Tailored welding tooling and welding method for lower frame

A frame body and welder technology, applied in the field of elevators, can solve the problem that the symmetry of the two ends of the front beam and the two ends of the rear beam of the lower frame is not stable relative to the middle beam, and achieves the improvement of welding quality, which is conducive to adjusting the position and the symmetry is stable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

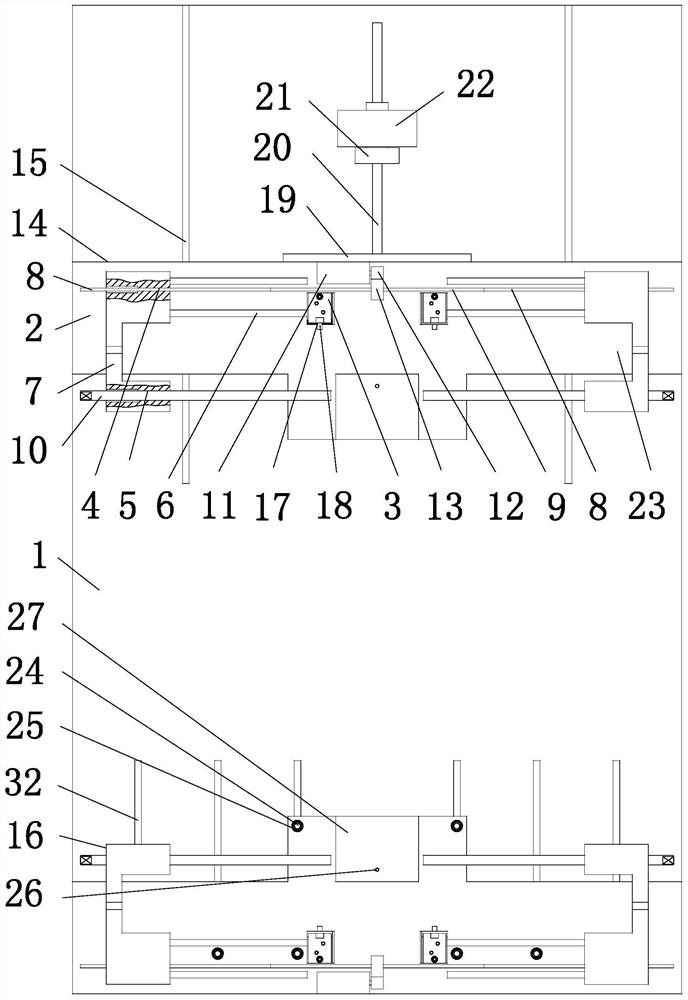

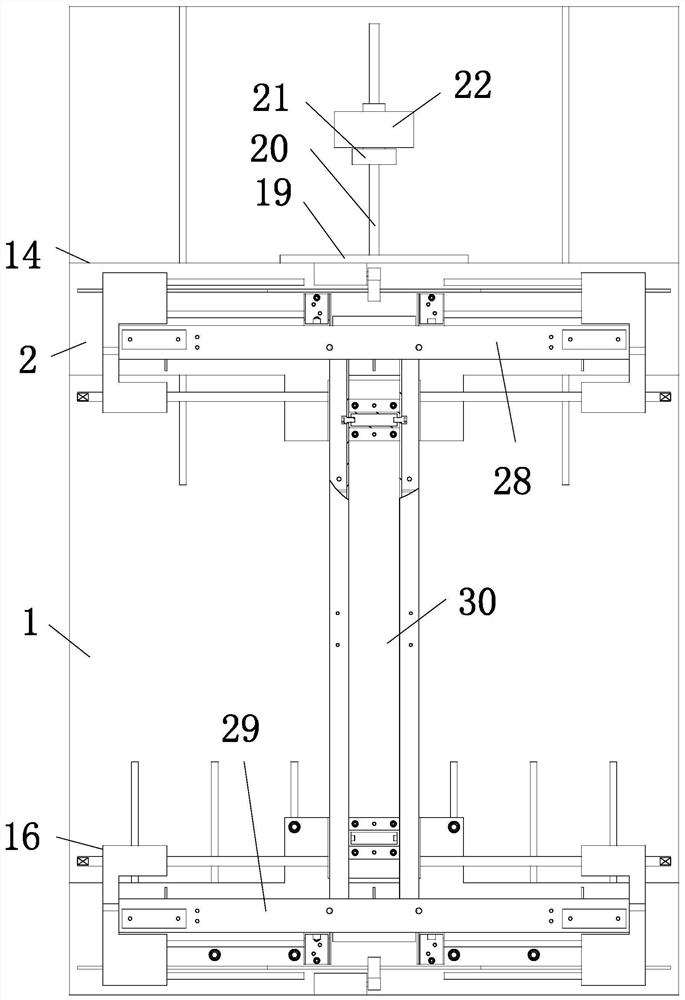

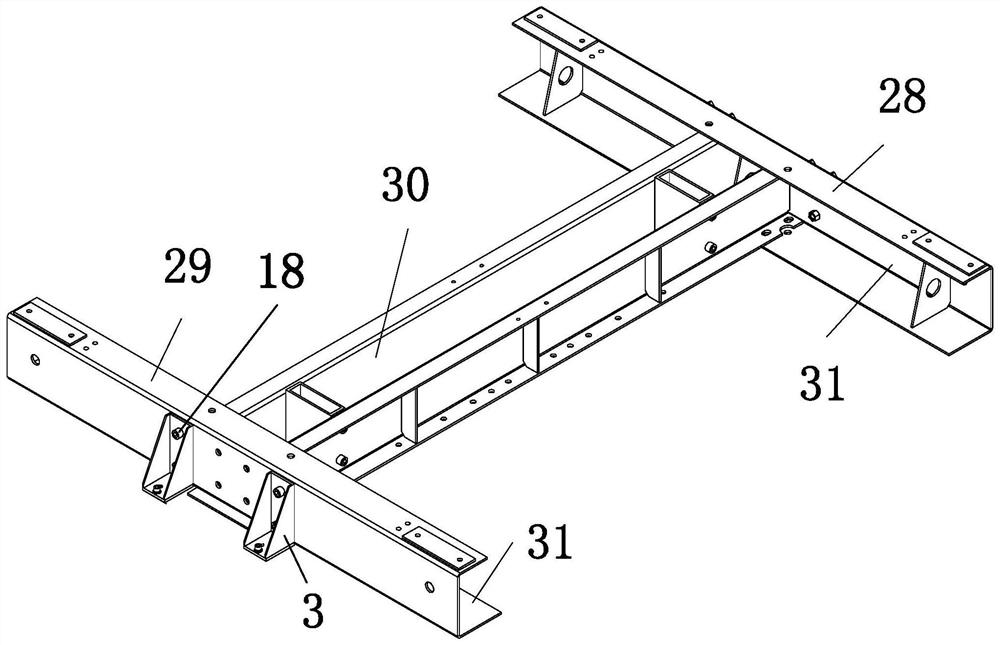

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 , attached figure 2 Shown: a lower frame body tailor welding tool, including: a base 1, two positioning devices arranged symmetrically; A positioning slider 7 is respectively provided with a positioning screw hole 4 and an adjustment screw hole 5 and is slidably connected to the bottom plate 2 through the transverse guide rail 6, and each end is provided with a screw thread that is adapted to the positioning screw hole 4 and is screwed one by one. The drive shaft 9 of the section 8, the center beam positioning screw 10 screwed one by one with the adjustment screw holes 5, the positioning stepper motor 11 screwed with the bottom plate 2, and the output shaft key connection of the positioning stepper motor 11 The driving gear 12, the driven gear 13 keyed to the driving shaft 9 and meshed with the driving gear 12; the screw threads of the two

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap