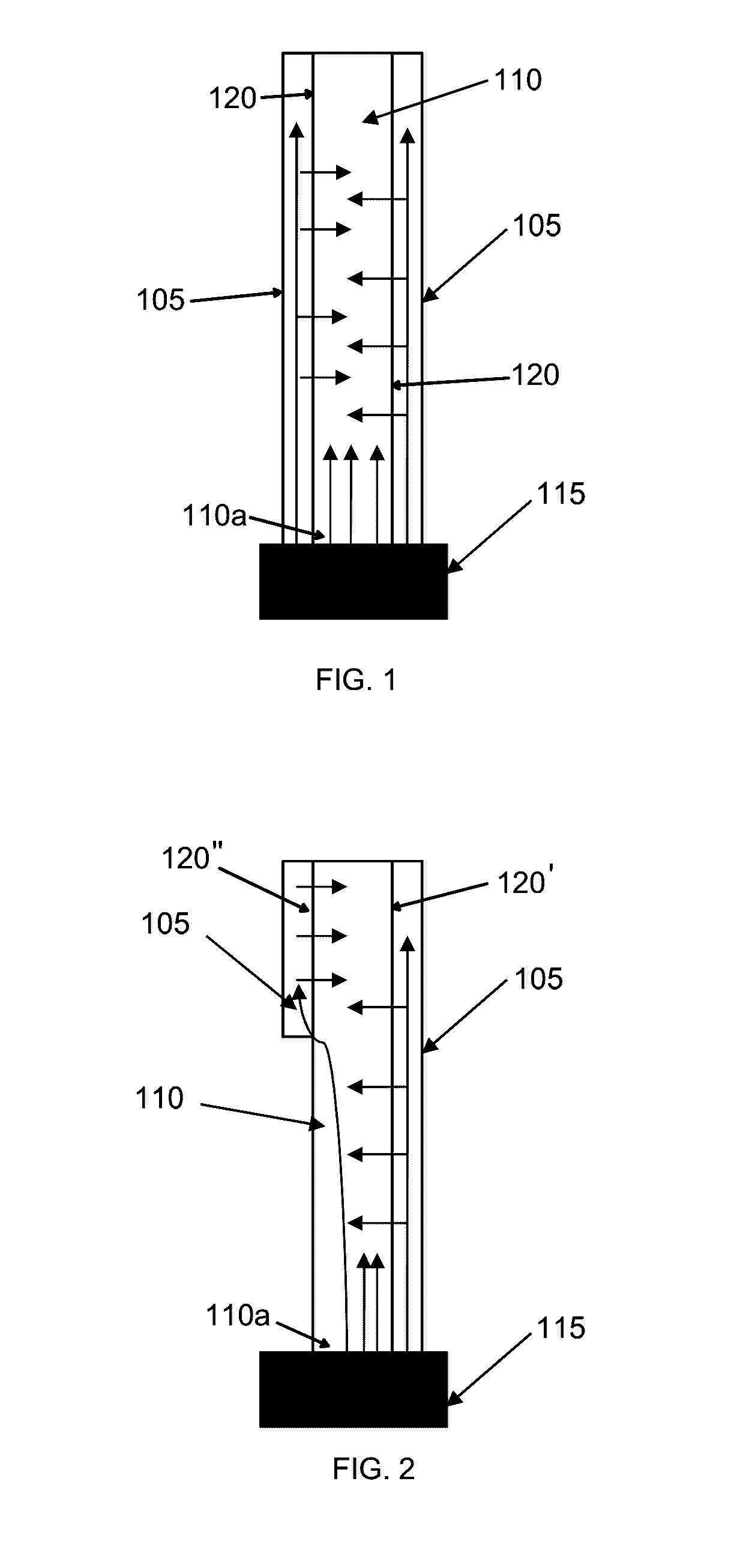

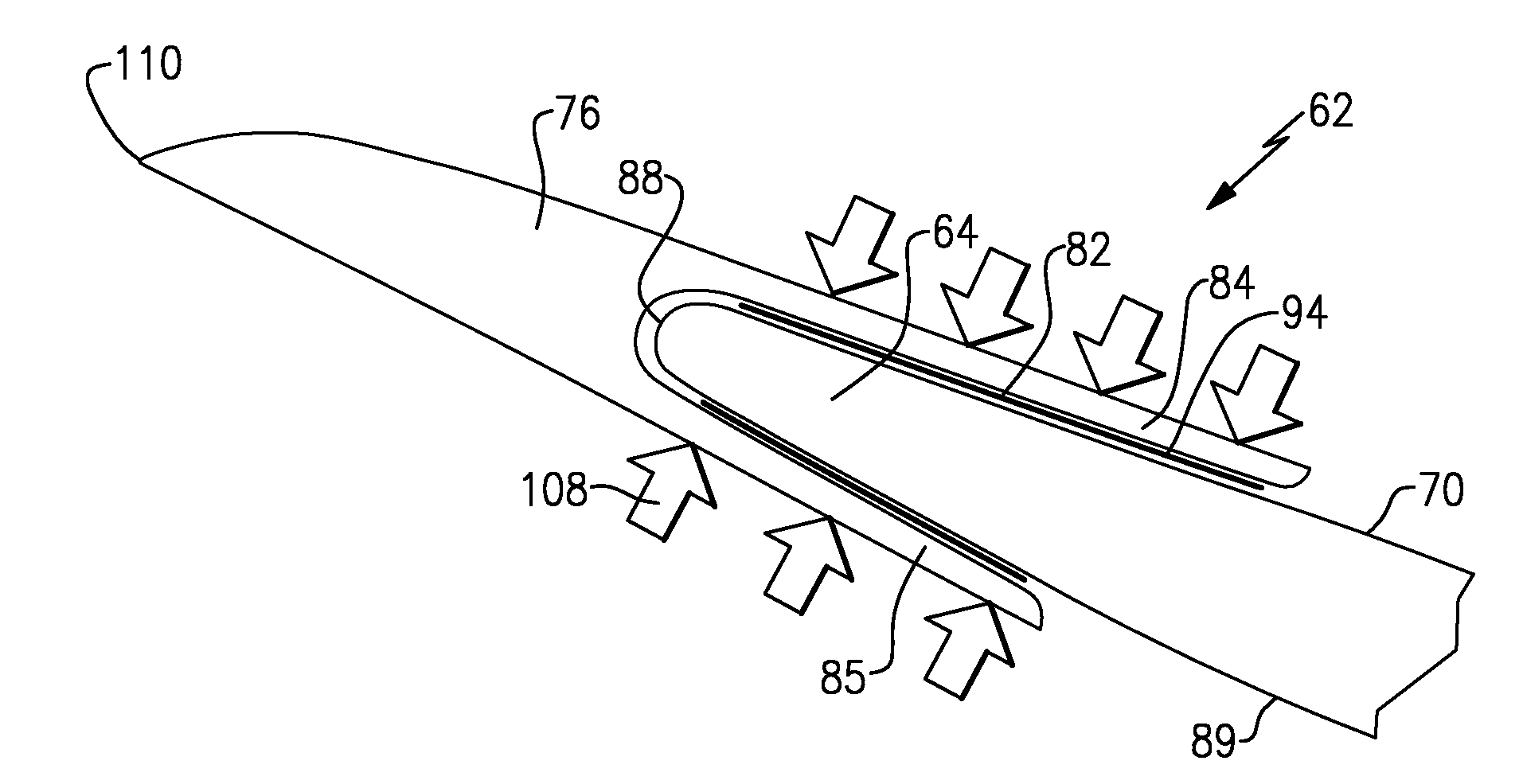

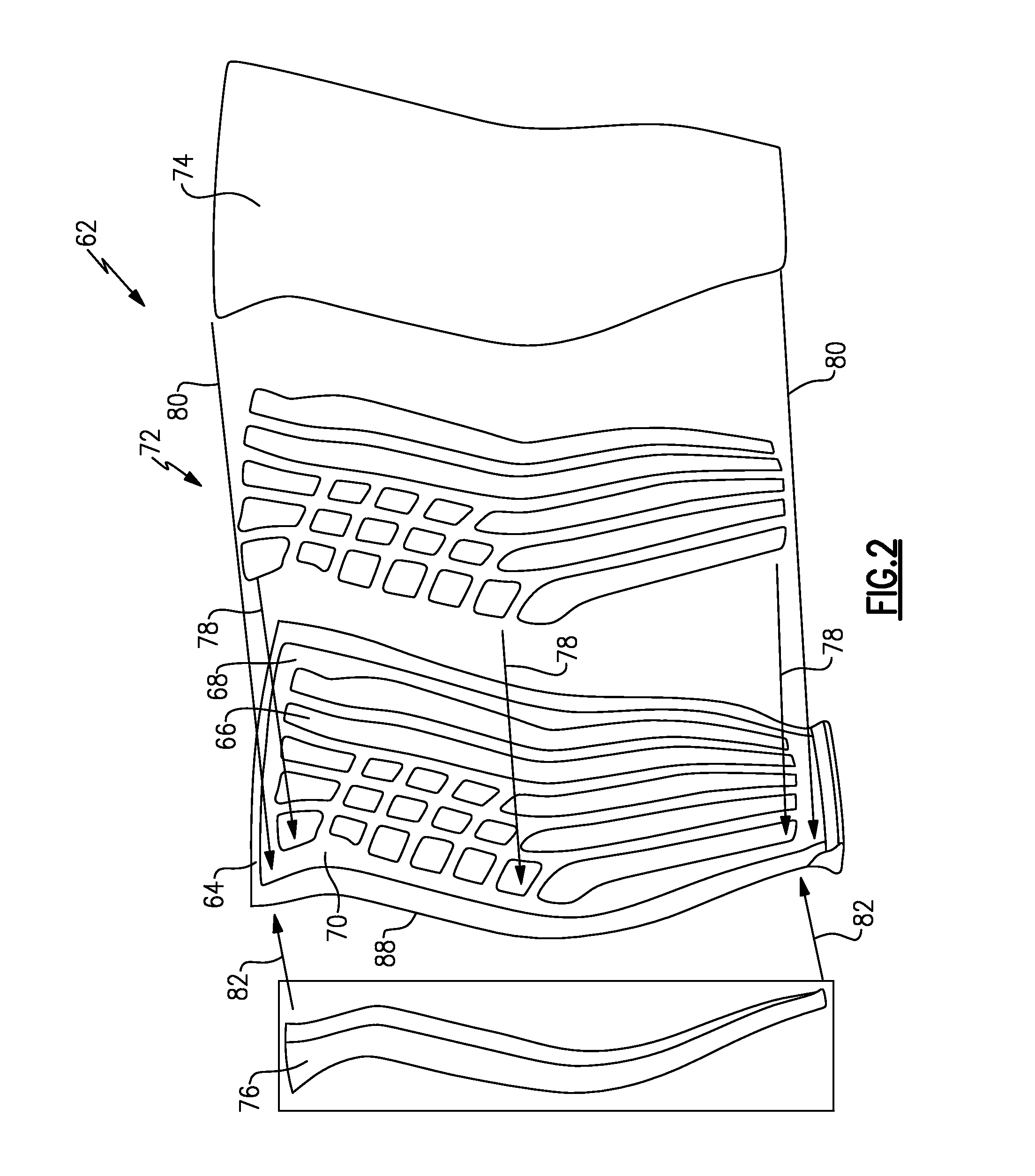

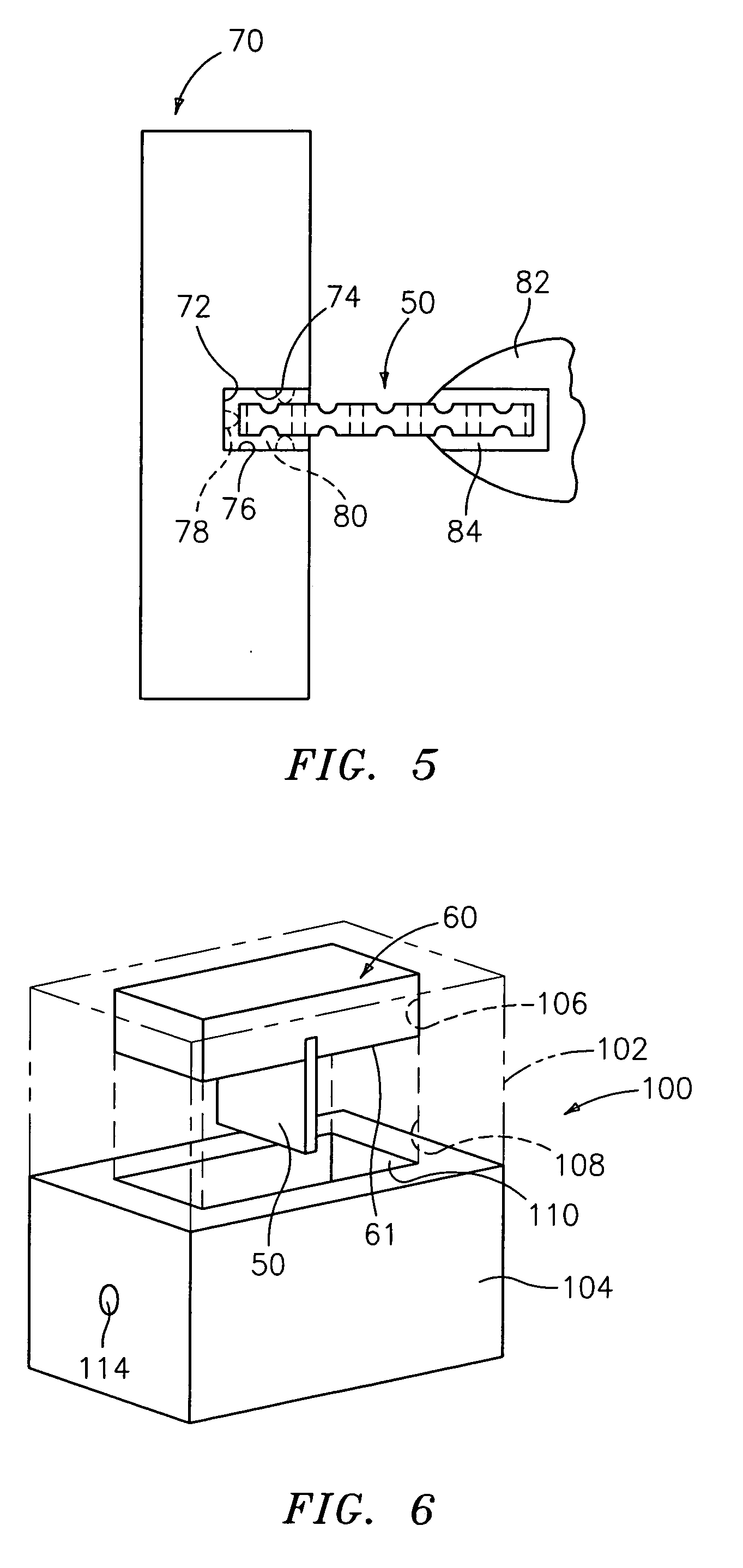

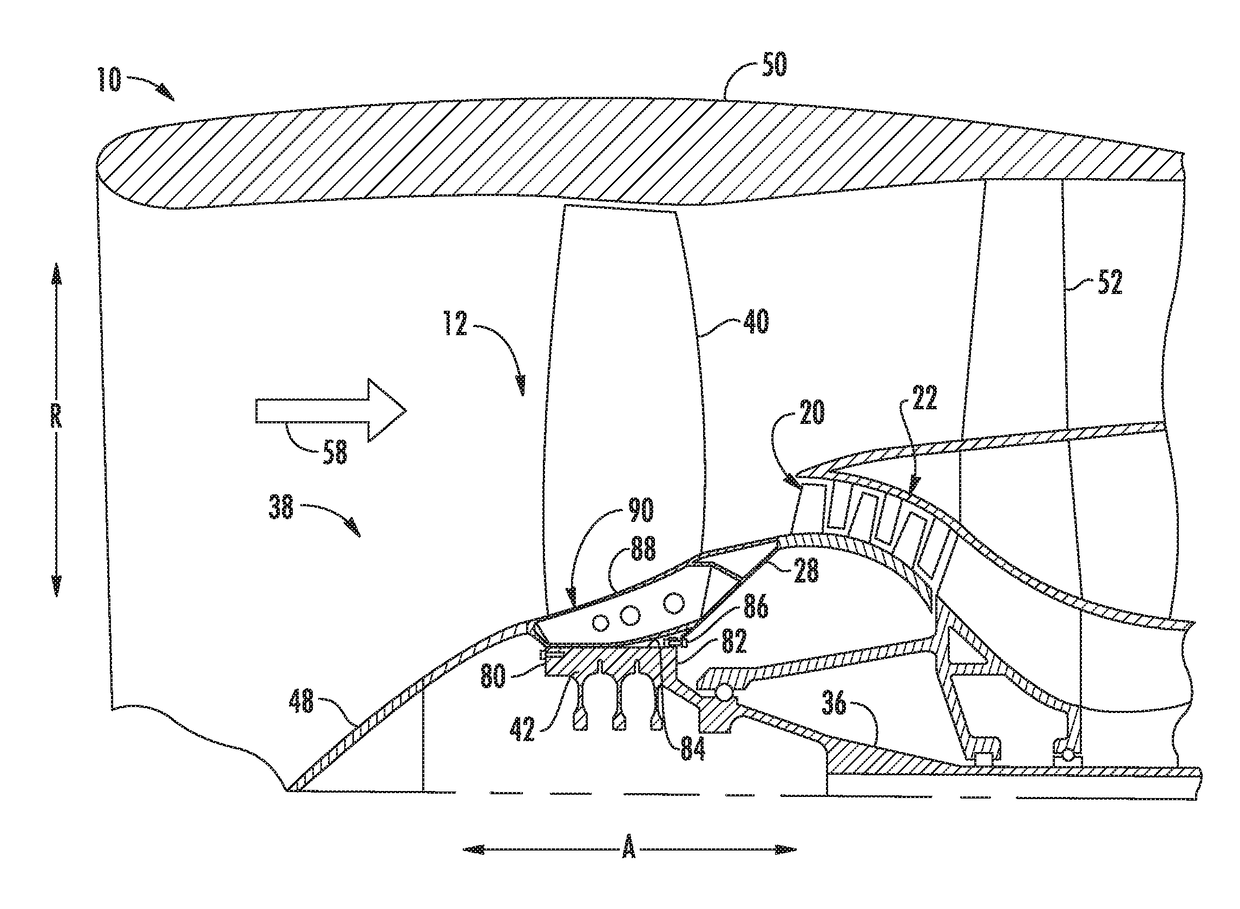

Airfoil leading edge chamber cooling with angled impingement

An airfoil cooling arrangement (12), including: a leading edge chamber (54) configured to cool an interior surface (68) of an airfoil; and an impingement orifice (60) configured to direct an impingement jet (64) toward an impingement location (66) disposed on the interior surface and offset from a camber line (28) of the airfoil The airfoil cooling arrangement is effective to guide post impingement cooling fluid along the interior surface, through a leading portion (76) of the leading edge chamber, and then back toward a trailing edge (22) of the airfoil in a helical motion (114). A stagnation region (104) is formed adjacent the interior surface and on a trailing edge side of the impingement location, and a relatively high static pressure associated therewith is effective to contribute to the helical motion (114) of the post impingement cooling fluid within the leading edge chamber

Owner:SIEMENS AG +1

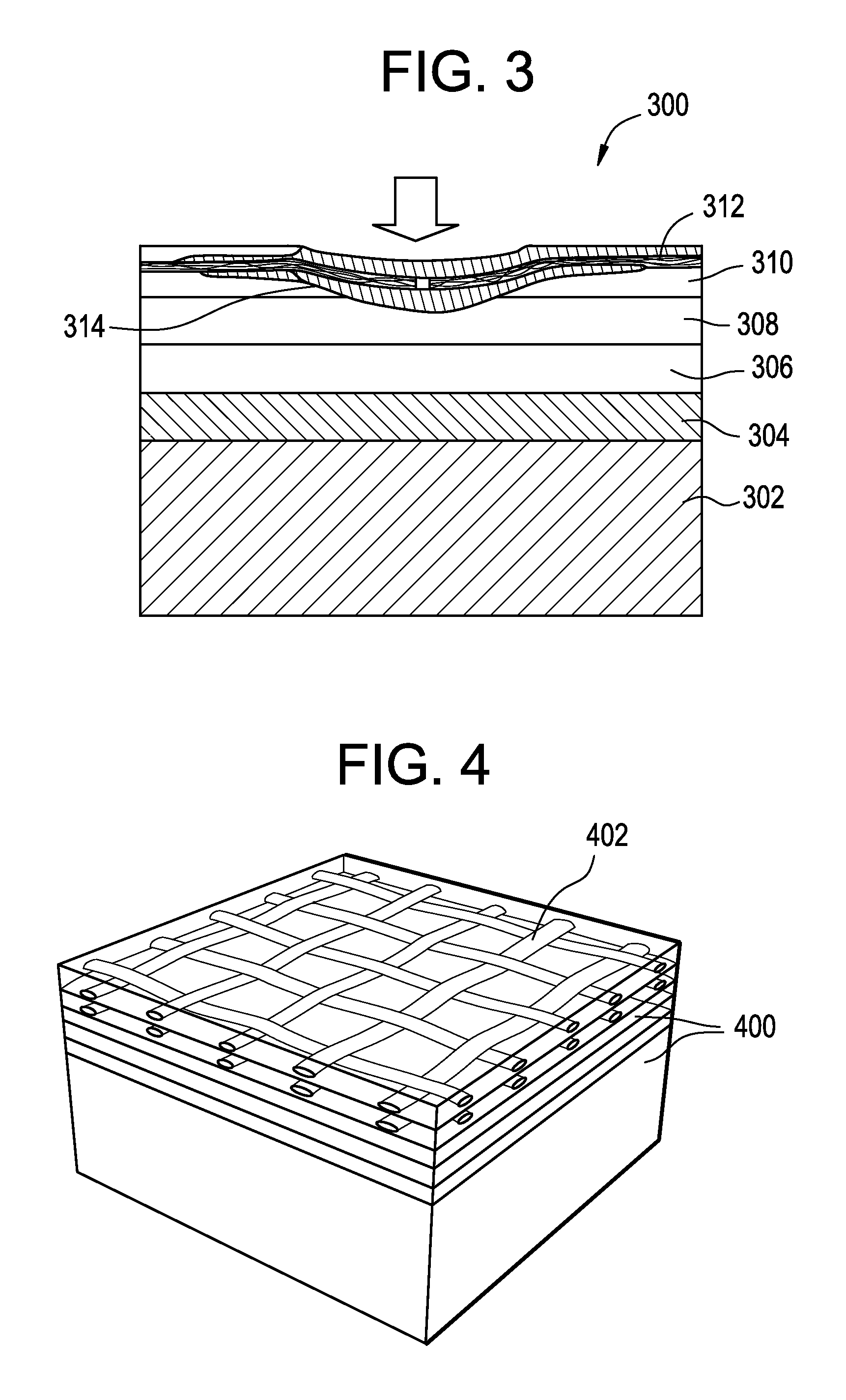

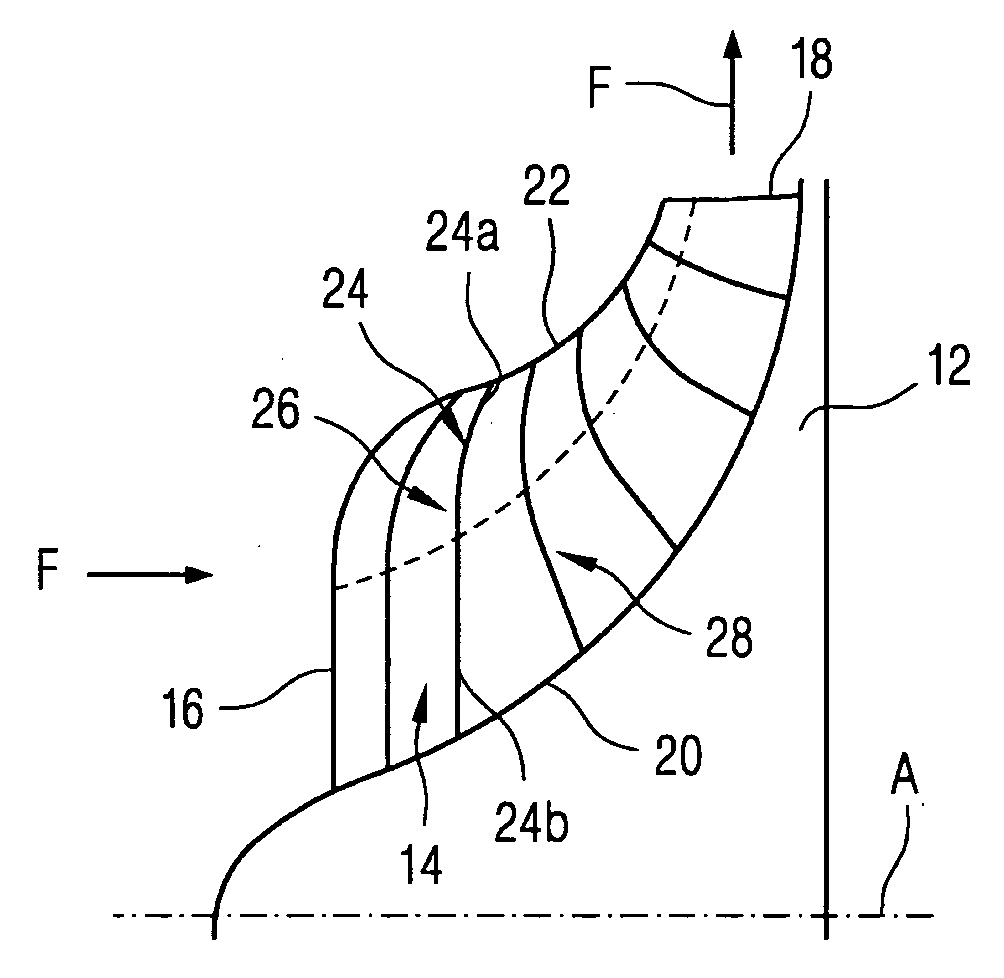

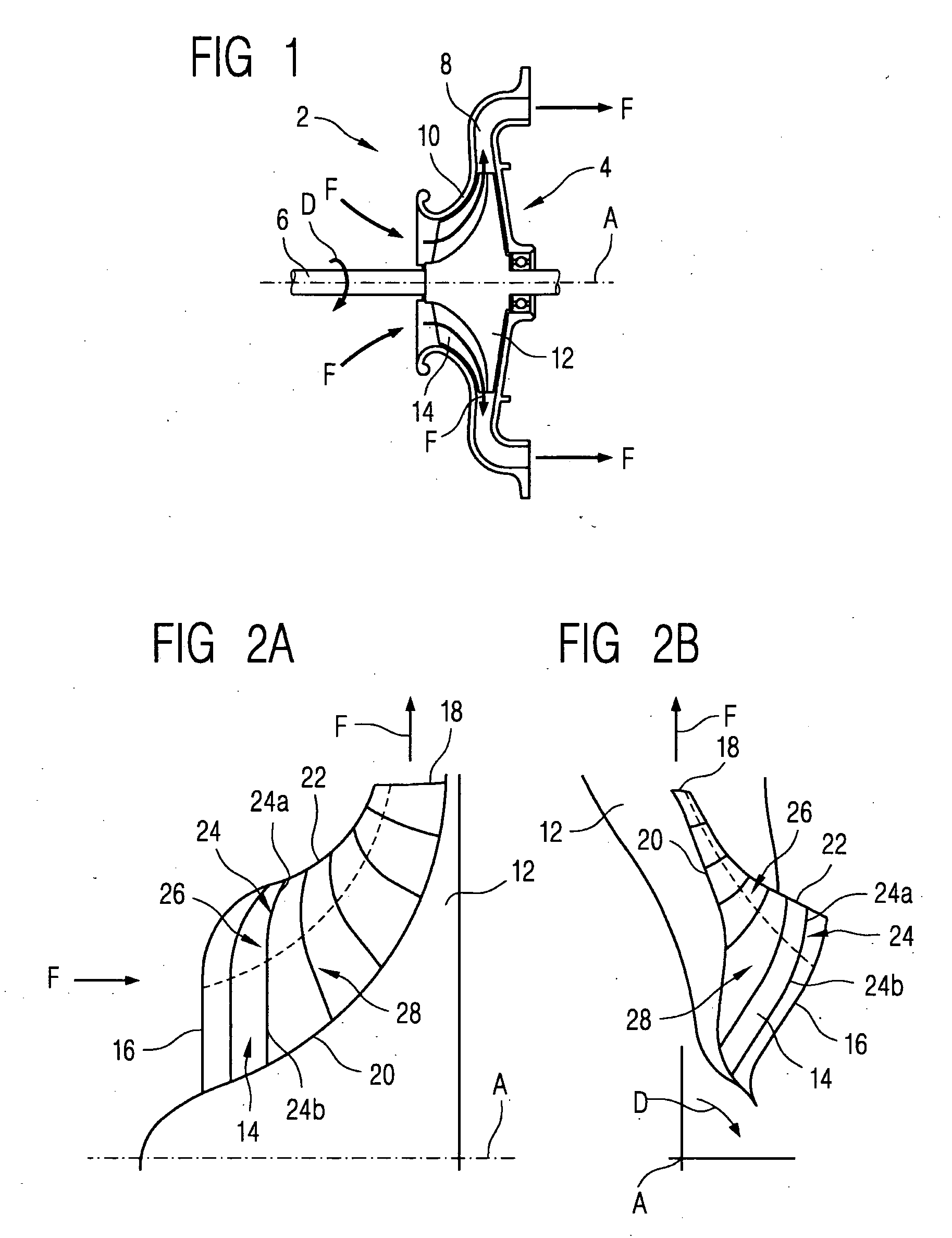

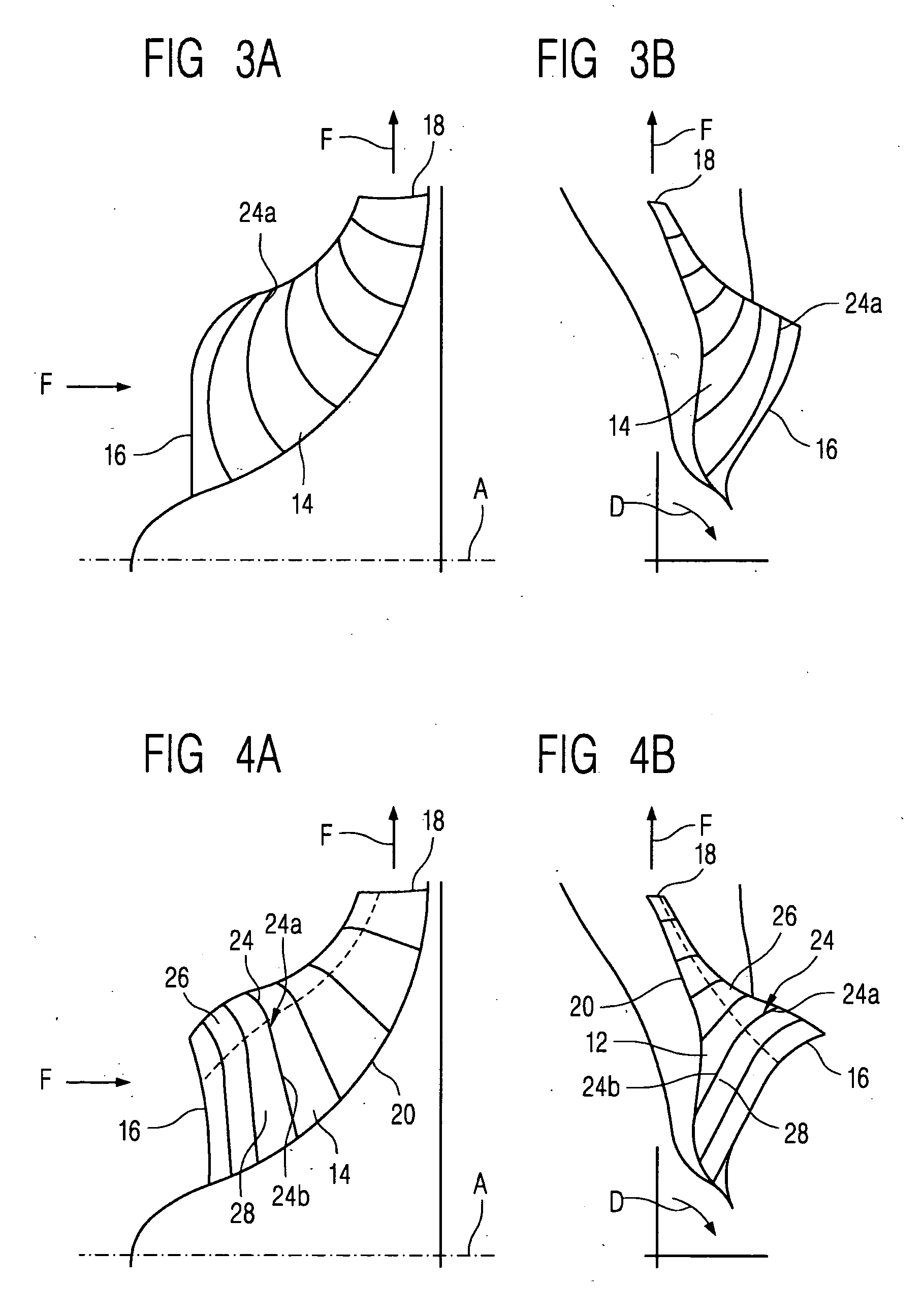

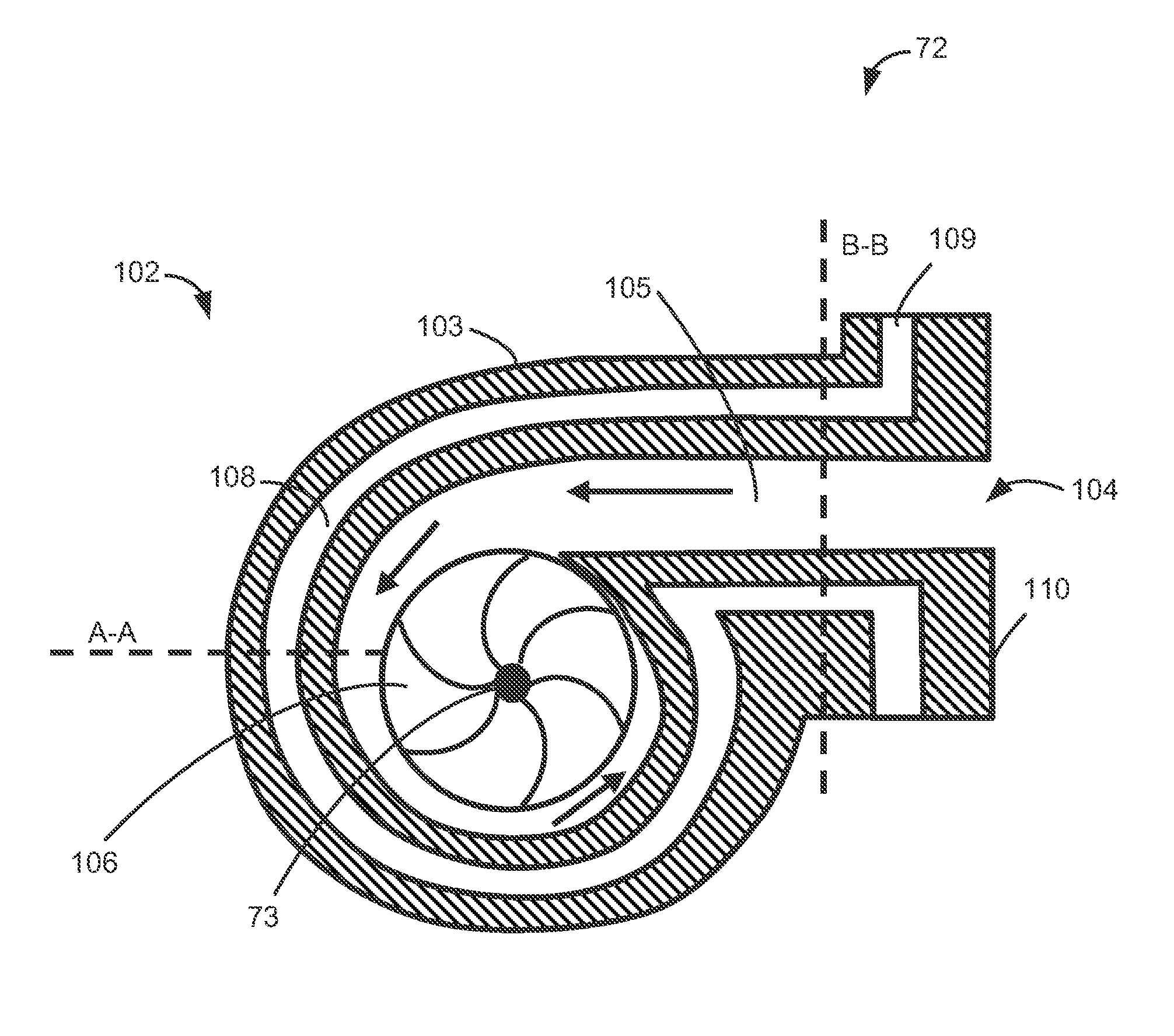

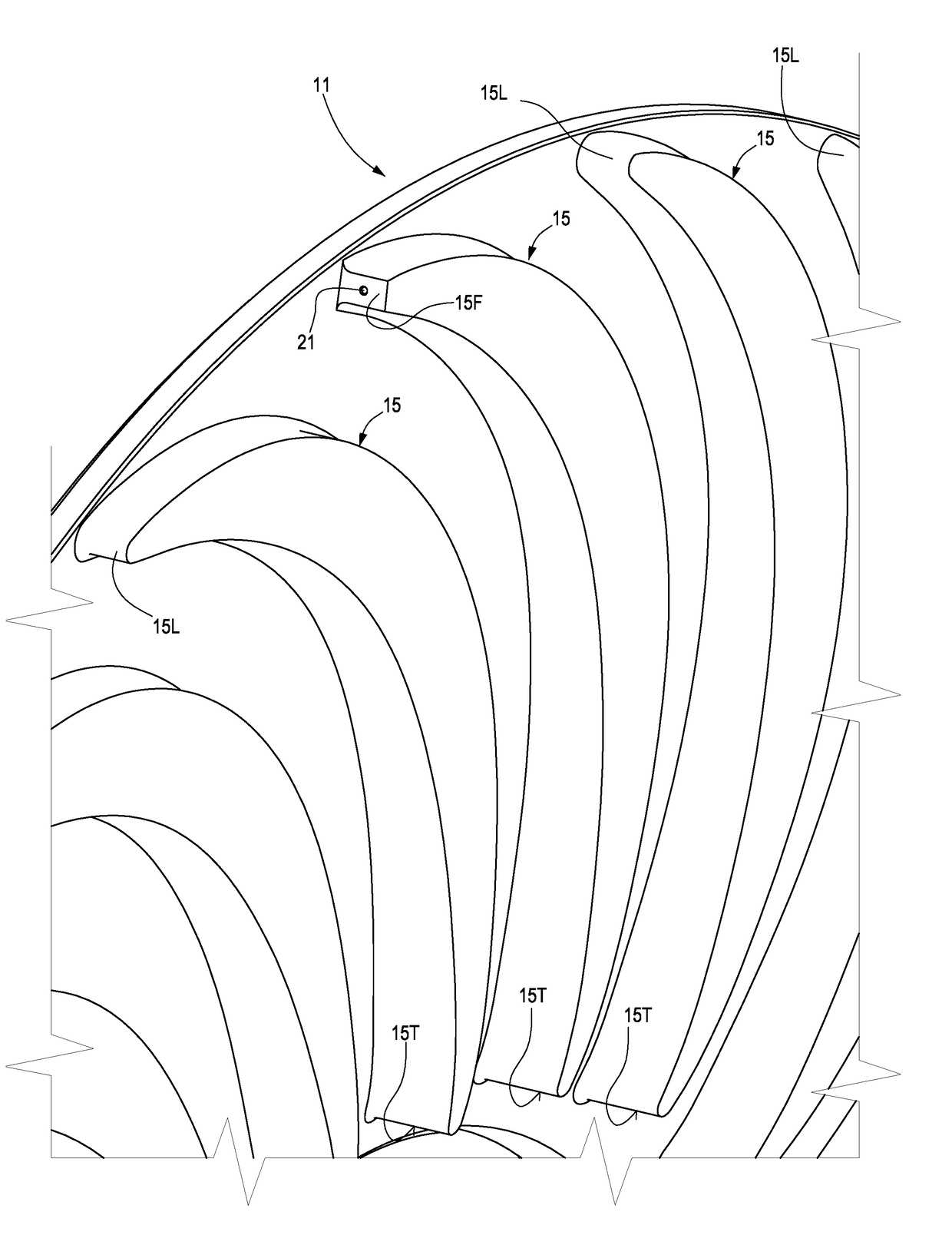

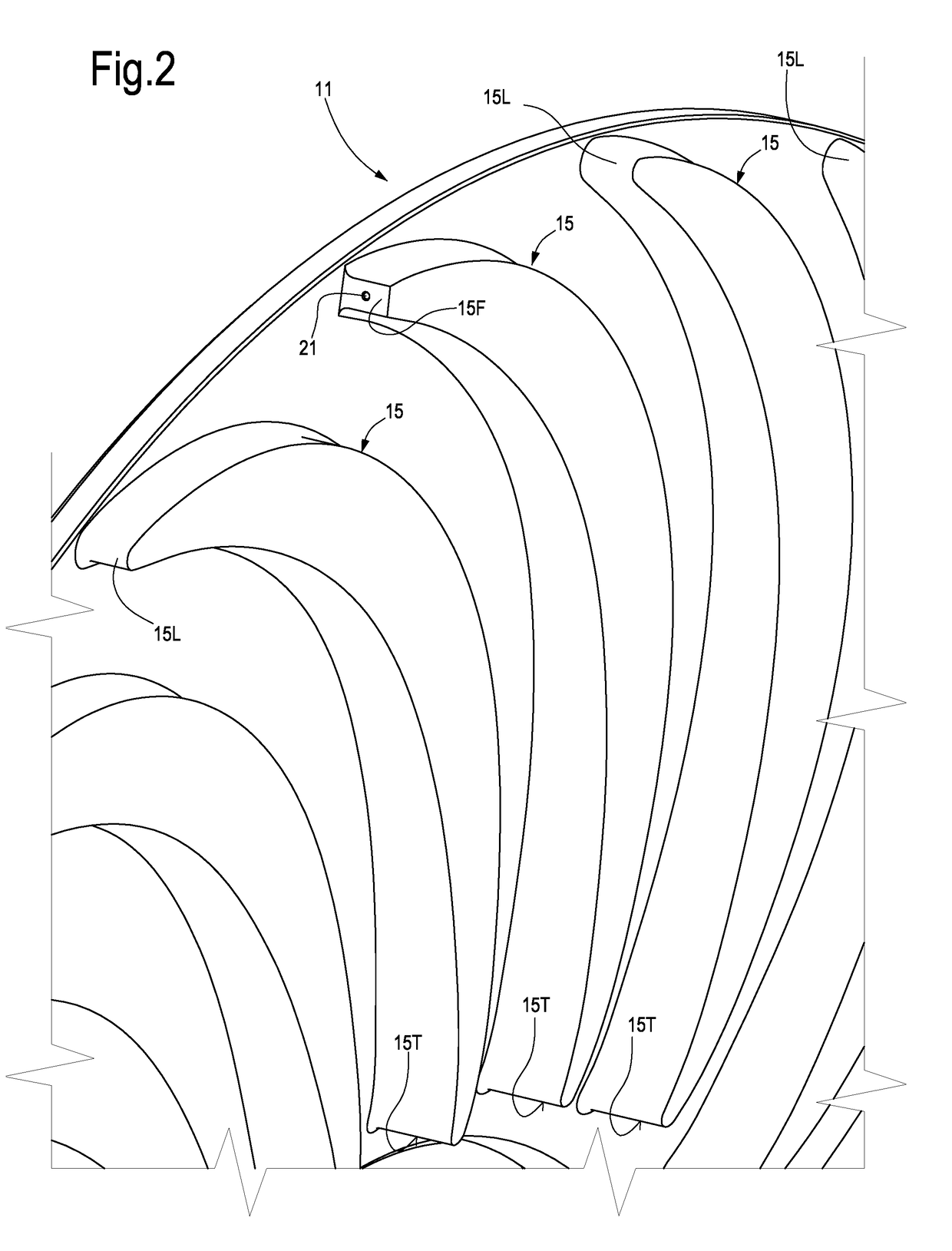

Radial Compressor Rotor

ActiveUS20090220346A1Stable flow behaviorImprove efficiencyPropellersPump componentsMechanical engineeringGeneratrix

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

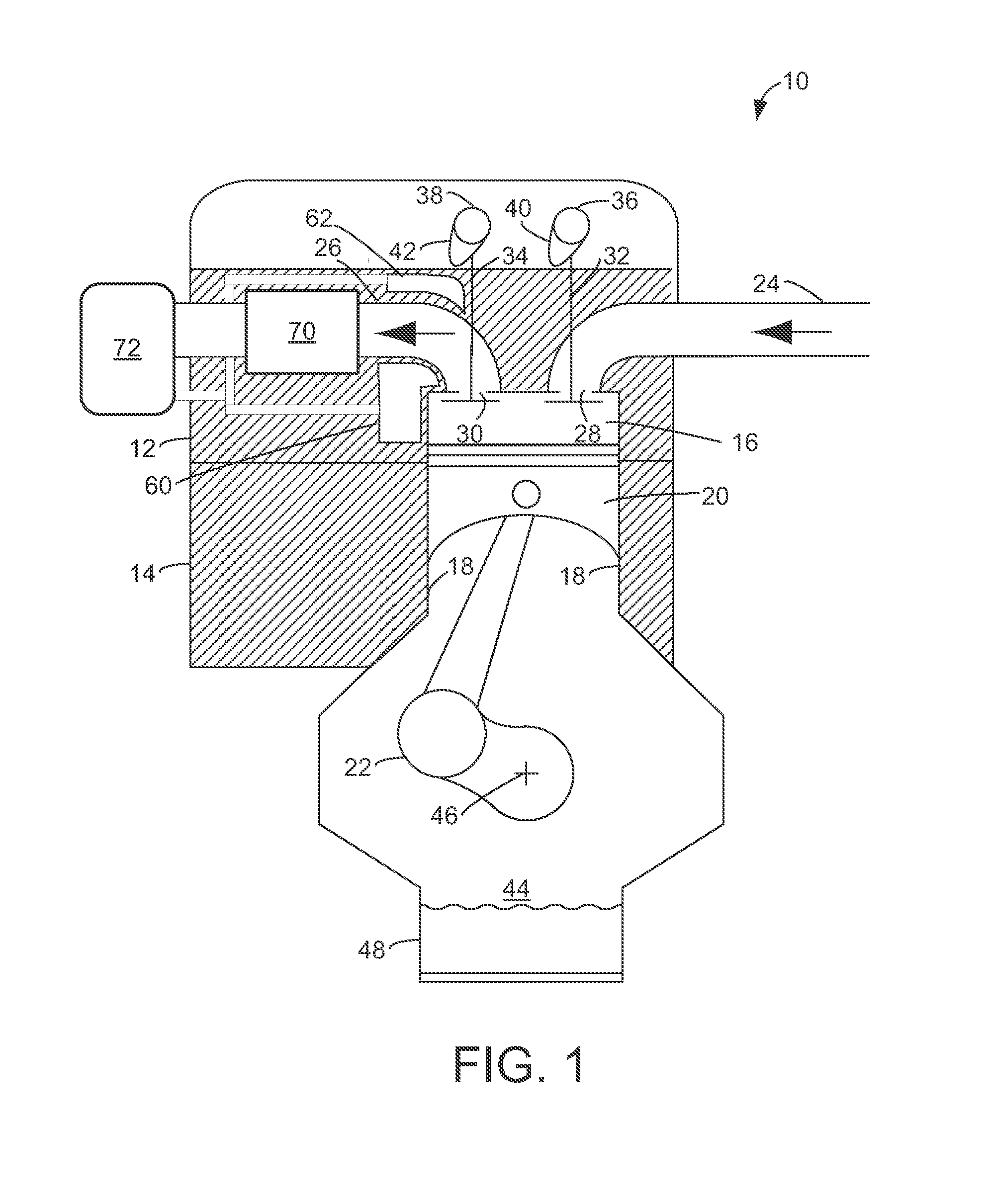

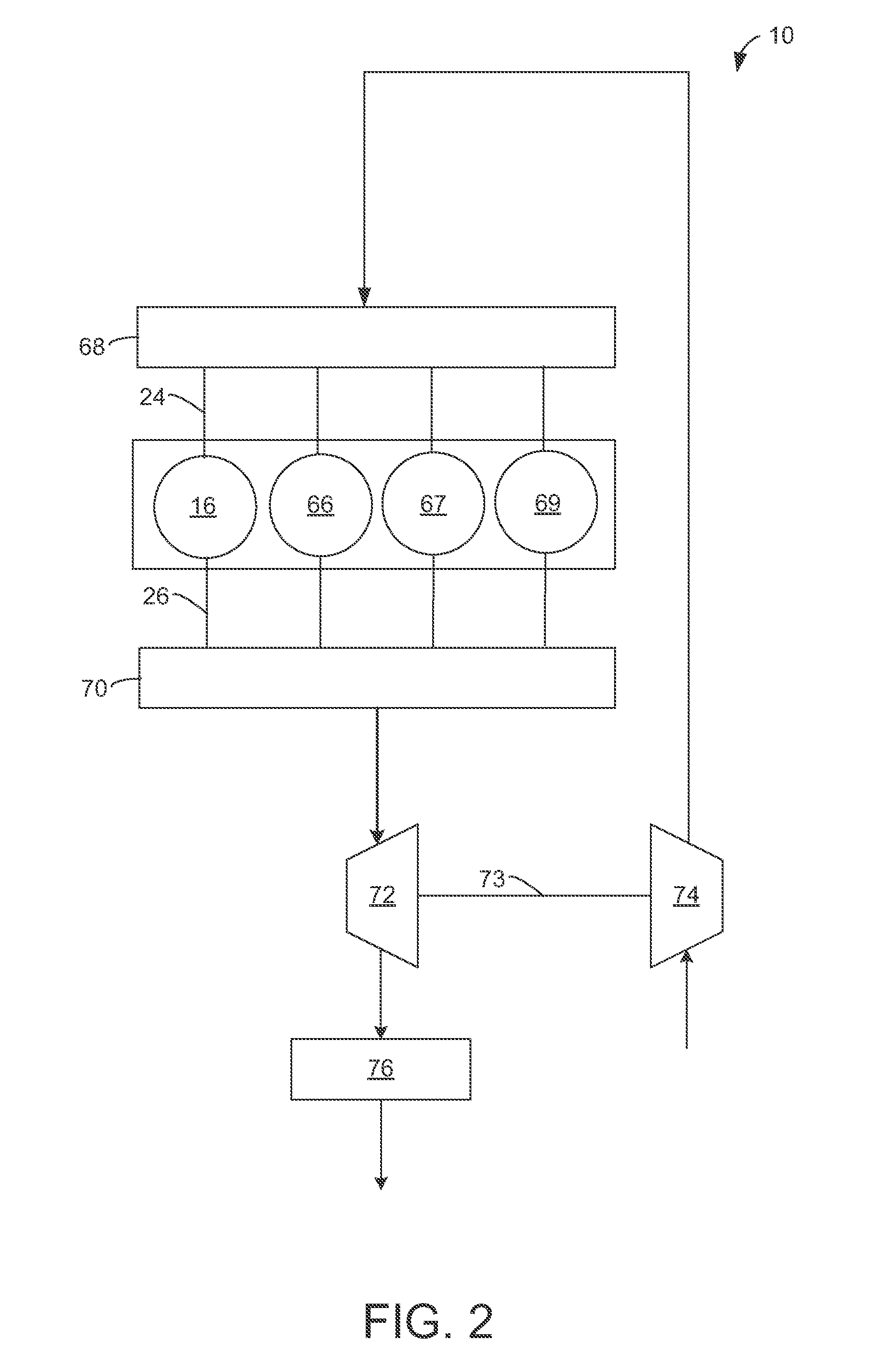

Cylinder head with turbine

InactiveUS20120055424A1Large amount of heatA large amountPump componentsEngine fuctionsCylinder headRadial turbine

Owner:FORD GLOBAL TECH LLC

Method of bonding a leading edge sheath to a blade body of a fan blade

Owner:RAYTHEON TECH CORP

Investment casting cores and methods

Owner:RAYTHEON TECH CORP

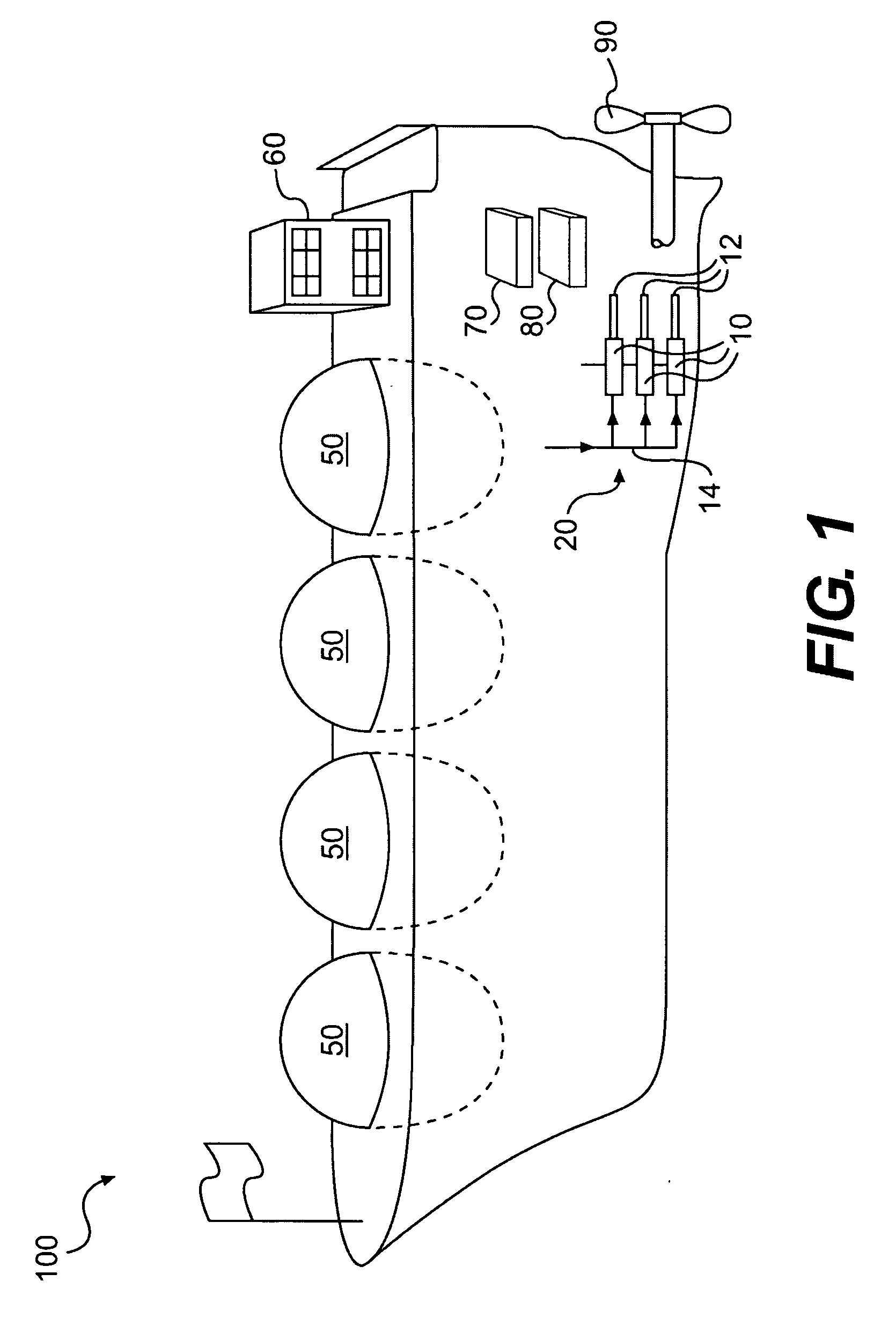

Engine with intake air temperature control system

Owner:SOLAR TURBINES

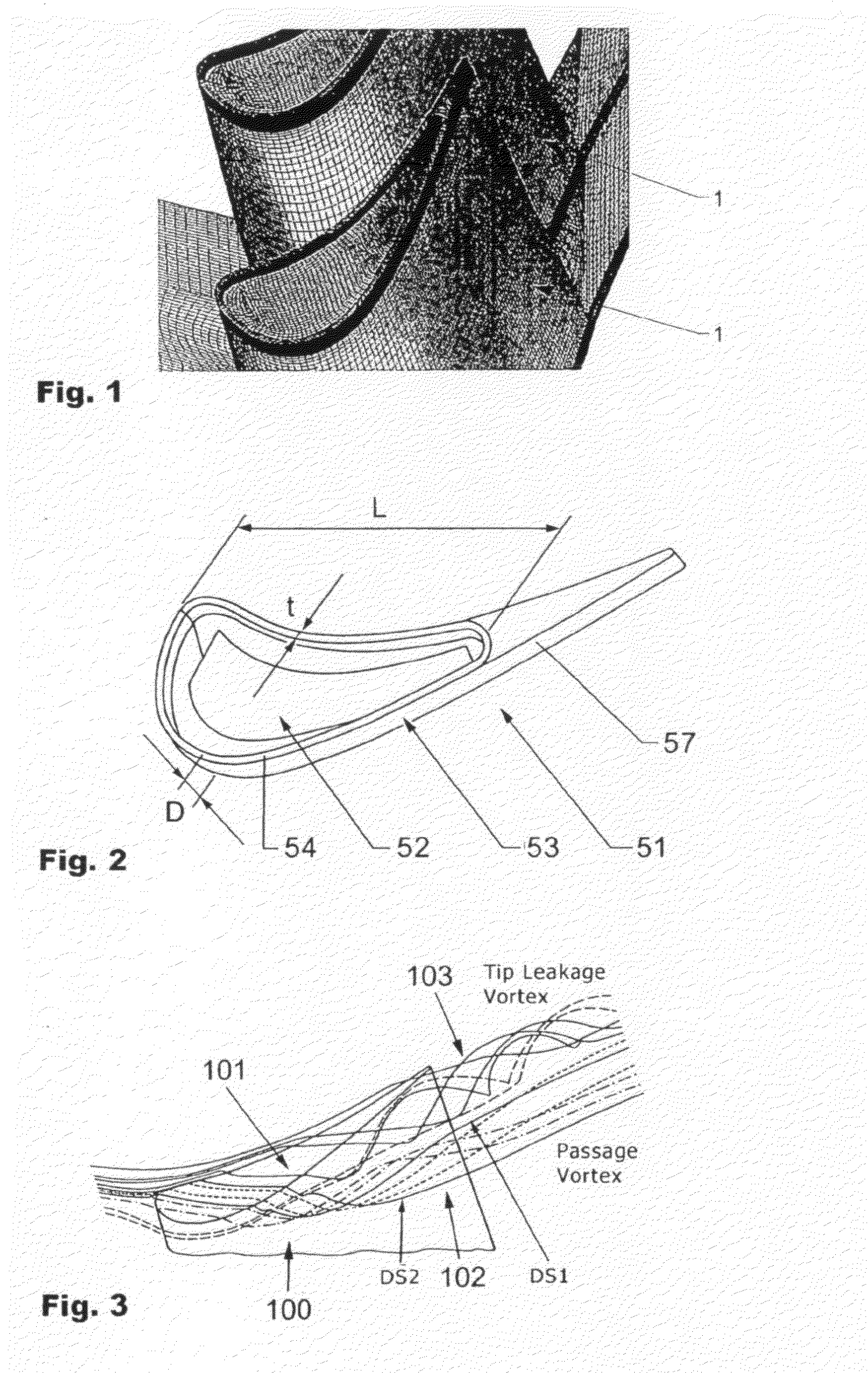

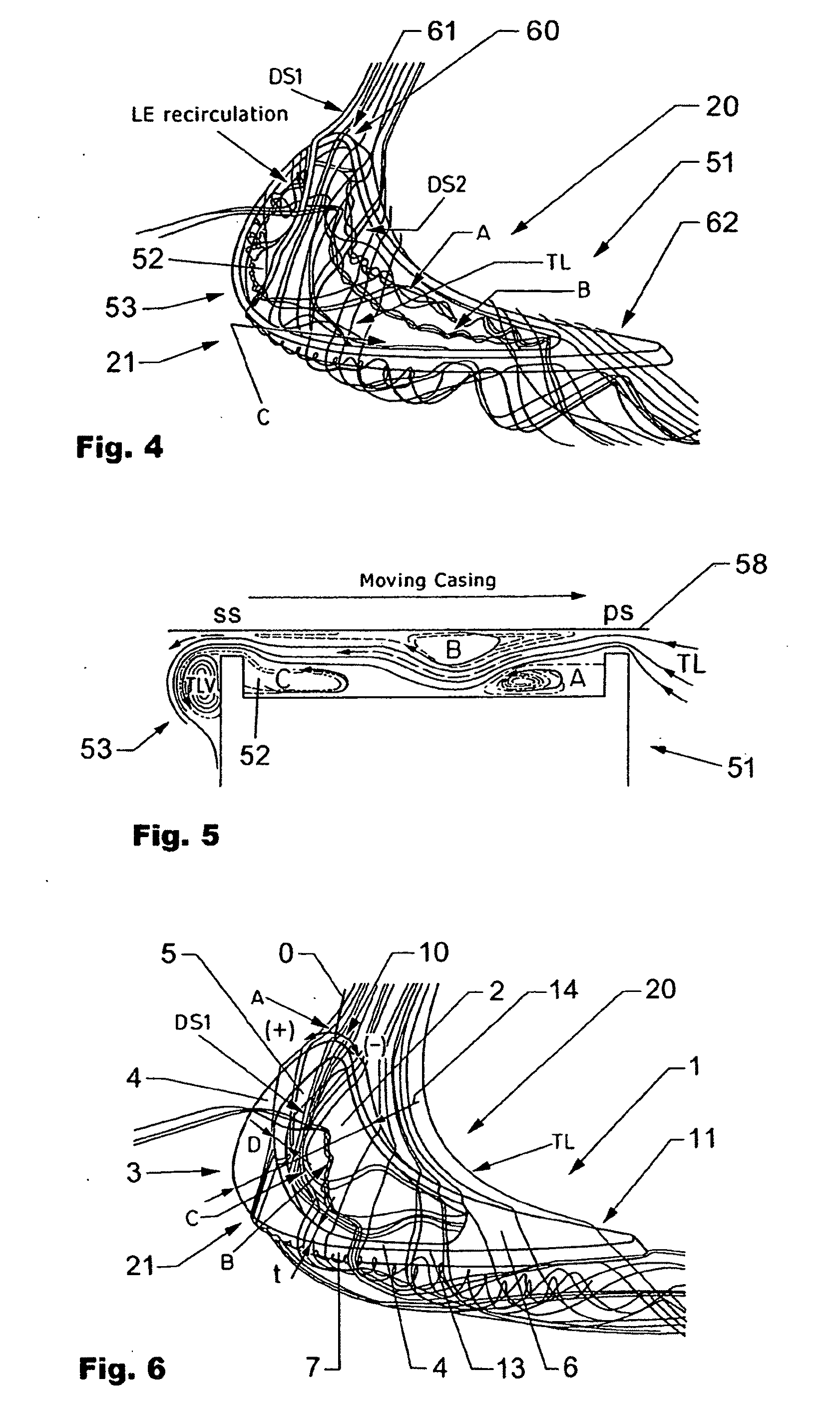

Turbine Blade With Recessed Tip

InactiveUS20090180887A1Improve performanceReduce heat loadBlade accessoriesLeakage preventionTurbine bladeAerodynamics

Owner:ZURICH ETH

Method for repairing a turbine engine vane assembly and repaired assembly

Owner:GENERAL ELECTRIC CO

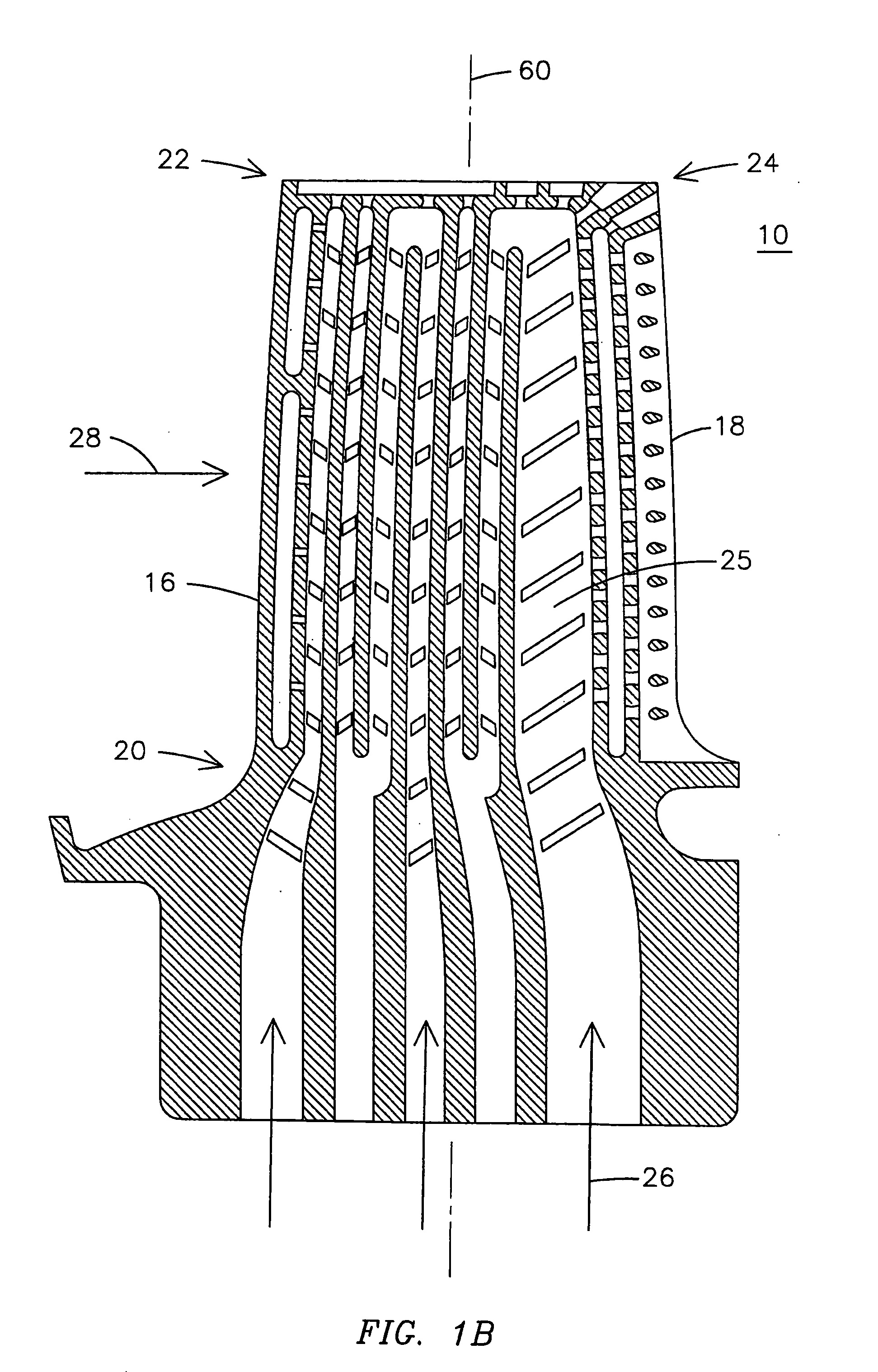

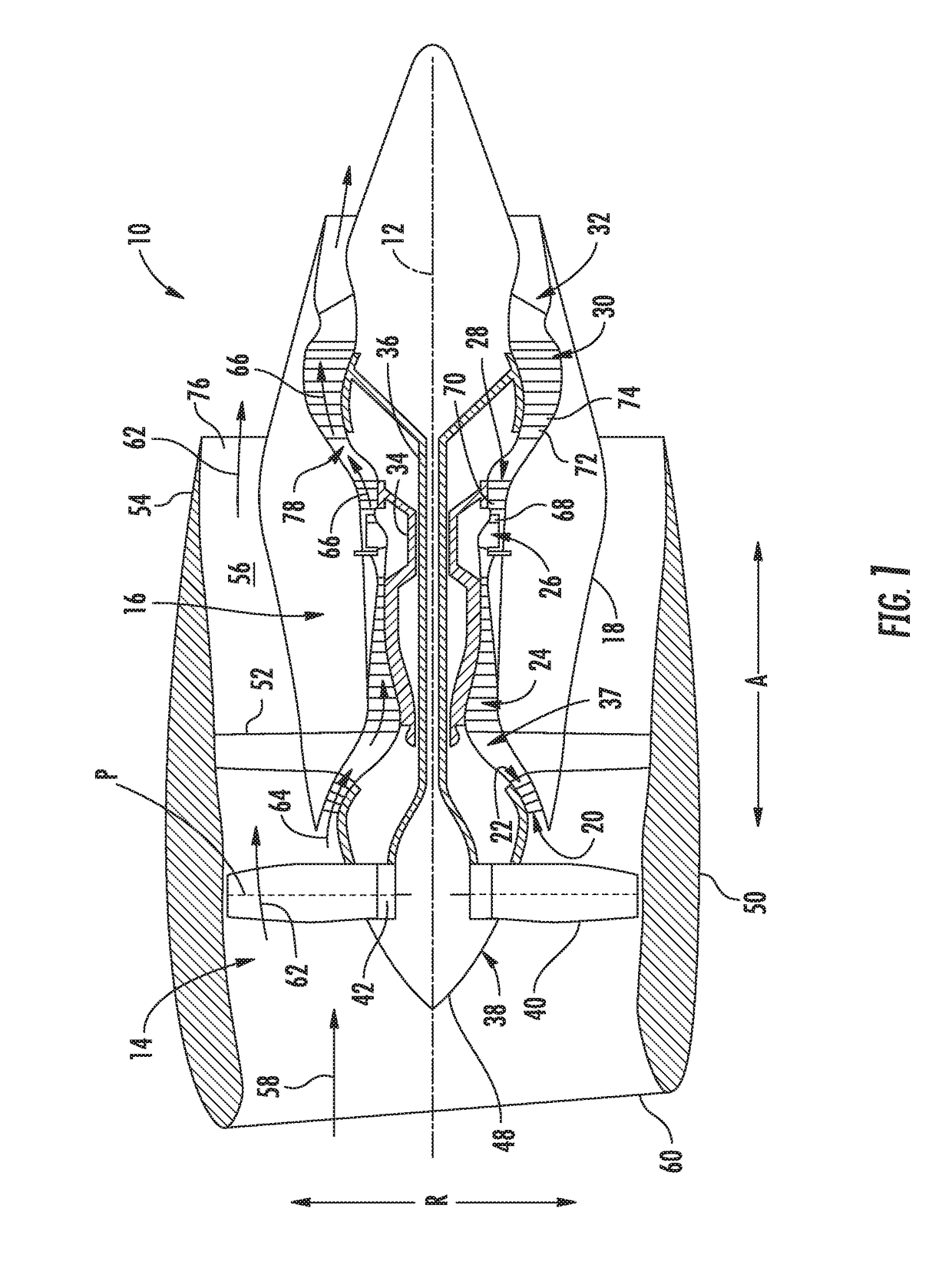

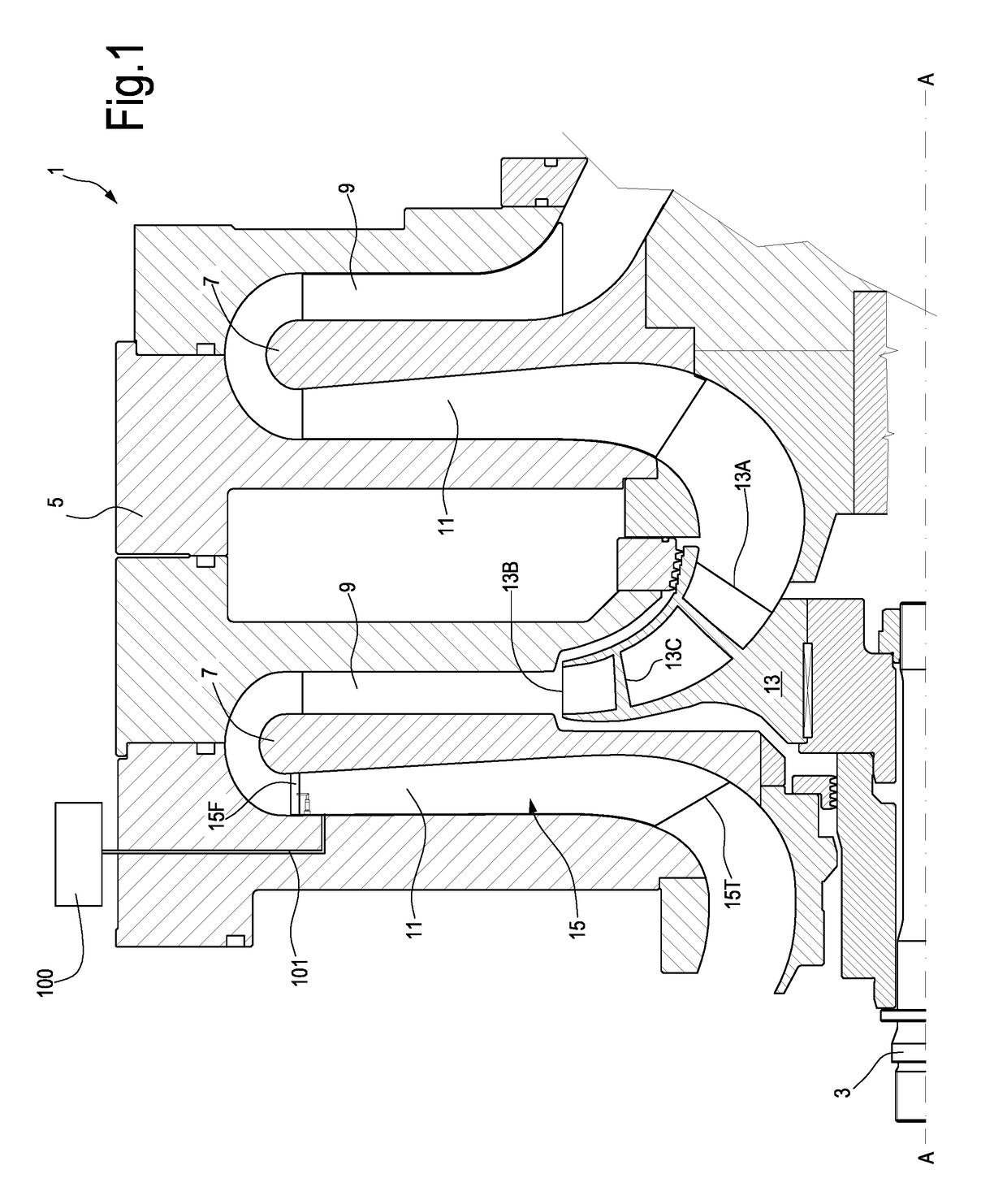

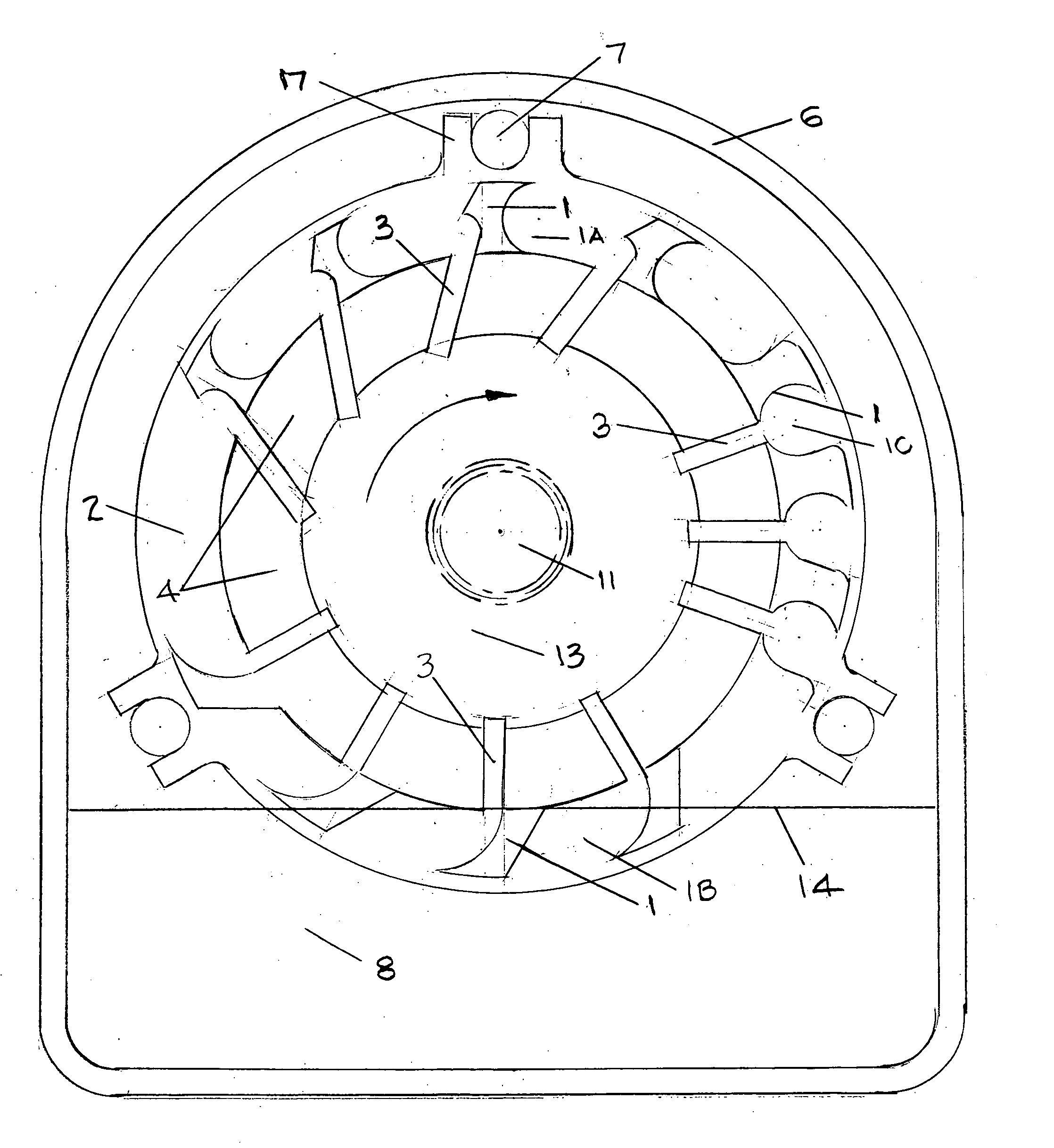

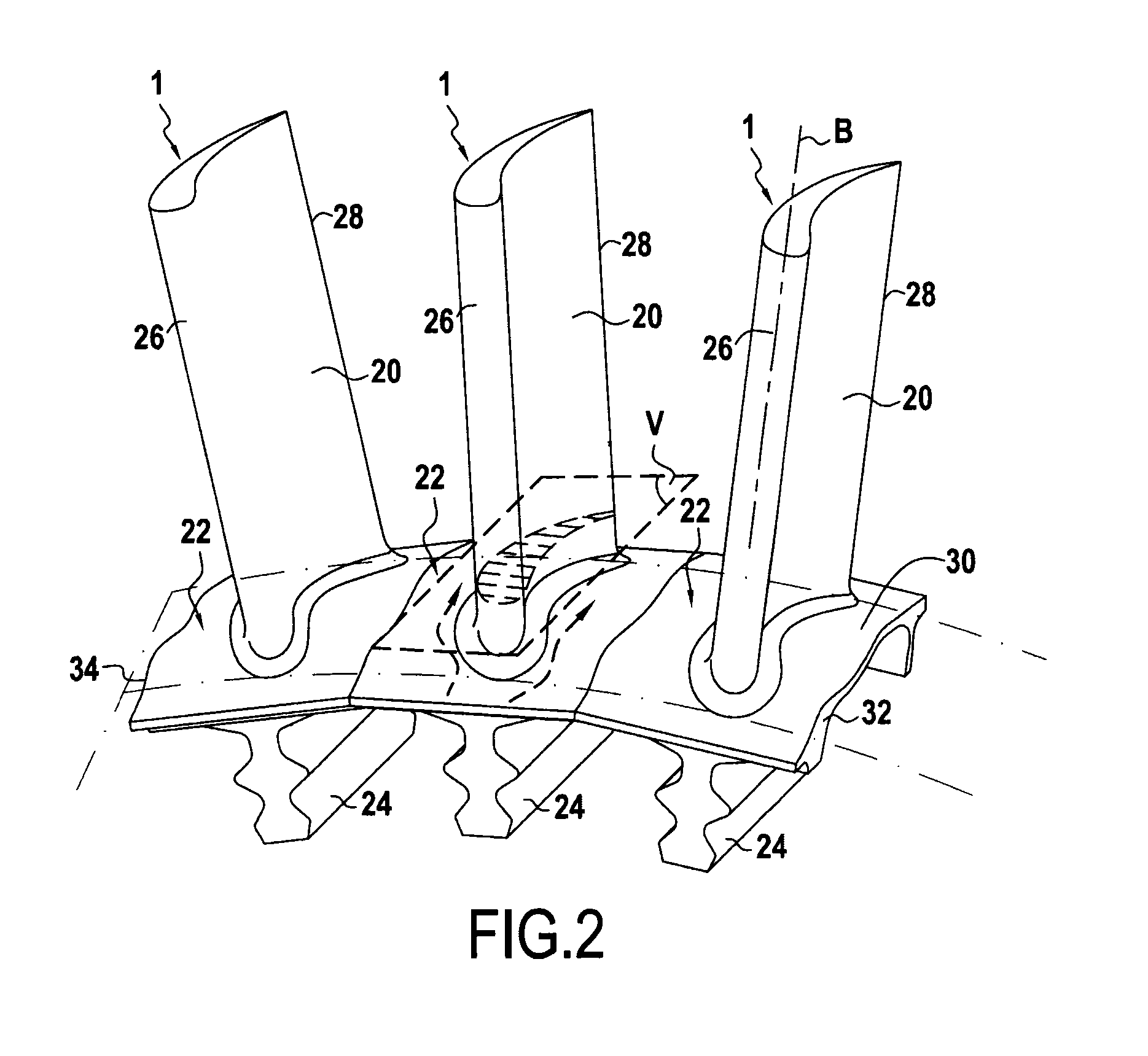

Cooled aerofoil blade or vane

ActiveUS20110058958A1Promoting a favourable pressure gradientPressure lossEngine manufactureBlade accessoriesTurbineCooling fluid

An aerofoil blade or vane (1) suitable for the turbine of a gas turbine engine includes a longitudinally extending aerofoil portion (7) having facing wall parts (20, 22). The wall parts being interconnected by a generally longitudinally extending divider member (17) to partially define first and second cooling fluid passage portions (11, 15) disposed in side-by-side generally longitudinally extending relationship. The first and second passage portions being interconnected in series fluid flow relationship by a bend passage portion (13). The first passage portion is adapted to direct cooling fluid to the bend portion and the second passage portion being adapted to exhaust cooling fluid from the bend portion. The divider member has a first local thickening (33) in the region of the bend portion to provide a localised contraction of the downstream end of the first passage portion to accelerate the cooling fluid flow before it enters the bend passage portion. The divider member has a second local thickening (31) in the region of the bend portion to provide a localised progressive series narrowing and opening of the upstream end of the second passage portion in the general direction of cooling fluid flow.

Owner:ROLLS ROYCE PLC

Noise suppression apparatus and methods of manufacturing the same

Owner:HONEYWELL INT INC

Low modulus insert for a component of a gas turbine engine

Owner:GENERAL ELECTRIC CO

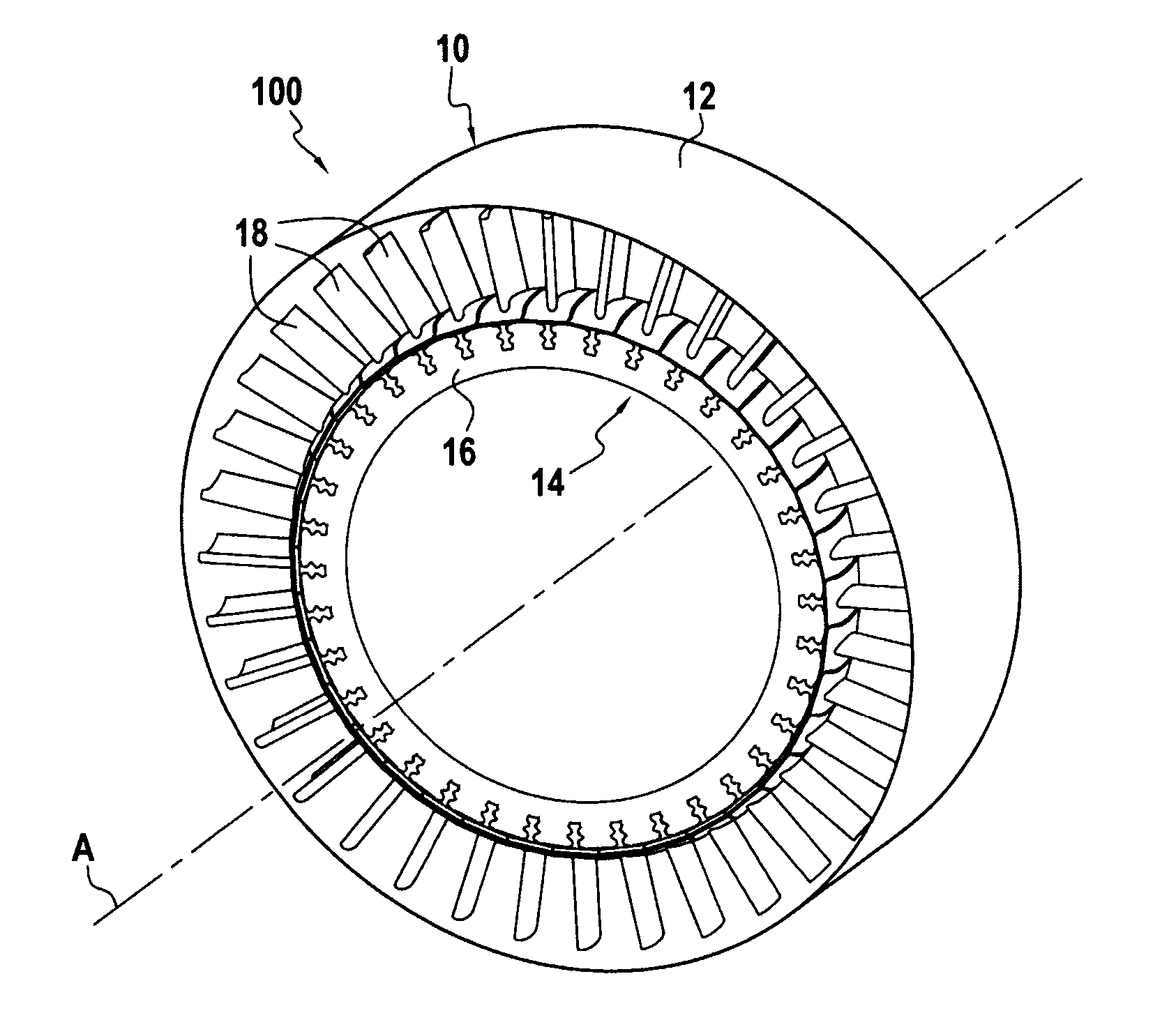

Hub for radial housing of a helical ring of a turbomachine with variable-pitch blades and assembly comprising such a hub

The present invention relates to a helical ring (100) comprising a polygonal body (110) and a plurality of cylindrical radial housings (150) arranged in said body, each housing (150) having a surface adapted to receive support means of a blade of a helix, characterised in that the surface of each housing (150) is arranged on a radially internal surface (201) of a corresponding hub (200), each hub (200) being a separate piece attached to the body (110) of the ring, intended to be received in a radial housing (21) of the latter, and in that it also comprises two projecting pins (32) relative to its external surface to be fastened to the edges of a housing of the annular body, the two projecting pins forming a centring axis.The invention also relates to a manufacturing process of such a ring, a helix and a turbomachine fitted with such a ring.

Owner:SAFRAN AIRCRAFT ENGINES

Measuring total pressure of a fluid in a turbomachine

ActiveUS20180156059A1Improve accuracyLess sensitiveEngine fuctionsBlade accessoriesTrailing edgeEngineering

Owner:NUOVO PIGNONE SPA

Turbine nozzles with slip joints impregnated by oxidation-resistant sealing material and methods for the production thereof

Owner:HONEYWELL INT INC

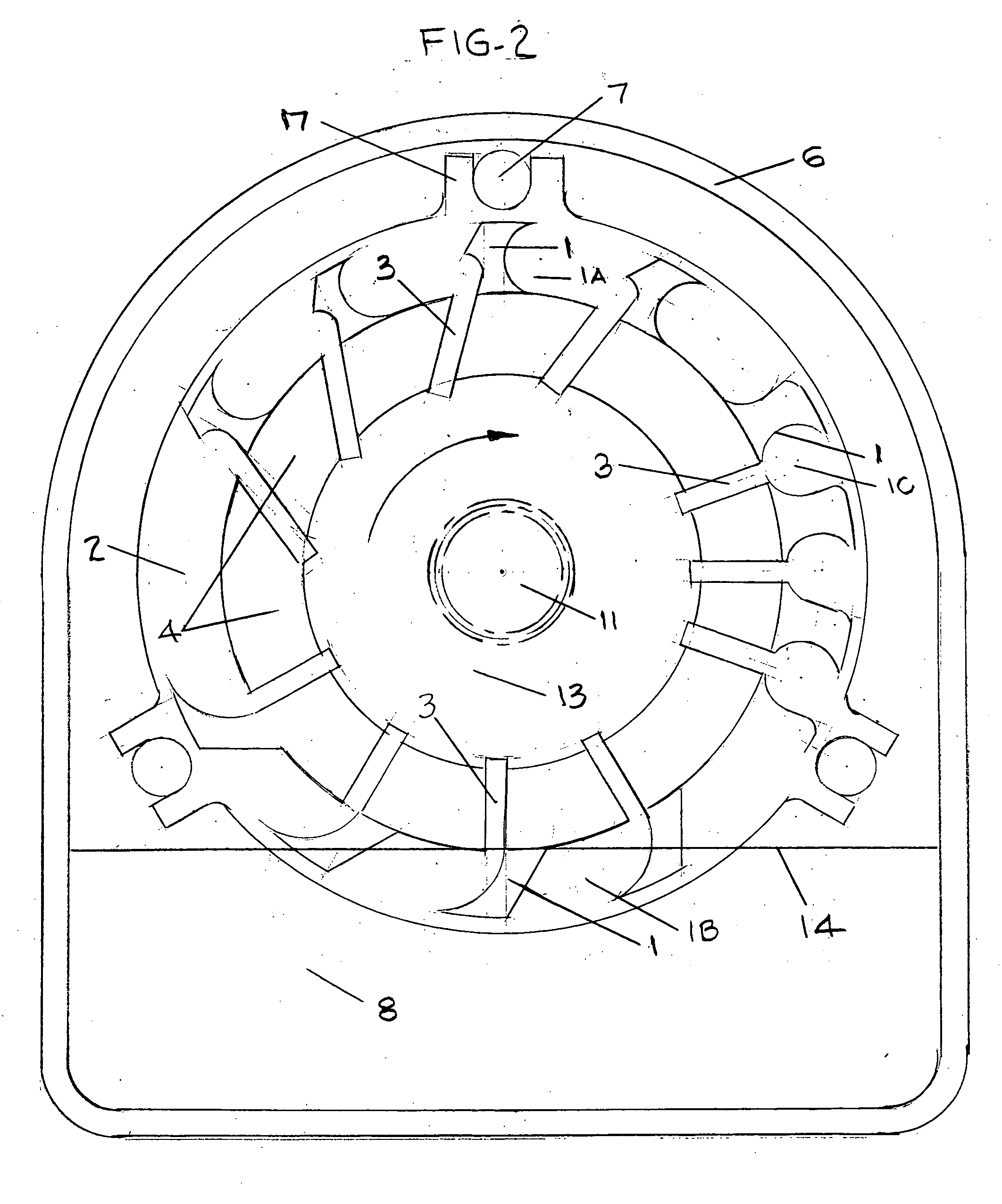

Wet friction device with inward and outward circulating cooling means

Owner:ASCHAUER GEORGE REISCH

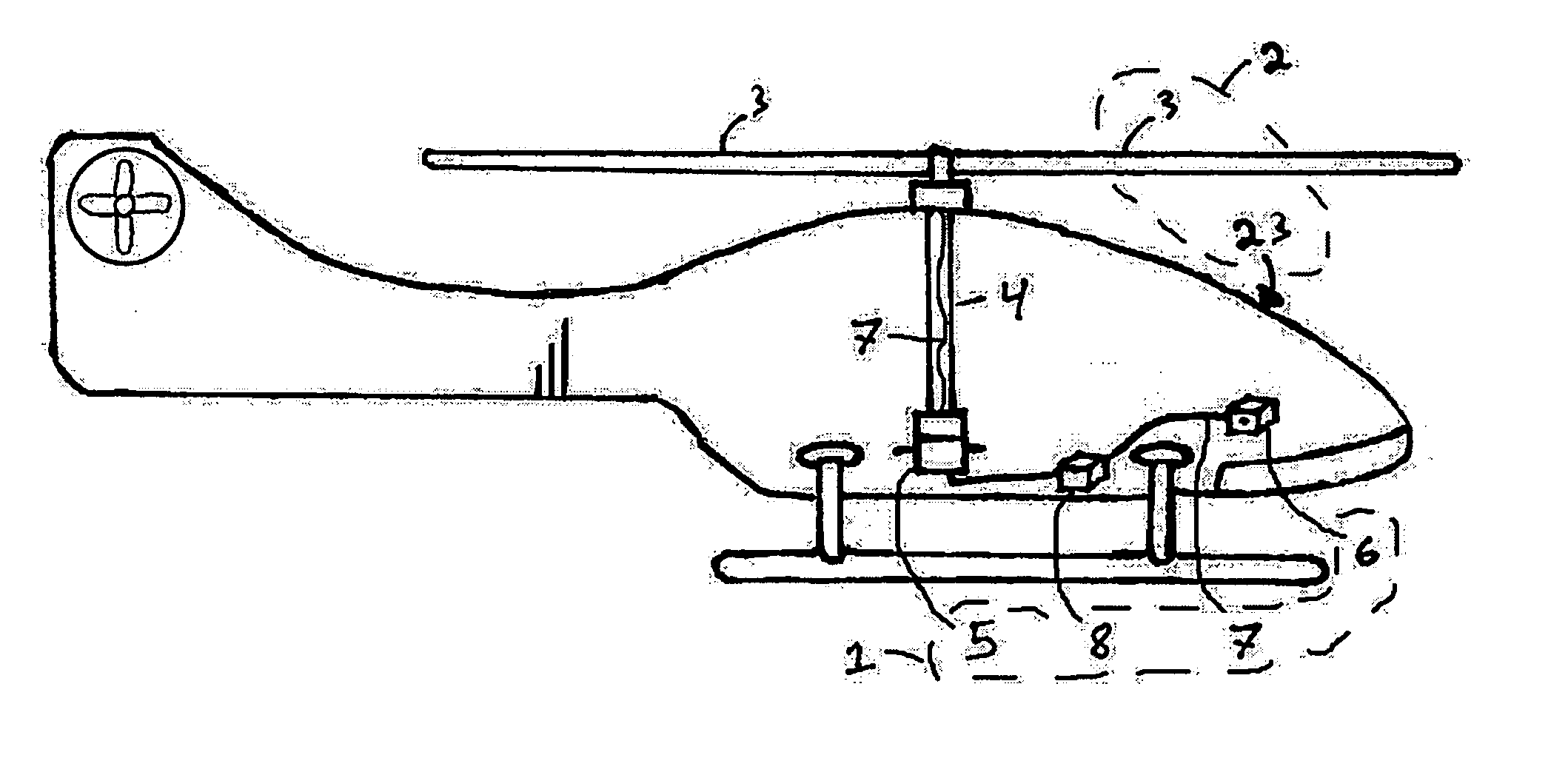

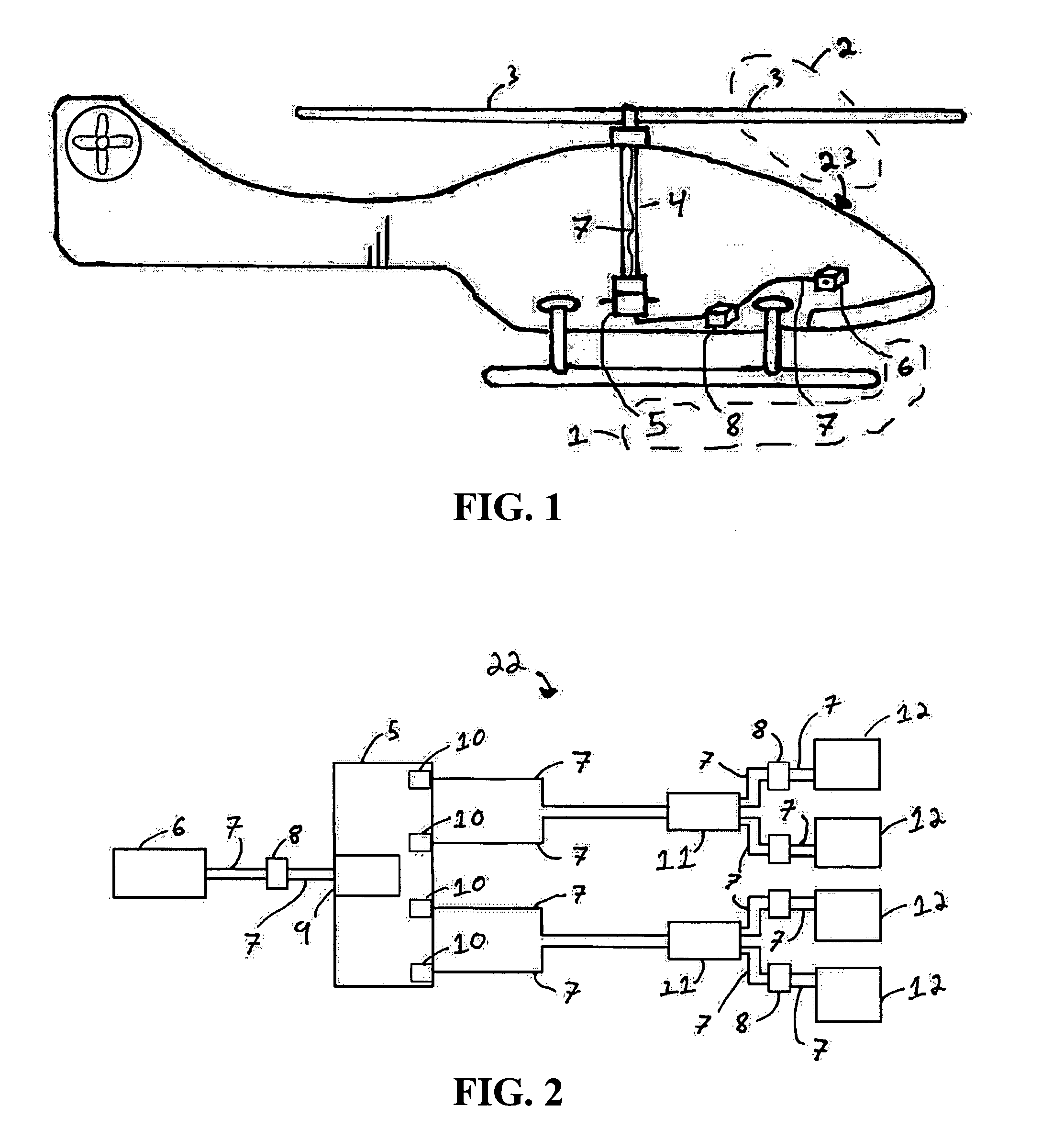

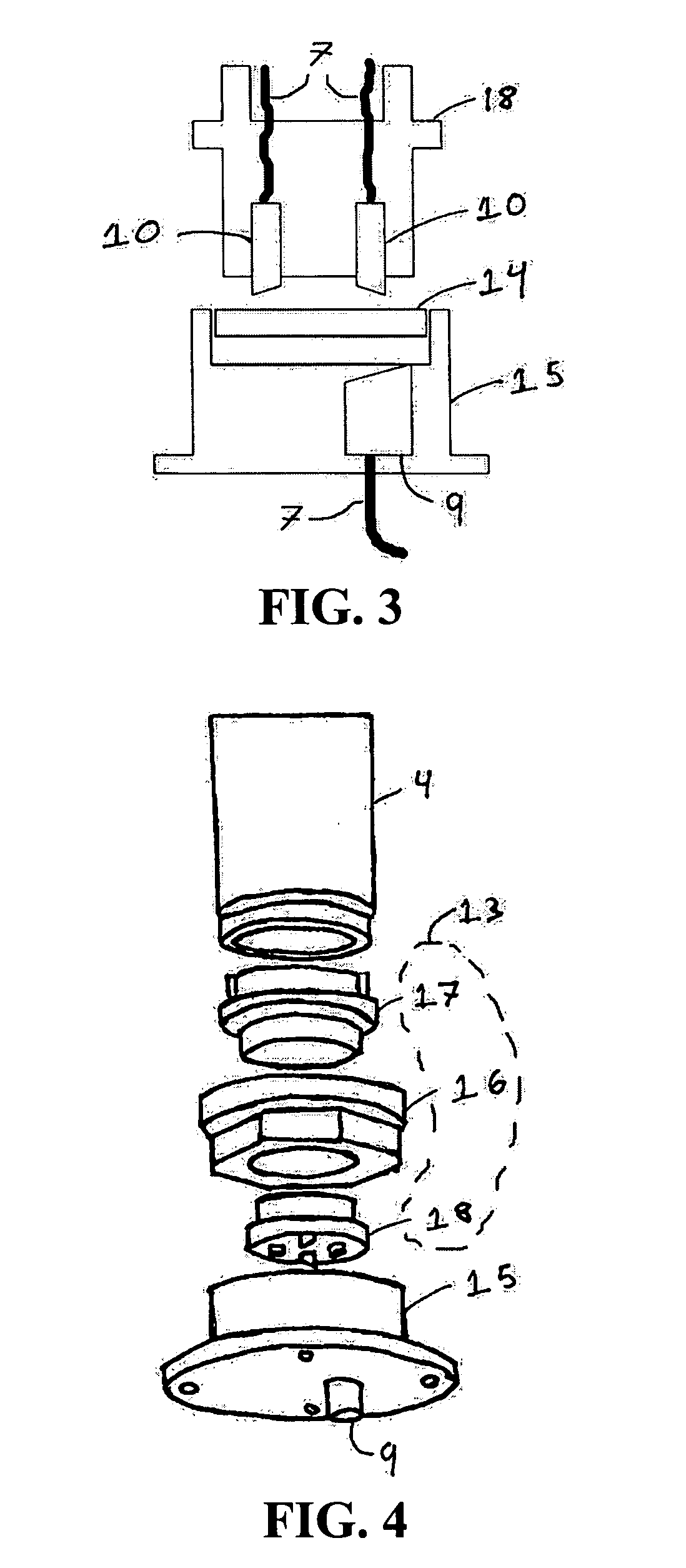

Helicopter blade emergency detachment system

Owner:BOICE WILLIAM SPENCER +2

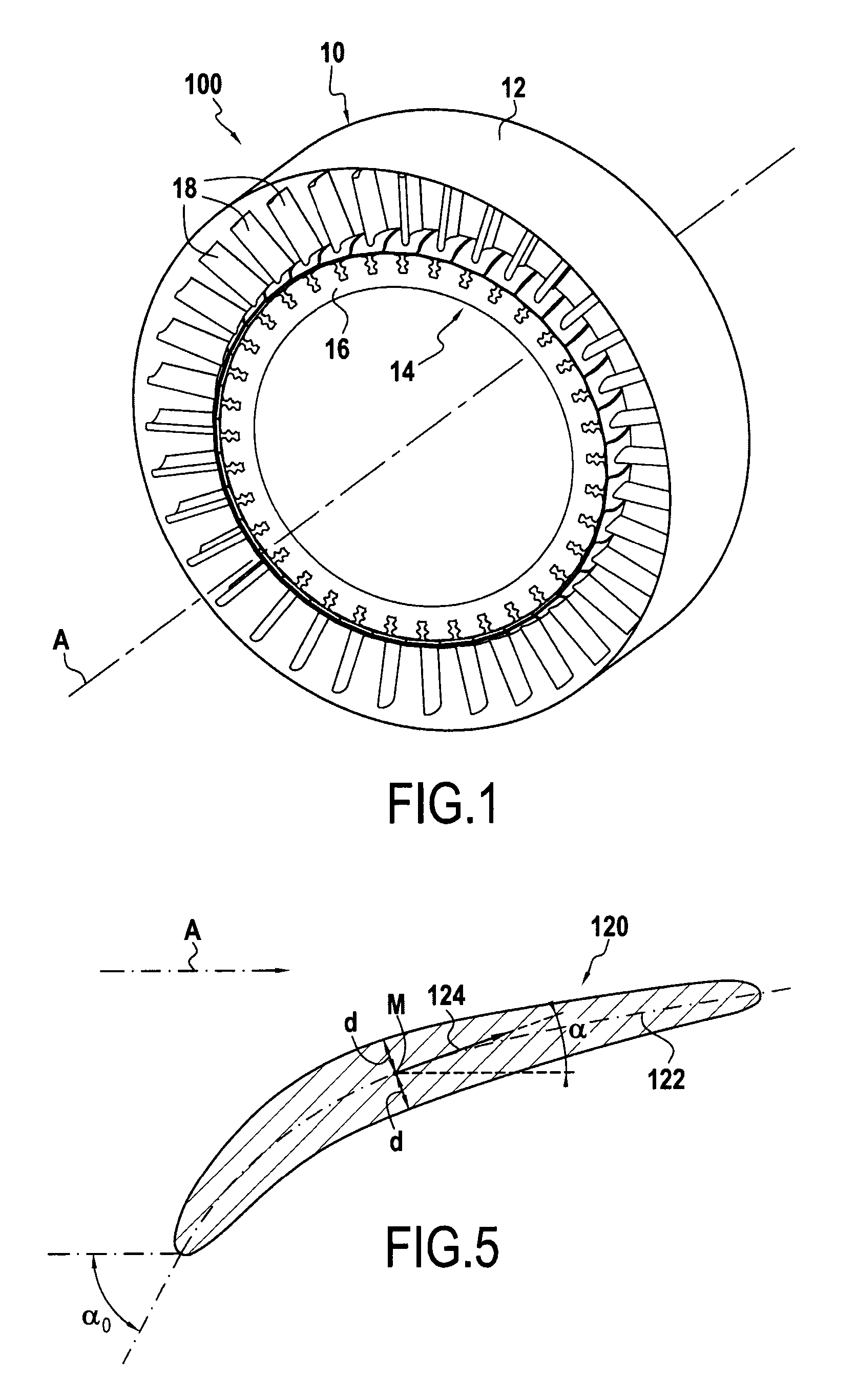

Airfoil and platform assembly for supersonic flow

ActiveUS9458720B2Improve aerodynamic performanceControl deflectionEngine manufactureBlade accessoriesLeading edgeEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Vibrometer mounting mechanism

ActiveUS20090071256A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesMechanical engineeringRotary machine

Owner:MITSUBISHI HEAVY IND LTD

Coated substrates and methods of producing the same

Owner:HONEYWELL INT INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap