Rear-axle folding and unfolding device for spiral pipe welding unit

A technology of spiral welded pipe and rear axle, which is applied in the field of rear axle adjustment device of spiral welded pipe unit, can solve the problems of non-adjustable reversing speed, overshoot of rear axle angle, hysteresis, etc., and achieve the effect of improving process requirements and meeting stable welded pipe forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

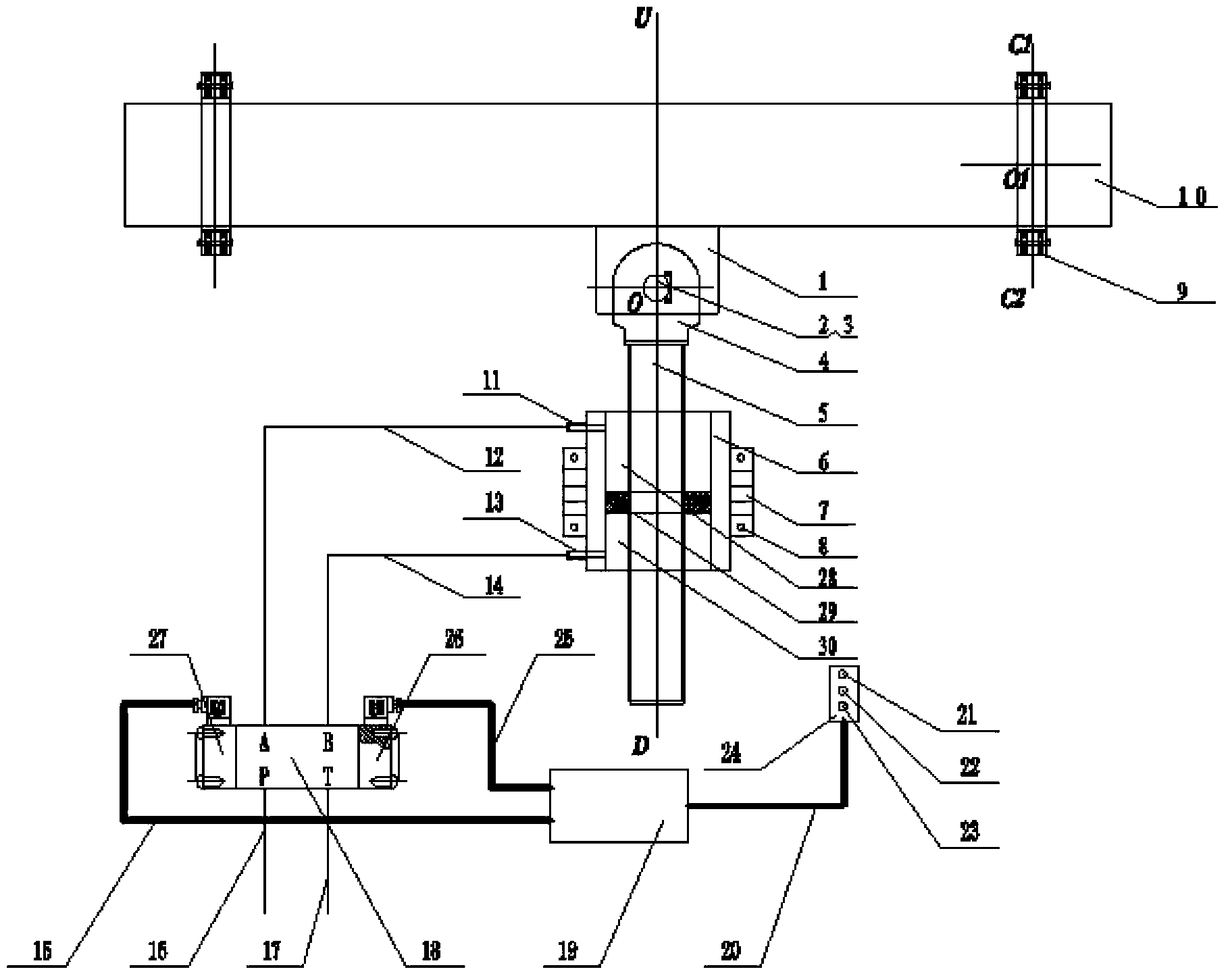

[0021] A retractable rear axle device of a spiral welded pipe unit, including a rear axle assembly, a swing cylinder assembly, and a proportional reversing assembly;

[0022] The rear axle assembly is a rigid platform and is placed horizontally. A rear axle swing cylinder connecting lug 1 perpendicular to the rear axle assembly is welded in the middle of the side. The rear axle swing cylinder connecting lug 1 is provided with a round hole. The spherical top of the swing cylinder assembly is also provided with a round hole, the rear axle assembly and the swing cylinder assembly are inserted into the round hole at the spherical top, and the rear axle swing cylinder is connected to the round hole of the lug 1, two The connecting cylindrical pin 2 in the round hole is fixed, and a radial cancellation positioning plate 3 inserted into the connecting cylindrical pin 2 is installed on the horizontal upper side closely fitting with the connecting lug 1 of the rear axle swing cylinder, so

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap