Phosphorus-containing indoor-temperature high-plastic-deformation magnesium alloy

A deformed magnesium alloy and high plasticity technology, applied in the field of magnesium alloy materials, can solve the problems of not fully utilizing the performance advantages of magnesium alloys, coarse product grains, and low mechanical properties, so as to improve room temperature plasticity and processability, and improve compression and elongation The effect of improving plasticity and processing performance at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of a kind of phosphorus-containing deformed magnesium alloy of the present invention is described in detail as follows:

[0029] Step 1: Prepare materials

[0030] The raw materials are metal magnesium ingots, metal aluminum ingots, metal zinc ingots, elemental red phosphorus and AlMn20 aluminum-manganese master alloy ingots.

[0031] The underflux, covering agent and refining agent required for the experiment can use the existing underflux, covering agent and refining agent for magnesium alloy preparation, such as: underflux RJ-2, covering agent RJ-6, refining agent RJ-5.

[0032] The prepared raw materials are dried, in which the metal magnesium ingots, metal aluminum ingots, metal zinc ingots, and elemental red phosphorus are dried at a temperature of 100°C±10°C, while the AlMn20 aluminum-manganese master alloy ingots are dried at a temperature of 150°C±10°C. Down drying, the function of drying is to remove the moisture in the raw materials and

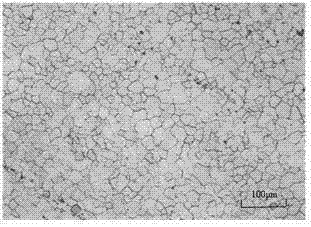

Embodiment 1

[0043] Example 1 is used to prepare a phosphorus-containing deformed magnesium alloy provided by the present invention.

[0044] (1) Raw material preparation: Weigh metal magnesium, metal aluminum, metal zinc, AlMn20 aluminum-manganese alloy and simple red phosphorus with a purity of 99.9wt%, so that the percentage of each element in the total mass of raw materials is: Al5.98%, Zn1.06 , Mn0.32, P0.23%. The raw materials are dried, wherein Mg, Al, Zn and P are dried at a temperature of 100°C, and the AlMn20 master alloy is dried at a temperature of 150°C.

[0045] (2) Metal alloy melting: Preheat the crucible to 200-250°C, and continuously inject SF into the crucible 6 Gas, put the weighed magnesium ingots, aluminum ingots, and zinc ingots into the crucible and add the bottom flux to heat and melt. The mass of the bottom flux accounts for 1.5%-2.5% of the mass of the charge. After melting, add the weighed aluminum-manganese intermediate alloy and continue heating. After the alum

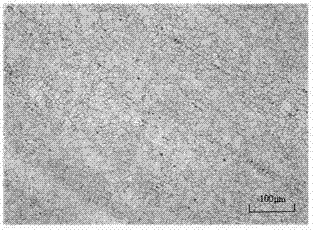

Embodiment 2

[0051] The raw materials and preparation method are basically the same as those in Example 1, except that 0.32% by mass of phosphorus is added to obtain magnesium alloy cast rod B2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap