High-temperature-resistant and corrosion-resistant waterproof board for tunnels and production process thereof

A production process and high temperature resistant technology, applied in tunnels, tunnel linings, layered products, etc., can solve the problems of not being able to adapt to high ground temperature tunnel environments, waterproof boards are not resistant to high temperatures, and are not resistant to corrosion, so as to improve physical and mechanical properties and High temperature resistance, high transparency, good effect of high temperature creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

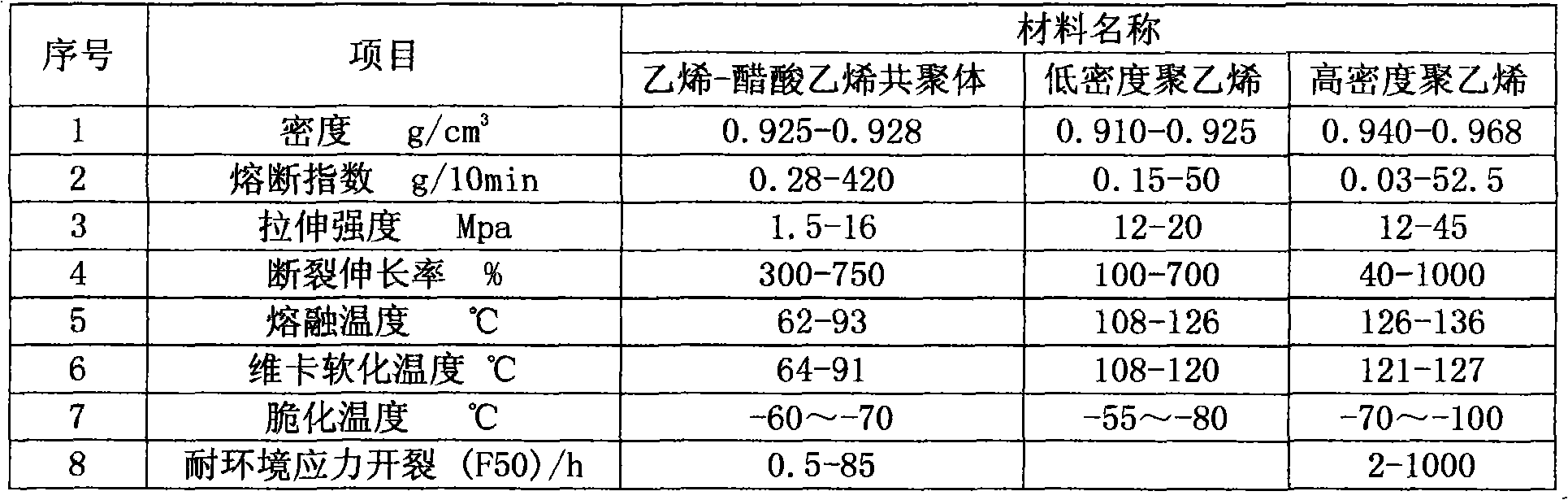

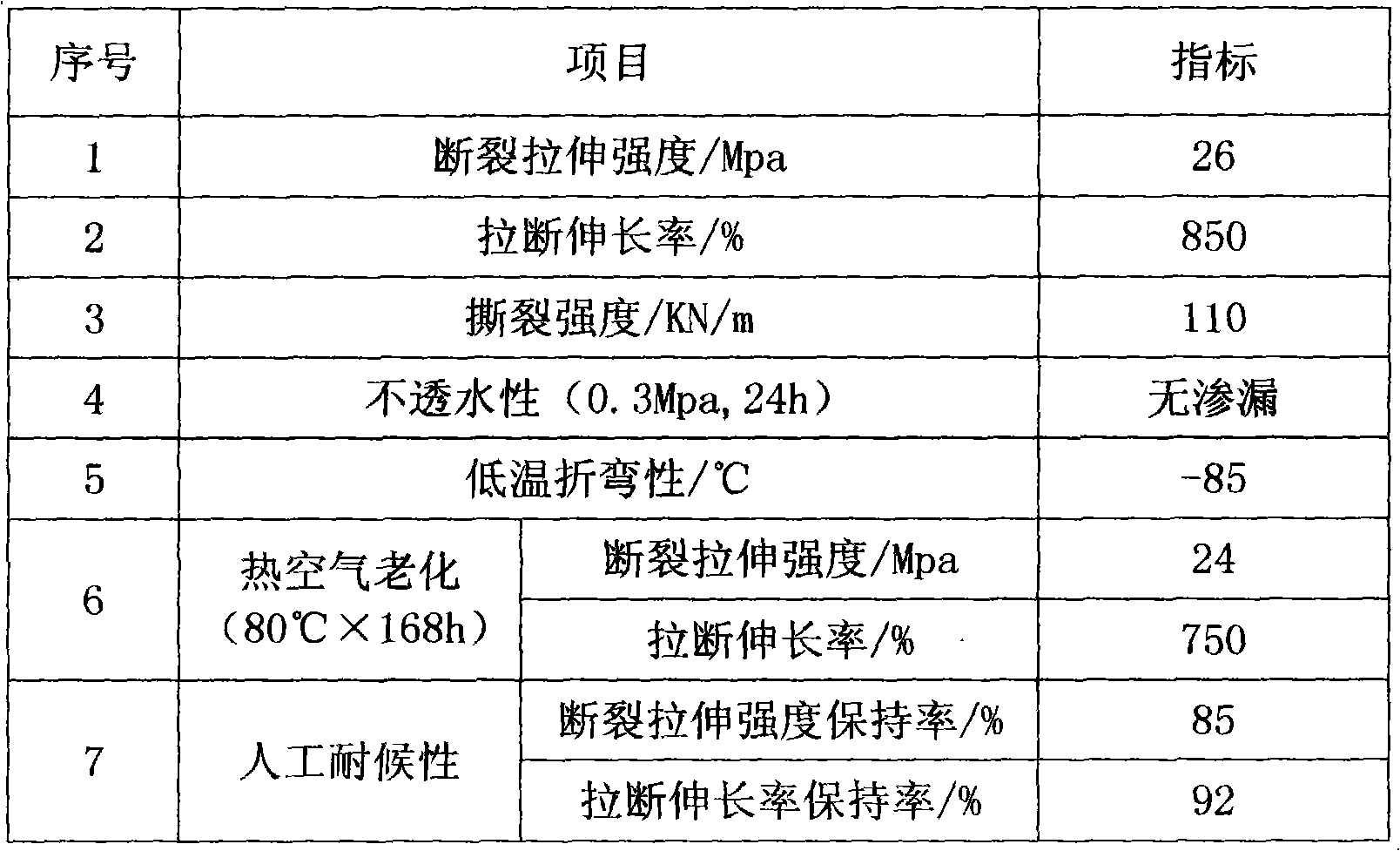

[0024] Example 1 A high-temperature and corrosion-resistant waterproof board for tunnels, with high-density polyethylene HDPE as the main raw material, random copolymerized polypropylene PPR and BE2045 double-resistant carbon black produced by Beijing Yisanyou Plastic Technology Co., Ltd. as auxiliary materials, using The upper and lower two-layer composite structure, the upper layer is made of high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black materials containing antioxidants, high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black containing antioxidants The mass ratio between them is 1:0.04:0.26; the lower layer is made of high-density polyethylene HDPE and random copolymerized polypropylene PPR and carbon black material, and the mass ratio of high-density polyethylene HDPE and random copolymerized polypropylene PPR is 1 : 0.25. Its specific production process is as follows:

[0025] (1) Parallel compoundin

example 2

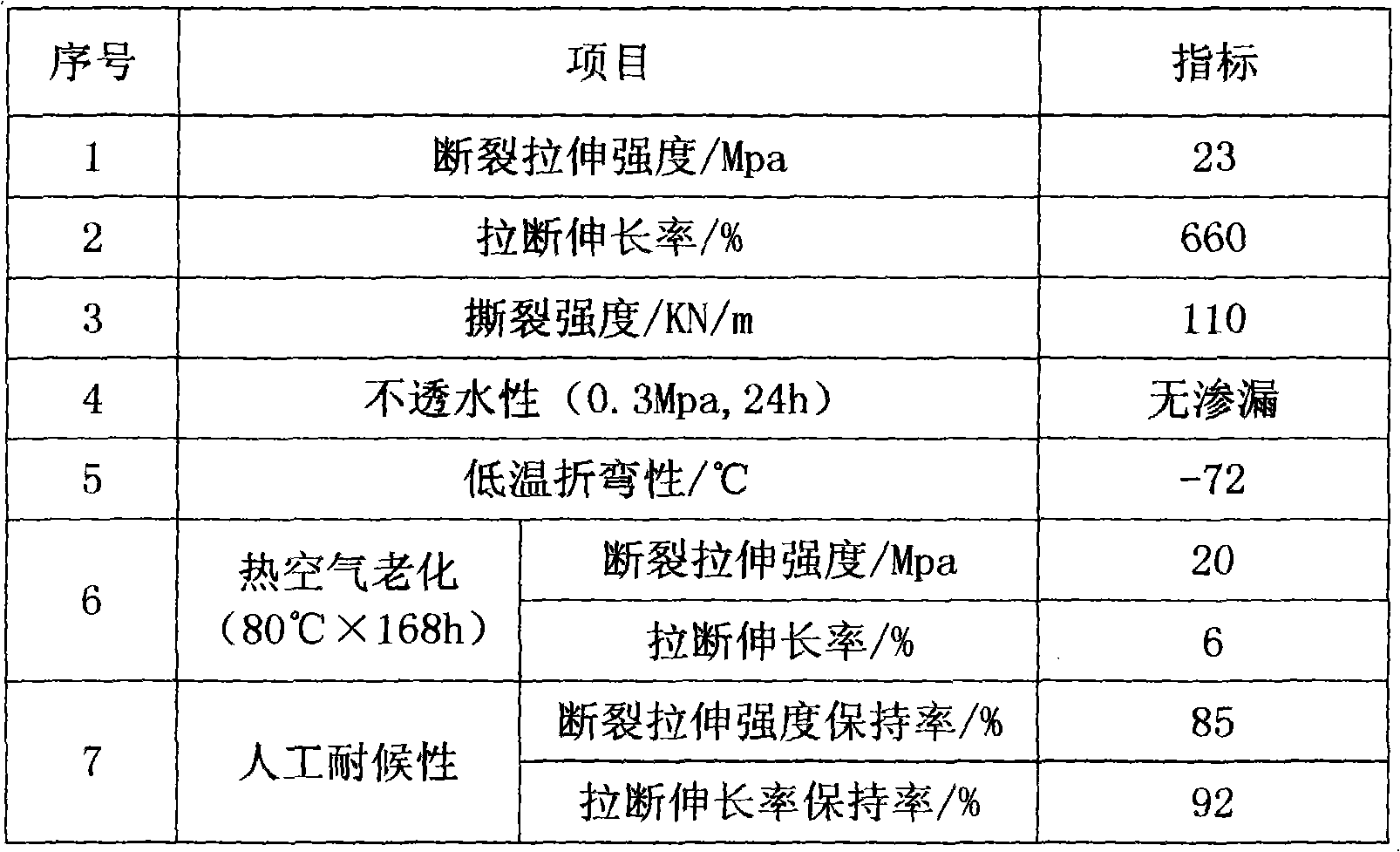

[0032] Example 2 A high-temperature and corrosion-resistant waterproof board for tunnels, with high-density polyethylene HDPE as the main raw material, random copolymerized polypropylene PPR and BE2045 double-resistant carbon black produced by Beijing Yisanyou Plastic Technology Co., Ltd. as auxiliary materials, using The upper and lower two-layer composite structure, the upper layer is made of high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black materials containing antioxidants, high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black containing antioxidants The mass ratio between them is 1:0.01:0.15; the lower layer is made of high-density polyethylene HDPE and random copolymerized polypropylene PPR and carbon black materials, and the mass ratio of high-density polyethylene HDPE and random copolymerized polypropylene PPR is 1 : 0.1. Its specific production process is as follows:

[0033] (1) Parallel compoundin

example 3

[0040] Example 3 A high-temperature and corrosion-resistant waterproof board for tunnels, with high-density polyethylene HDPE as the main raw material, random copolymerized polypropylene PPR and BE2045 double-resistant carbon black produced by Beijing Yisanyou Plastic Technology Co., Ltd. as auxiliary materials, using The upper and lower two-layer composite structure, the upper layer is made of high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black materials containing antioxidants, high-density polyethylene HDPE, random copolymerized polypropylene PPR and carbon black containing antioxidants The mass ratio between them is 1:0.1:0.35; the lower layer is made of high-density polyethylene HDPE and random copolymerized polypropylene PPR and carbon black materials, and the mass ratio of high-density polyethylene HDPE and random copolymerized polypropylene PPR is 1 : 0.4.

[0041] Its specific production process is as follows:

[0042] (1) Parallel co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap