Helical corrugated winding pipe

A technology of winding pipes and corrugations, applied in the field of plastic pipes, can solve the problems of complex production process, high raw material cost, high product cost, etc., and achieve the effect of reducing product cost, simple production process and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

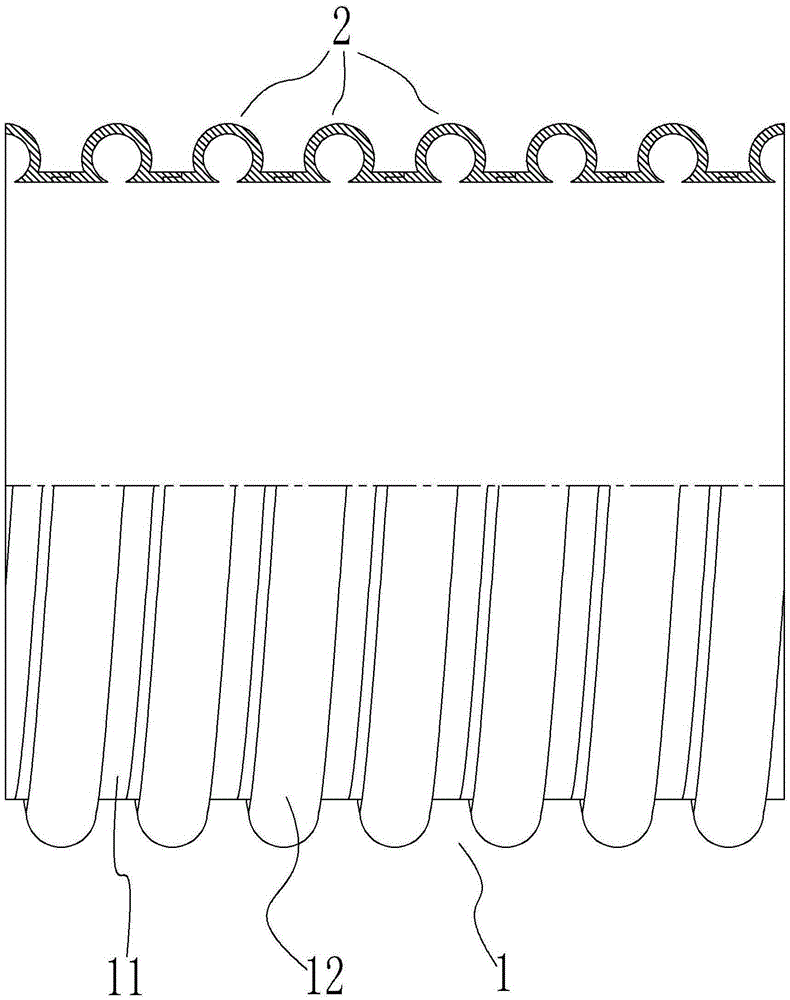

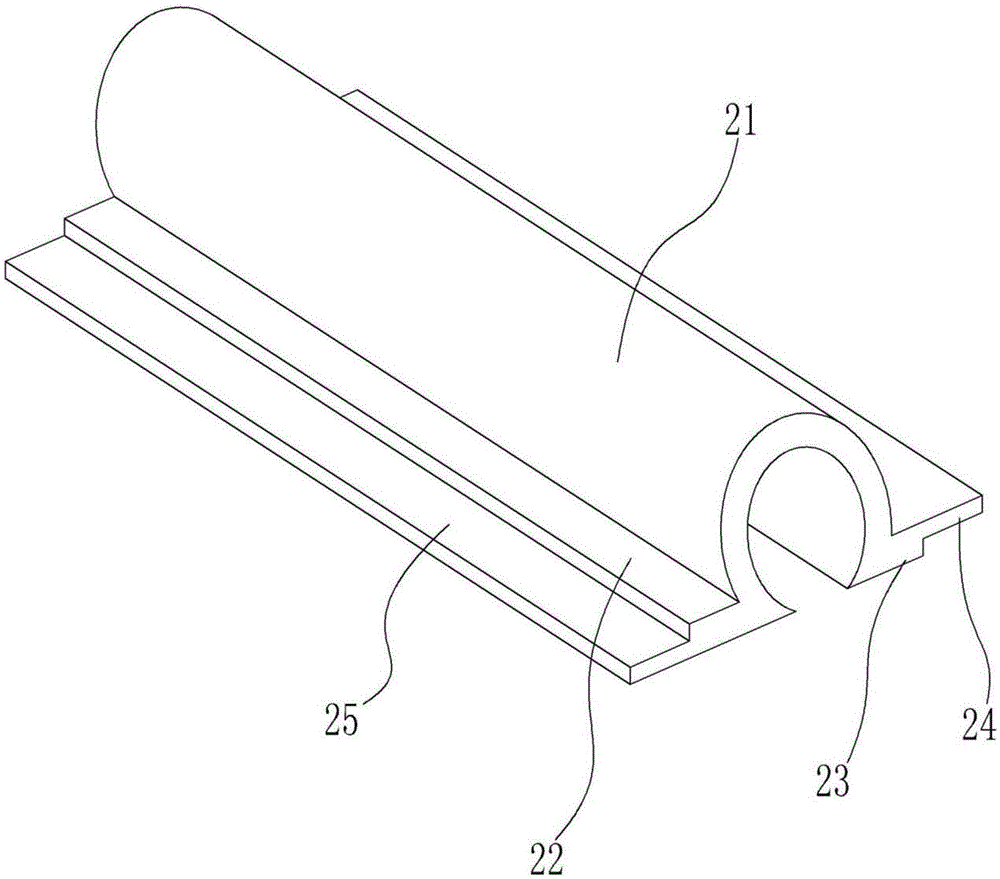

[0011] Such as figure 1 , figure 2 As shown, the present invention is a pipe body 1 formed by helically winding and bonding an Ω-shaped strip 2. The pipe body 1 includes a pipe wall 11 and a spiral corrugation arranged on the outside of the pipe wall 11 and integrally formed with the pipe wall 11. structure 12, the strip 2 includes a substrate and a corrugated protrusion 21 integrally formed and connected with the substrate, wherein: the substrate includes a first substrate 22 and a second substrate 23 with the same thickness, and the cross section of the corrugated protrusion 21 is The ring is intercepted by a plane and has a special-shaped shape with an opening. The first substrate 22 and the second substrate 23 are respectively connected to both sides of the opening of the corrugated protrusion 21, and the first substrate 22

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap