Reinforcing sheet for wind power generator blades, reinforcing structure of wind power generator blade, wind power generator, method for reinforcing the wind power generator blade

a generator blade and reinforcing sheet technology, applied in wind energy generation, wind motors with parallel air flow, liquid fuel engine components, etc., can solve the problem of inability to reinforce the above-mentioned portion, and achieve the effect of easy and sufficient reinforcement of wind power and easy and reliable securement of rigidity of wind power generator blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

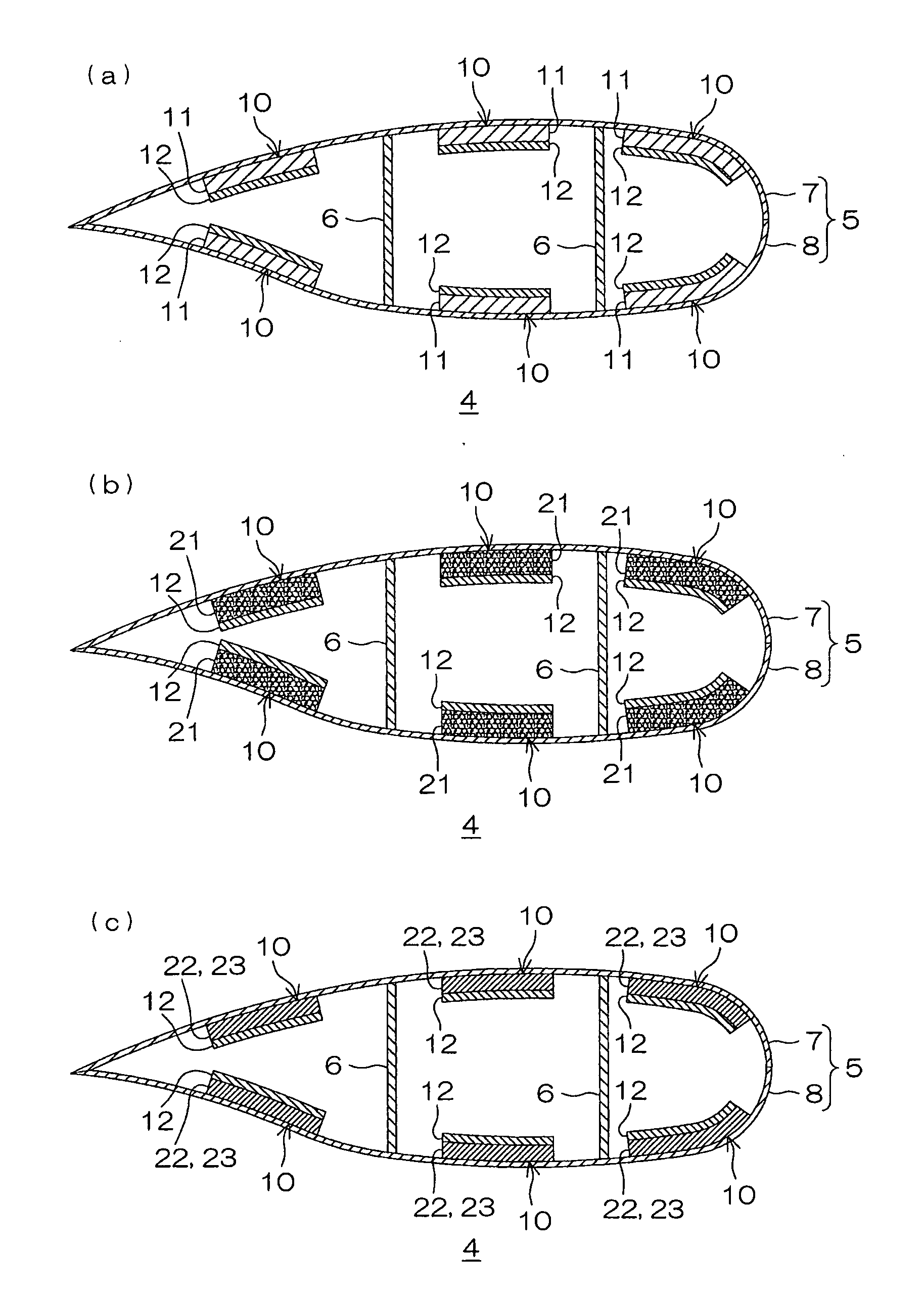

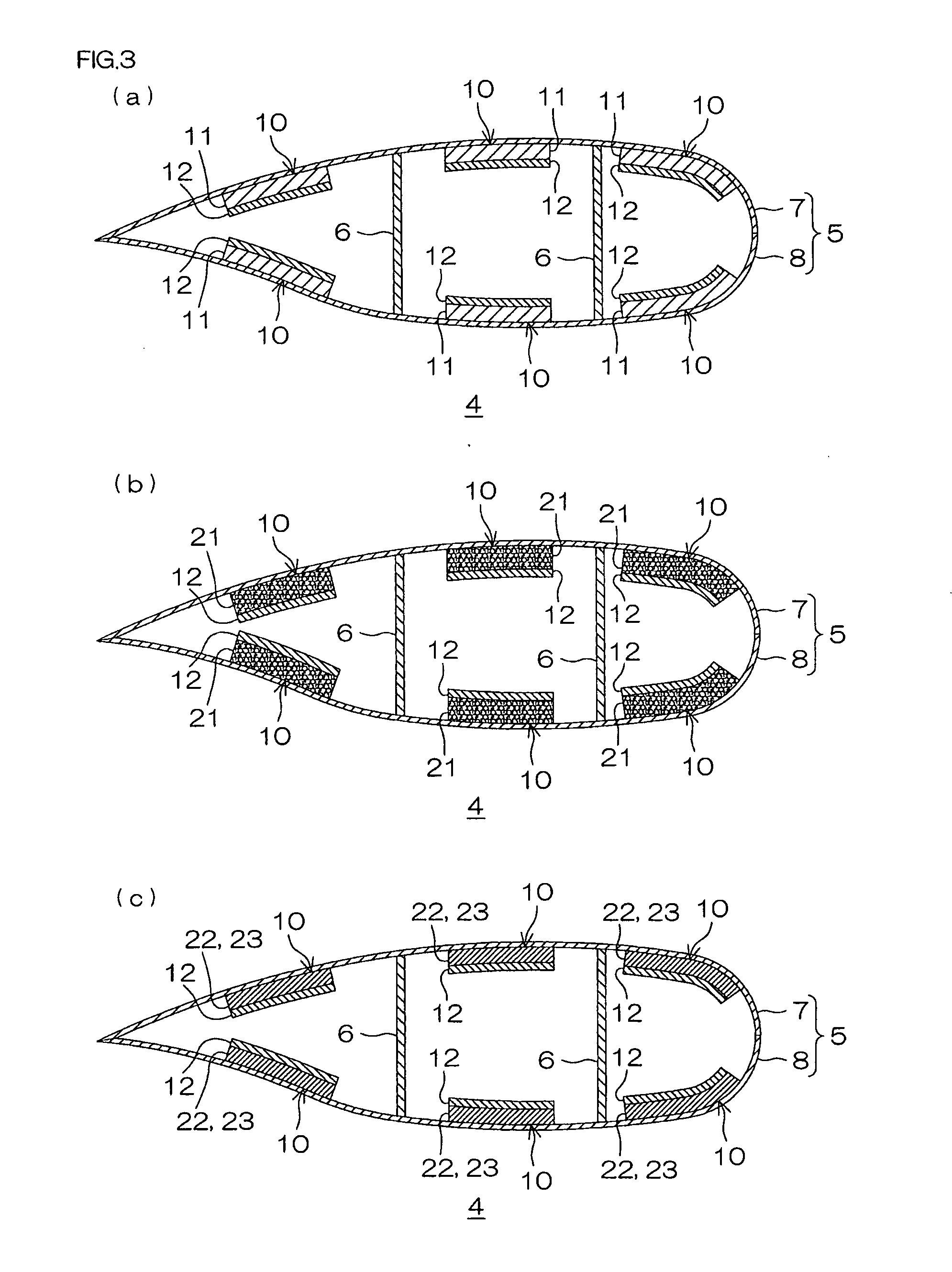

[0035]The reinforcing sheet for wind power generator blades of the present invention includes a resin layer and a restricting layer laminated on the resin layer.

[0036]The resin layer is formed by molding a resin composition in a sheet form.

[0037]The resin composition is not particularly limited as long as it contains at least a resin component. The resin composition optionally contains a curing agent, a crosslinking agent, a foaming agent, and a tackifier depending upon the kind of the resin component.

[0038]The resin component is not particularly limited, and examples thereof include thermosetting resin and thermoplastic resin. Preferably, a thermosetting resin is used.

[0039]The thermosetting resin is not particularly limited and examples thereof include epoxy resin, acrylic resin, and synthetic rubber.

[0040]The epoxy resin is not particularly limited, and examples thereof include aromatic epoxy resin, aliphatic and alicyclic epoxy resin, and ring containing nitrogen epoxy resin.

[0041]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap