Heat dissipation plate of electric automobile battery pack and battery pack of electric automobile

A technology for electric vehicles and heat sinks, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as smoke, explosion, and severe battery combustion, and achieve convenient output and input, reduce manufacturing costs, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

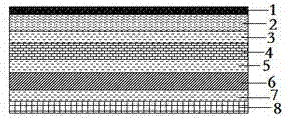

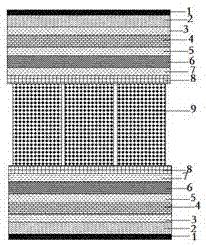

[0021] Such as figure 1 As shown, a heat dissipation plate of an electric vehicle battery pack includes, from top to bottom, an alumina magnesium corrosion-resistant layer 1, an aluminum-magnesium alloy metal plate 2, and a first carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 3. Aluminum foil layer 4, second carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 5, heat dissipation polyester film 6, third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 7 and battery Electrode connection plate 8, the battery electrode connection plate has a patterned conductive circuit, wherein the thickness of the aluminum oxide magnesium corrosion-resistant layer is 50 nanometers, the thickness of the aluminum-magnesium alloy metal plate is 100 microns, the first , The thickness of the second and third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layers is 20 microns, wherein the diameter of the carbon nan

Embodiment 2

[0023] Such as figure 1 As shown, a heat dissipation plate of an electric vehicle battery pack includes, from top to bottom, an alumina magnesium corrosion-resistant layer 1, an aluminum-magnesium alloy metal plate 2, and a first carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 3. Aluminum foil layer 4, second carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 5, heat dissipation polyester film 6, third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 7 and battery Electrode connection plate 8, the battery electrode connection plate has a patterned conductive circuit, wherein the thickness of the aluminum oxide magnesium corrosion-resistant layer is 100 nanometers, the thickness of the aluminum-magnesium alloy metal plate is 150 microns, the first , The thickness of the second and third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layers is 30 microns, the diameter of the carbon nanotubes

Embodiment 3

[0025] Such as figure 1 As shown, a heat dissipation plate of an electric vehicle battery pack includes, from top to bottom, an alumina magnesium corrosion-resistant layer 1, an aluminum-magnesium alloy metal plate 2, and a first carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 3. Aluminum foil layer 4, second carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 5, heat dissipation polyester film 6, third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layer 7 and battery Electrode connection plate 8, the battery electrode connection plate has a patterned conductive circuit, wherein the thickness of the aluminum oxide magnesium corrosion-resistant layer is 200 nanometers, the thickness of the aluminum-magnesium alloy metal plate is 200 microns, the first , the thickness of the second and third carbon nanotube modified ethylene-vinyl acetate copolymer adhesive layers is 50 microns, the diameter of the carbon nanotubes

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap