Method for preventing dry dedusting explosion venting after converter blowing breaking off

A technology of dry dust removal and converter blowing, applied in the manufacture of converters, etc., can solve the problems of increasing the difficulty of control and changing the operating process system, so as to achieve the effect of stable smelting control, perfect operation and smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

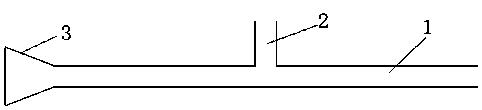

Image

Examples

Embodiment 1

[0016] Embodiment 1: The method for preventing explosion and venting by dry dust removal after converter blowing is interrupted is specifically described as follows.

[0017] In a 120t converter in a factory, heat number 1 is interrupted in converter blowing, and when the oxygen lance reaches the oxygen shut-off point in the process of raising the lance, the injection system is turned on, and the particle size is injected into the furnace with nitrogen through the nozzles evenly arranged at the furnace mouth. Mixed powder of carbon powder and coal powder less than 0.2mm. The number of nozzles is 2, the angle between the injection angle and the liquid surface is 75 degrees, the pressure used for injection is 0.8MPa, the injection volume of combustible powder is 20kg, and the injection time is controlled at 60s. After injection, the concentration of CO entering the electric field increased from 7% to 12% before injection, and O 2 The concentration of the gas is reduced from 4.5% b

Embodiment 2

[0018] Embodiment 2: The method for preventing explosion and venting by dry dust removal after converter blowing is interrupted is specifically described as follows.

[0019] In a 120t converter in a factory, furnace number 2 is interrupted when the converter blowing is interrupted, and when the oxygen lance reaches the oxygen shut-off point during the oxygen lance lifting process, the injection system is turned on, and the particle size is injected into the furnace with nitrogen through the nozzles evenly arranged at the furnace mouth. ≤0.2mm toner. The number of nozzles is 8, the angle between the injection angle and the liquid surface is 30 degrees, the pressure used for injection is 0.6MPa, the injection volume of combustible powder is 100kg, and the injection time is controlled at 20s. After injection, the concentration of CO entering the electric field increased from 8% to 14% before injection, and O 2 The concentration of the gas is reduced from 4.6% before injection to 2

Embodiment 3

[0020] Embodiment 3: The method for preventing explosion and venting by dry dust removal after converter blowing is interrupted is specifically described as follows.

[0021] In a 120t converter in a certain factory, when the converter blowing was interrupted for heat number 3, when the oxygen lance was lifted and the oxygen shut-off point was reached, the injection system was turned on, and the particle size was injected into the furnace with nitrogen through the nozzles evenly arranged at the furnace mouth. ≤1.8mm coal powder. The number of nozzles is 4, the angle between the injection angle and the liquid surface is 60 degrees, the pressure used for injection is 0.8MPa, the injection volume of combustible powder is 50kg, and the injection time is controlled at 50s. After injection, the concentration of CO entering the electric field increased from 10% to 17% before injection, and O 2 The concentration of the gas is reduced from 4.2% before injection to 1.8%, which prevents a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap