Welding fixture with error compensation function

A technology of error compensation and welding fixtures, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to compensate, low yield rate, and reduce the welding quality of workpieces, etc., to achieve convenient operation and high yield rate High, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

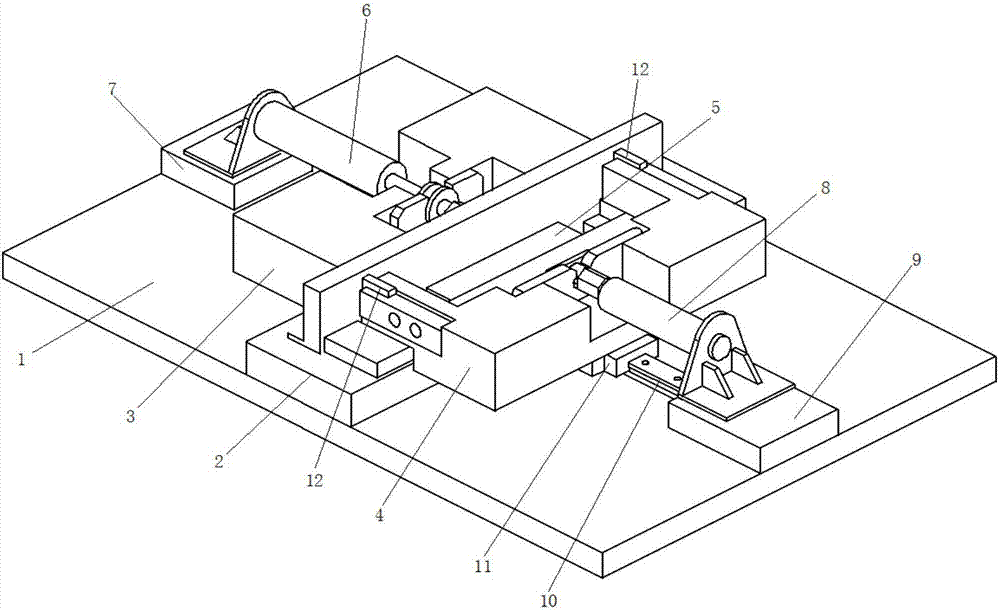

[0013] Attached below figure 1 An embodiment of the present invention is described.

[0014] The welding fixture with error compensation function has a bottom plate 1. The middle of the bottom plate 1 is provided with a welding platform 2 and the left and right sides of the welding platform 2 are respectively provided with a positioning seat 3 and a clamping seat 4. The bottom plate on the left side of the positioning seat 3 1 is provided with a positioning power device and the positioning power device is matched with the positioning base 3. The bottom plate 1 on the right side of the clamping base 4 is provided with a sliding clamping power device and the sliding clamping power device is suitable for the clamping base 4 After being connected, the clamping base 4 is driven to slide to the right by the sliding clamping power device, and the welding workpiece on the welding platform 2 against the positioning power device is clamped and fixed in the welding space 5 on the left side of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap