Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Screen printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

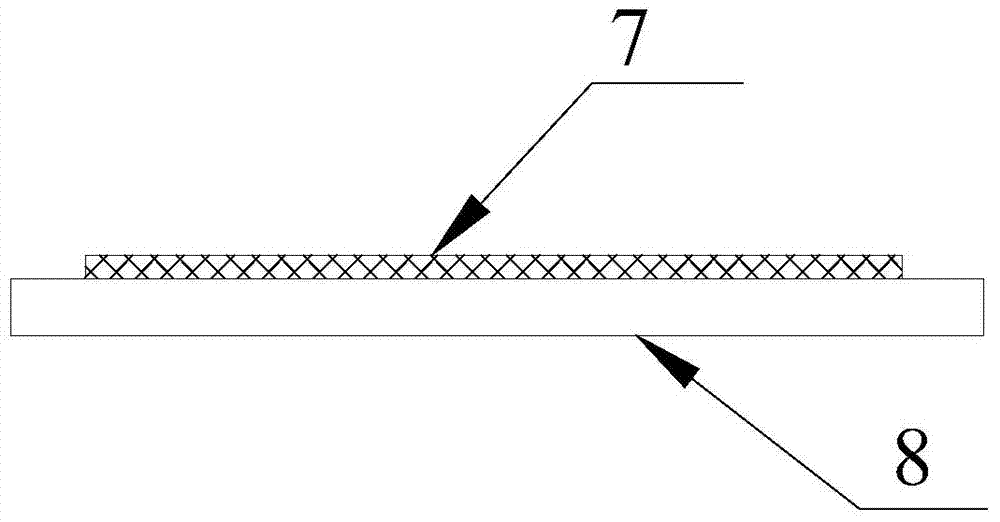

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One color is printed at a time, so several screens can be used to produce a multicoloured image or design.

Low-silver-content composite conductive silver paste and preparation method thereof

InactiveCN104282356AImprove conductivityReduce silver contentNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteScreen printing

The invention relates to a low-silver-content composite conductive silver paste and a preparation method thereof, and belongs to the technical field of electroconductive slurry. The low-silver-content composite conductive silver paste can be used for screen printing. At present, the conductive silver paste preparation technology in China is high in production cost, complex in preparation technology and the like. According to the low-silver-content composite conductive silver paste, silver-plated copper powder and silver-plated glass powder are adopted to replace pure silver powder, so that the production cost of the silver paste is effectively reduced; the mode that spherical particles and platy particles are combined is selected, so that the conductivity of the silver paste is improved; the silver-plated glass powder with the low specific density is adopted, so that the stability of the conductive silver paste is improved, and the storage life of the silver paste is prolonged. The problems existing in silver paste production at present in China are well solved, the sliver paste preparation technology is simple, the silver paste is good in conductivity and impressionability (including automatic and semi-automatic screen printing and the like), and high in adhesion capacity with various substrates such as a PET film, and has significant application value.

Owner:肖淑勇

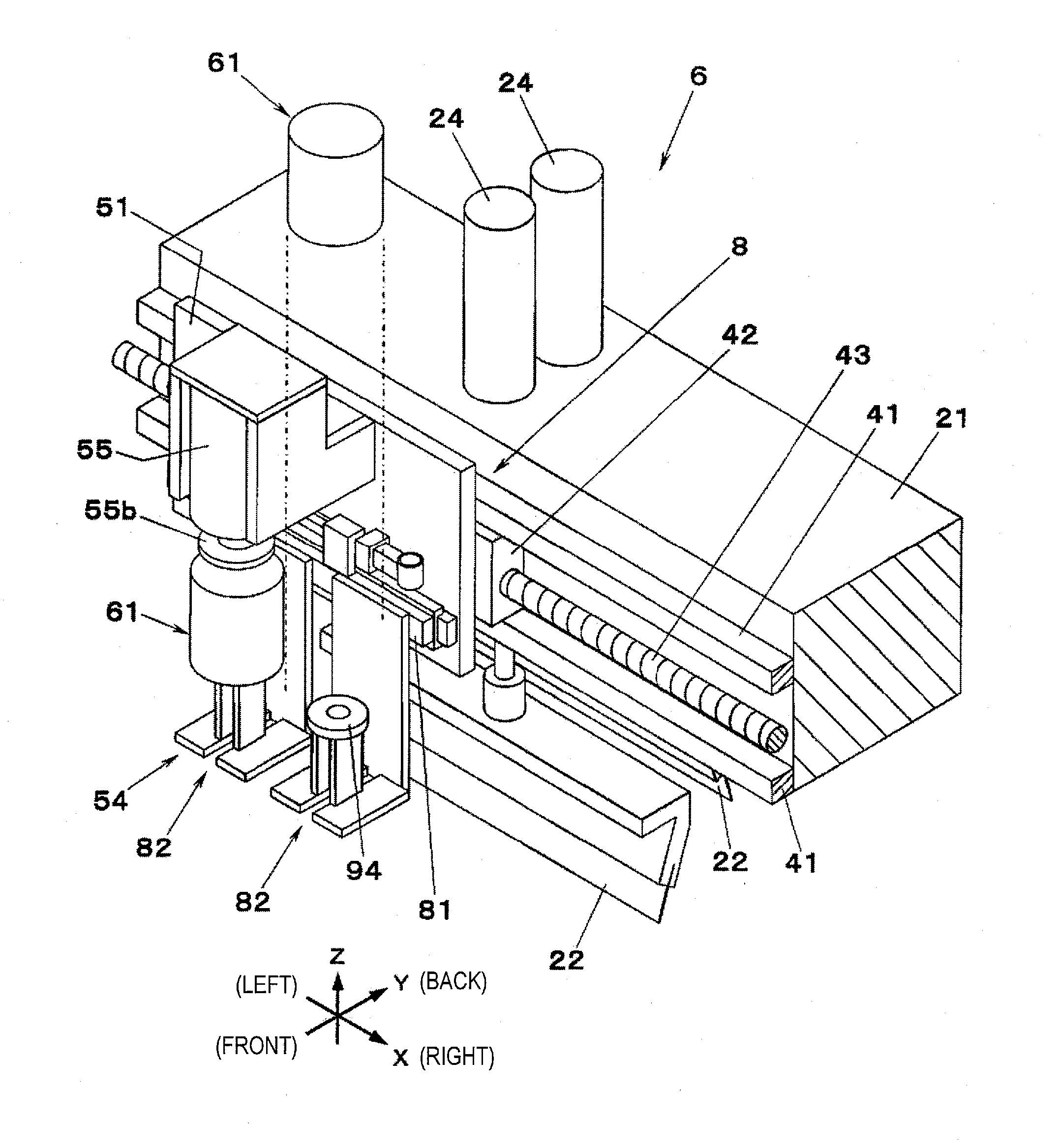

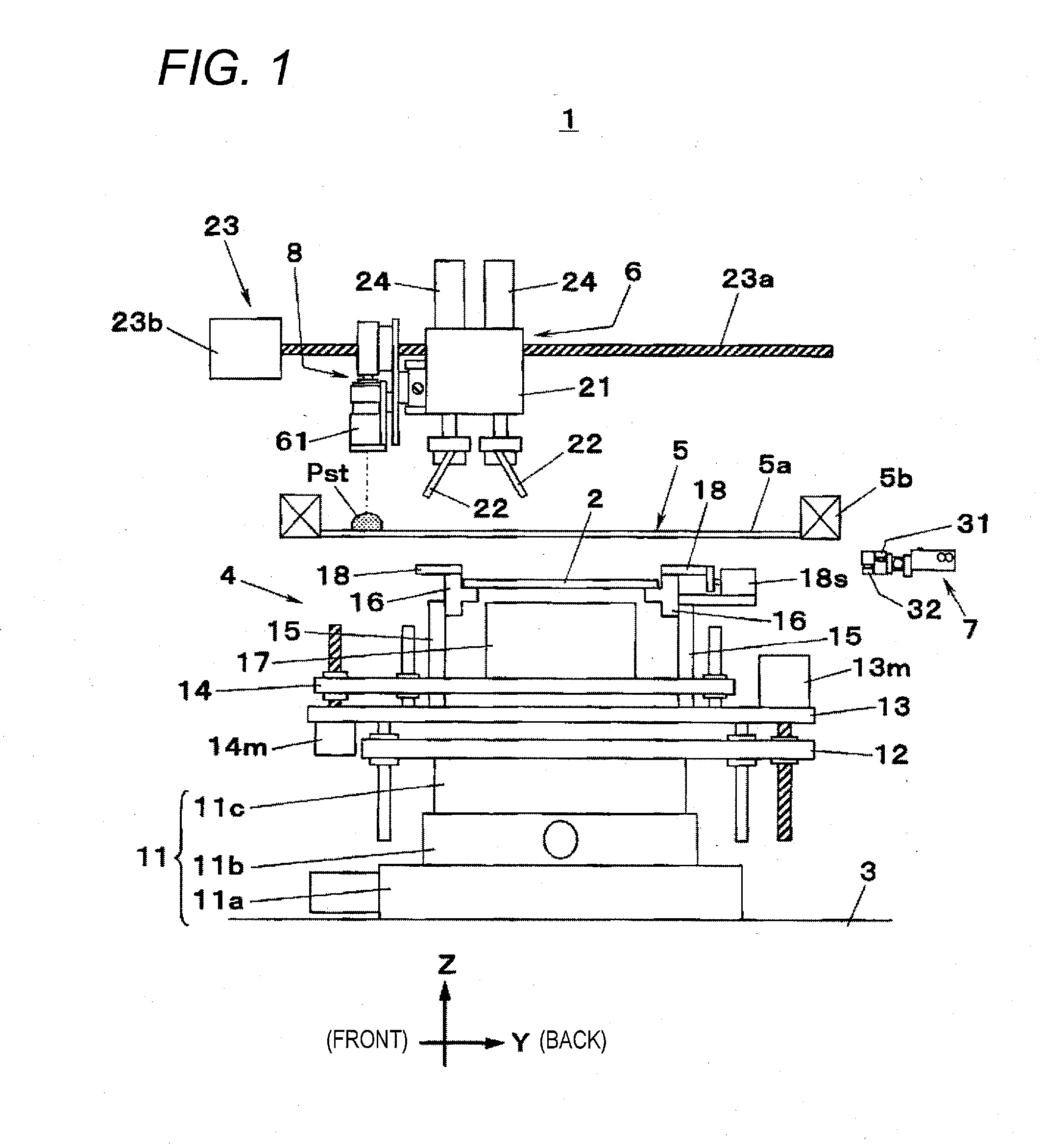

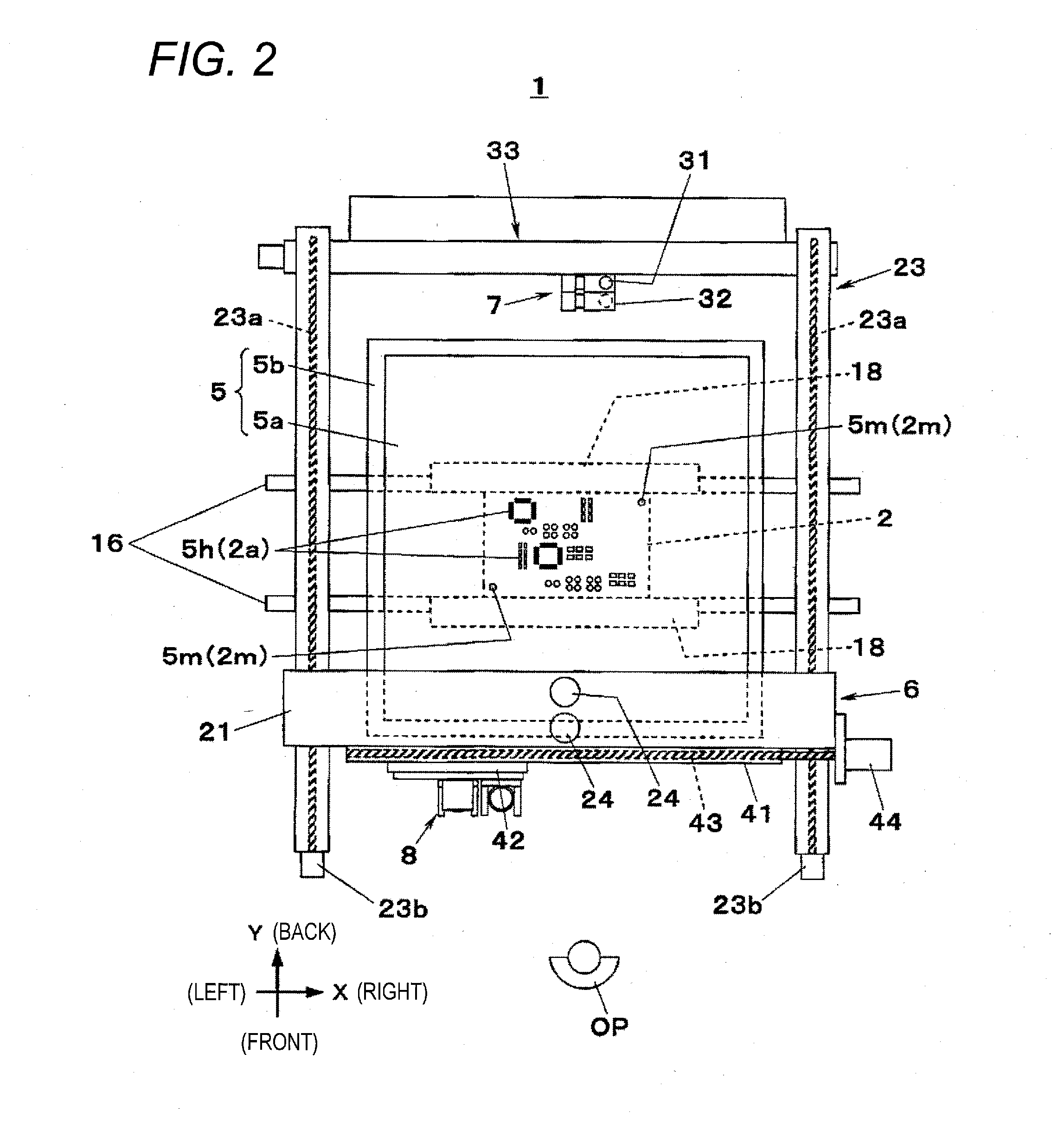

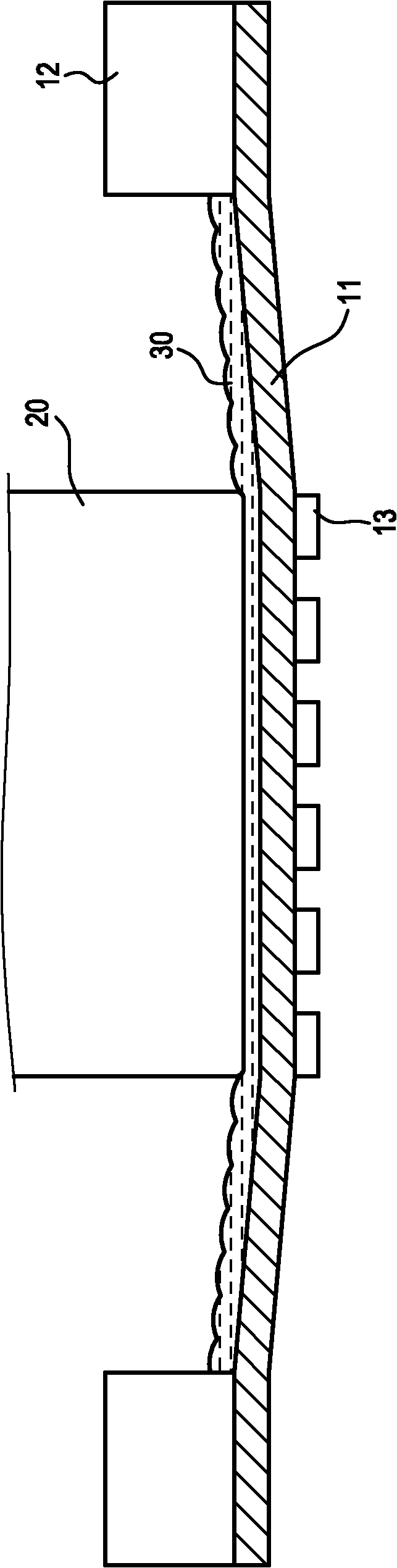

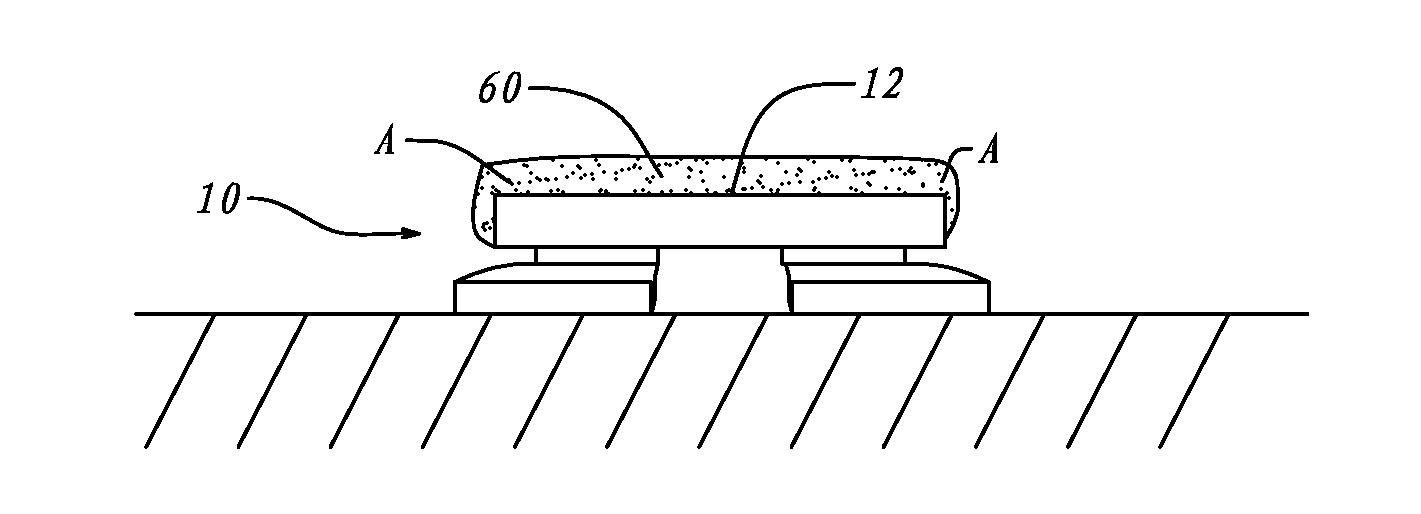

Paste supply apparatus, screen printing machine, paste supply method and screen printing method

ActiveUS20140366754A1Improve work efficiencyInking apparatusLiquid surface applicatorsScreen printingEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for isolating films on two sides of substrate layer and preparing process for heterogenous junction solar cell

ActiveCN103426973APrevent leakageNo damageFinal product manufactureSemiconductor devicesScreen printingSilver paste

The invention discloses a method for isolating films on the two sides of a substrate layer. The method comprises the following steps of 1, photoetching photoresist narrow lines at the periphery of the front side and / or the back side of the substrate layer and at the portion close to the edge of the substrate layer, 2, respectively and correspondingly producing film layers on the front side and the back side of a substrate, 3, using organic solvent to remove the photoresist narrow lines in the step 1 before the work procedure for forming a silver grid electrode of the solar cell, and 4, using low-temperature silver paste silk screen to print the silver grid electrode and drying the low-temperature silver paste to enable the organic solvent used in the step 3 to be volatized. The method can effectively avoid the phenomenon of cell electric leakage or cell short circuit caused by electrical connection between the films on the two sides of the substrate layer. Furthermore, the method can avoid damage of laser isolation methods, mechanical isolation methods and the like to the cell and guarantee that the efficiency of the cell is not affected.

Owner:TRINA SOLAR CO LTD

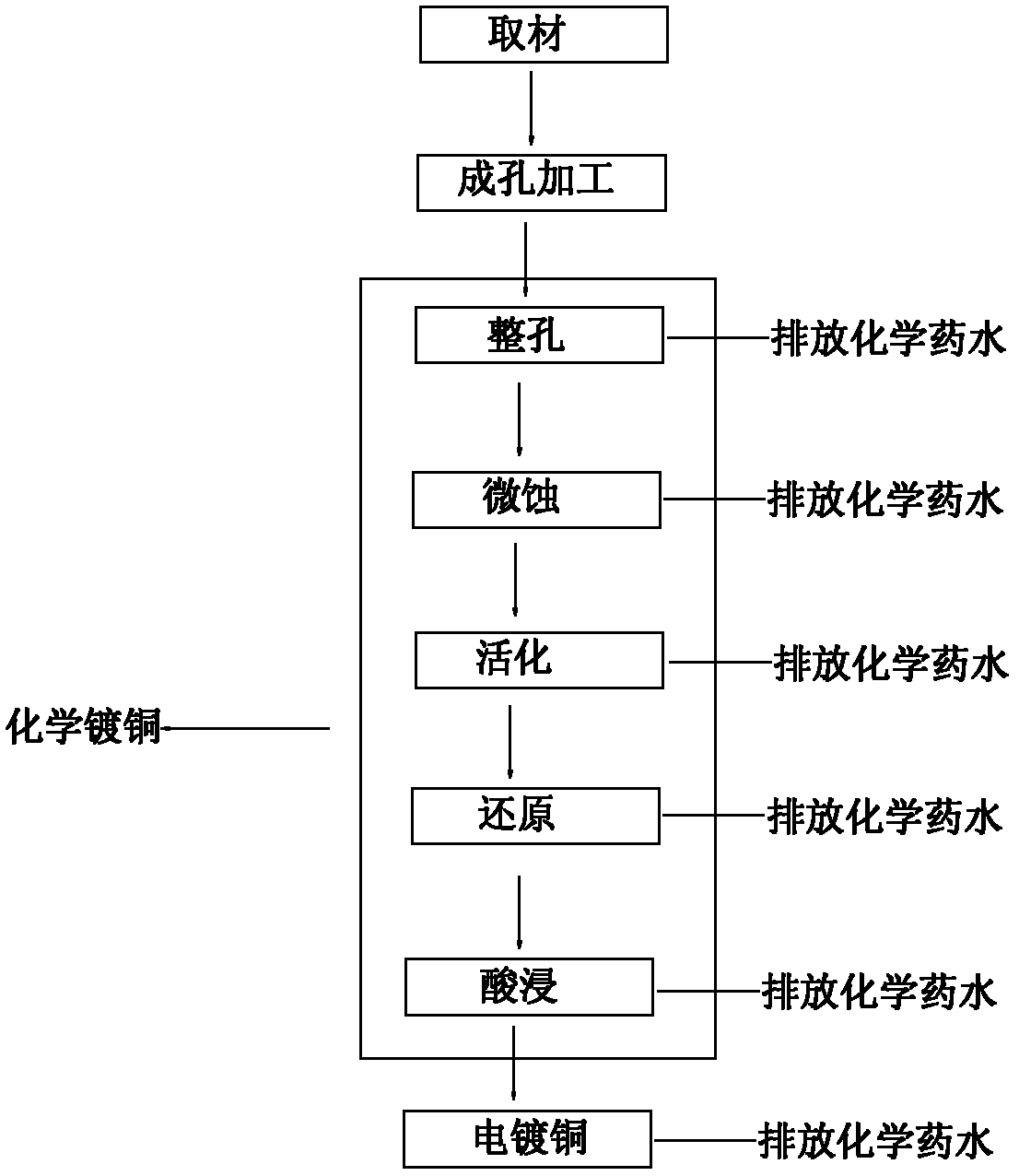

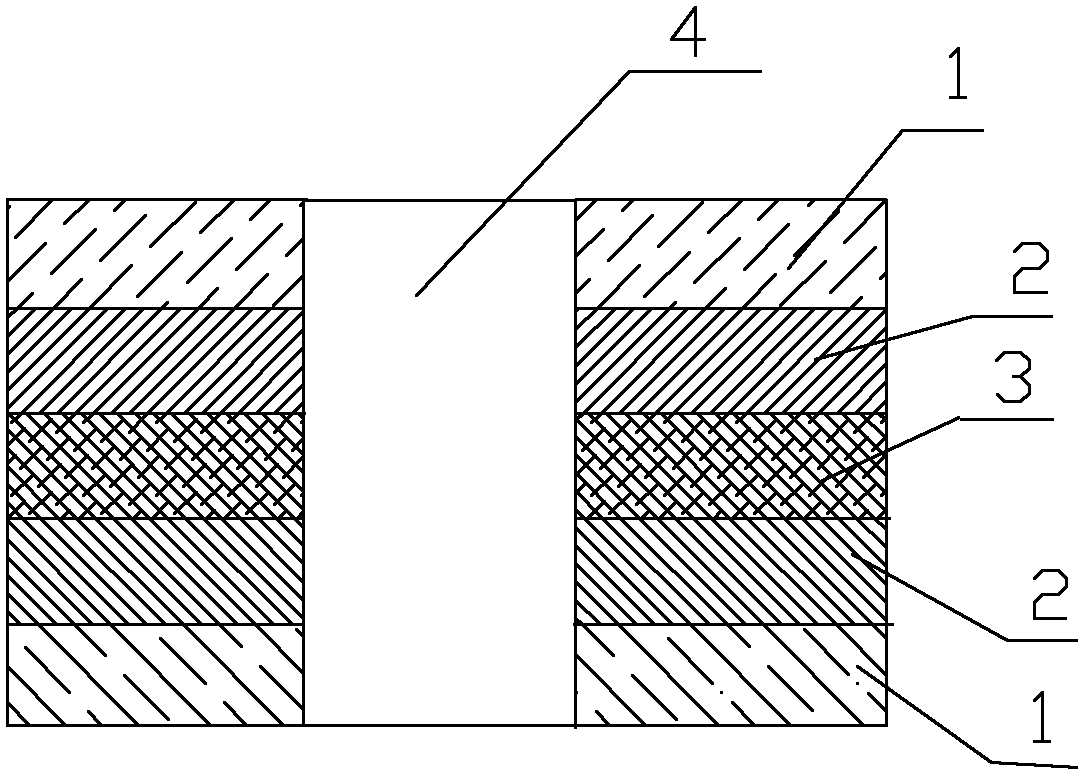

Manufacturing process of interlayer copper connector of printed circuit board

InactiveCN102638946AReduce investmentReduce investment riskPrinted element electric connection formationScreen printingInsulation layer

Owner:SHENZHEN HONGHAI ELECTRON MATERIAL TECH CO LTD

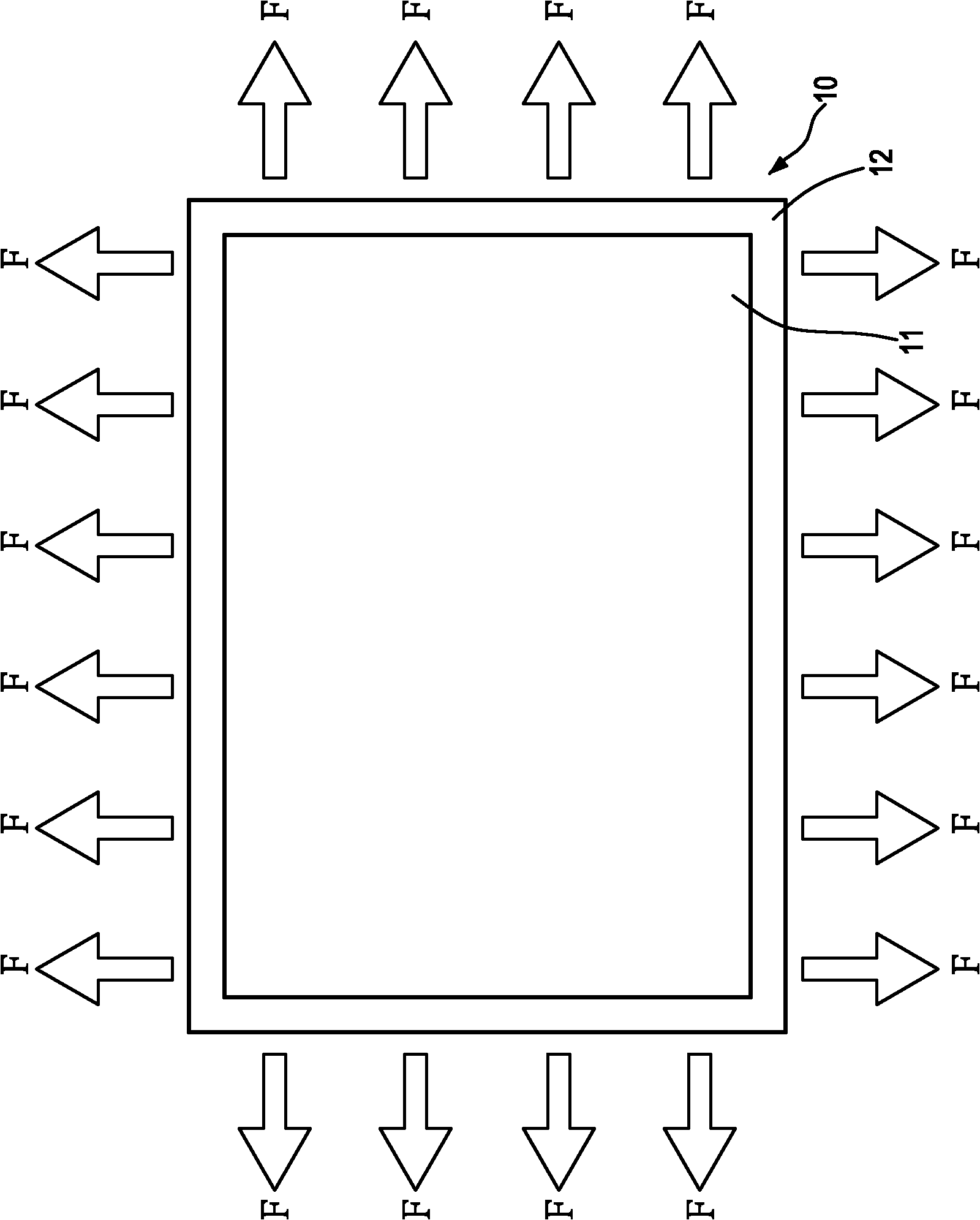

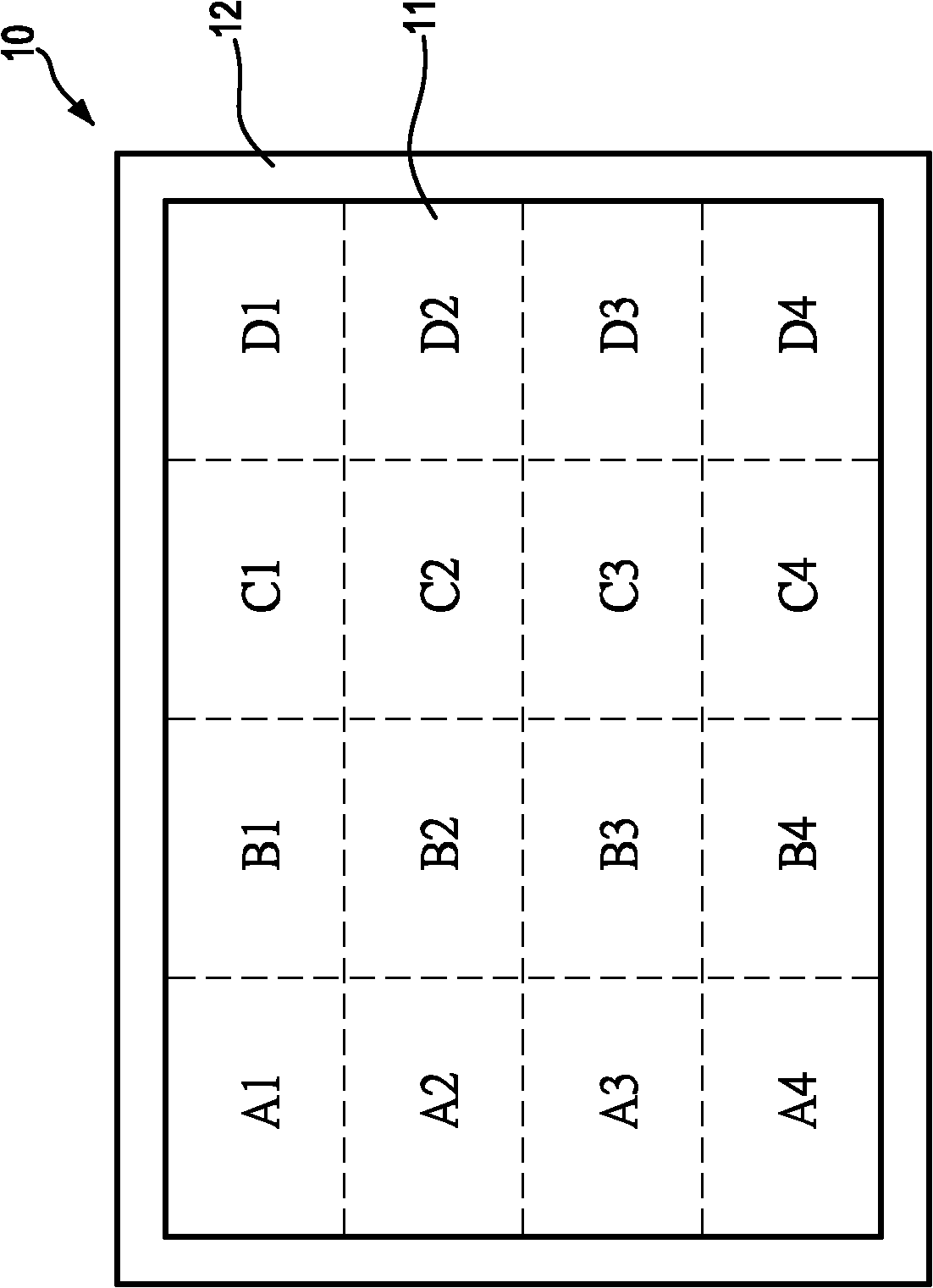

Printing screen having anisotropic tensile force and manufacturing method thereof

Owner:FAITHFUL PRINTING EQUIP & SUPPLY

Production method of glue attached G/G capacitive screen

InactiveCN103500045ASmall footprintReduce manufacturing costInput/output processes for data processingScreen printingUltraviolet lights

Owner:无锡宇宁智能科技有限公司

Analog printing preprocessing process

ActiveCN103465660AReduce deformationReduce generationOther printing apparatusGraphicsScreen printing

Owner:山东泰宇消防科技集团有限公司

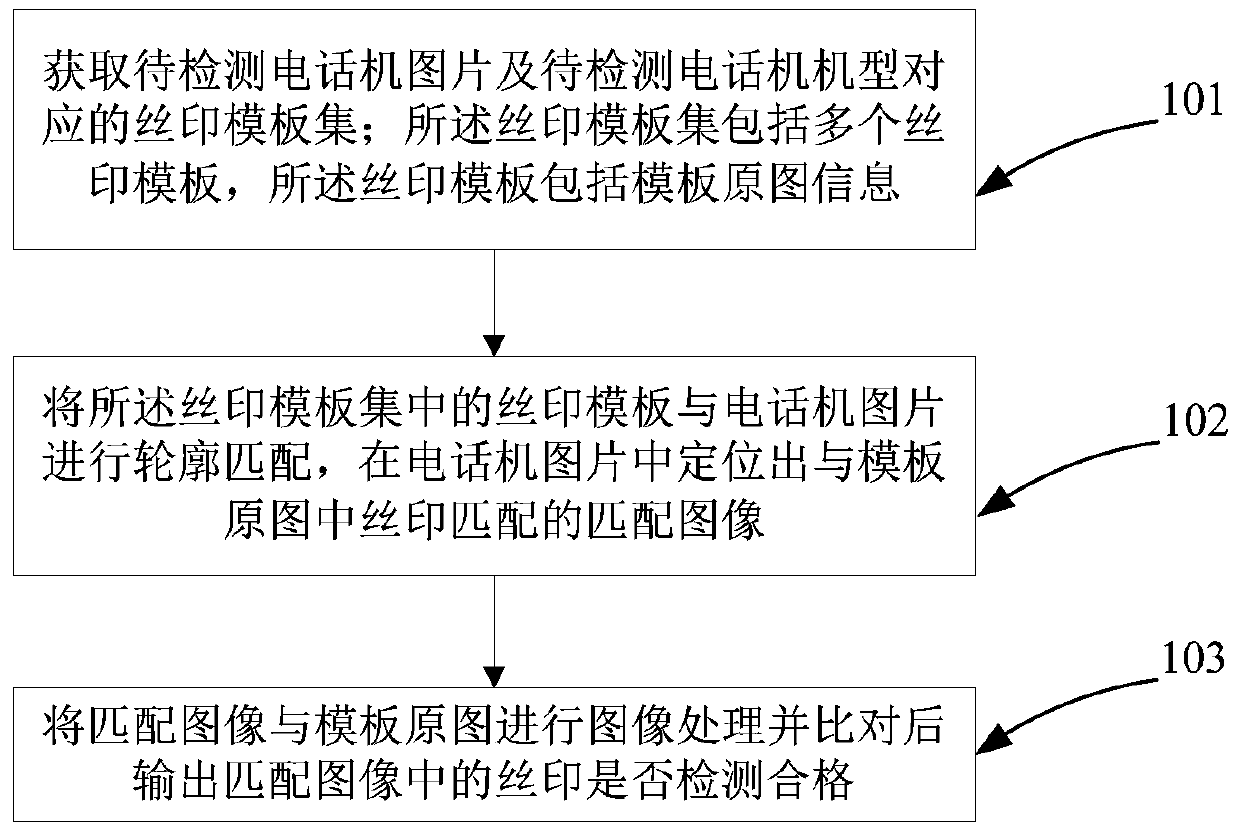

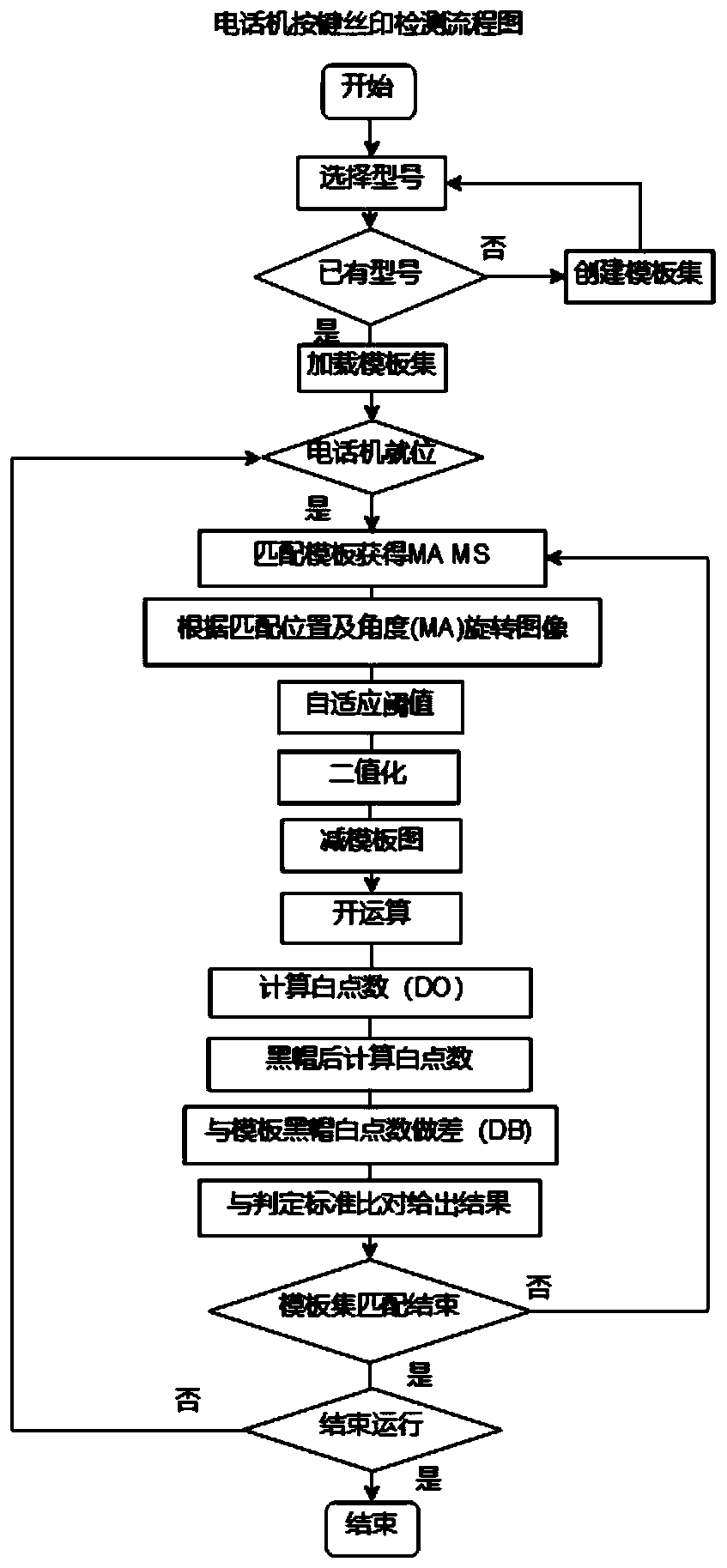

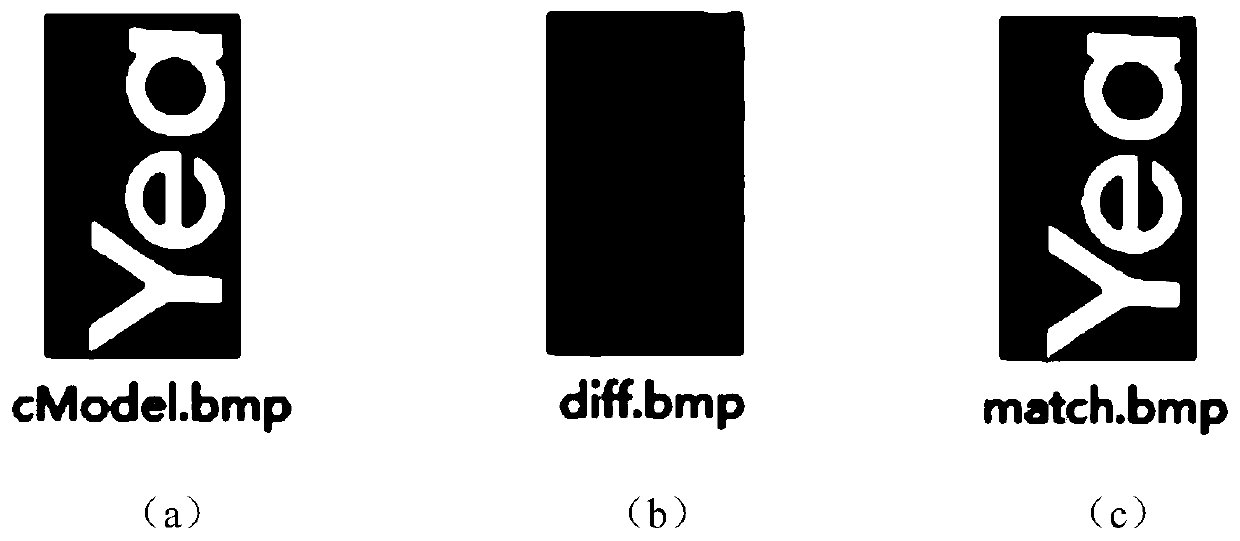

Telephone screen printing quality detection method and system

ActiveCN111028209AImprove screen printing qualityIncrease productivityImage enhancementImage analysisScreen printingContour matching

Owner:NANJING WANLIDA TECH

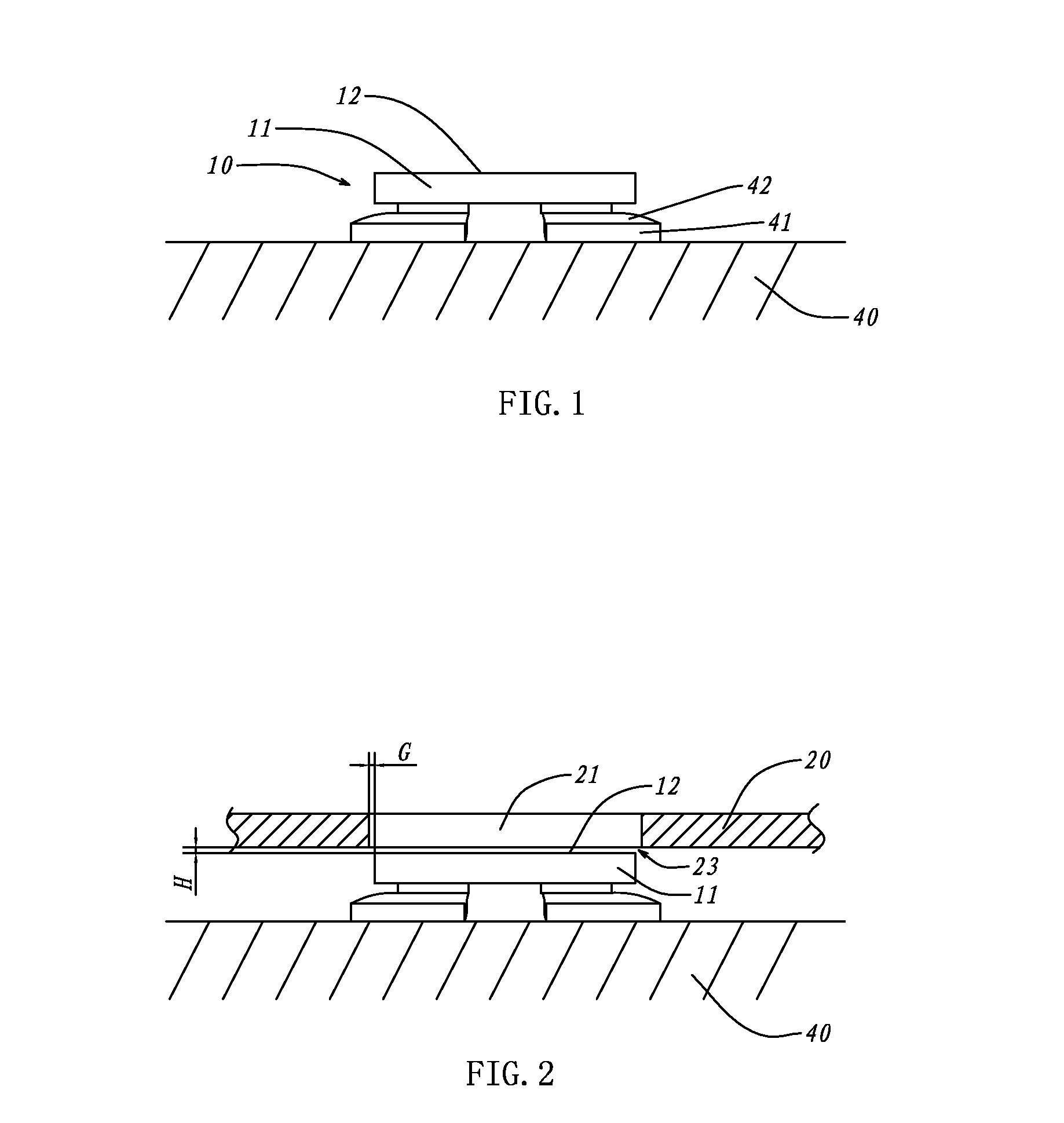

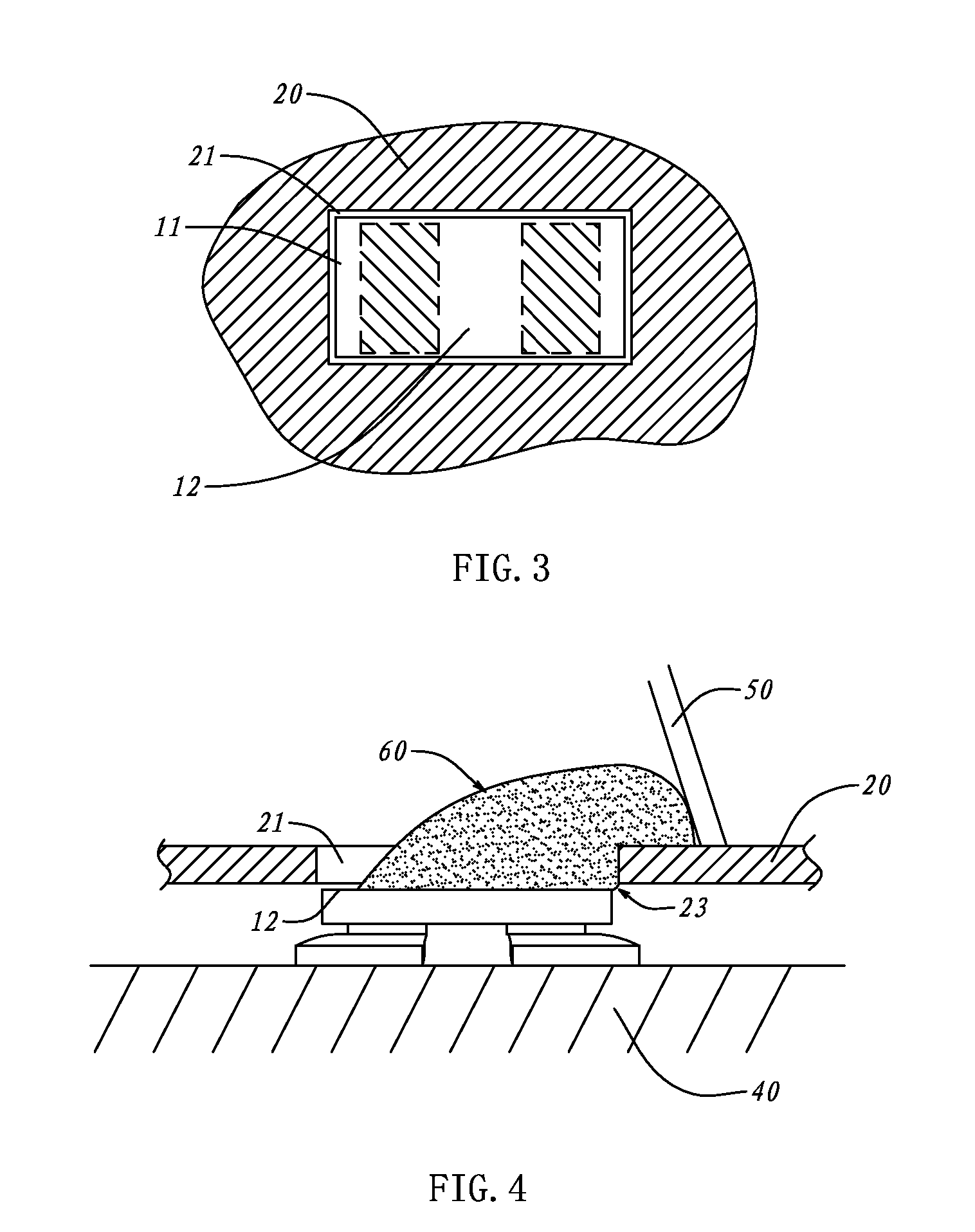

Screen printing method of LED module with phosphor

ActiveUS20150140706A1Ensure consistencyShort costSolid-state devicesPattern printingScreen printingPhosphor

Owner:XIAMEN FRIENDLY LIGHTING TECHNOLOGY CO LTD

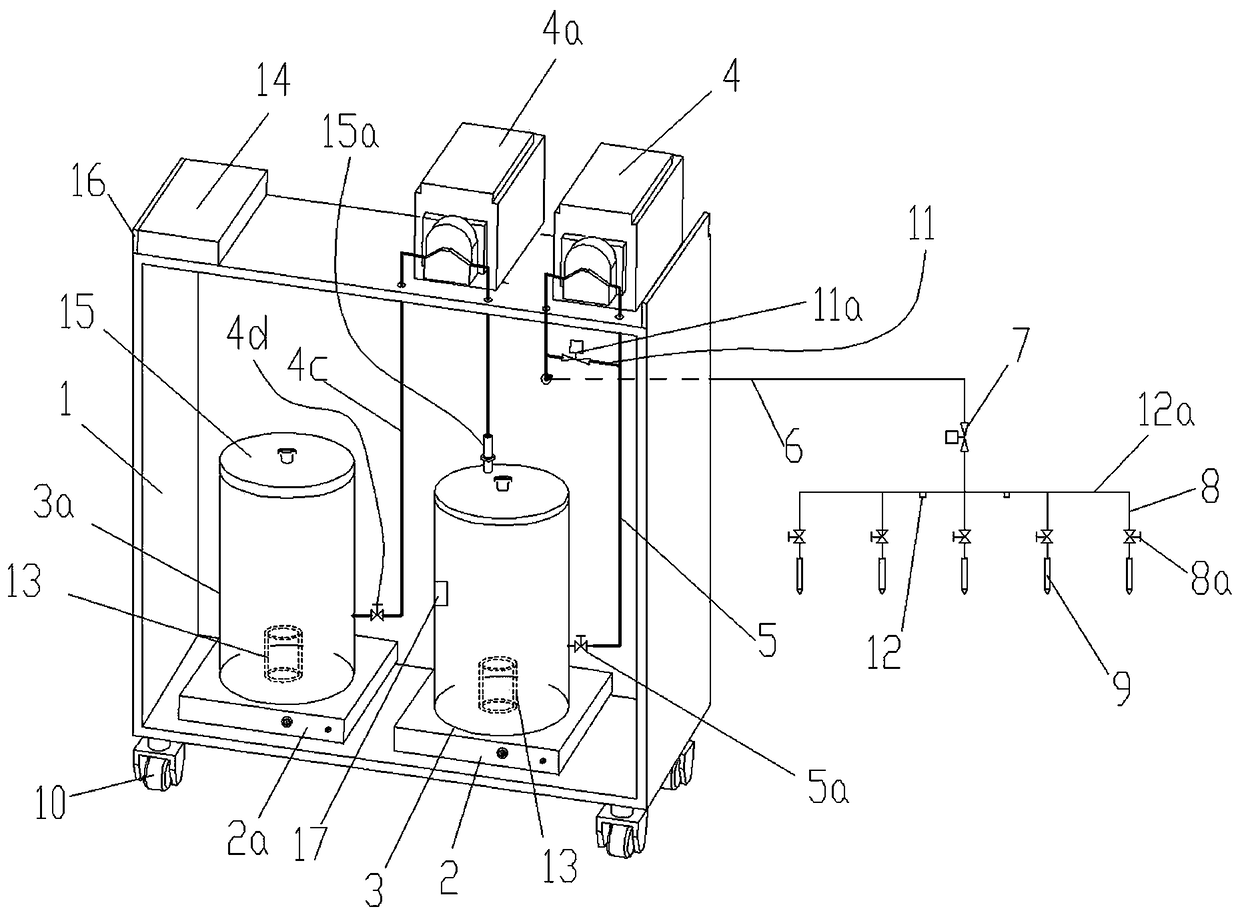

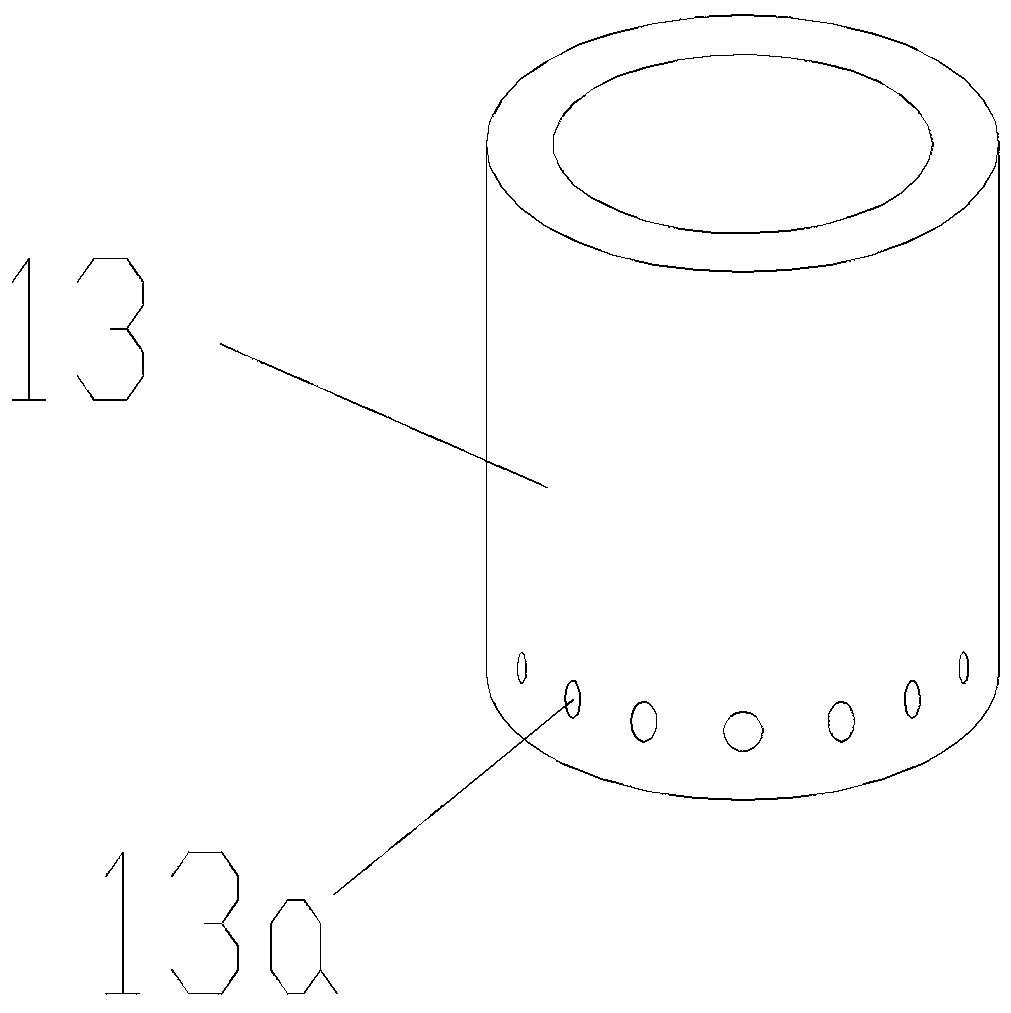

Screen printing ink automatic feeding device

PendingCN109203646AEasy to adjust supplyRealize automatic supplyScreen printersScreen printingPeristaltic pump

Owner:海控三鑫(蚌埠)新能源材料有限公司

ZrO2 ceramic surface electric conduction method

ActiveCN113004060AScreen printingGlaze

The invention provides a ZrO2 ceramic surface electric conduction method. The ZrO2 ceramic surface electric conduction method comprises the steps: (1) processing a plurality of grooves in the surface of a ZrO2 ceramic finished product; (2) ball-milling glaze powder, electrically conductive ceramic powder and gloss oil to obtain electric conductive slurry, wherein the glaze powder comprises Al2O3 and SiO2 and further comprises at least one of Na2O, K2O, CaO, MgO, B2O3 and ZnO; (3) carrying out silk-screen printing on the electric conductive slurry at the grooves of the ZrO2 ceramic finished product, and drying to obtain a zirconium oxide blank; and (4) carrying out sintering treatment on the zirconium oxide blank at the sintering temperature of 600 DEG C-1200 DEG C, and then carrying out polishing treatment to prepare the zirconium oxide ceramic with the electrically conductive surface. According to the method, the surface electrically conductive zirconium oxide ceramic is obtained at a relatively low sintering temperature and is resistant to acid and alkali corrosion; and moreover, good electrical conductivity is achieved, a metalized layer is firmly combined with a zirconia ceramic matrix, is not easy to crack and fall off, has a mirror surface effect and does not have macroscopic pores.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Partially-aluminized packaging film and manufacturing method thereof

The invention discloses a partially-aluminized packaging film and a manufacturing method thereof. The partially-aluminized packaging film structurally comprises a transparent plastic film, an aluminizing layer and a printing ink layer, wherein the plastic film is made of any one material of OPP, BOPP and PET, and the aluminizing layer is provided with at least one opening. The manufacturing method of the partially-aluminized packaging film includes the following process of coating of a water-based complex adhesive, vacuum aluminizing, washing and printing, wherein any water-based complex adhesive for food packaging can serve as the water-based complex adhesive, and any of offset printing, intaglio printing and silk-screen printing can be adopted as the printing mode. The partially-aluminized packaging film has the advantages that the manufacturing process is simple, cost is low, and no pollution is generated.

Owner:王萍

Synchronous plate registration based on silk-screen printing technology and synchronous registration system and method for plates

ActiveCN113815304AImprove adhesionServes as an initial coverScreen printersFinal product manufactureScreen printingTextile printer

The invention discloses a synchronous plate registration method based on a silk-screen printing technology. The synchronous plate registration method comprises the following steps: establishing an embossing digital model, embossing a base material by matching an upper pressing plate engraved with concave-convex patterns with a lower pressing plate below the base material, then carrying out silk-screen printing on the base plate by using a prepared silk-screen printing plate type, and printing a preset pattern on the surface of the base plate. The invention further discloses a synchronous plate registration system based on the silk-screen printing technology and the synchronous registration plate. The concave-convex patterns and the patterns are established by adopting the same digital model, and the matching degree of the concave-convex patterns and the patterns is high. A distance sensor or a scanning mode is adopted, strict cutting of a base material can be achieved, patterns can be aligned with patterns through a positioning frame, and a high-quality product is obtained. The patterns are pressed on the surface of the base material in a continuous embossing mode, the pressure maintaining time is long, the indentation depth is far higher than that of the patterns pressed by a printing roller, the patterns are clearer, the cost of the silk-screen printing mode is only 1 / 10 of that of an ink-jet printing mode, and the cost can be effectively reduced.

Owner:陈竹

N-type single-sided cell preparation method

ActiveCN107437574ALow costReduce production efficiencyFinal product manufactureSemiconductor devicesScreen printingBack surface field

Owner:浙江环艺电子科技有限公司

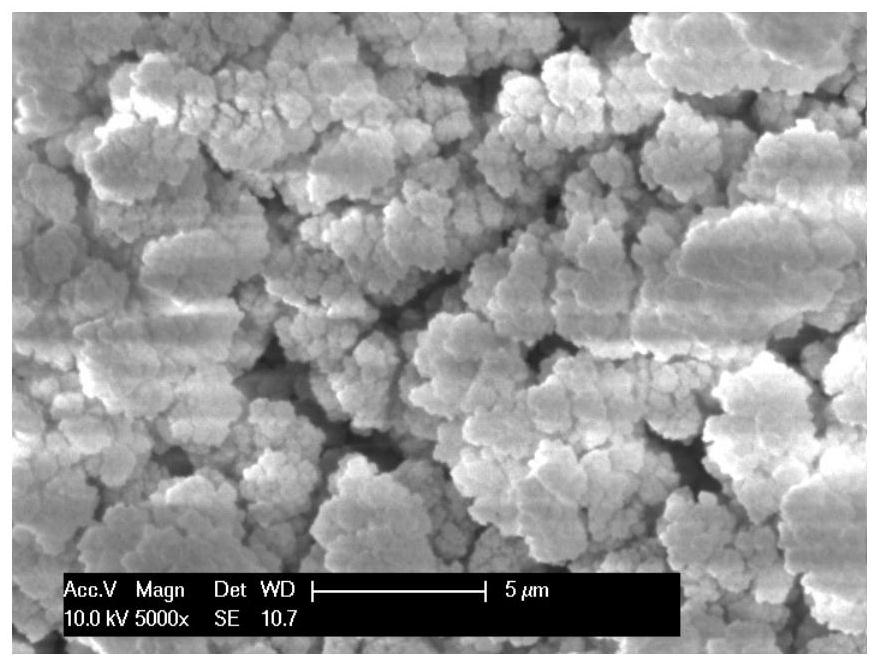

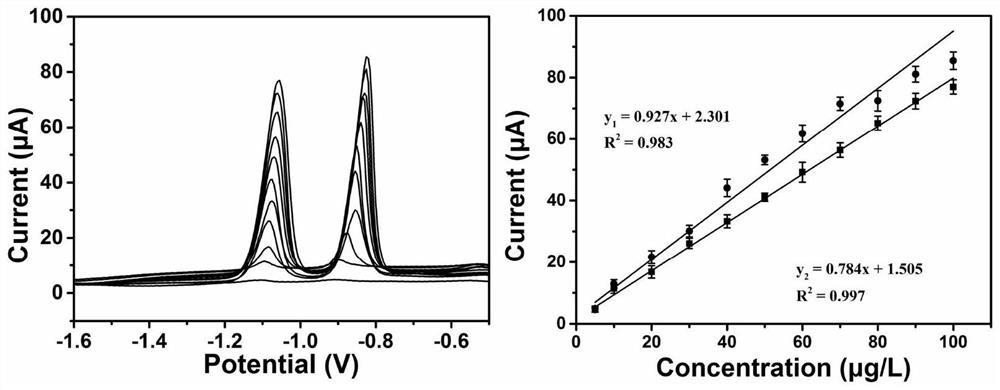

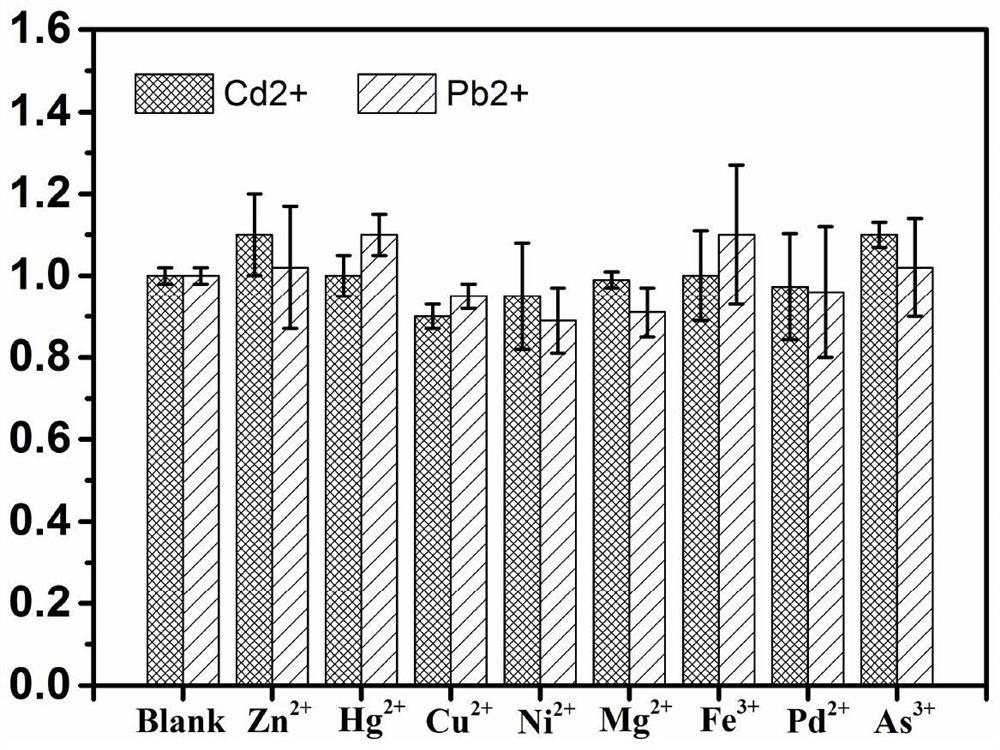

Electrochemical sensor electrode for rapidly and simultaneously detecting lead and cadmium ions as well as preparation method and application of electrochemical sensor electrode

PendingCN114216944AAchieving Specific DetectionImprove stabilityMaterial analysis by electric/magnetic meansSquare wave anodic stripping voltammetryBovine serum albumin

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap