Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Helix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A helix (/ˈhiːlɪks/), plural helixes or helices (/ˈhɛlɪsiːz/), is a type of smooth space curve, i.e. a curve in three-dimensional space. It has the property that the tangent line at any point makes a constant angle with a fixed line called the axis. Examples of helices are coil springs and the handrails of spiral staircases. A "filled-in" helix – for example, a "spiral" (helical) ramp – is called a helicoid. Helices are important in biology, as the DNA molecule is formed as two intertwined helices, and many proteins have helical substructures, known as alpha helices. The word helix comes from the Greek word ἕλιξ, "twisted, curved".

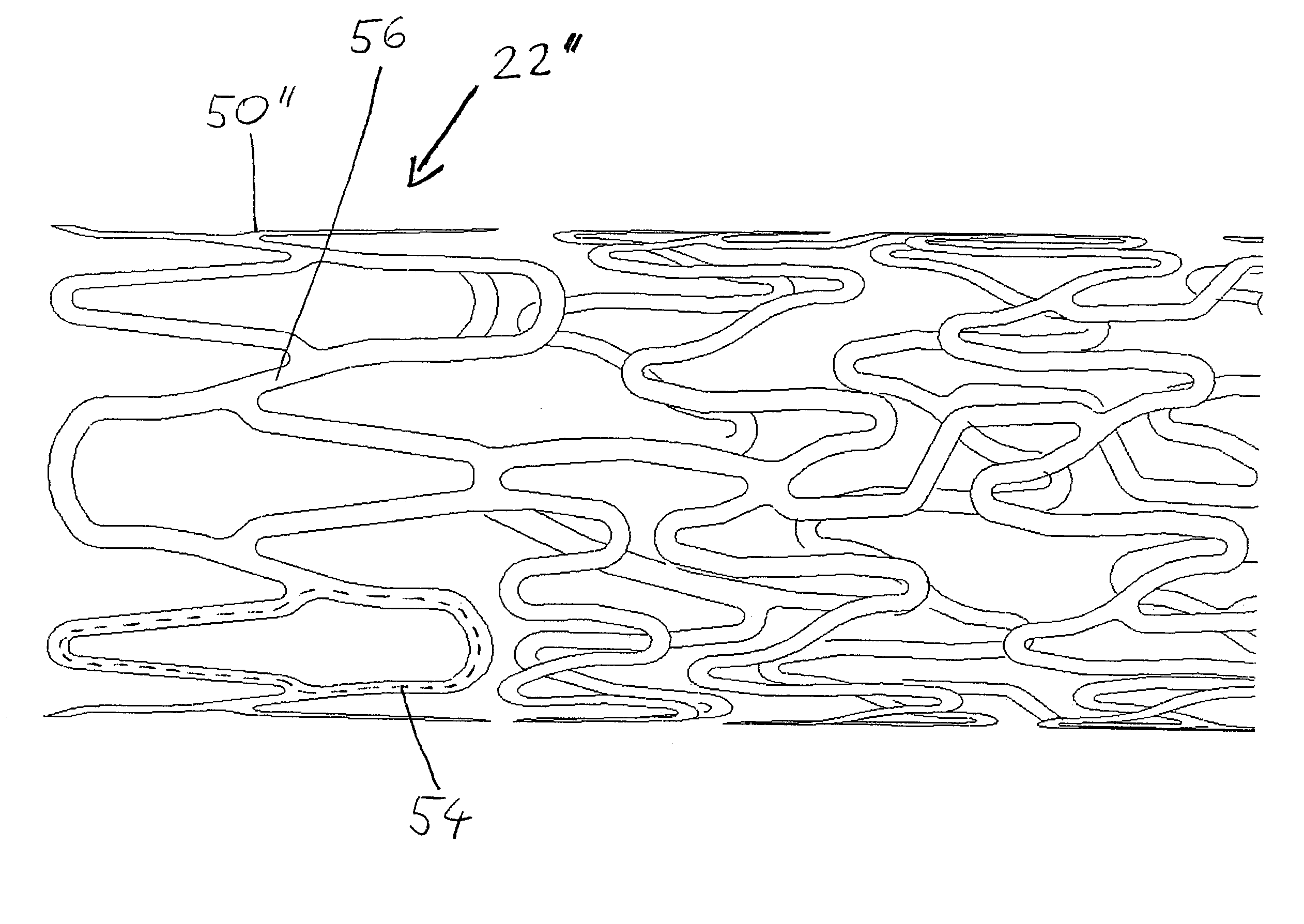

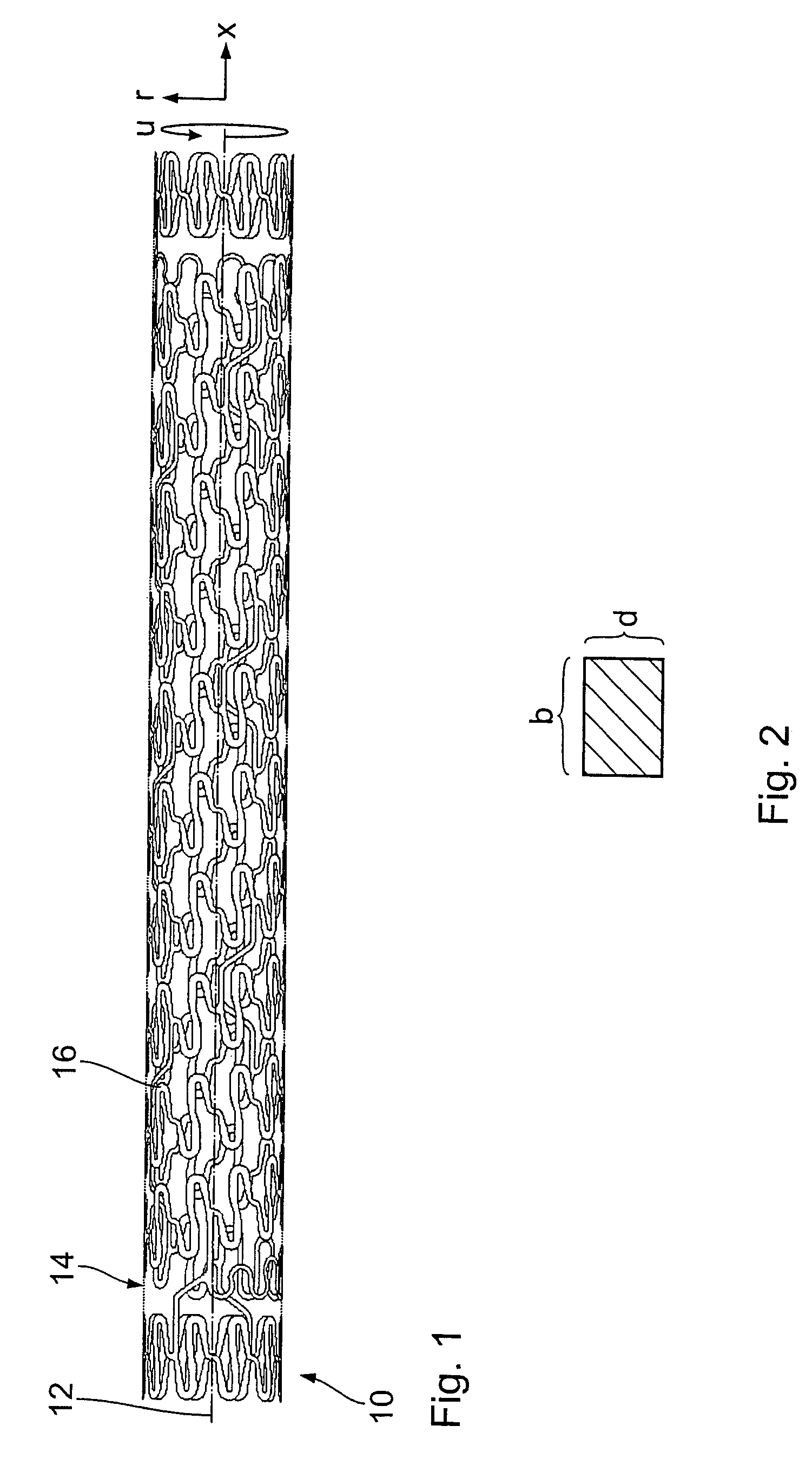

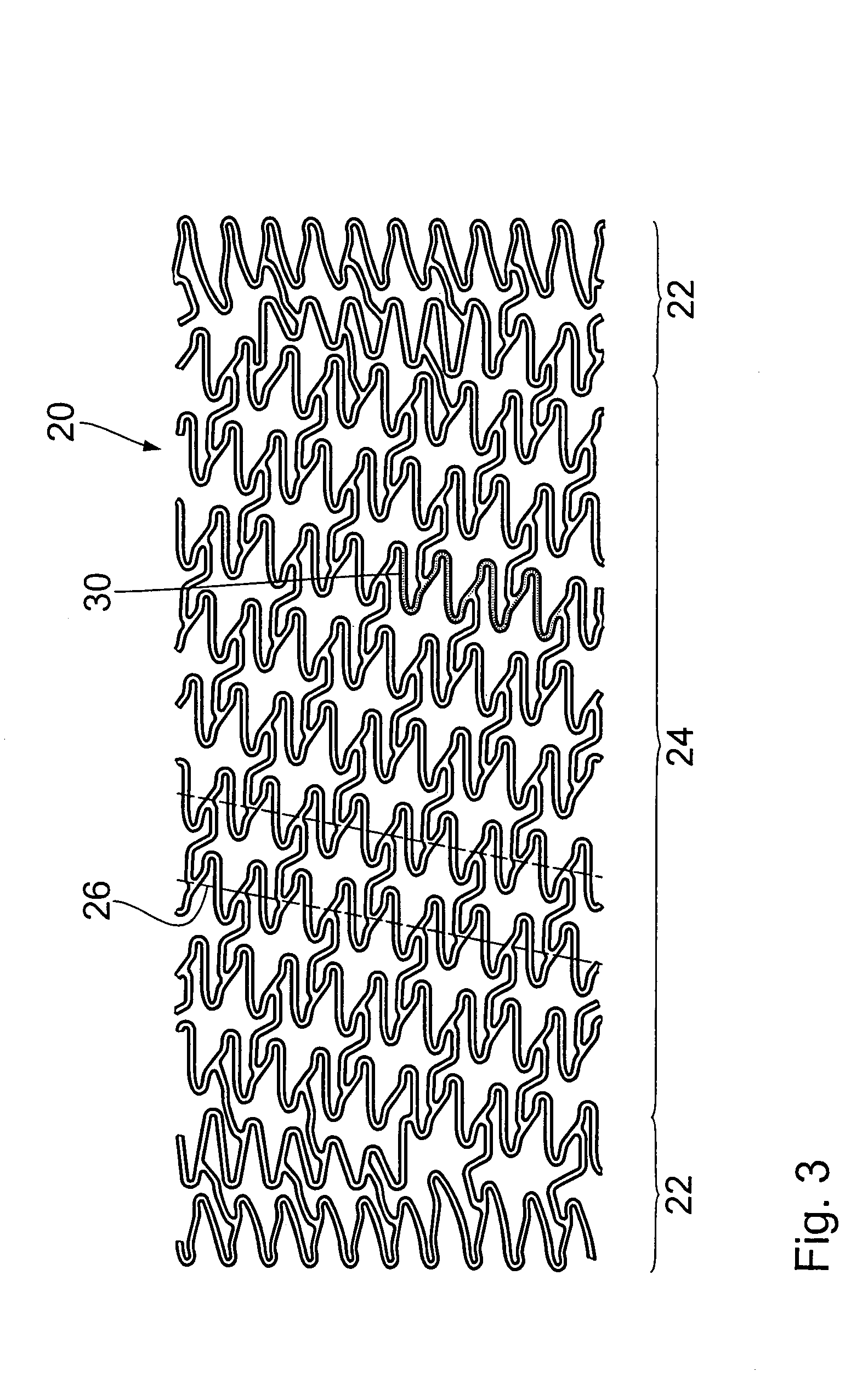

Stent

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

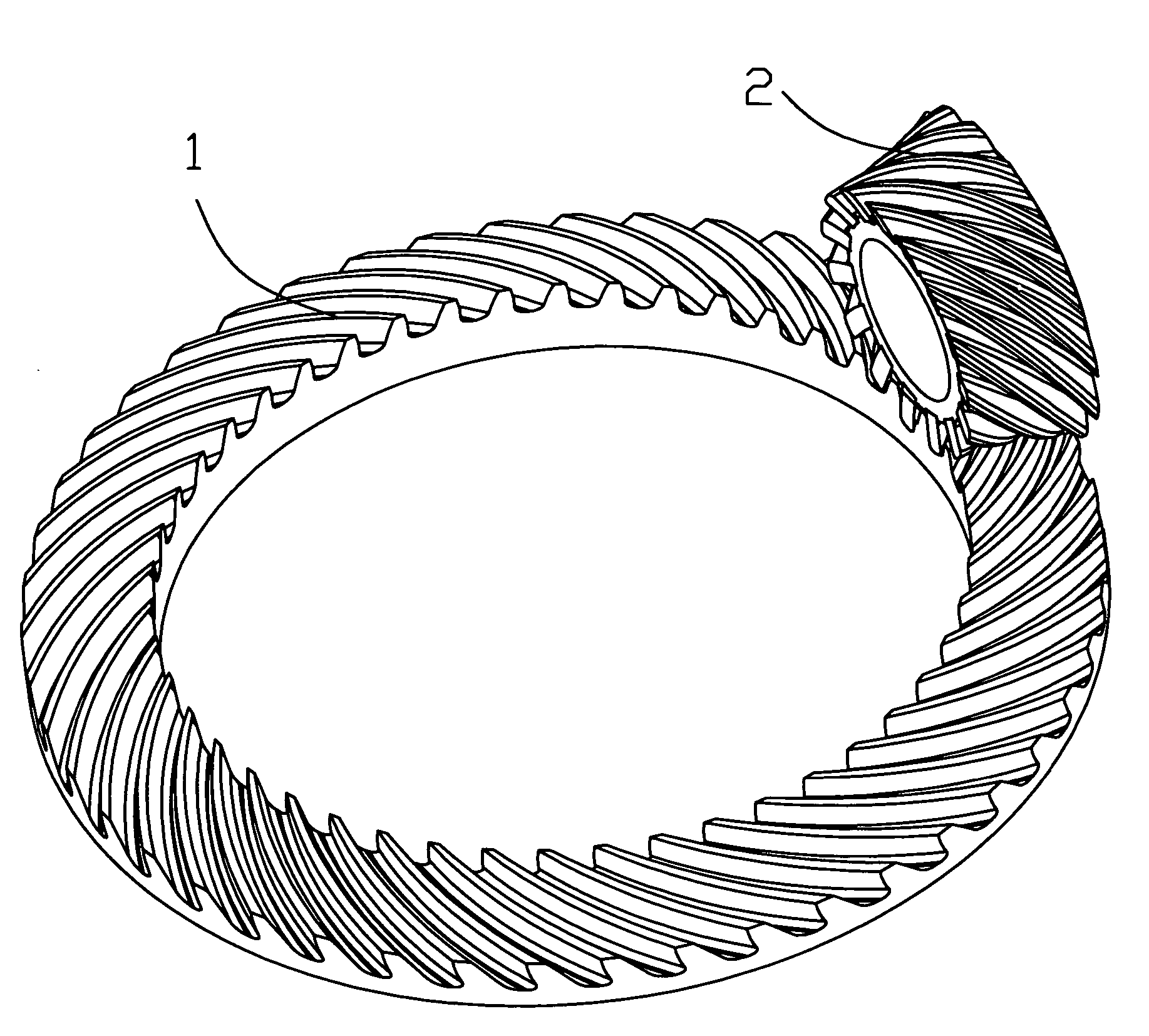

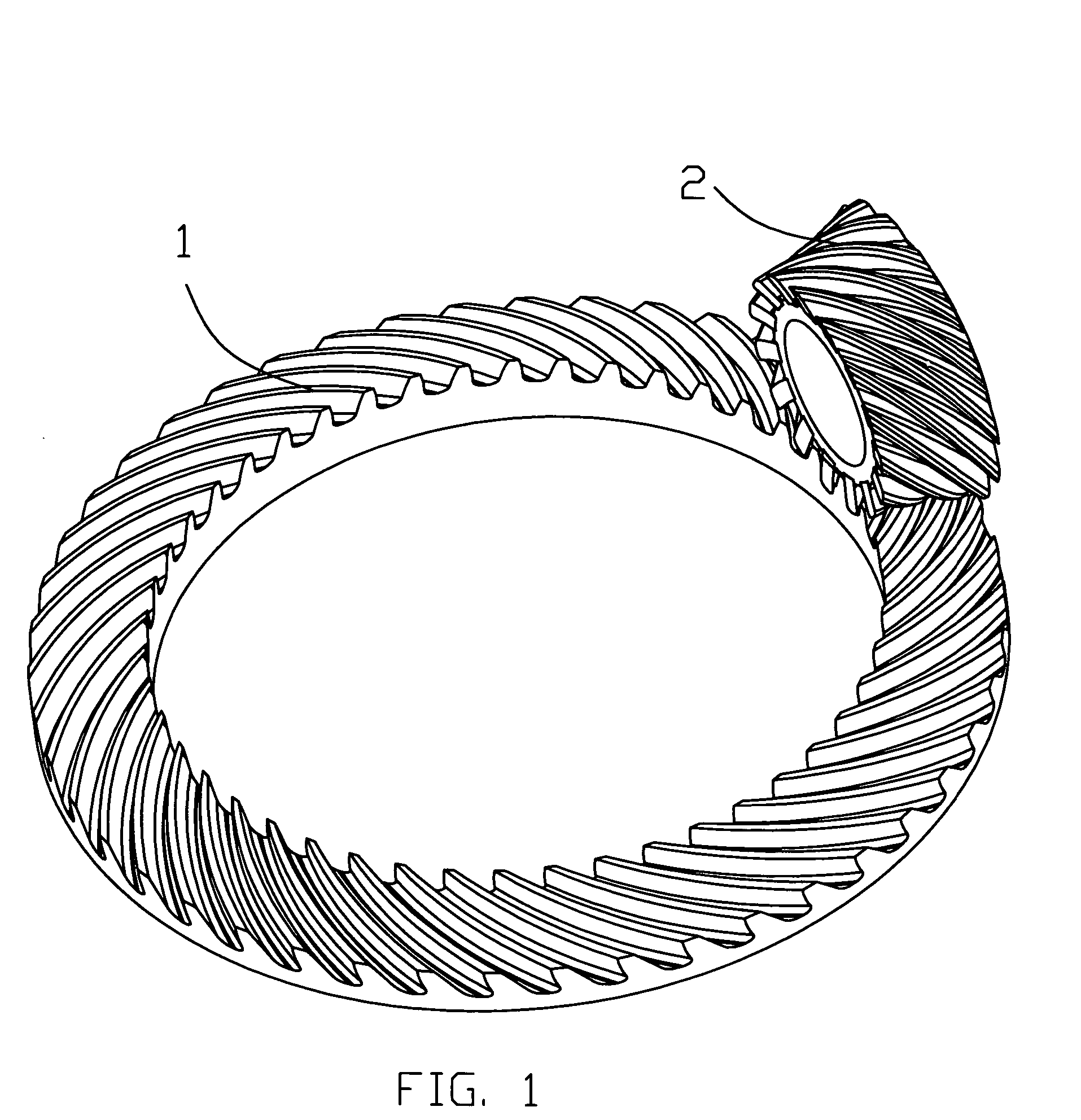

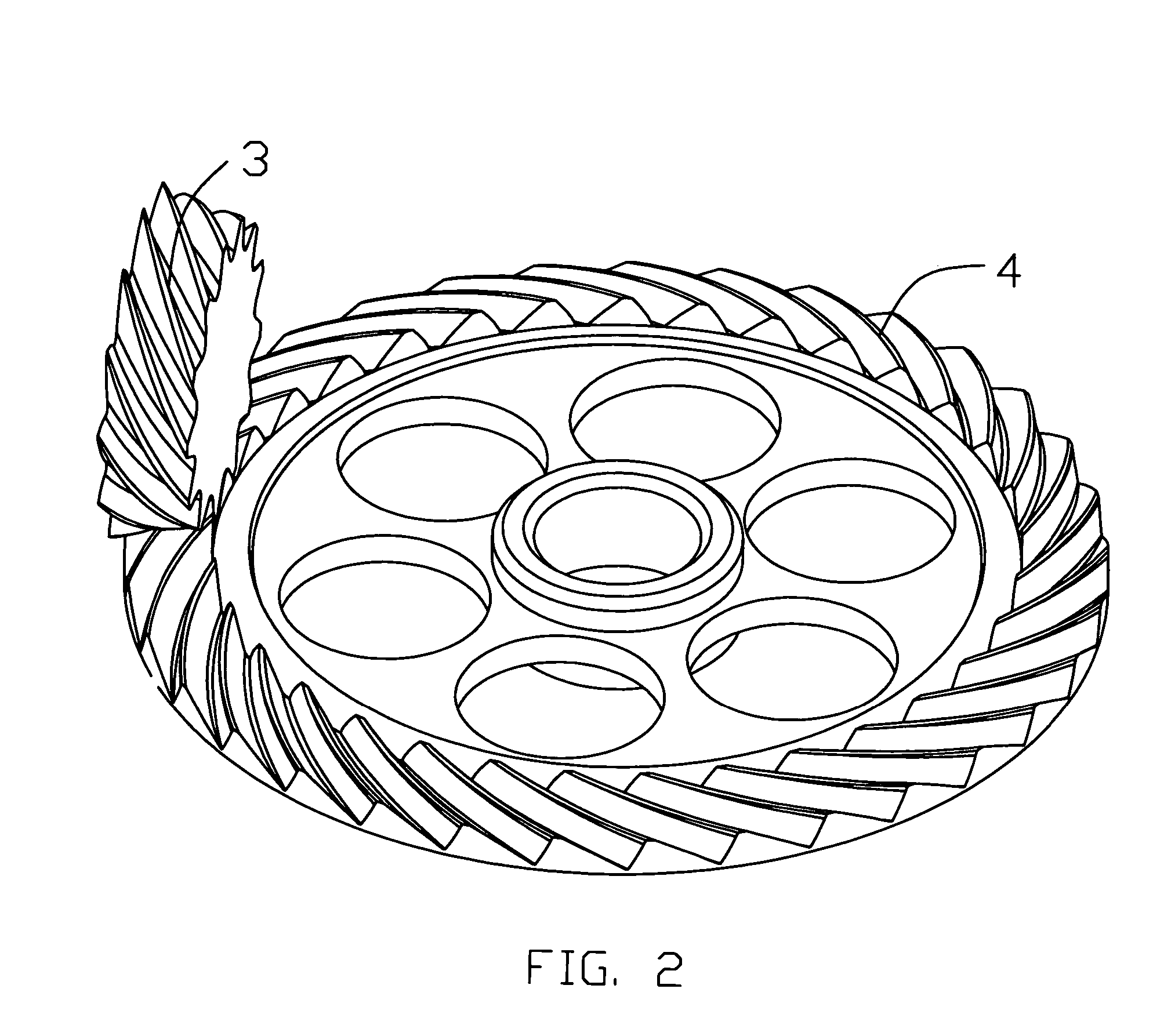

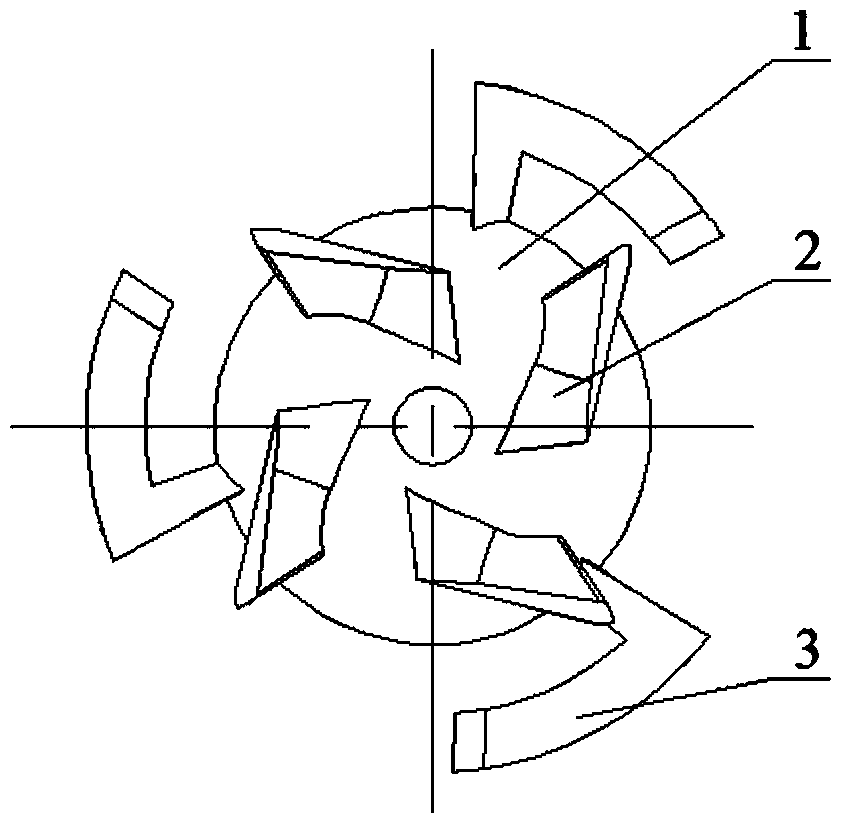

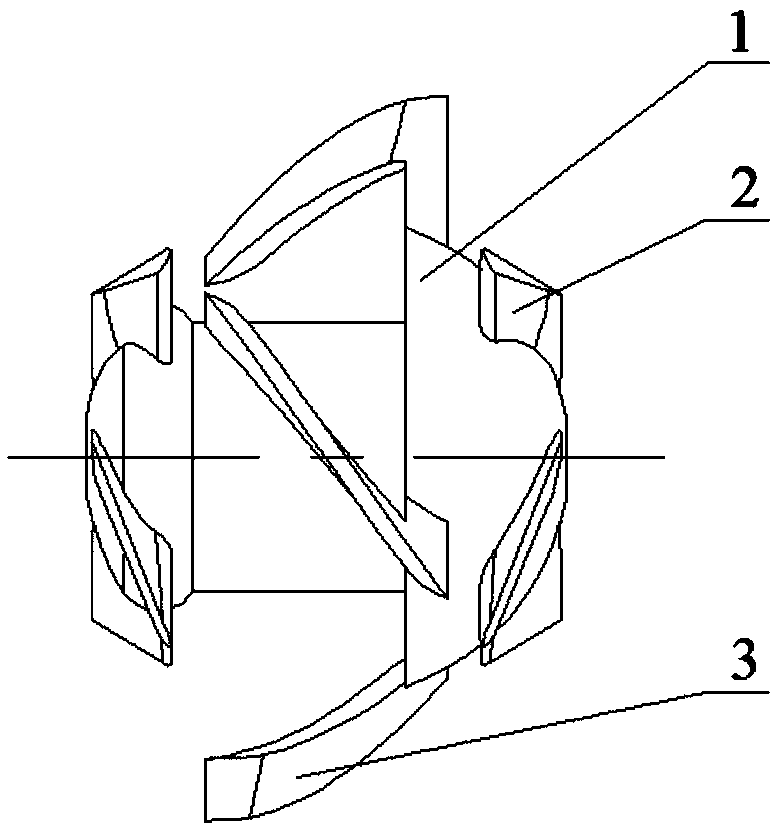

Method of generation of face enveloping gears

InactiveUS20060090340A1Faster in ratioLow production costMetal-working apparatusGear wheelsEngineeringHelix

Owner:FLEYTMAN YAKOV

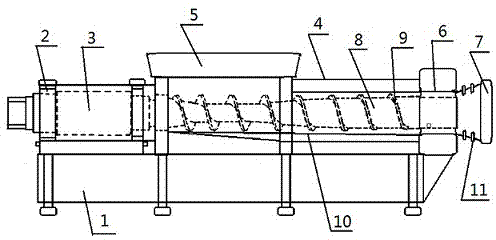

Single-screw extruder

Owner:NANNING SUGAR INDUSTRY CO LTD

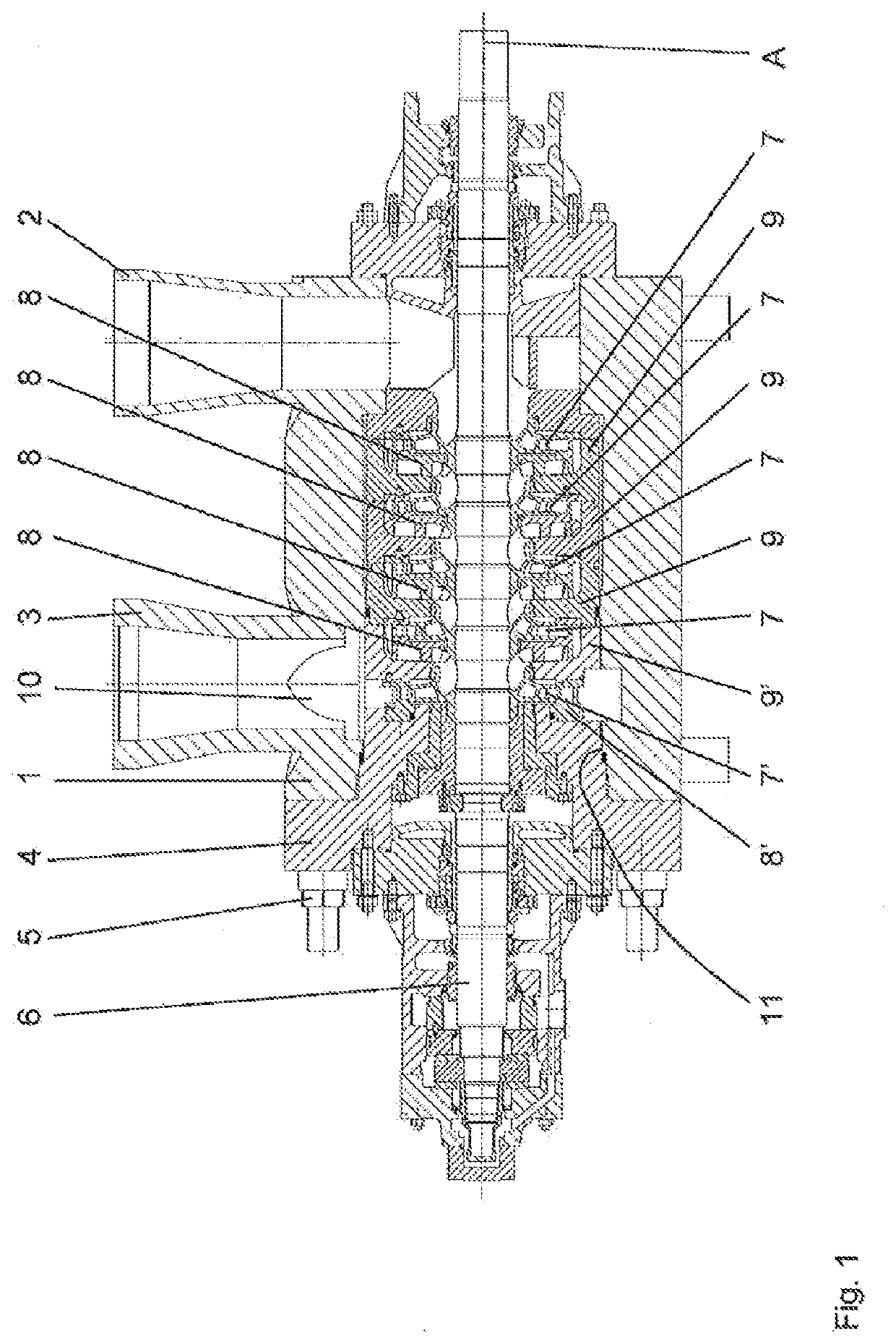

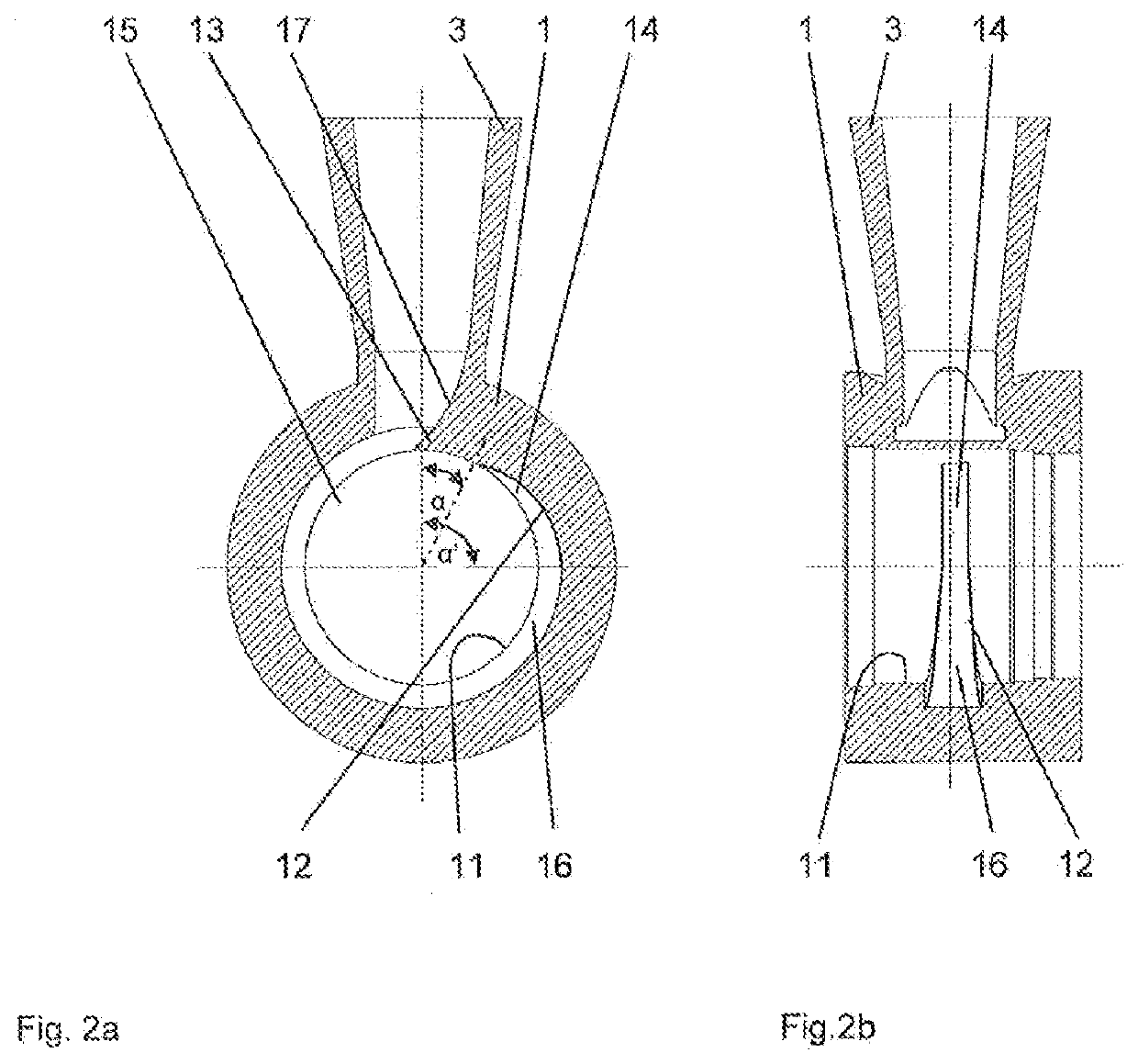

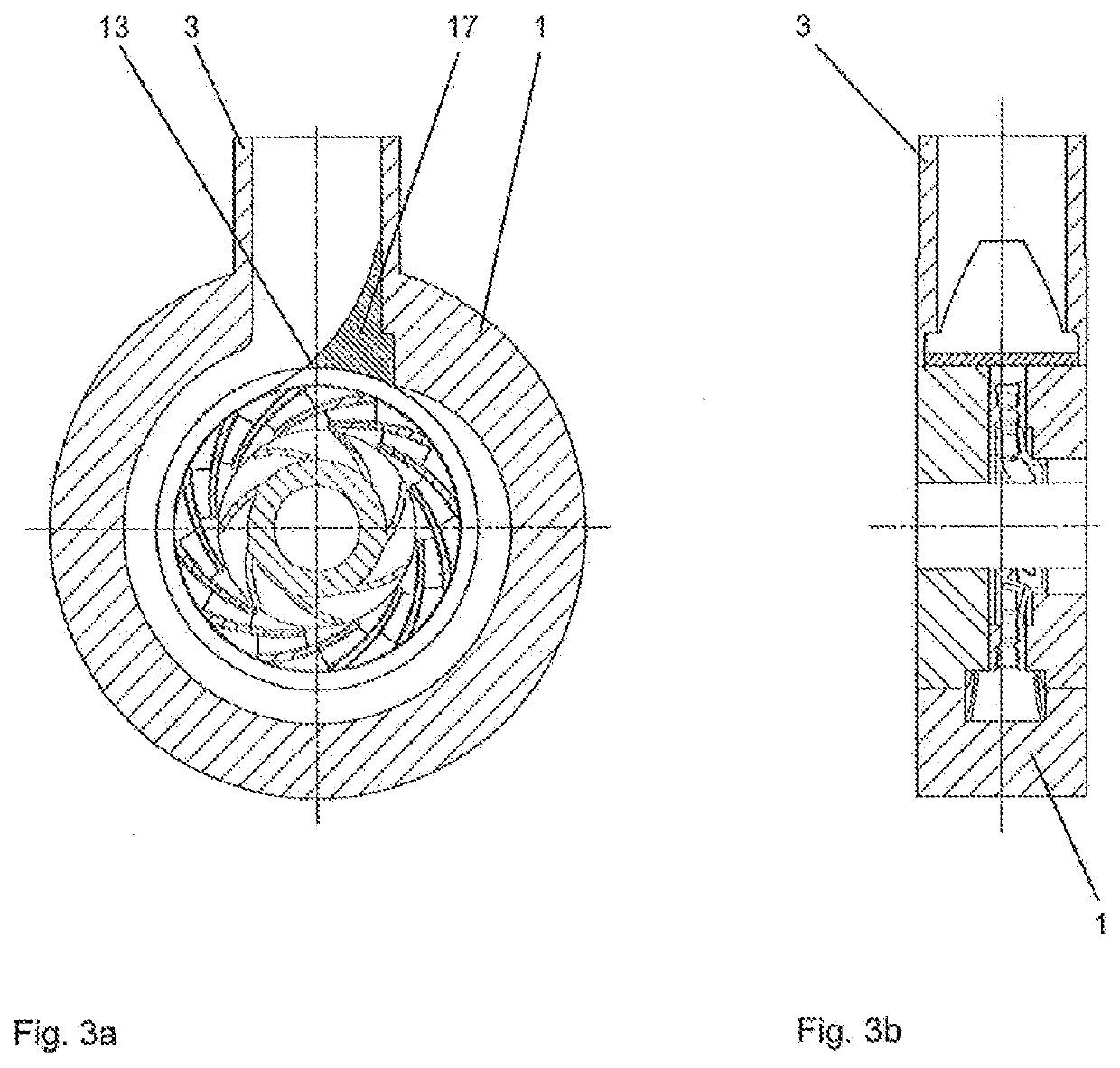

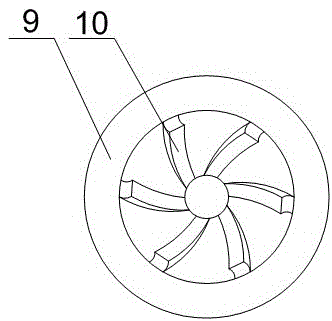

Hub for radial housing of a helical ring of a turbomachine with variable-pitch blades and assembly comprising such a hub

The present invention relates to a helical ring (100) comprising a polygonal body (110) and a plurality of cylindrical radial housings (150) arranged in said body, each housing (150) having a surface adapted to receive support means of a blade of a helix, characterised in that the surface of each housing (150) is arranged on a radially internal surface (201) of a corresponding hub (200), each hub (200) being a separate piece attached to the body (110) of the ring, intended to be received in a radial housing (21) of the latter, and in that it also comprises two projecting pins (32) relative to its external surface to be fastened to the edges of a housing of the annular body, the two projecting pins forming a centring axis.The invention also relates to a manufacturing process of such a ring, a helix and a turbomachine fitted with such a ring.

Owner:SAFRAN AIRCRAFT ENGINES

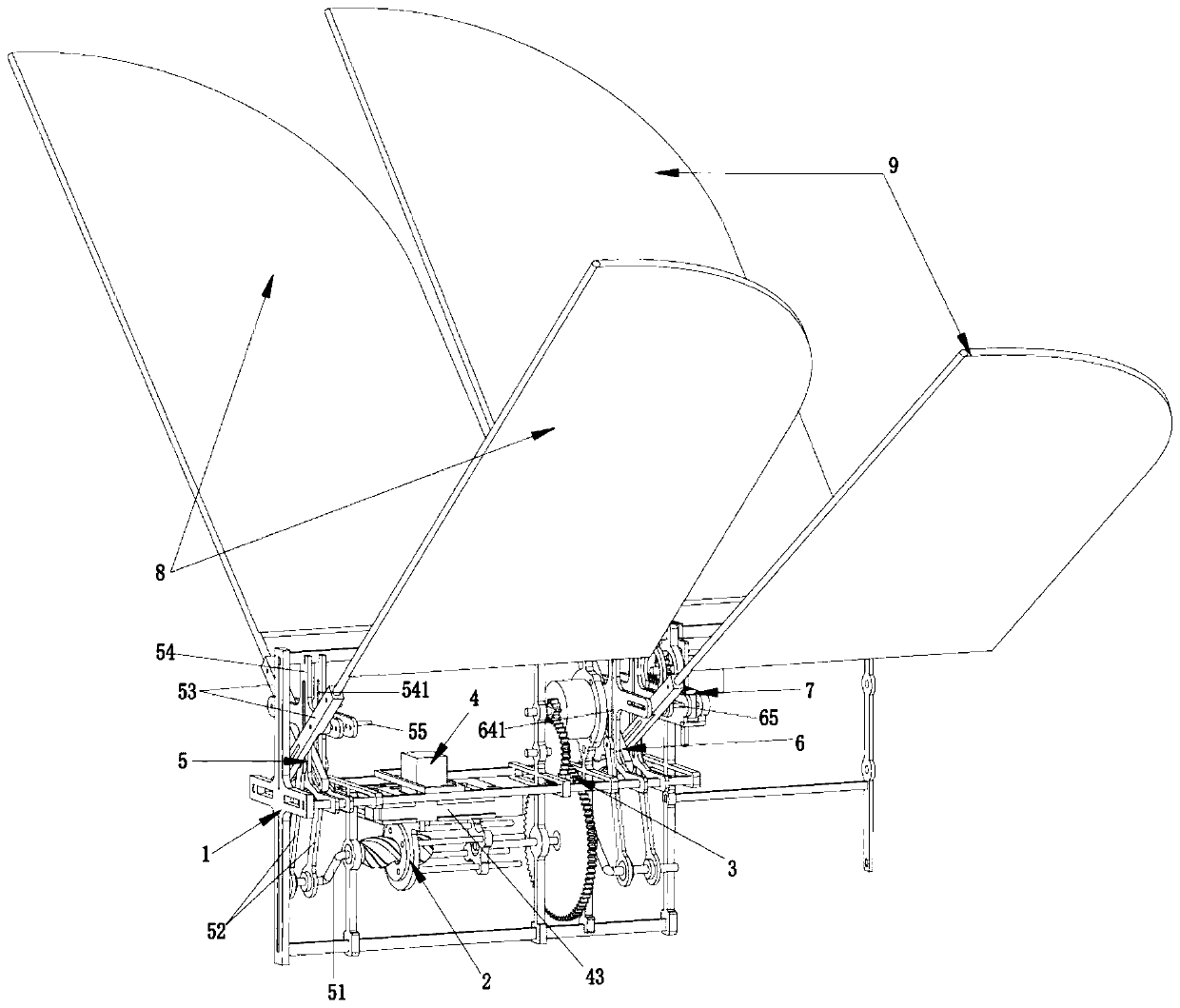

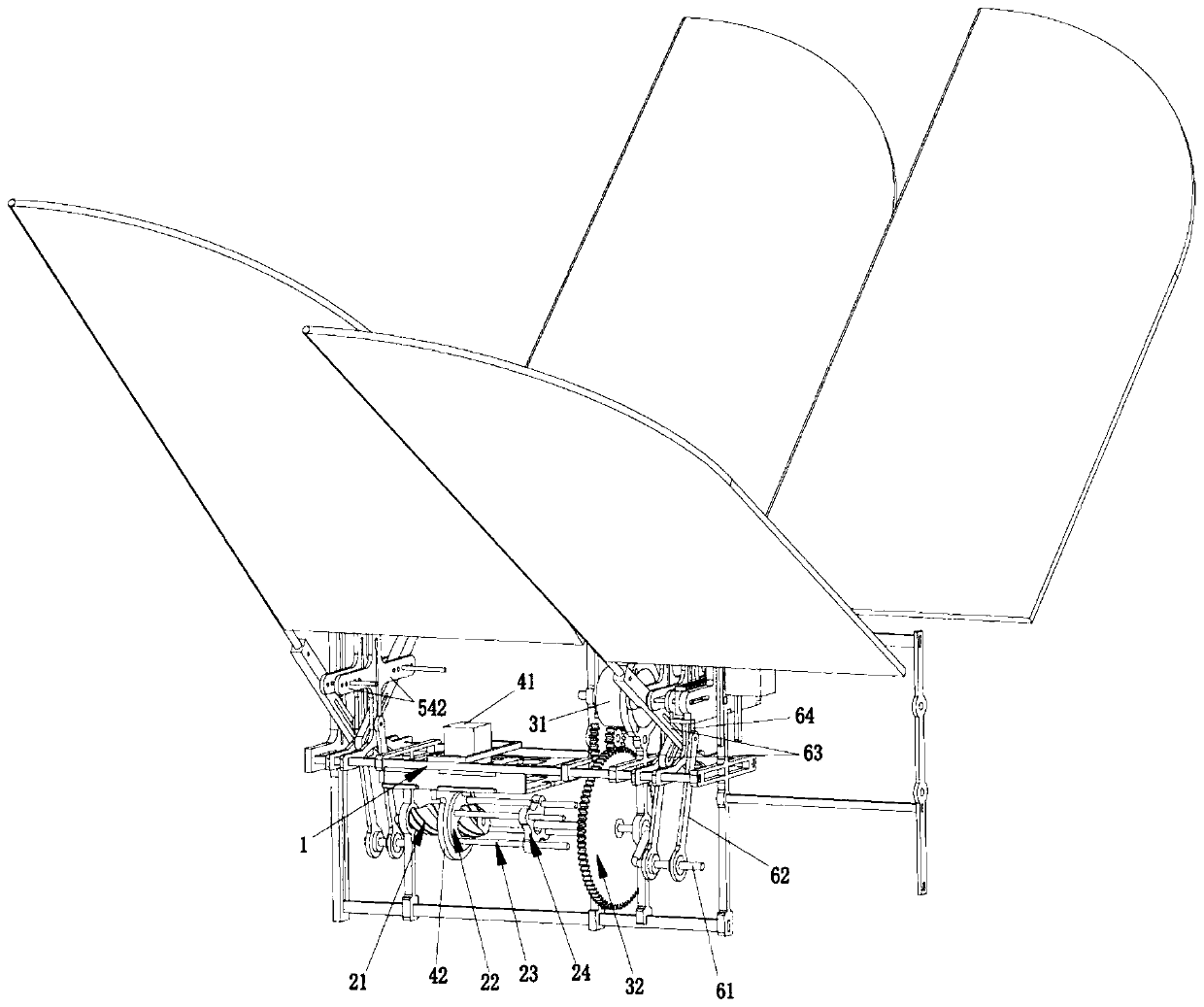

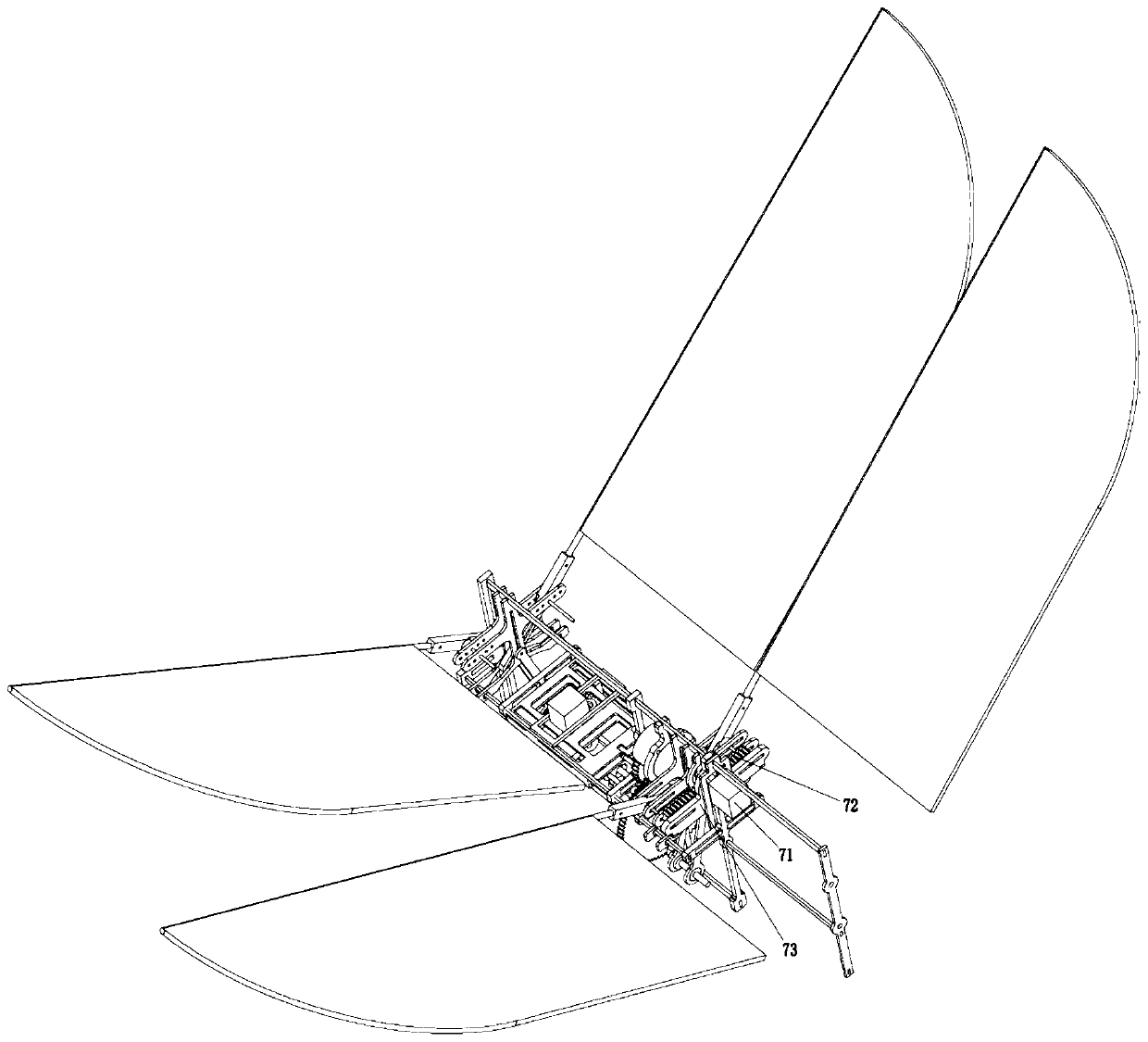

Phase changing flapping mechanism and dragonfly-imitated flapping wing aircraft

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

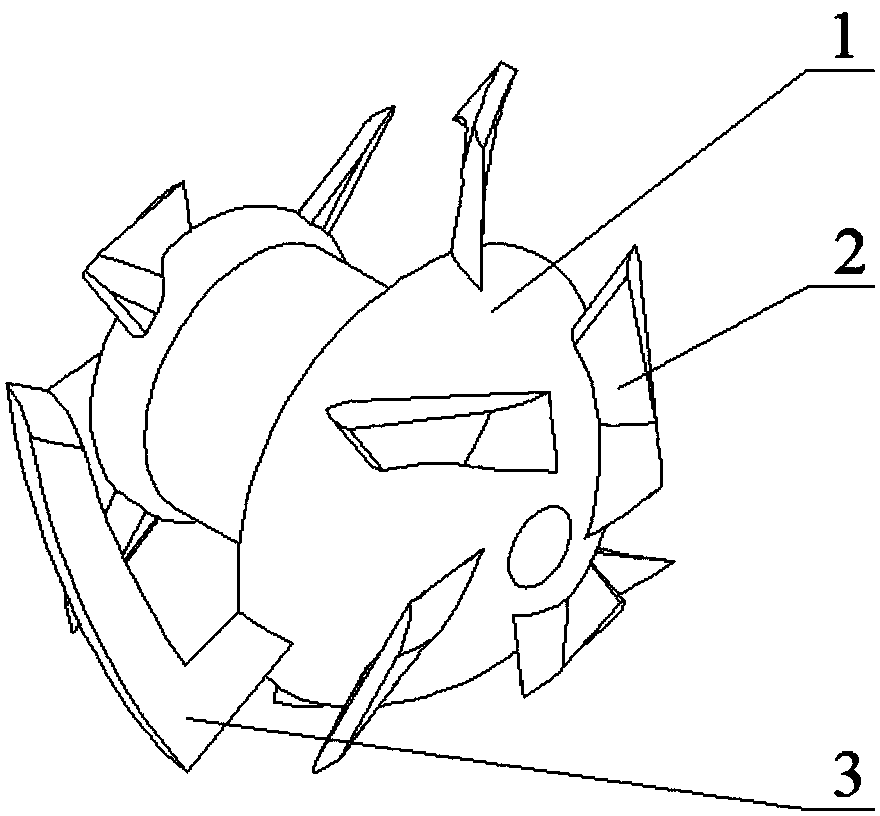

High flow disturbance sphere rotor inside heat exchange pipe

ActiveCN103411474AImprove the mixing effectIncrease tangential movementHeat transfer modificationRotary device cleaningRadial motionSpiral blade

Owner:BEIJING UNIV OF CHEM TECH

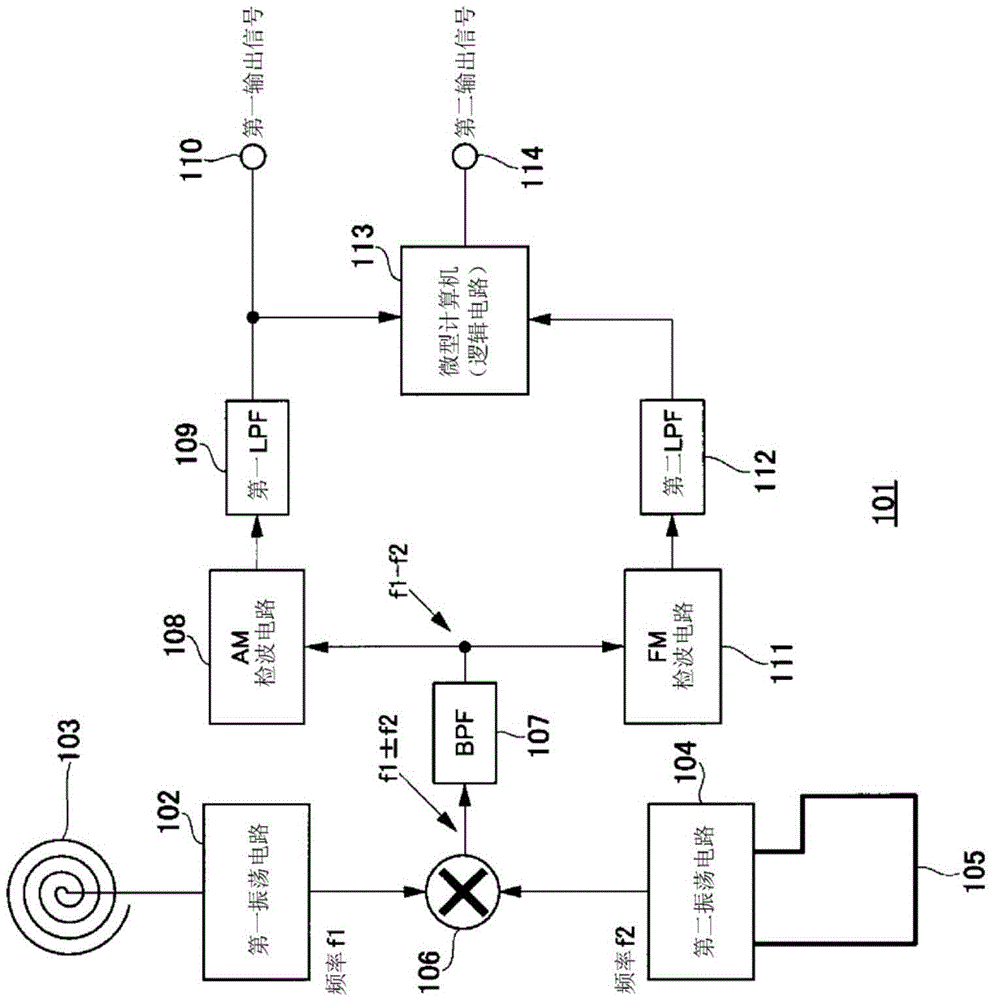

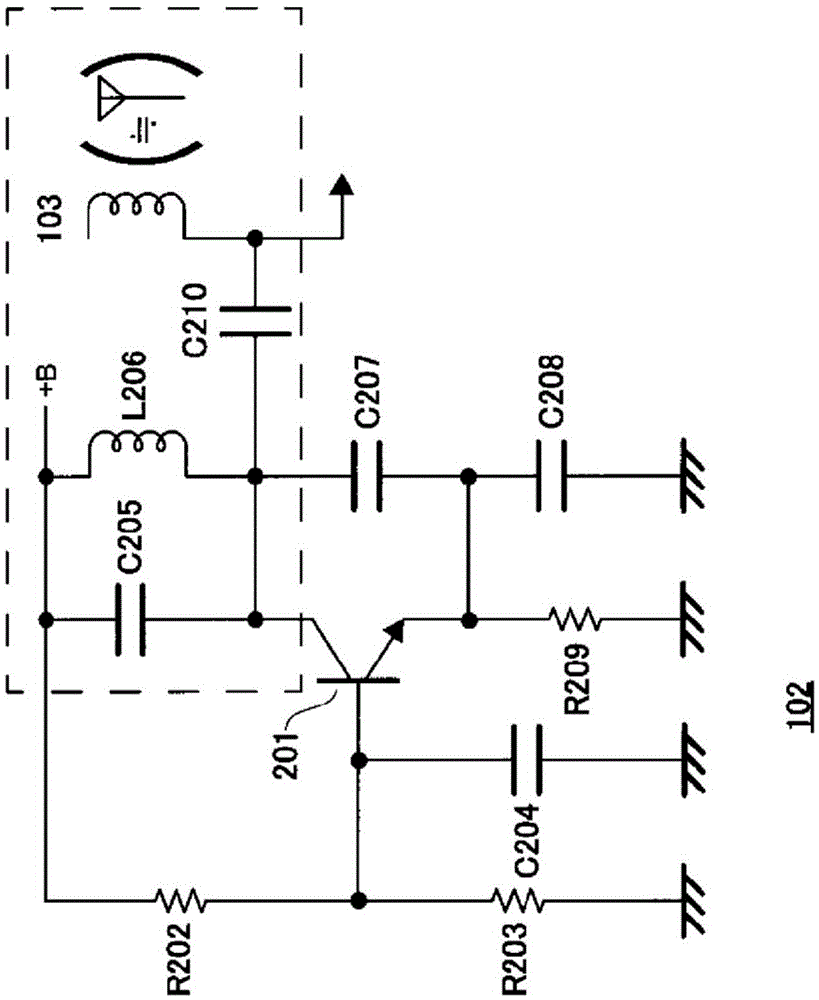

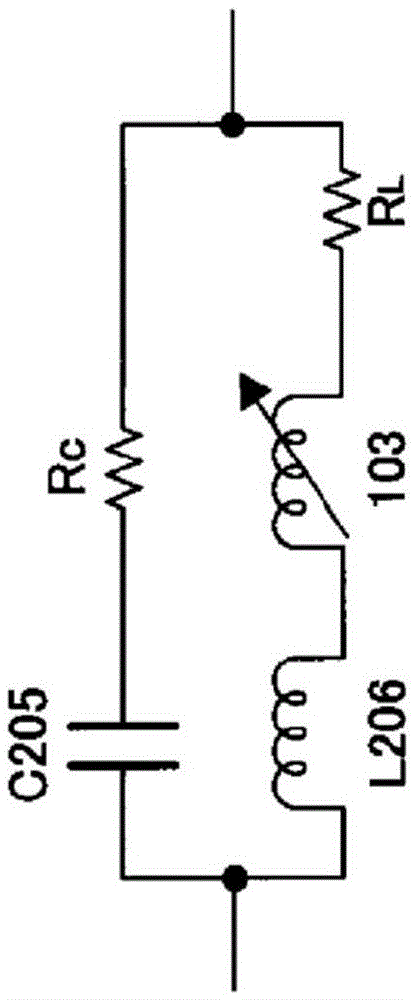

Proximity sensor

InactiveCN105556846AFree detection distanceFreely set the detection distanceElectronic switchingDetection using electromagnetic wavesProximity sensorResonance

Owner:NAT UNIV CORP KYUSHU INST OF TECH (JP) +1

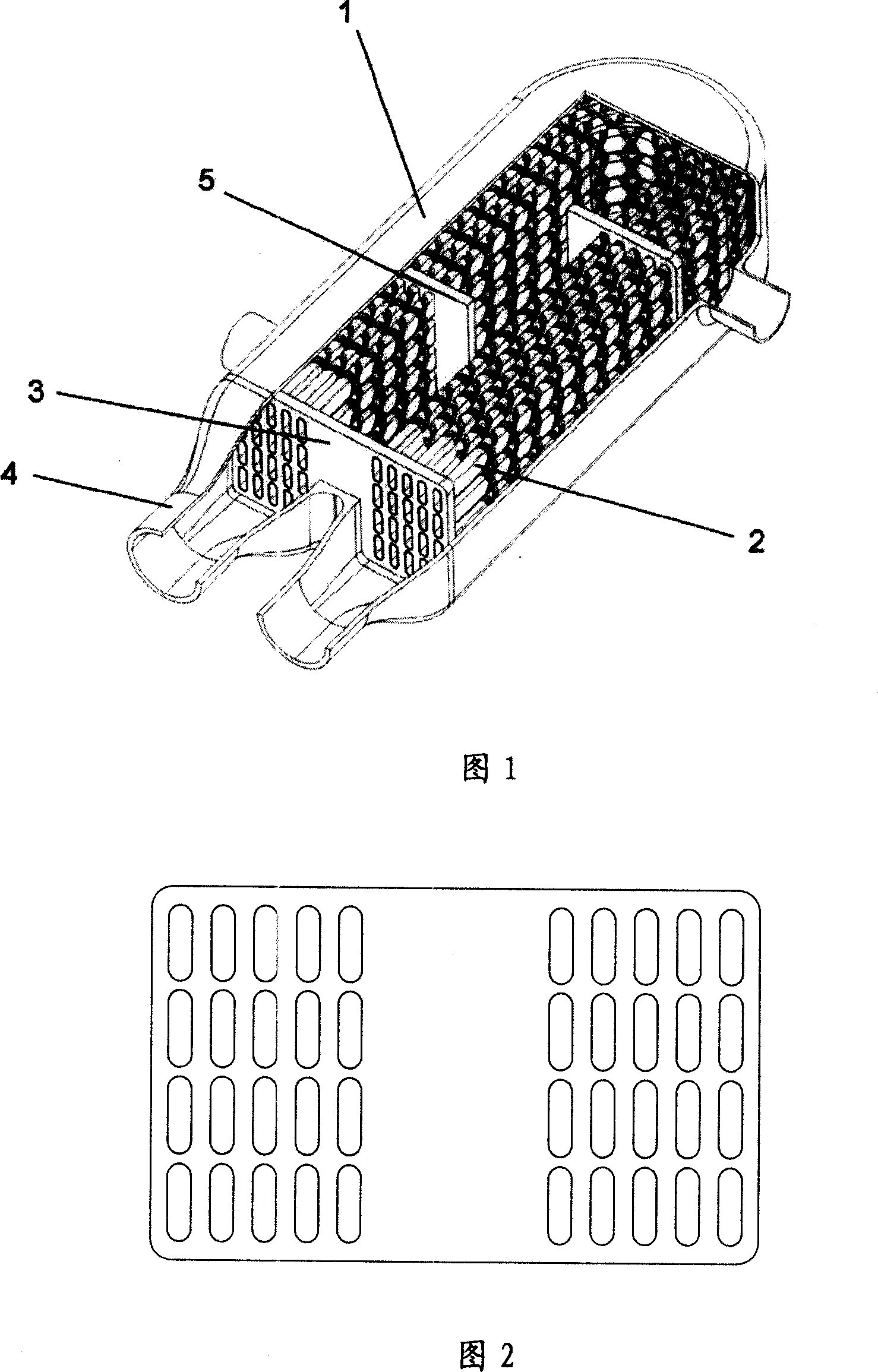

Shell-and-tube type heat exchanger employing crossed spiral tube

ActiveCN101101186ACompact layoutRapid coolingStationary conduit assembliesTubular elementsSiphonEngineering

Owner:BEIJING U BRIDGE CHAOYANG +1

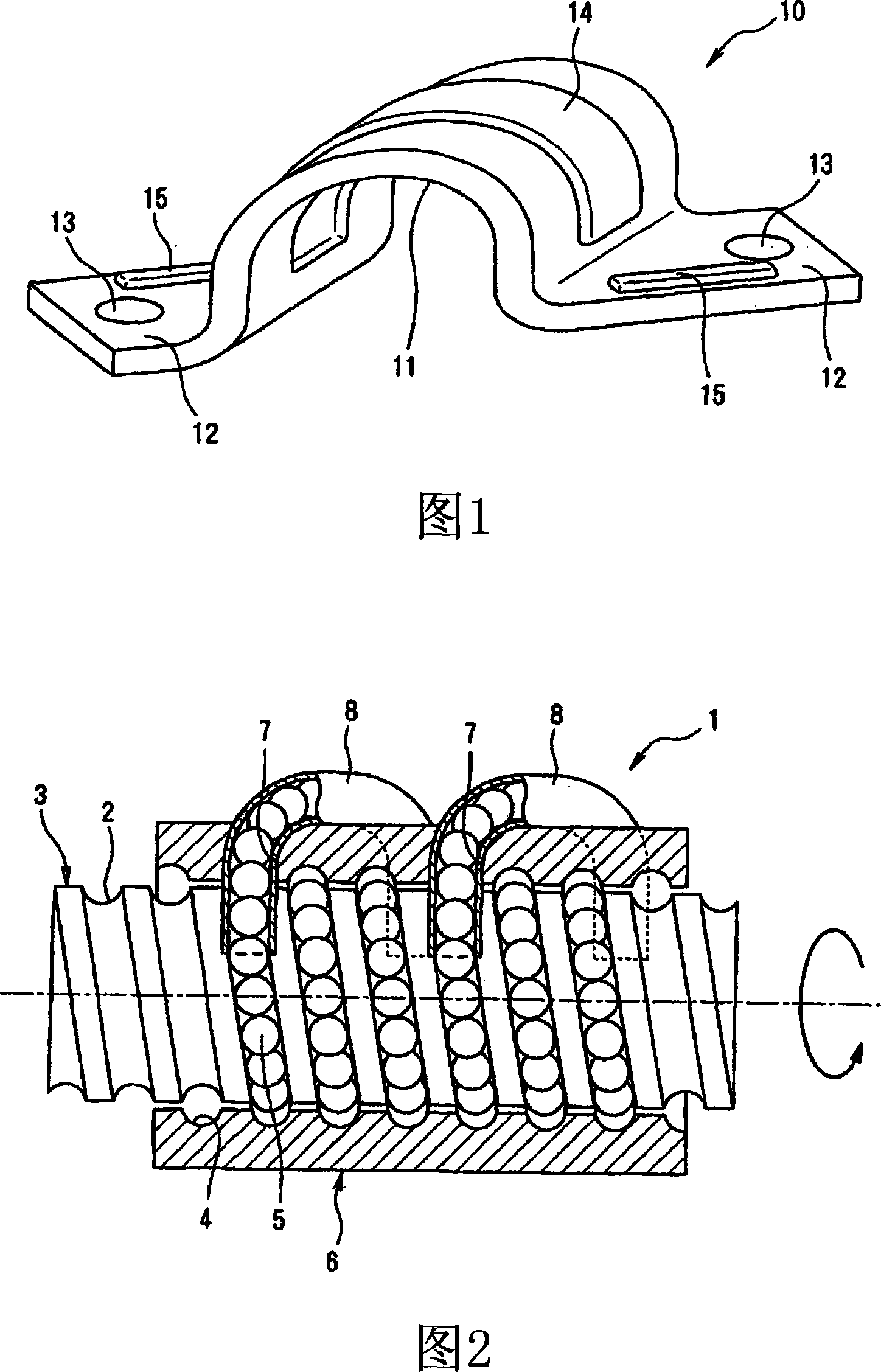

Ball screw device

Owner:NSK LTD

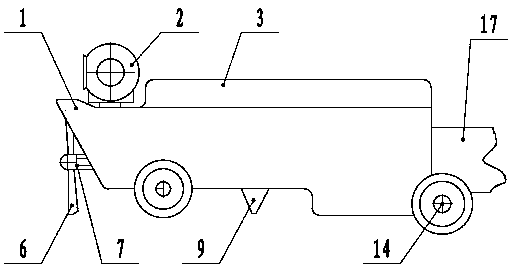

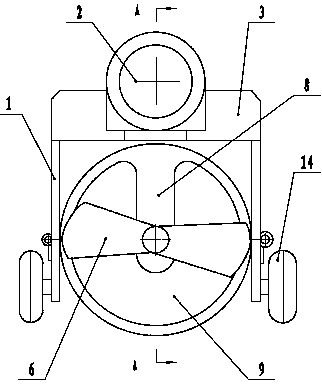

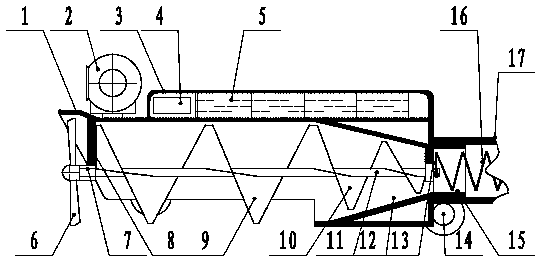

Online farmland soil remediation device

InactiveCN108856279AImprove continuityImprove work efficiencyContaminated soil reclamationSpiral bladeSoil remediation

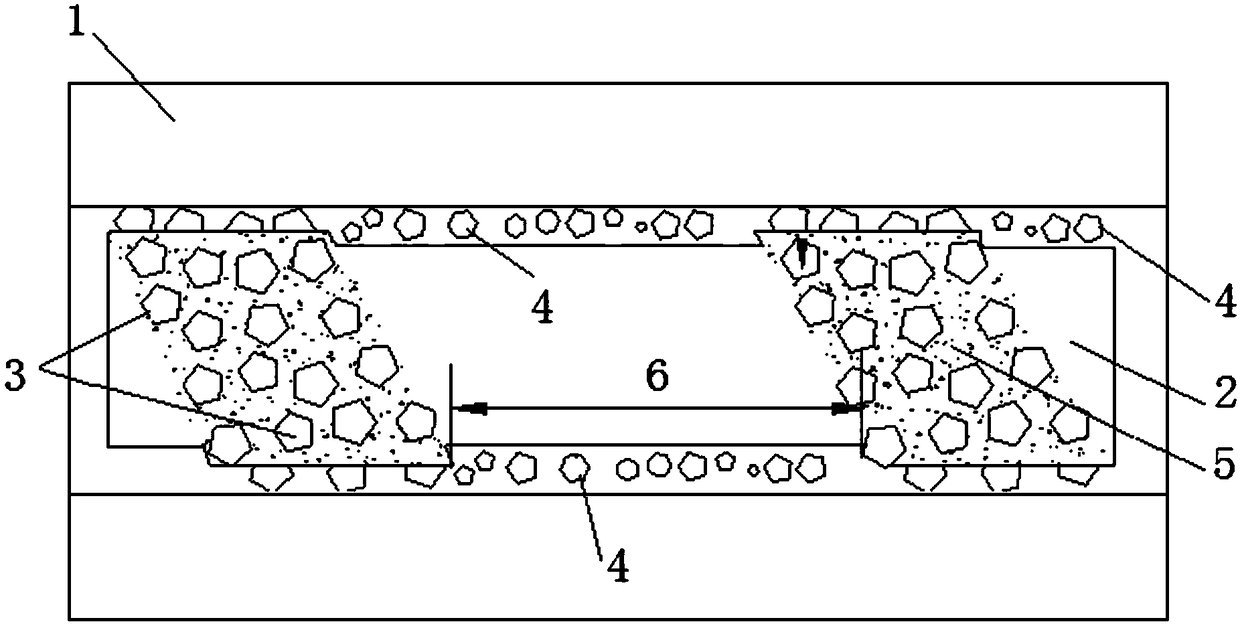

The invention discloses an online farmland soil remediation device. The device comprises a machine body, a hollow rotating shaft and a liquid medicine box; a travelling mechanism is installed on the bottom of the machine body; the machine body is of a box-shaped structure with an opening in front side, and a shovel board is arranged on the front side of the machine body; the hollow rotating shaftis transversely arranged at a central position of a cavity of the machine body, liquid outlet holes communicated with a cavity of the hollow rotating shaft are evenly formed in a shaft body of the hollow rotating shaft, and a spiral blade is fixedly arranged on the periphery of the hollow rotating shaft; a pump is installed on the side wall of the liquid medicine box; the pump is connected with awater suction pipe and a water outlet pipe, and the other end of the water outlet pipe is connected with the hollow rotating shaft through a rotating connector. According to the online farmland soil remediation device, by adopting an online work mode, farmland soil is remediated, the work continuity is high, and the working efficiency is high; through the hollow rotating shaft, liquid medicine conveying is conducted so that a liquid medicine can be in full contact with the soil, and the remediation effect is guaranteed; meanwhile, by controlling a telescoping device, the action depth of the shovel board can be adjusted, so that use is more flexible.

Owner:SUZHOU XUNYU NEW MATERIAL TECH CO LTD

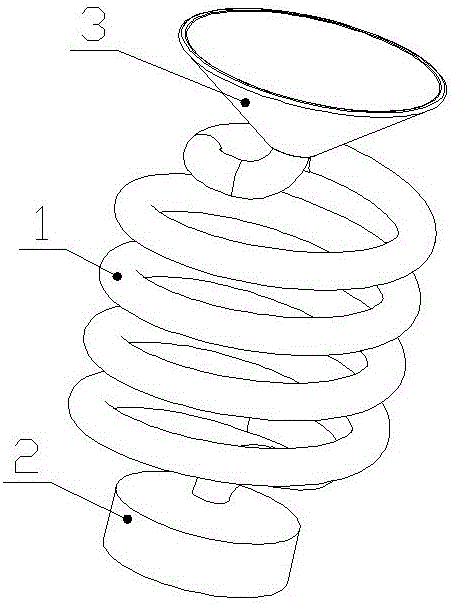

Spiral radiator and spiral funnel

InactiveCN106643210AIncrease cooling areaImprove heat dissipation and cooling efficiencyDomestic cooling apparatusCorrosion preventionEngineeringVirus

Owner:缪其明

Dissociation-solidification abrasive particle composite wire saw cutting method for photovoltaic polycrystalline silicon cells

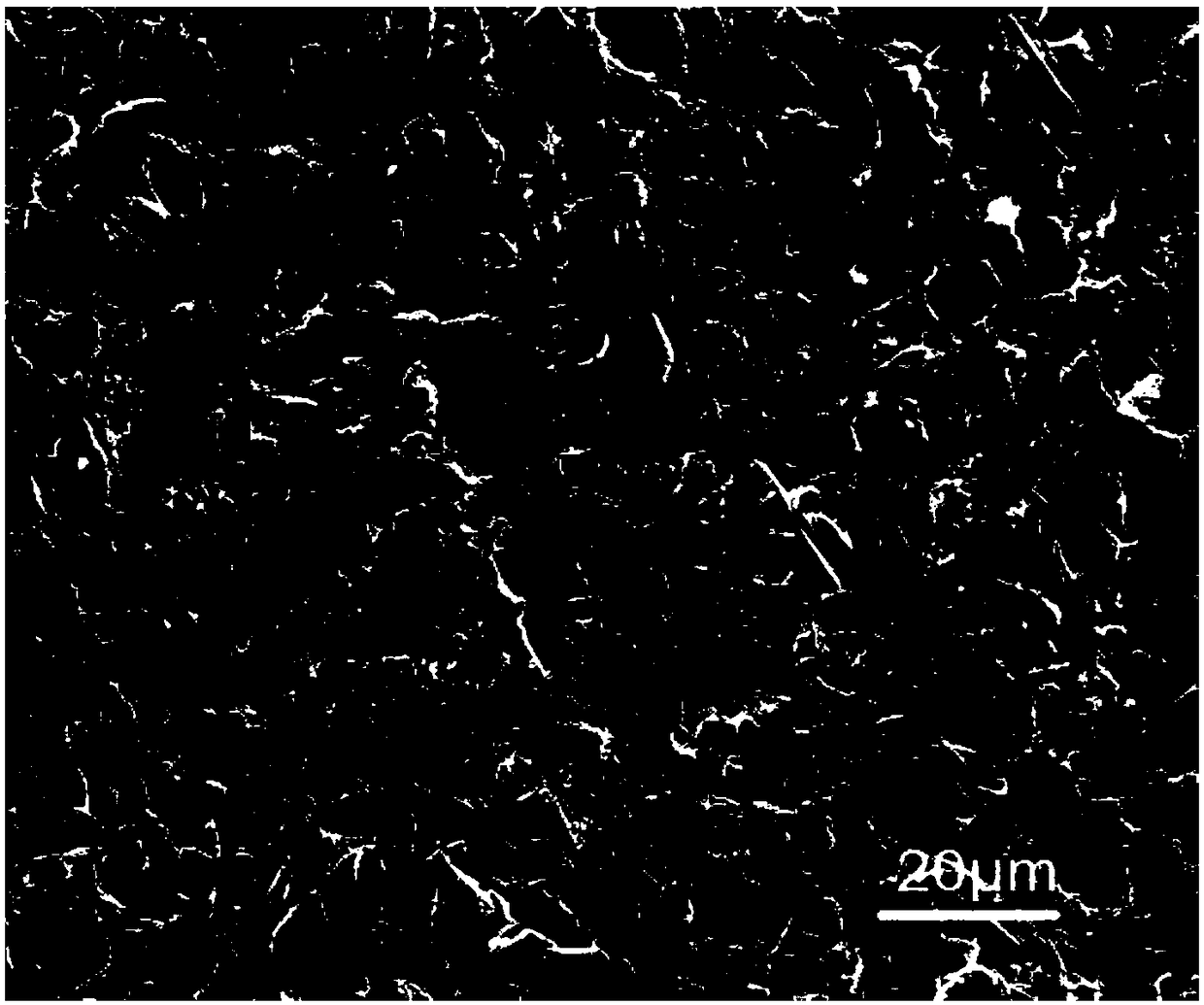

InactiveCN108437244AImprove processing efficiencyImprove surface accuracyFine working devicesWear particleMicroscopic scale

Owner:SHANDONG UNIV

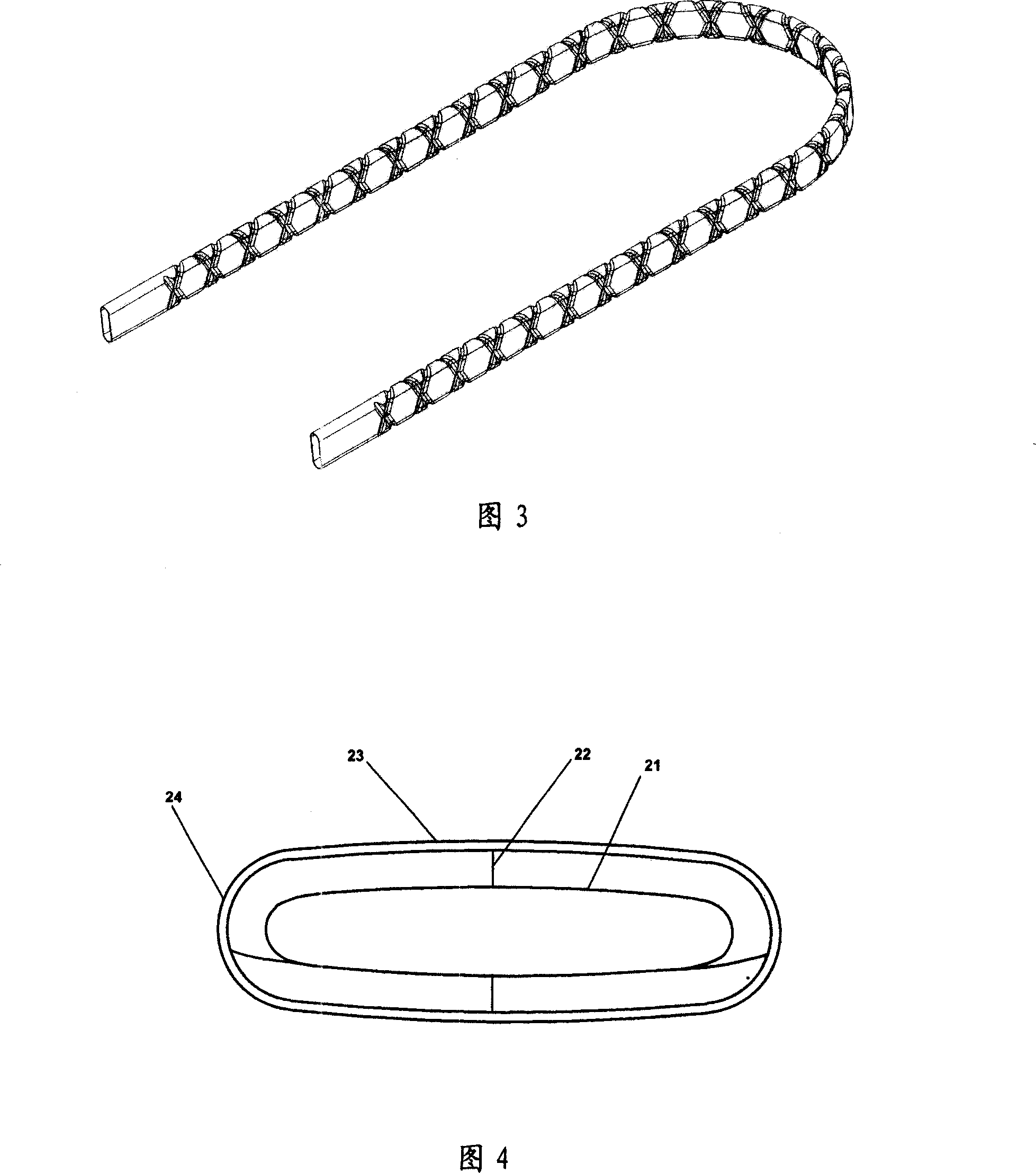

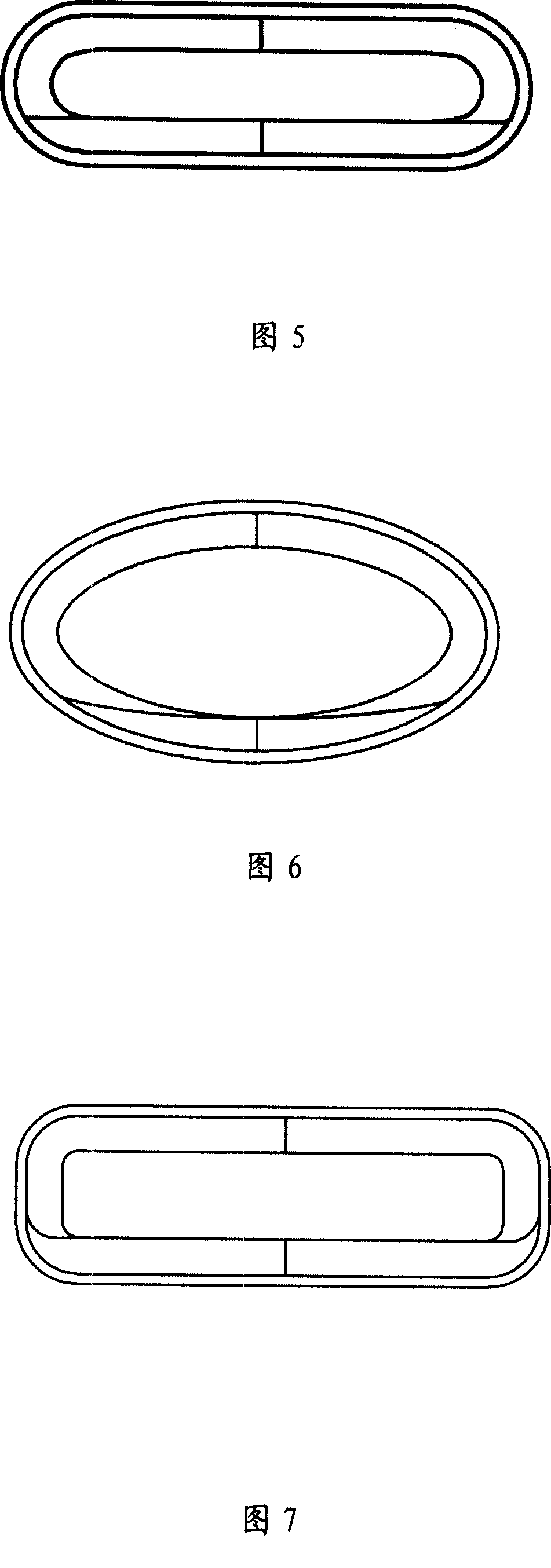

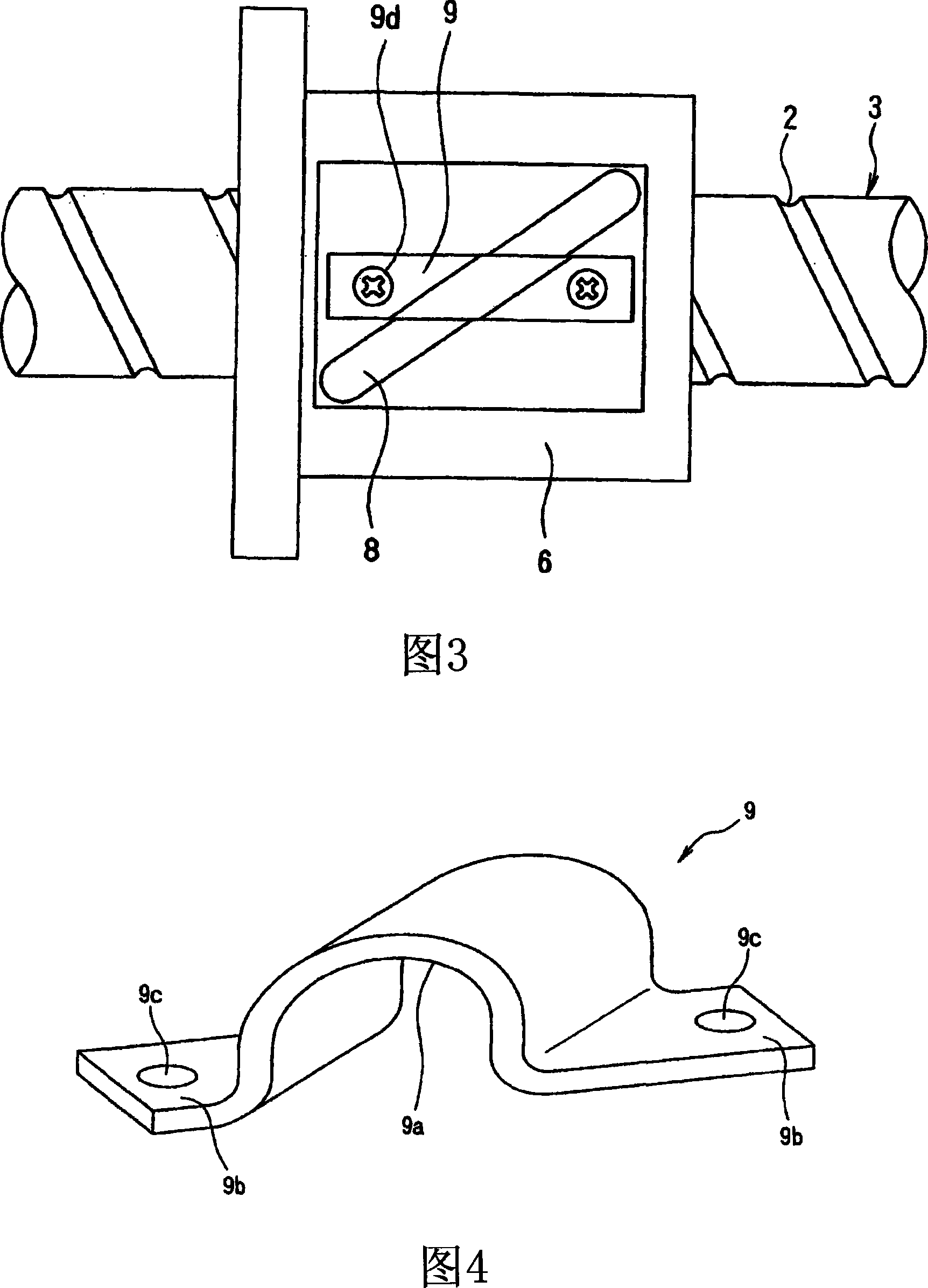

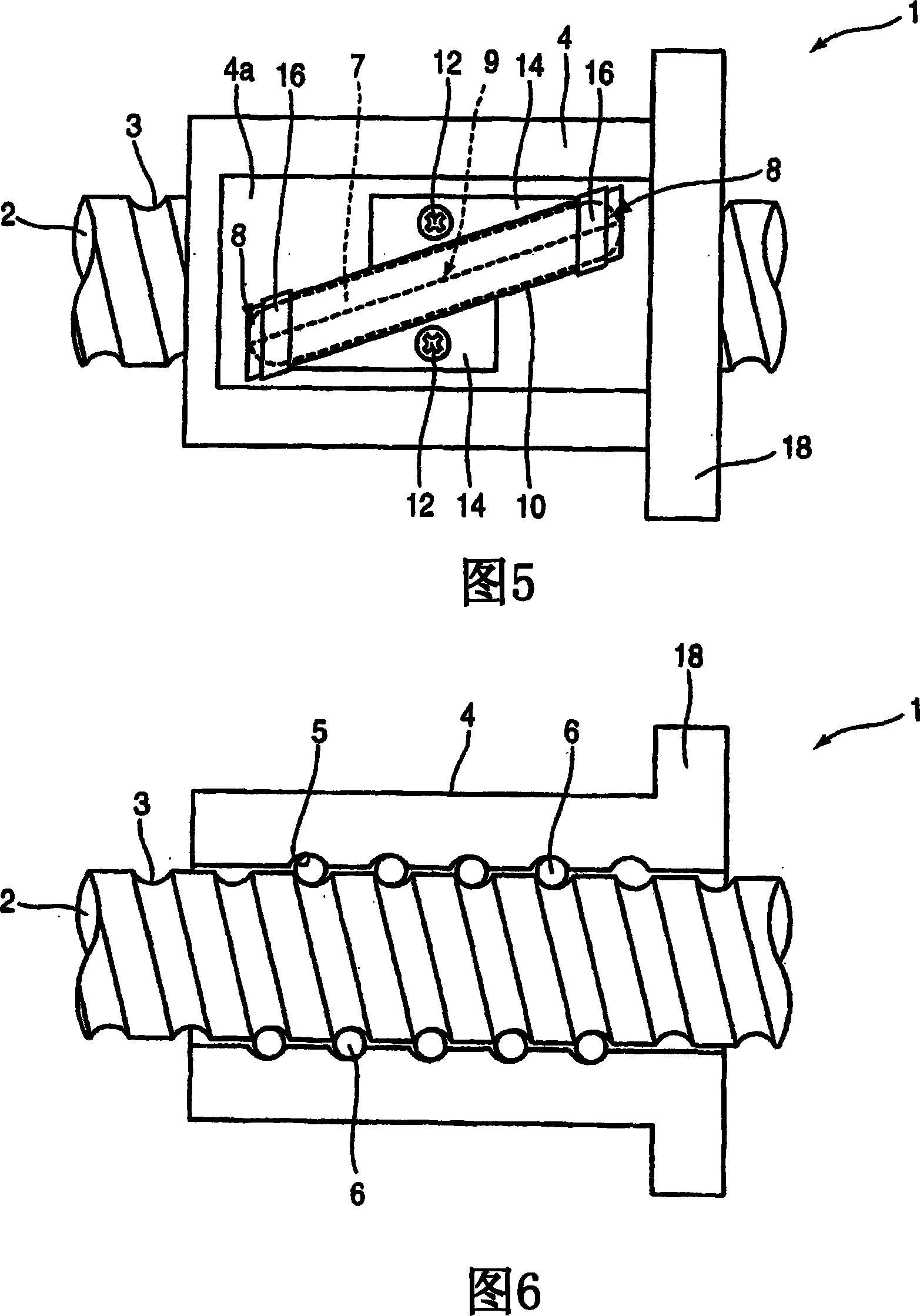

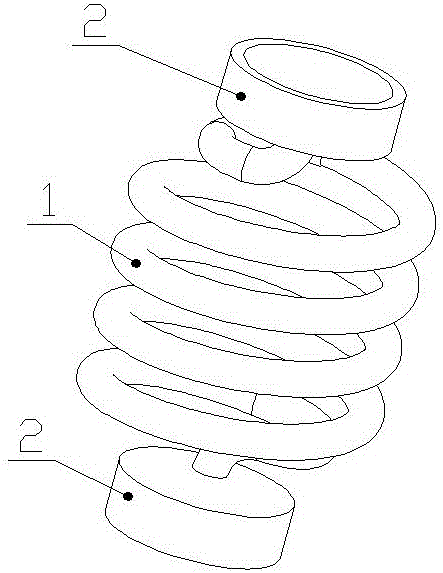

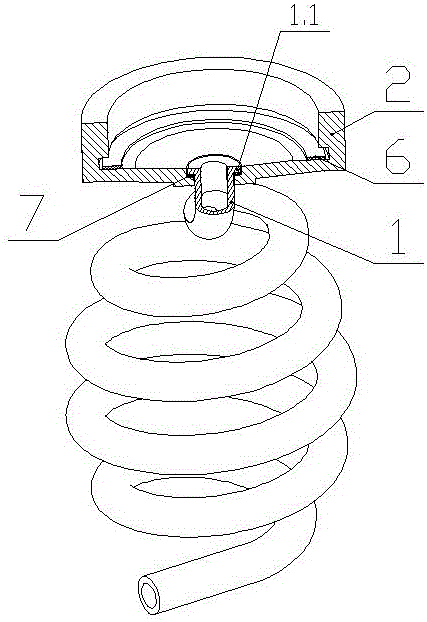

Anti-tangle elastic wire for coiled hoses and wires

InactiveUS20090242688A1Time loss due to tanglement is not negligibleShort circuitEngineeringElectric wire

An anti-tangle means for coiled materials; such as a coiled electric wires, coiled lawning hoses, compressed air hose, and coiled telephone wires, is provided. The means is comprised of a long elastic wire and a case for rewinding the wire. The rewinding elastic wire penetrates inside of a helix that is formed by the coiled material. Retracted length of the elastic wire is same as the retracted coiled hoses / coiled wires and fully stretched length of the wire is the same as the stretched length of the hoses / wires. One end of the elastic wire is connected to one end of the coiled material and the other end is connected to a ribbon spring that is installed inside of a case. The case has a stopper to control the tension of the elastic wire. The elastic wire with proper tension prevents tangling of the coiled material.

Owner:SUNG UN

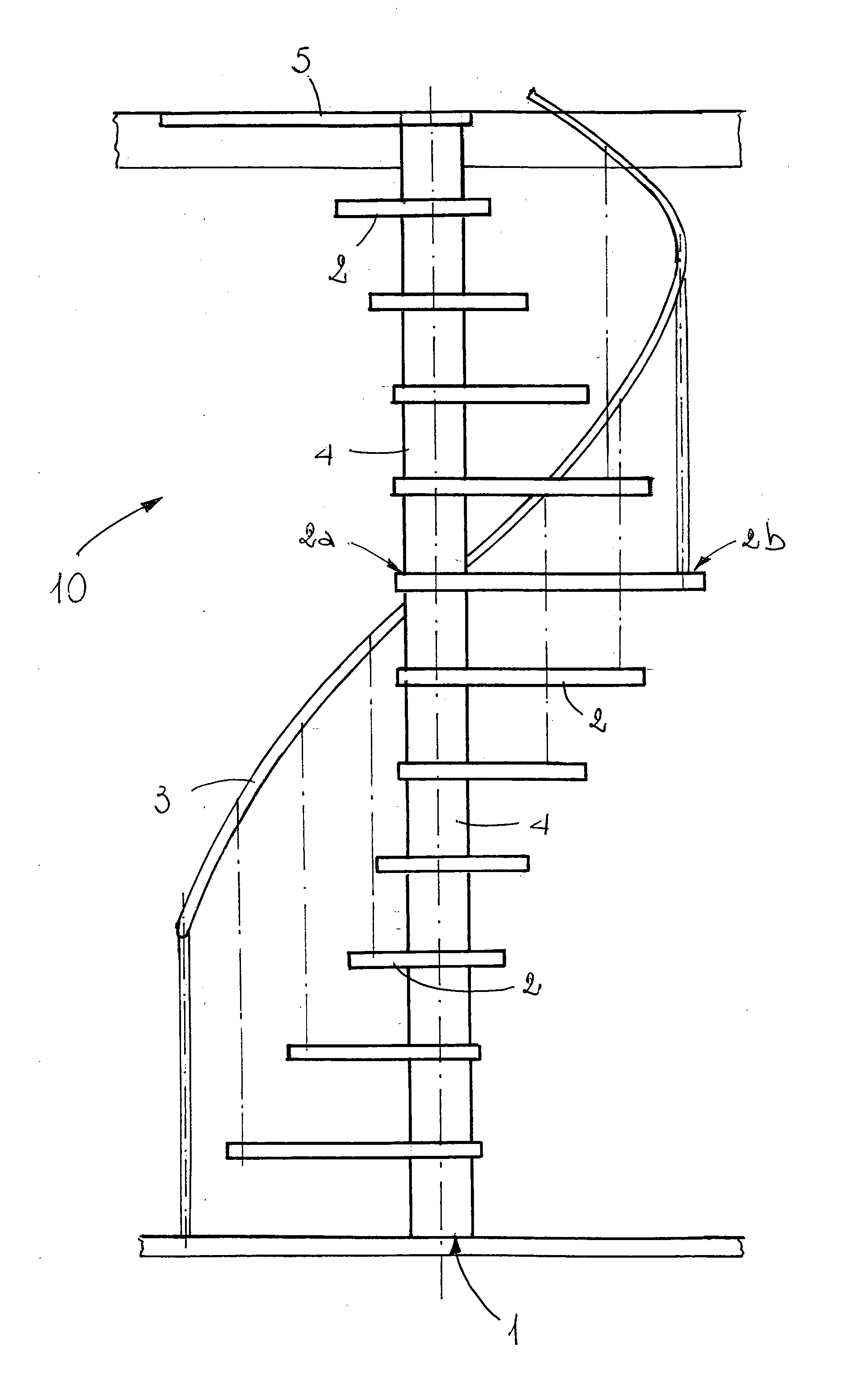

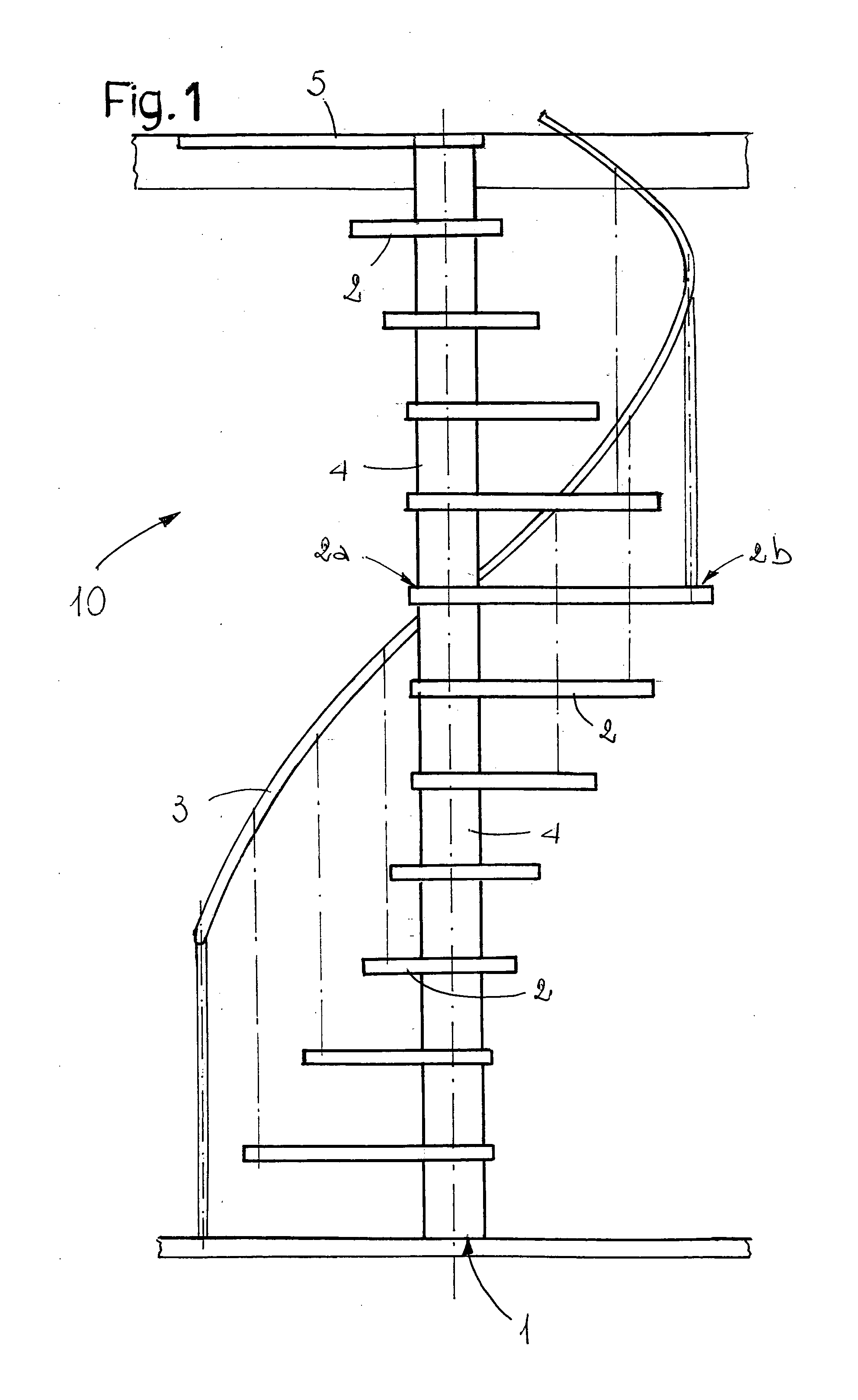

Spiral staircase

Owner:ALBINI & FONTANOT

Ground sewer detecting and clearing robot

PendingCN109868893ASimple structureReduce artificial downhole serious poisoning accidentsSewer systemsSpiral bladeSludge

Owner:ZIGONG MODERN AUTUMN HARVEST MACHINERY CO LTD

Fixed-length shearing device for machining prestressed spiral rib steel wires

The invention discloses a prestressed spiral-assisted fixed-length shearing device for steel wire processing in the technical field of steel wire processing. A blade protection device is provided on the upper surface of the board, and two fixed guard plates with the same structure are installed on the outer surface of the box. A cutting device is installed on the inner wall of the fixed guard plate, and a connecting rod is installed on the top of the cutting device. The rod is set in the mounting hole, the mounting hole is set on the surface of the power disc, the center of the power disc is provided with a power shaft, and the power shaft is connected to the box, the top of the power disc is provided with a metering disc, and the metering A rotating pointer is installed at the center of the disc surface, a bracket is installed on the top of the box, and a vertically downward fixed pointer is installed on the top of the bracket, the cutting efficiency is greatly improved, and the cost of manual labor is reduced at the same time.

Owner:YANGZHOU JINNUOER STAINLESS STEEL CO LTD

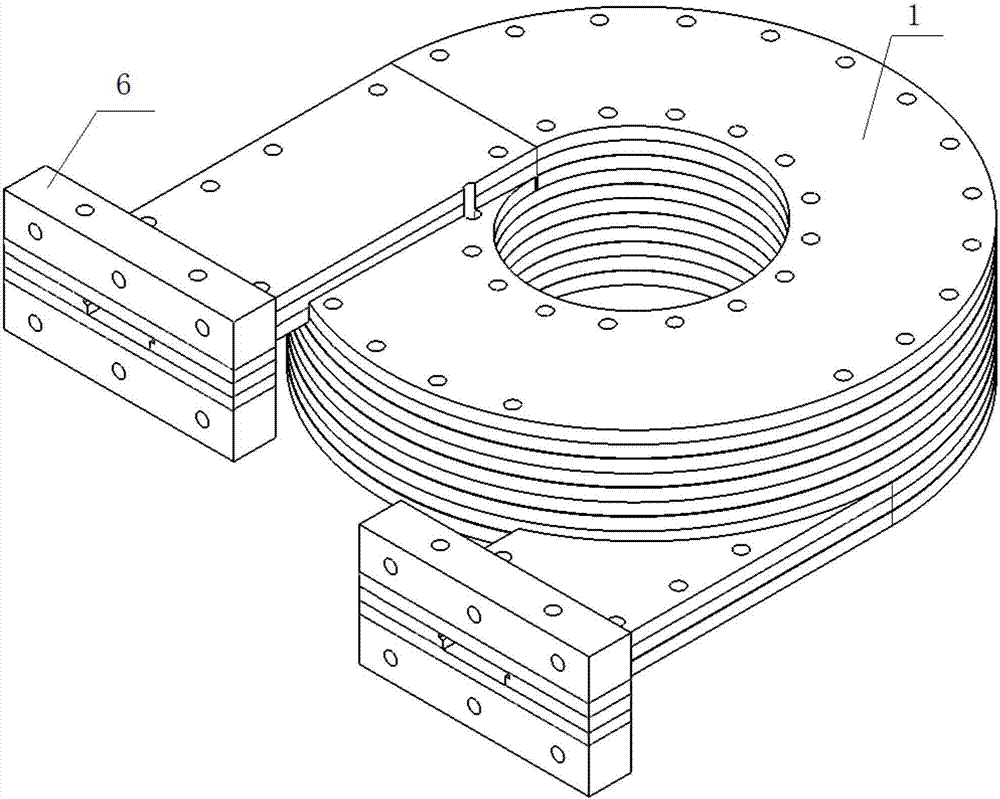

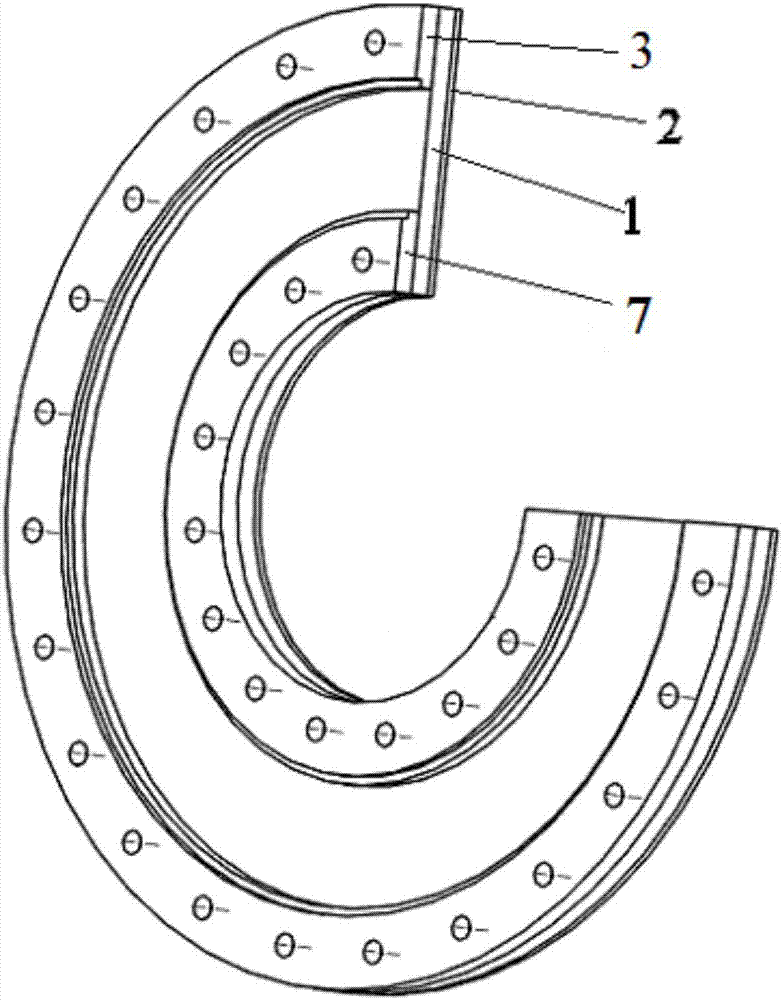

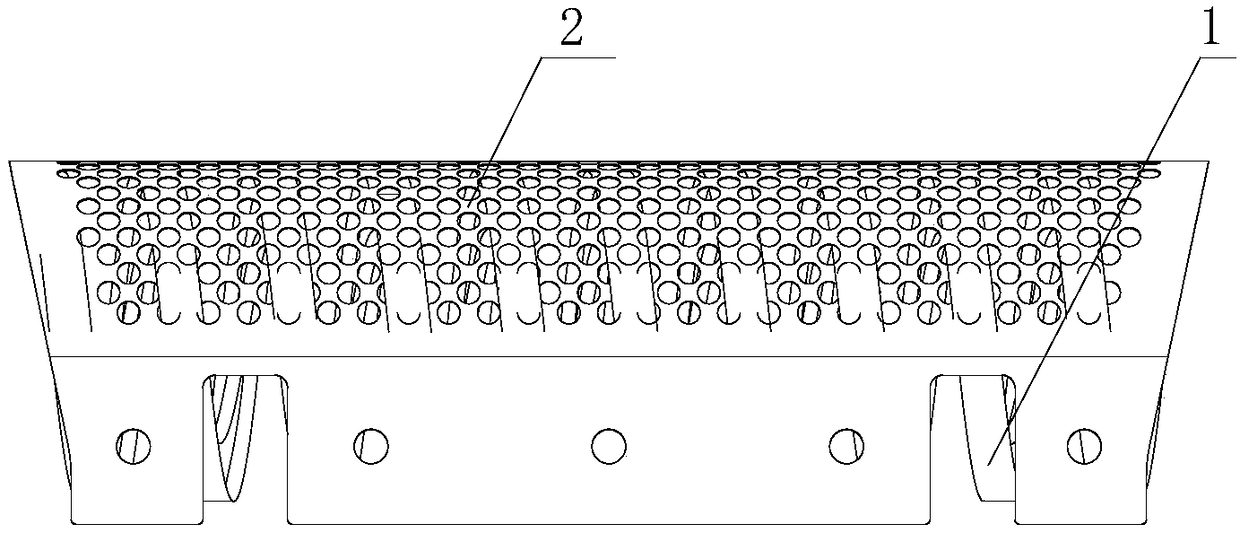

Helical corrugated winding pipe

Owner:HUBEI SHUIZHIYI TECH CO LTD

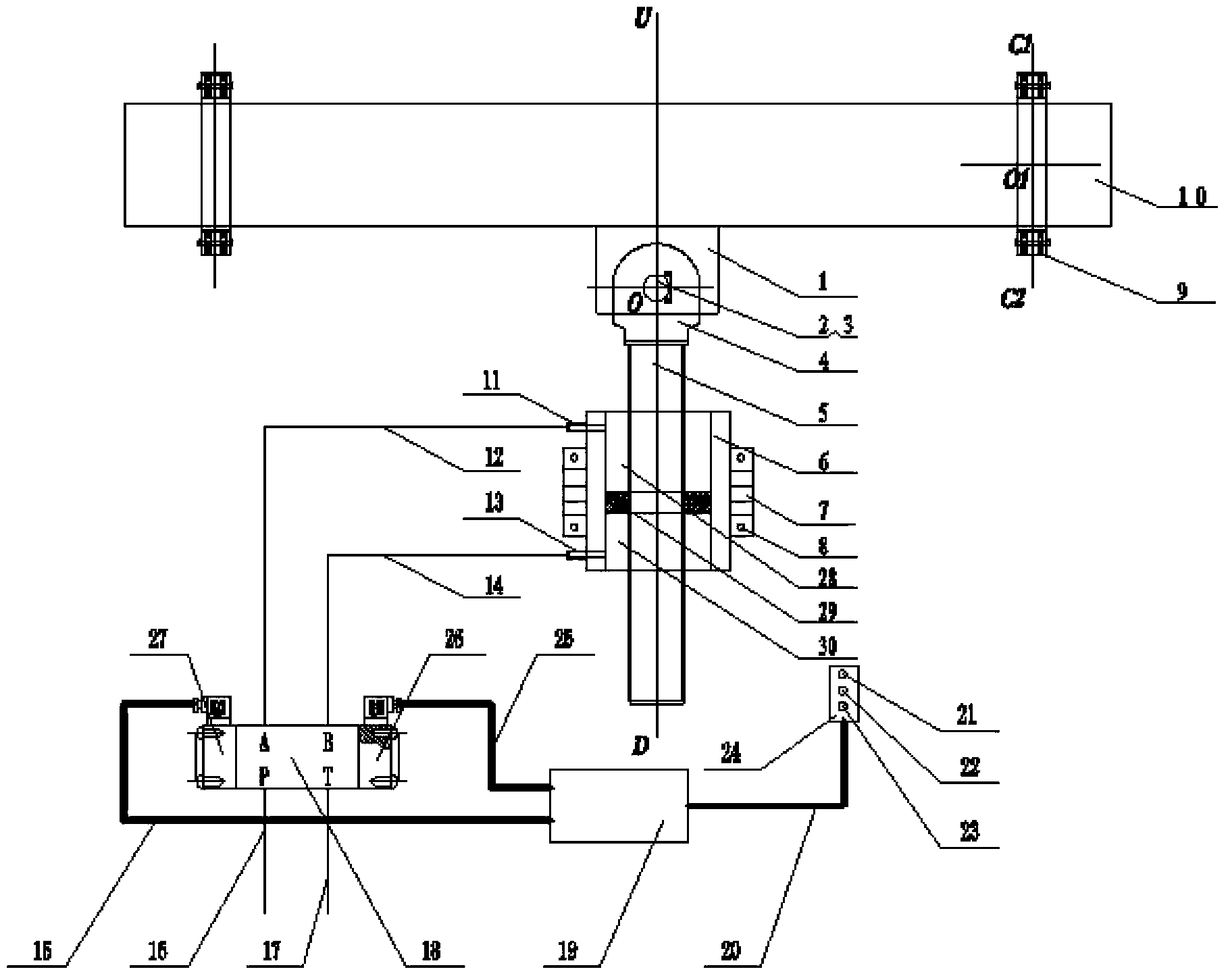

Rear-axle folding and unfolding device for spiral pipe welding unit

InactiveCN103624103AMeet the requirements of stable welded pipe formingImprove welding qualitySpherical formPipe welding

Owner:JIANGSU TONGYU STEEL PIPE GRP

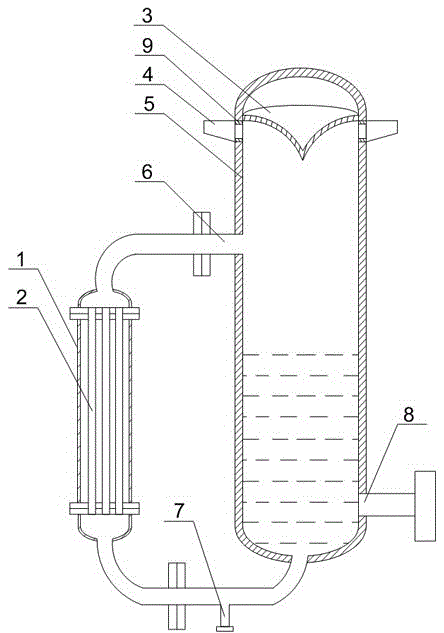

Steam generation tank for power station

InactiveCN106524102AEasy dischargeImprove efflux efficiencySolar heating energySteam generation heating methodsPower stationEngineering

Owner:付建军

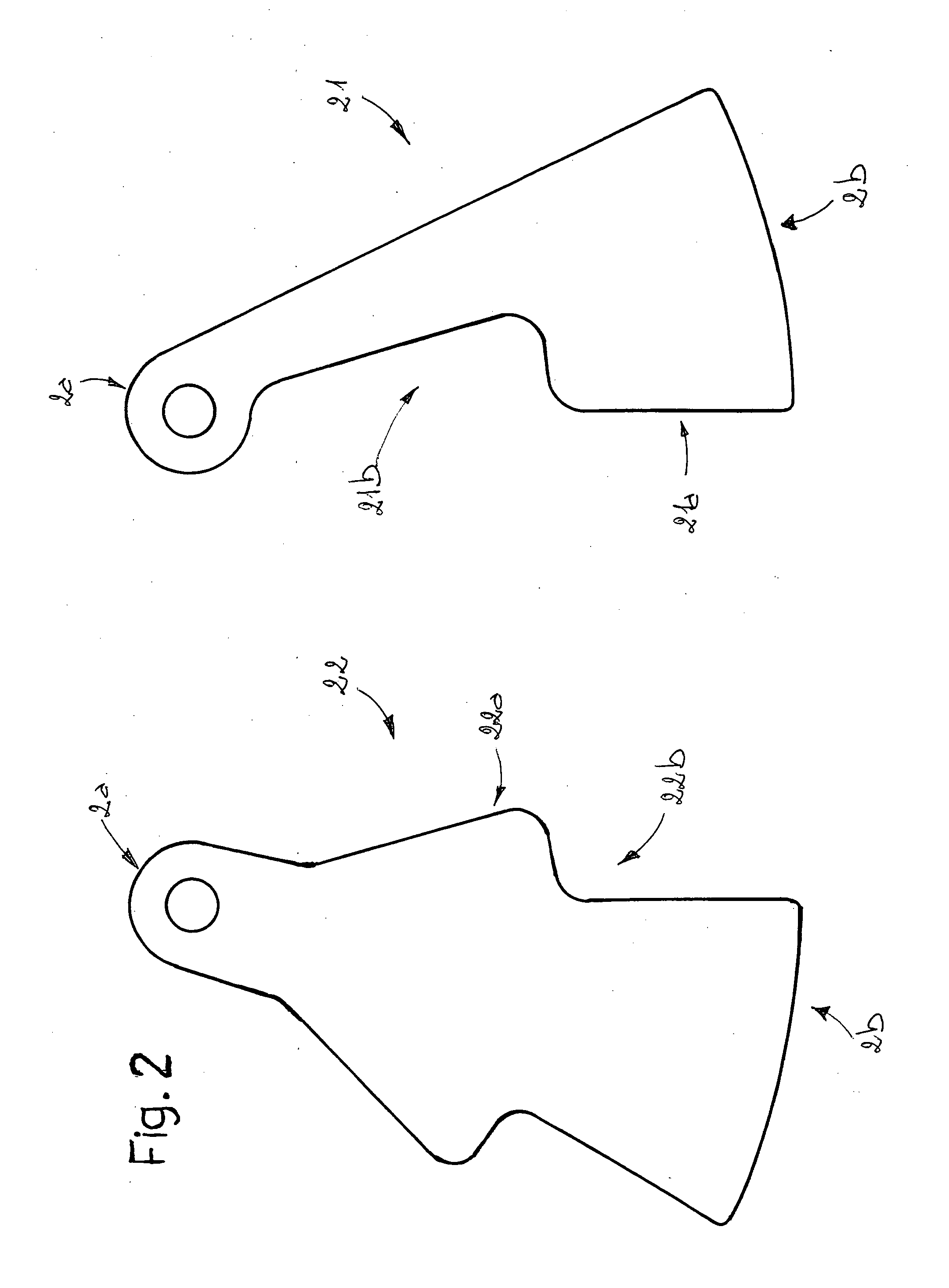

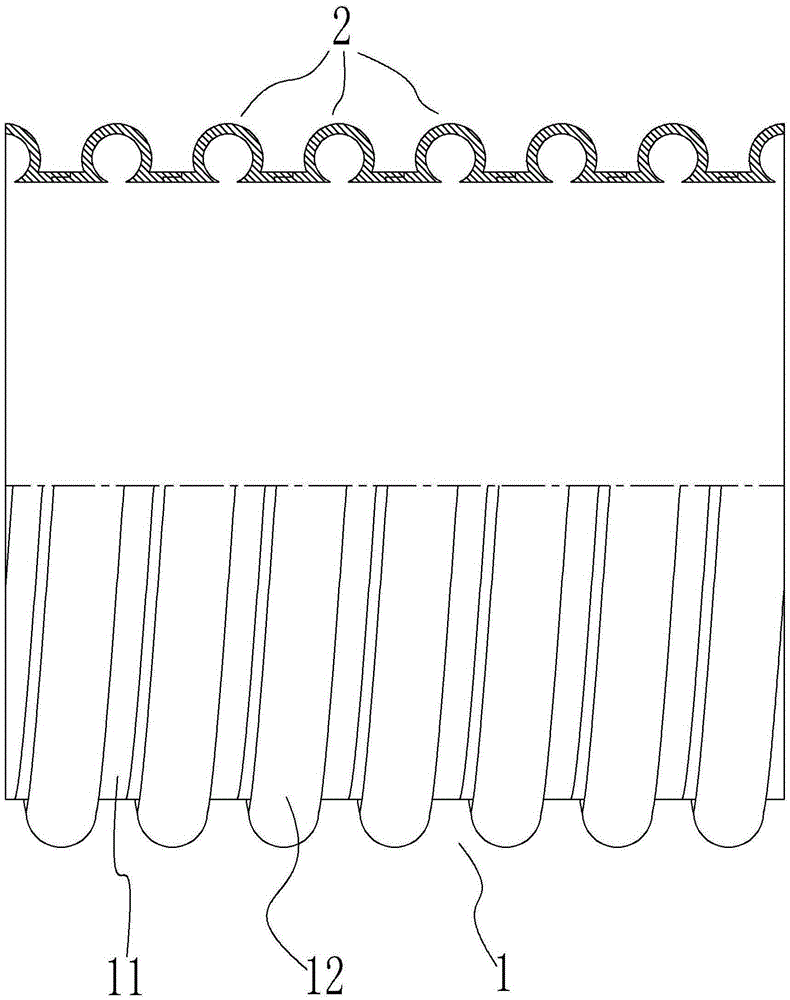

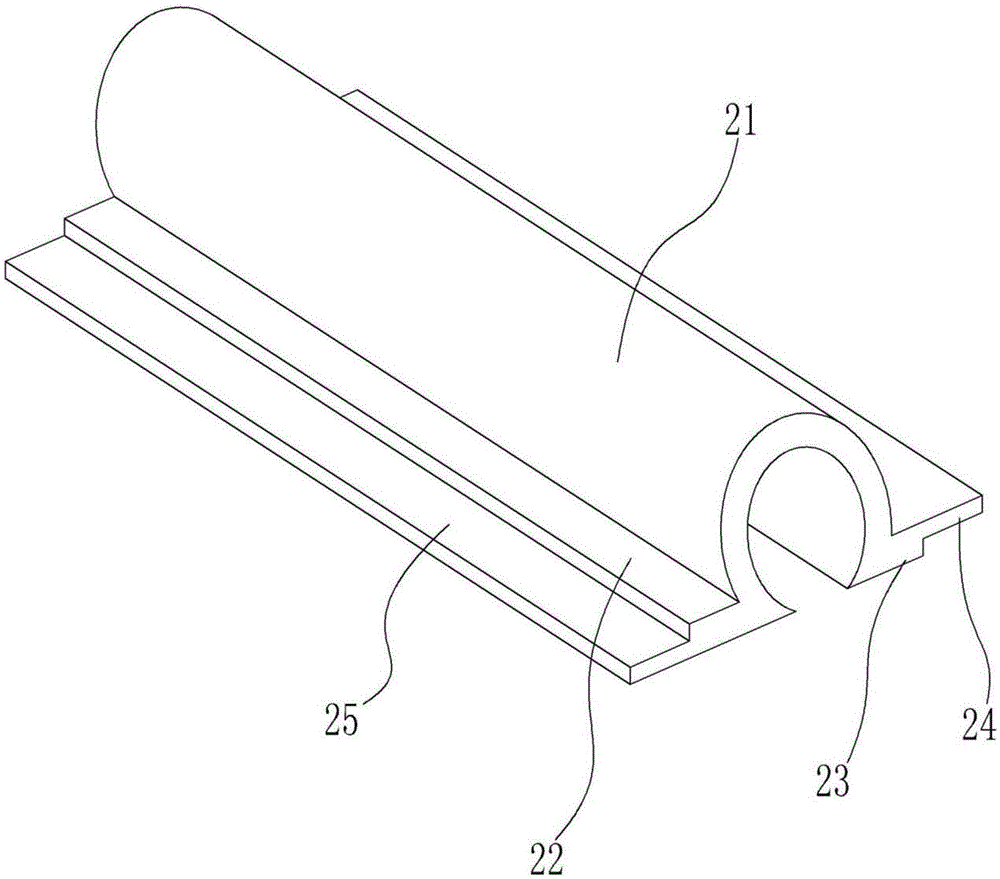

Spiral blade and shaver comprising same

PendingCN109202968AEasy to processReduce processing costsMetal working apparatusSpiral bladePulp and paper industry

Owner:浙江海顺电工有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap