Preparation method of mesoporous silica in situ doped acrylic resin bone cement composite for enhancing durable release capacity of medicines

A technology of mesoporous silica and acrylic resin, applied in medical science, prosthesis, etc., can solve the problem of the influence of nanoparticle composite PMMA bone cement on drug release characteristics, and achieve enhanced sustainable release time, sustained uniform release, and voids. The effect of a large space fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mesoporous hollow spherical silica nanomaterials are in-situ doped with acrylic resin bone cement composite materials, and the specific preparation process is as follows:

[0038] (1). Preparation of hollow silica nanomaterials

[0039] Take 0.9 g of ferric chloride hydrate and add it to 30 mL of ethylene glycol, stir to dissolve, then add 4 g of anhydrous sodium acetate and 0.8 g of sodium citrate in turn, stir and mix, then transfer the liquid into the reaction kettle, at 150 After reacting at a temperature of ℃ for 10 h, the reactant was taken out, washed twice with water and ethanol and dried to obtain the synthesized ferric oxide.

[0040] Take 40 mg of prepared ferric oxide and add it to 35 mL of deionized water, then add 0.9 mL of hydrazine hydrate, sonicate for 10 min, then add 150 mL of deionized water and 30 μL of ethyl orthosilicate, mechanically Stir the reaction for 2 h, remove the supernatant and continue to add 150 mL of deionized water, 0.9 mL of hydrazine

Embodiment 2

[0049] Mesoporous rod-shaped silica nanomaterials are in-situ doped with acrylic resin bone cement composite materials, and the specific preparation process is as follows:

[0050] (1). Preparation of mesoporous rod-shaped silica nanomaterials

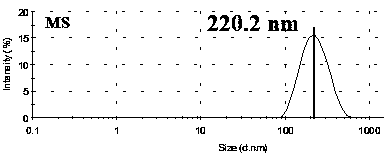

[0051] Add 25 g of polyvinylpyrrolidone and 250 mL of 1-pentanol into a closed round-bottomed flask, mix ultrasonically for 2 h, then add 30 mL of absolute ethanol, 7.5 mL of ultrapure water and 6 mL of 0.3 M lemon Sodium dihydrate aqueous solution, mixed well, added 7.5 mL ammonia solution with a mass fraction of 20%, 0.6 mL ethyl orthosilicate, stirred for 30 h, collected by centrifugation, washed with deionized water and ethanol and dried to obtain mesoporous Rod-shaped silica sphere nanomaterials. see image 3 It is a transmission electron microscope image of a rod-shaped silica nanomaterial, which shows that it has been successfully prepared.

[0052] (2). Preparation of aminated rod-shaped silica nanomaterials

[0053] Disperse

Embodiment 3

[0059] Mesoporous tubular silica nanomaterials are in-situ doped with acrylic resin bone cement composites, and the specific preparation process is as follows:

[0060] (1). Preparation of Mesoporous Tubular Silica Nanomaterials

[0061] Dissolve 10 g of tetraethyl orthosilicate in 7 mL of ethanol, add 75 µL of HCl solution at room temperature, and react for 35 min; dissolve 3 g of P123 in 35 mL of ethanol, then add it to the above-reacted solution, and continue to react for 35 min , vacuum filtered to the polycarbonate template, and soaked in the ethanol solution containing P123 prepared above for 3h. Subsequently, the polycarbonate template was moved into the reaction kettle and maintained at a temperature of 70° C. for 2 days, and finally the polycarbonate template was removed using dichloromethane to obtain a mesoporous tubular silica sphere nanomaterial. see Figure 4 It is a transmission electron microscope picture of the tubular silica nanomaterial, which shows that it h

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap