Production method of glue attached G/G capacitive screen

A technology of glue bonding and production methods, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of long operation cycle and low unit output rate, and achieve the reduction of large equipment and shrink The effect of occupying less space and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

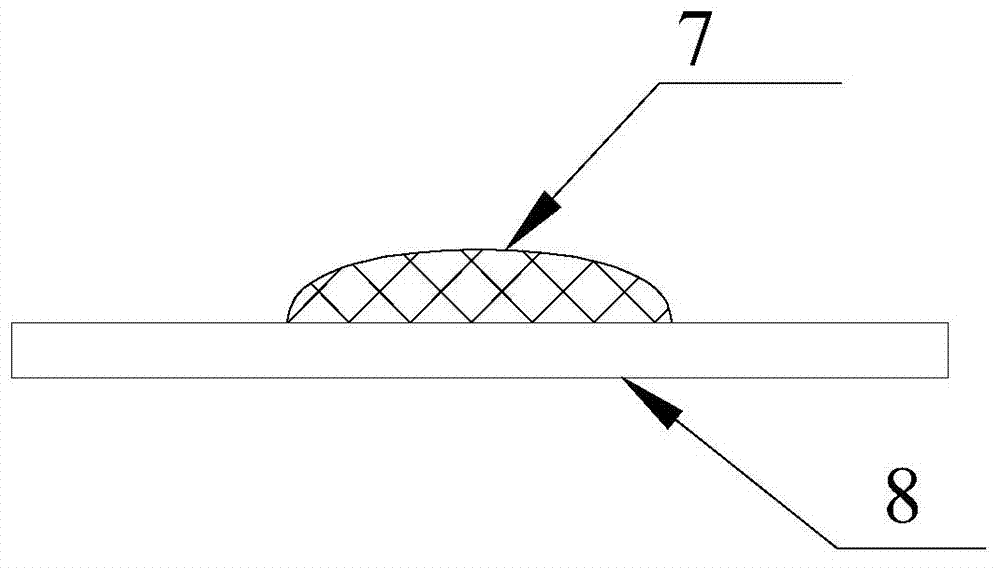

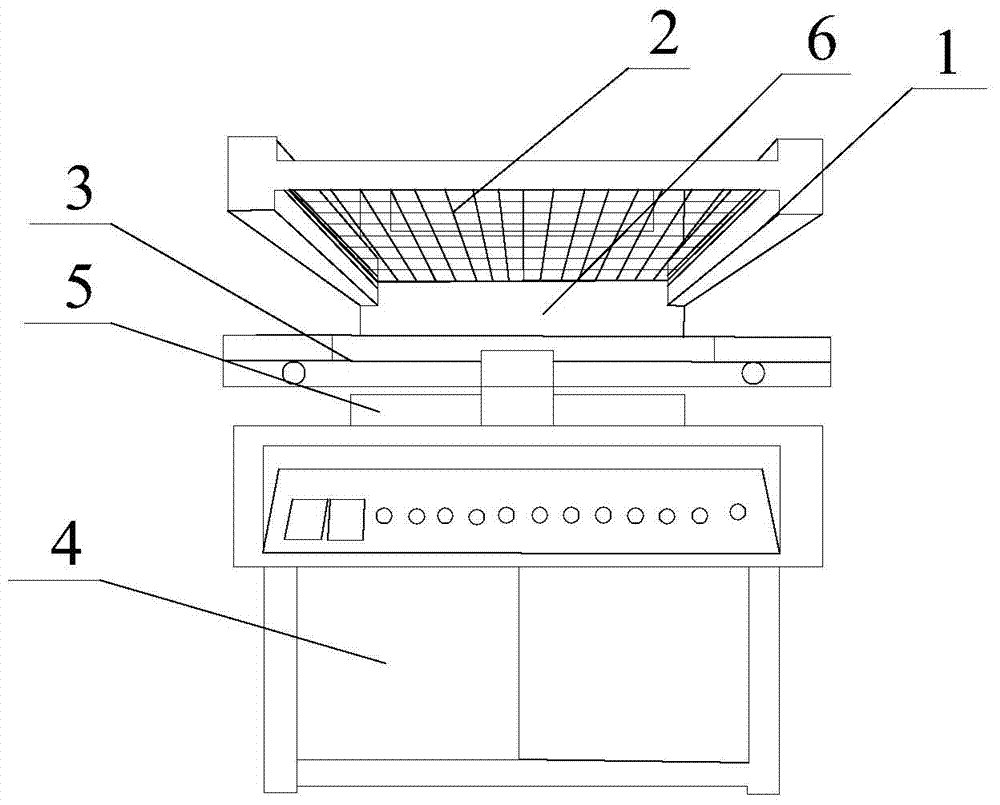

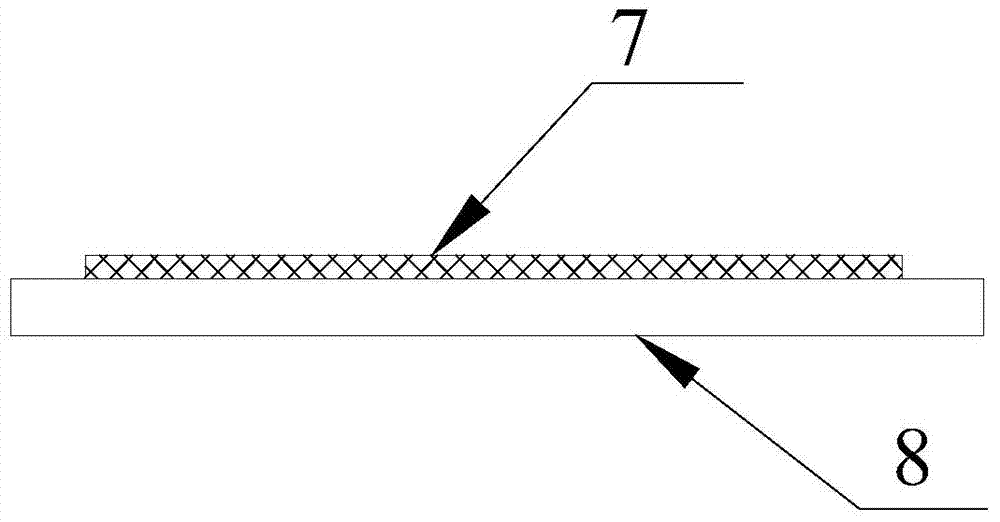

[0036] Such as Figure 2-4 In the illustrated embodiment, a production method for glue bonding of a G / G capacitive screen according to the present invention includes the following steps:

[0037] Step 1: Lift the screen support 1, install the screen printing plate 2 on the screen support 1, and adjust the angle of the scraper. The screen support 1 is made of aluminum, magnesium, steel, or aluminum-magnesium alloy kind made;

[0038] Step 2: Embedding the fitting fixture 3 in the installation groove on the platform 5, the fitting fixture 3 is a frame structure that penetrates up and down;

[0039] Step 3: Fix the glass assembly 8 on the platform 5 located below the laminating jig 3, so that the glass assembly 8 and the screen printing screen 2 are facing each other, and the glass assembly 8 is locat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap