Solid carbon dot zeolite composite material fingerprint developing powder and preparation method thereof

A composite material, carbon point zeolite technology, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc. Good dispersion, strong adhesion, clear fingerprint lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the carbon dot@Silicalite-1 zeolite composite material of the present invention comprises the following steps:

[0027] Step 1. Synthesis of carbon dots (CDs) via hydrothermal method:

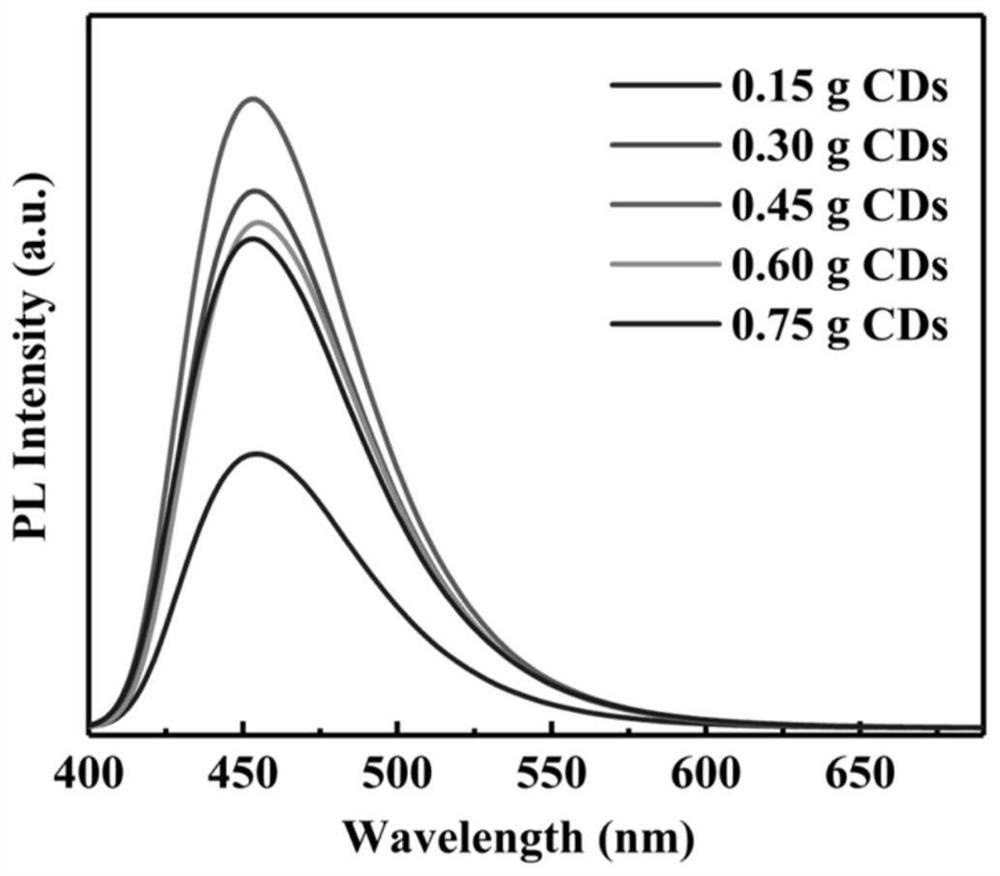

[0028] Dissolve 1 g of citric acid monohydrate and 3 mL of diethylenetriamine in 10 mL of deionized water, transfer the uniformly mixed solution into a polytetrafluoroethylene-lined stainless steel reactor (effective volume: 25 mL), and conduct a hydrothermal reaction at 180 °C 6h, obtain yellow-brown CDs solution;

[0029] Step 2, load CDs on Silicalite-1 zeolite:

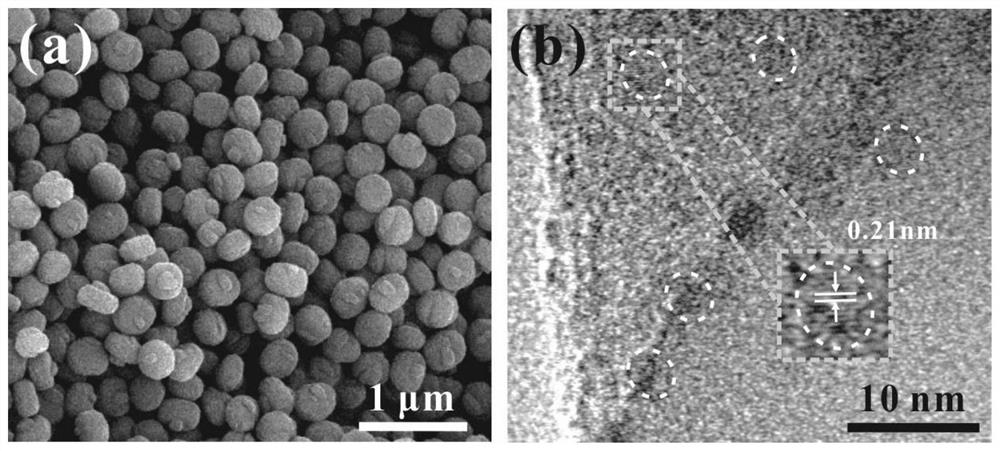

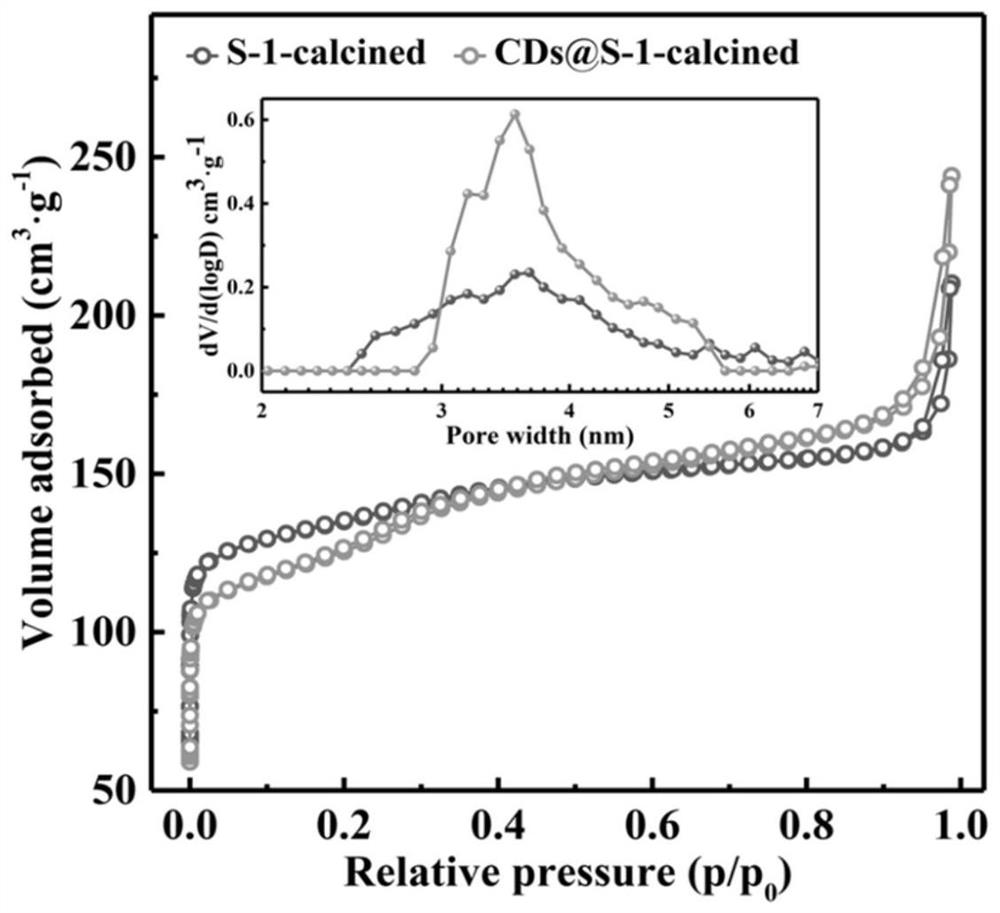

[0030] TPAOH, NaOH solution (1wt%), TEOs and H 2 O Mix evenly in the proportion of 10 g:0.5 g:15 g:20mL, stir for 10min, add 0.15g CDs (2wt%) sample to the solution, stir at room temperature for 24h until evenly stirred; then transfer the mixture to a 250mL flask , stirred at 100°C for 24h; the synthesized product was centrifuged at 8000rpm for 10min, washed with water three times, then dried at 60°

Embodiment 2

[0032] The preparation method of carbon point @Silicalite-1 zeolite composite material of the present invention comprises the following steps

[0033] Step 1 is the same as embodiment 1;

[0034] Step 2, load CDs on Silicalite-1 zeolite:

[0035] TPAOH, NaOH solution (1wt%), TEOs and H 2 O was uniformly mixed in the proportion of 20 g:4 g:35 g:60 mL, and after stirring for 10 min, 0.75 g of CDs (10 wt%) sample was added to the solution, and stirred at room temperature for 24 h until uniform; then the mixture was transferred to 250 mL In the flask, stirred at 100°C for 24h; the synthesized product was centrifuged at 8000rpm for 10min, washed with water three times, then dried at 60°C for 20h, and ground into powder.

Embodiment 3

[0037] The preparation method of carbon point @Silicalite-1 zeolite composite material of the present invention comprises the following steps

[0038] Step 1 is the same as embodiment 1;

[0039] Step 2, load CDs on Silicalite-1 zeolite:

[0040] TPAOH, NaOH solution (1wt%), TEOs and H 2 O was uniformly mixed in the proportion of 10g:0.5g:35g:60mL, and after stirring for 10min, 0.30g CDs (4 wt%) sample was added to the solution, and stirred at room temperature for 24h until uniform; then the mixture was transferred to a 250mL flask, Stir at 100°C for 24h; centrifuge the synthesized product at 8000rpm for 10min, wash with water three times, then dry at 60°C for 20h, and grind into powder.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap