Flexible liquid metal pattern based on laser activation selective metallization and preparation method thereof

A liquid metal and metal pattern technology, applied in the field of flexible sensors, can solve the problems of expensive femtosecond lasers, easy breakage of copper layers, loss of conductivity, etc., to achieve excellent acid/alkali corrosion resistance, excellent conductivity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

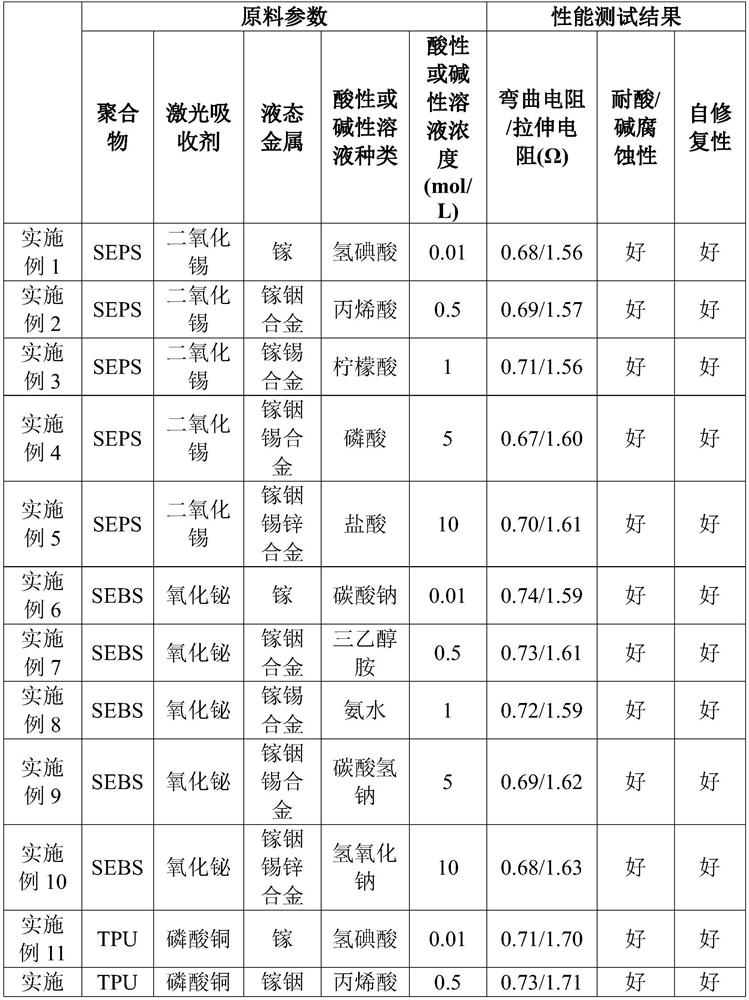

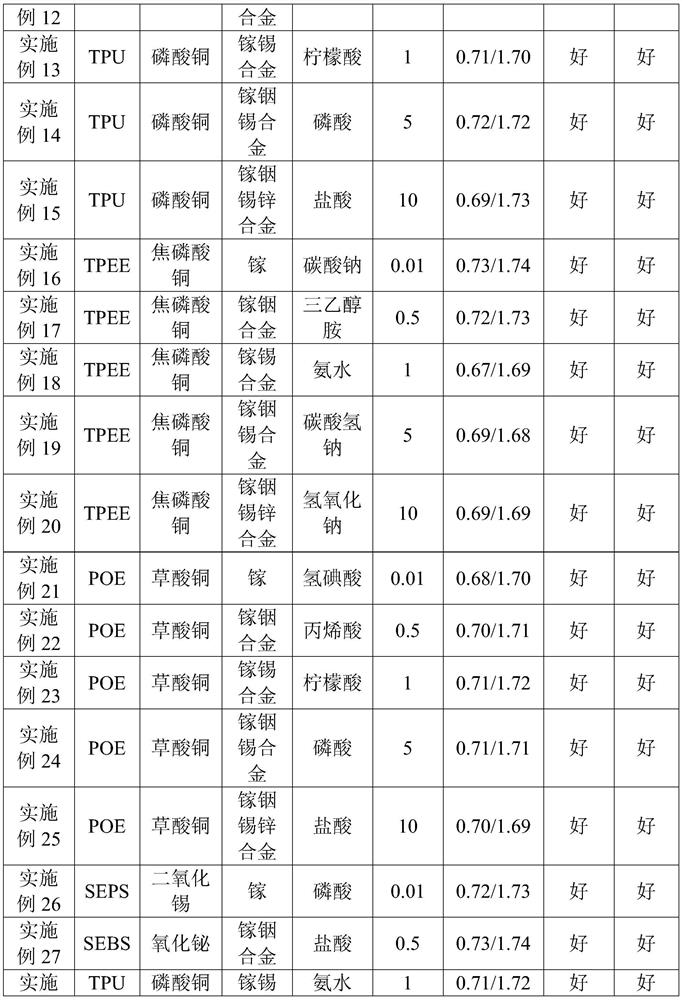

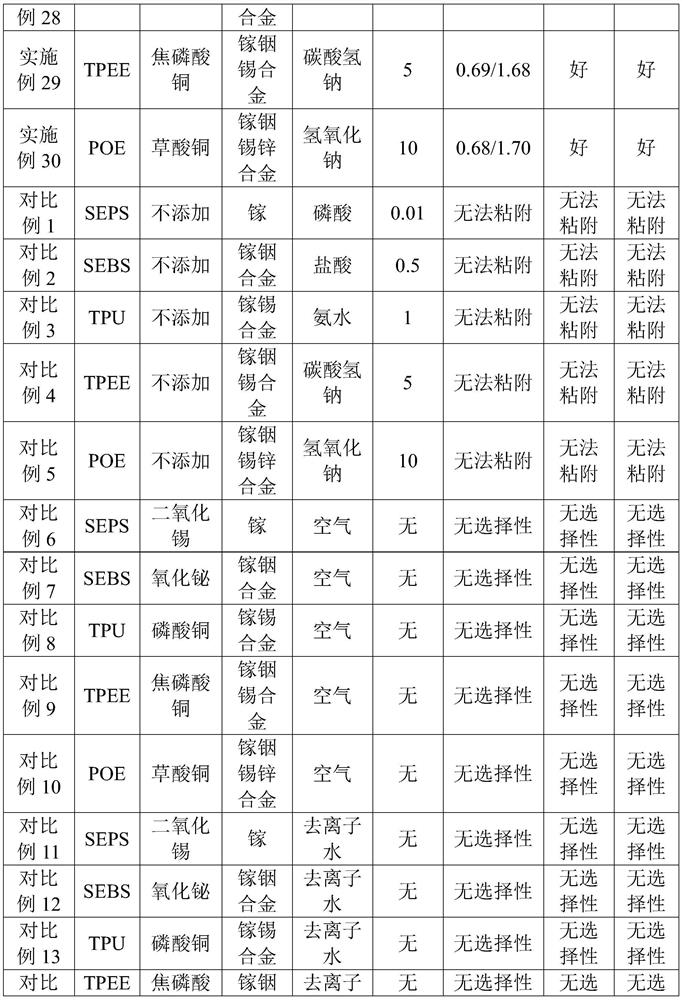

Embodiment 1

[0052] Tin dioxide is mixed with SEPS in an amount of 5wt.%, adopts twin-screw extruder to melt and blend extrude (temperature 210 ℃), granulate, and the pellet injection molding (temperature 260 ℃) of gained is made polymer / Laser absorber flexible composite material standard sample. A planar near-infrared pulsed laser (wavelength 1064nm) was used to irradiate the surface of the polymer / laser absorber flexible composite standard sample for laser activation. The laser power was 4W, the laser scanning speed was 1000mm / s, and the laser frequency was 40kHz. The polymer / laser absorber flexible composite material standard sample after laser irradiation was immersed in the electroless copper plating solution, and copper was plated at 50°C for 10 minutes to prepare a conductive copper pattern. In a 0.01mol / L hydriodic acid solution, the gallium element was dropped onto the copper-plated polymer / laser absorber flexible composite material standard sample, and a nylon brush was

Embodiment 2

[0054] The liquid metal used is gallium indium alloy, the acidic solution is a 0.5 mol / L acrylic acid solution, and other conditions are consistent with Example 1.

Embodiment 3

[0056] The liquid metal used is a gallium-tin alloy, the acidic solution is a 1mol / L citric acid solution, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap