Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Printing ink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink is a liquid or paste that contains pigments or dyes and is used to color a surface to produce an image, text, or design.Ink is used for drawing or writing with a pen, brush, or quill.Thicker inks, in paste form, are used extensively in letterpress and lithographic printing.. Ink can be a complex medium, composed of solvents, pigments, dyes, resins, lubricants, solubilizers, surfactants ...

Inkjet printing fluid

InactiveUS20120277366A1High optical densityPolyurea/polyurethane coatingsWater dispersiblePolymer science

An inkjet printing fluid composition comprising water, colorant, acrylic latex polymer, and a water dispersible polyurethane additive having an acid number greater than 50, preferably between 50 and 150, more preferably from 60 to 100, and most preferably from 60 to 90. The invention provides inkjet printing fluid compositions, such as pigment-based inkjet printing inks, which contain an acrylic latex polymer which provides increased optical density for printed images, and a water dispersible polyurethane additive that enables the latex-containing printing fluid to be recirculated for extended periods in a recirculating printing fluid printing system without significant fluid destabilization or pressure build up or filter clogging. The invention further provides a method for printing an inkjet image comprising: I) providing an inkjet printing fluid according to the invention; and II) jetting the inkjet printing fluid in the form of ink drops onto a recording element to form a printed image.

Owner:EASTMAN KODAK CO

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Ultraviolet (UV) gloss oil and preparation method thereof

Owner:上海奇想青晨新材料科技股份有限公司

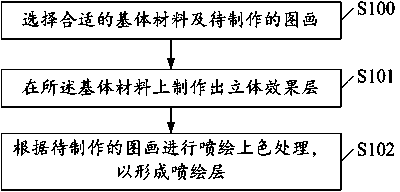

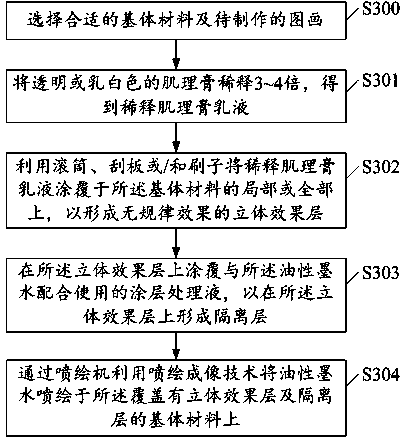

Method for manufacturing three-dimensional craft painting

ActiveCN103407319AImprove waterproof performanceGood sun protectionDecorative surface effectsSpecial ornamental structuresHigh volume manufacturingEngineering

Owner:XIAMEN HAOSHIDUO IND & TRADE CO LTD

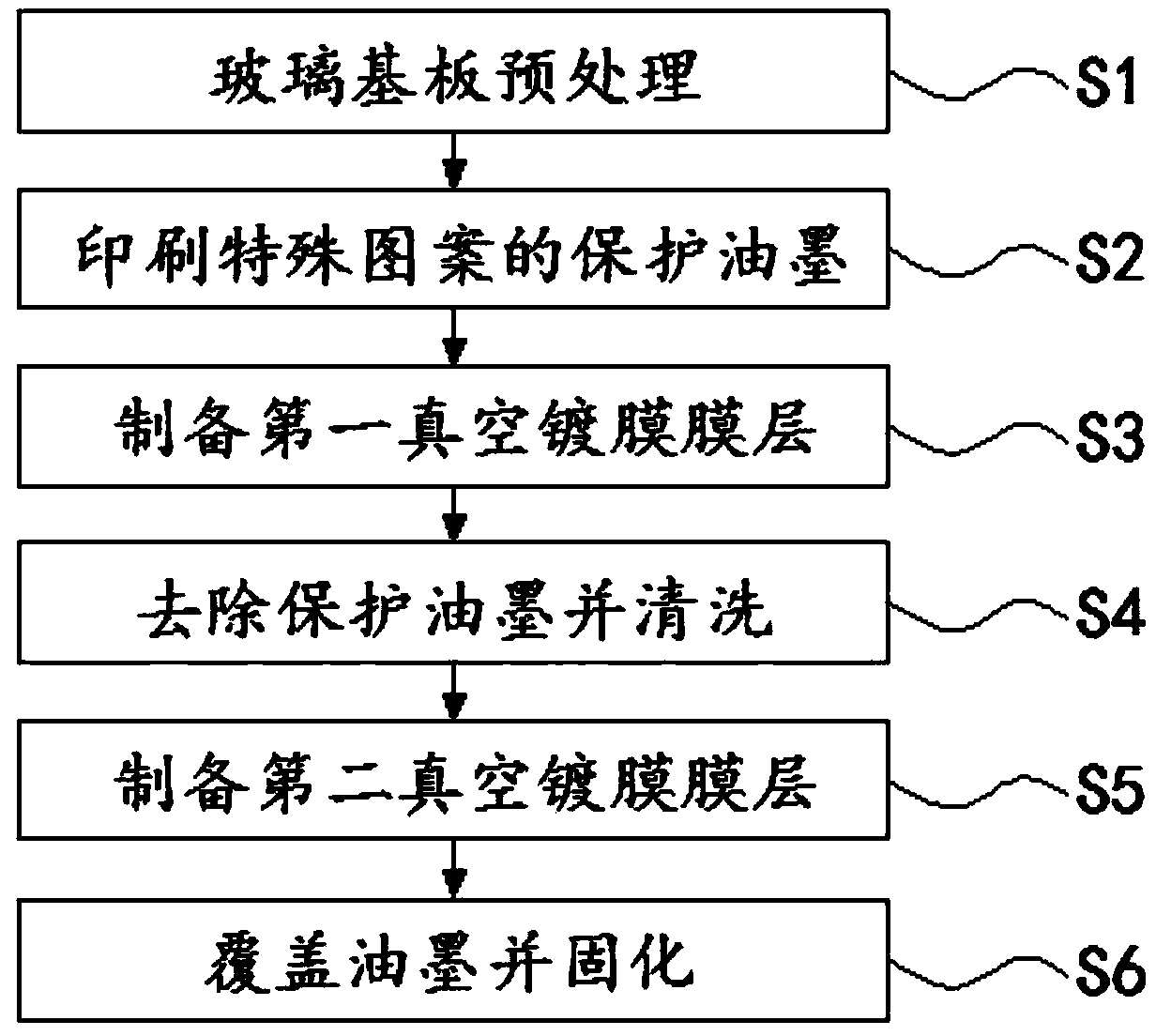

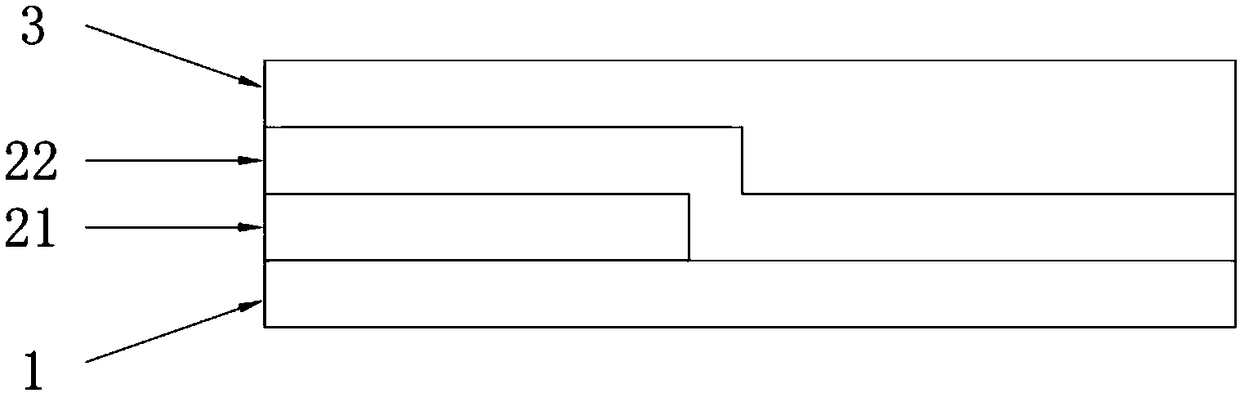

Method for preparing coated cover plate with two or more colors

Owner:FUJIAN HUIRUI TOUCH TECH

Colorful acid and alkali resistant laser printing ink and preparation method thereof

InactiveCN104403412AGood acid and alkali resistanceOvercome the disadvantage that it is easy to produce depletion when mixed with acid and alkaliInksChemistryPrinting ink

The invention discloses a colorful acid and alkali resistant laser printing ink and a preparation method thereof. The printing ink is composed of the following components in parts by weight: 0 to 30 parts of butanone, 10 to 30 parts of isopropanol, 2 to 6 parts of curing agent, 10 to 15 parts of pigment, and 10 to 30 parts of glycidyl ether epoxy resin. The glycidyl ether epoxy resin is adopted to produce the printing ink, aliphatic polyamine is further chosen as the curing agent, the acid and alkali resistant performance of the printing ink is strengthened through optimizing the formula, thus the shortage that the colorful laser printing ink is lost when being mixed with acid and alkali is overcome, moreover, the color of the laser printing product is more abundant, and the patterns are more clear.

Owner:深圳市天意通防伪包装材料有限公司

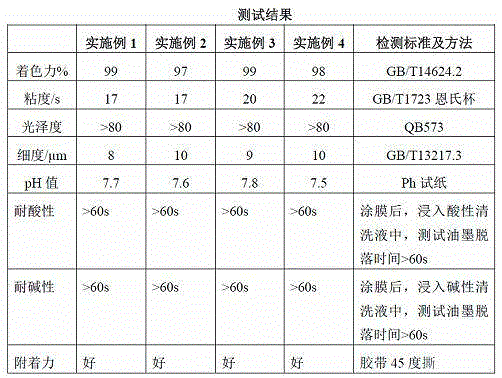

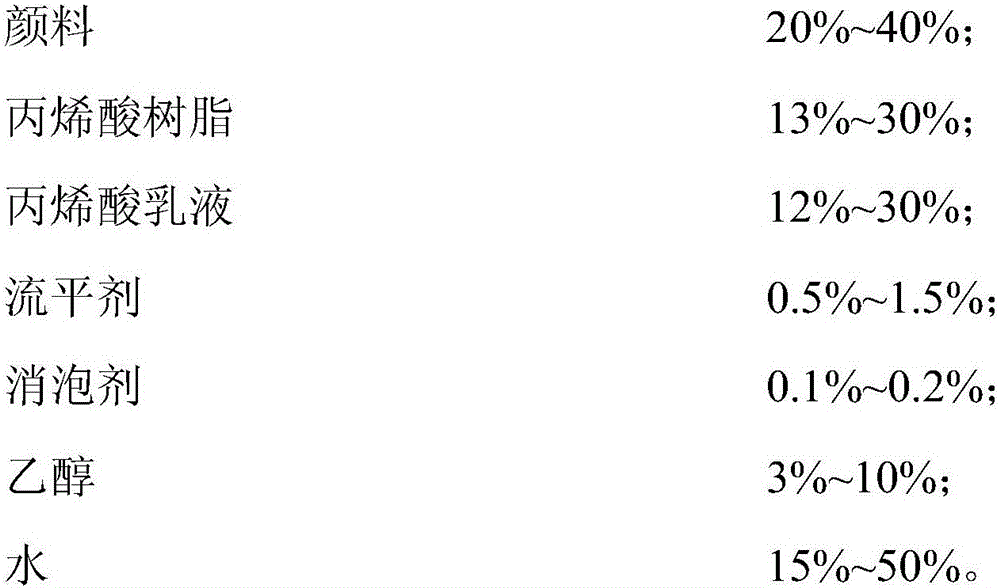

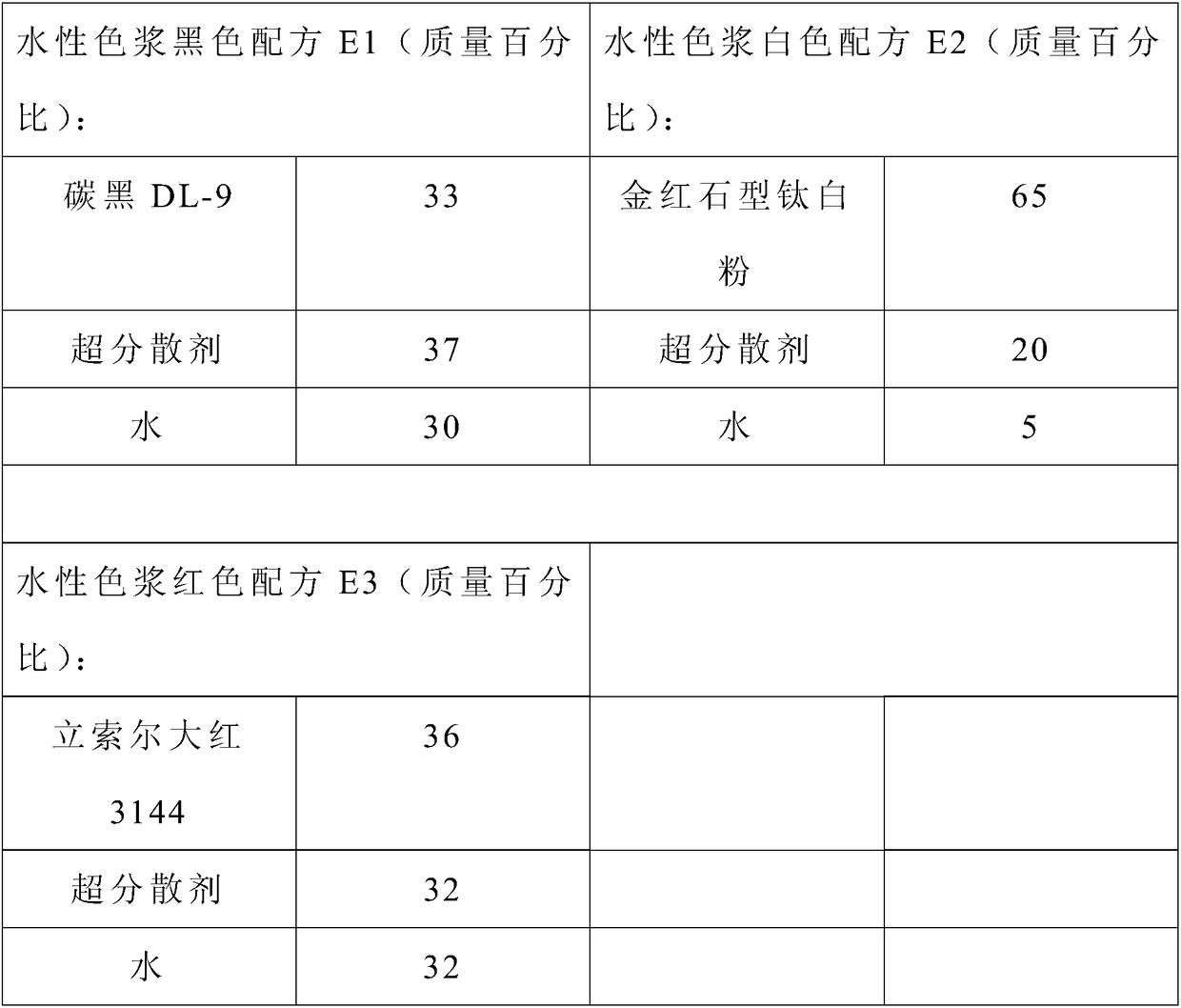

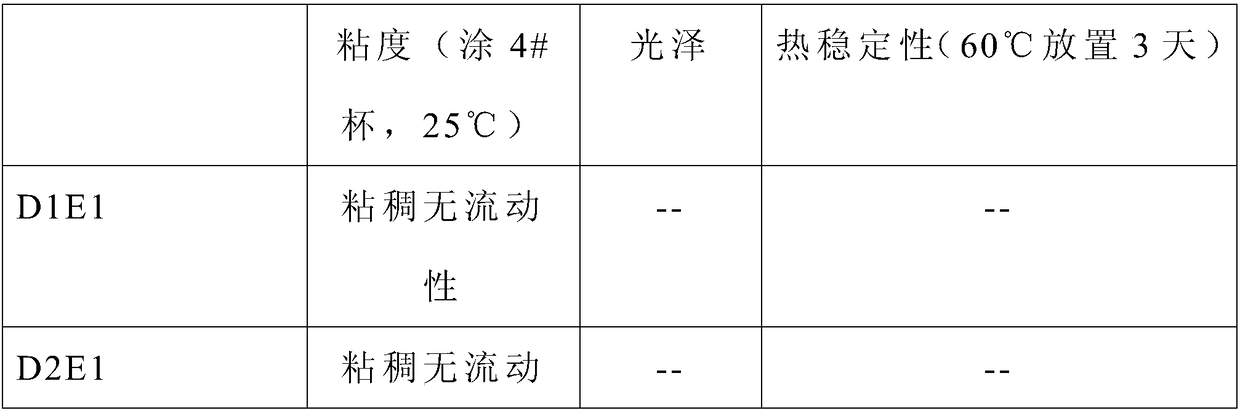

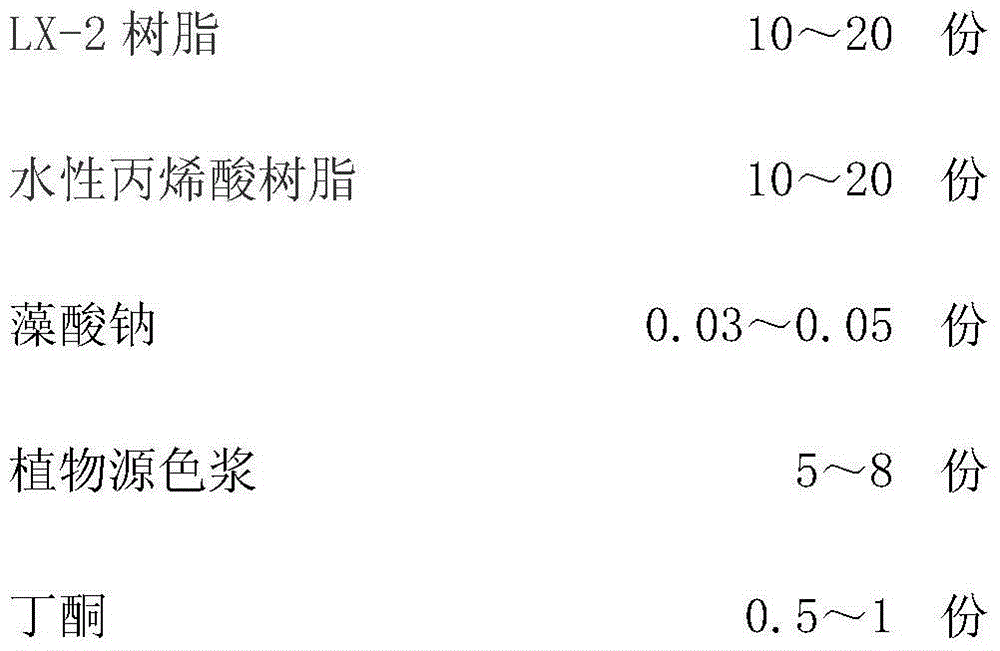

Waterborne printing ink for food package printing and preparation method of printing ink

Owner:JINAN UNIVERSITY

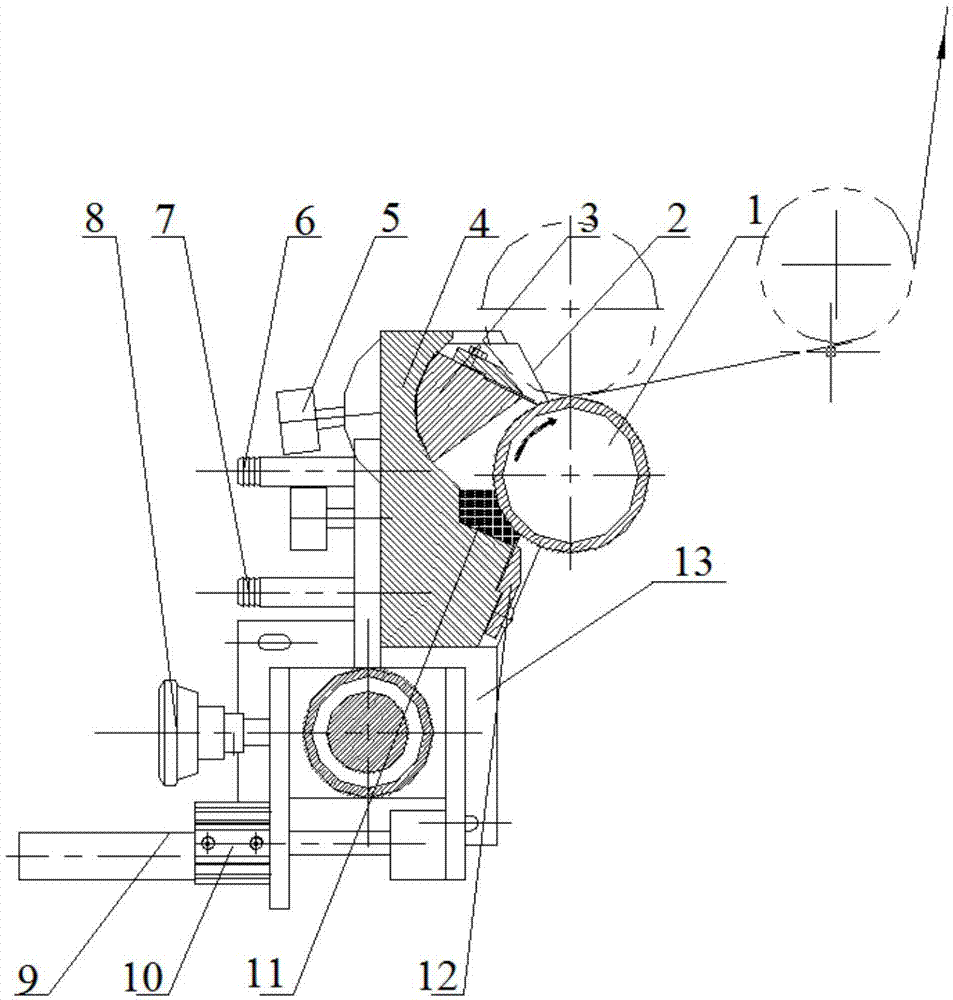

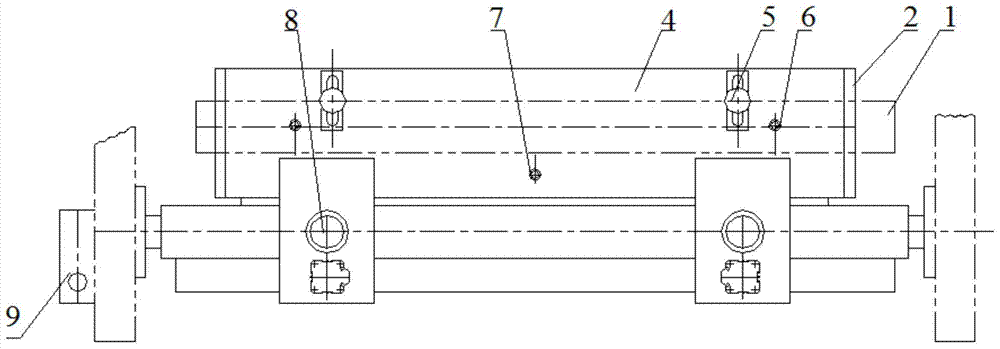

Closed scraper device used for gravure printing machine

InactiveCN104512092AInk storage space is smallIncrease viscosityRotary intaglio printing pressSolvent evaporationEngineering

Owner:SHAANXI BEIREN PRINTING MACHINERY

Novel ink

Owner:陈雁

Anti-counterfeiting weak solvent ink as well as preparation method and safety product thereof

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Partially-aluminized packaging film and manufacturing method thereof

The invention discloses a partially-aluminized packaging film and a manufacturing method thereof. The partially-aluminized packaging film structurally comprises a transparent plastic film, an aluminizing layer and a printing ink layer, wherein the plastic film is made of any one material of OPP, BOPP and PET, and the aluminizing layer is provided with at least one opening. The manufacturing method of the partially-aluminized packaging film includes the following process of coating of a water-based complex adhesive, vacuum aluminizing, washing and printing, wherein any water-based complex adhesive for food packaging can serve as the water-based complex adhesive, and any of offset printing, intaglio printing and silk-screen printing can be adopted as the printing mode. The partially-aluminized packaging film has the advantages that the manufacturing process is simple, cost is low, and no pollution is generated.

Owner:王萍

Environment-protective printing ink for printing packing box with patterns or characters and preparation method thereof

Owner:TIANJIN JINMA PACKAGING MATERIAL CO LTD

Rotary lifting type printing ink conveying plate tank device

InactiveCN111070886AEasy to transportRealize up and down functionLifting devicesPrinting press partsStructural engineeringPrinting ink

The invention discloses a rotary lifting type printing ink conveying plate tank device which comprises a bottom plate. A rotary column is arranged above the bottom plate, a guide rod is arranged on the bottom plate, the guide rod is an external threaded rod, a sleeve is arranged at the bottom of the rotary column, the sleeve is an internal threaded rod, the sleeve is in threaded matching connection with the guide rod, a support column is arranged on the rotary column, the sleeve, the rotary column and the support column are arranged in a cross shape, and a storage plate is arranged on the support column. The storage plate is horizontally arranged, the storage plate is provided with a plurality of printing ink storage tanks, the printing ink storage tanks are in a cylindrical shape, the plurality of printing ink storage tanks are arranged on the storage plate side by side, the two ends of the bottom plate are provided with a third tensioning wheel and a fourth tensioning wheel correspondingly, the two ends of the storage plate are provided with a first tensioning wheel and a second tensioning wheel correspondingly, and the first tensioning wheel, the second tensioning wheel, the third tensioning wheel and the fourth tensioning wheel are connected through tensioning ropes. The printing ink storage tank is used for storing printing ink, so that an up-down lifting function can be realized, and the printing ink can be conveyed more conveniently.

Owner:HUBEI AOSLONG TECH CO LTD

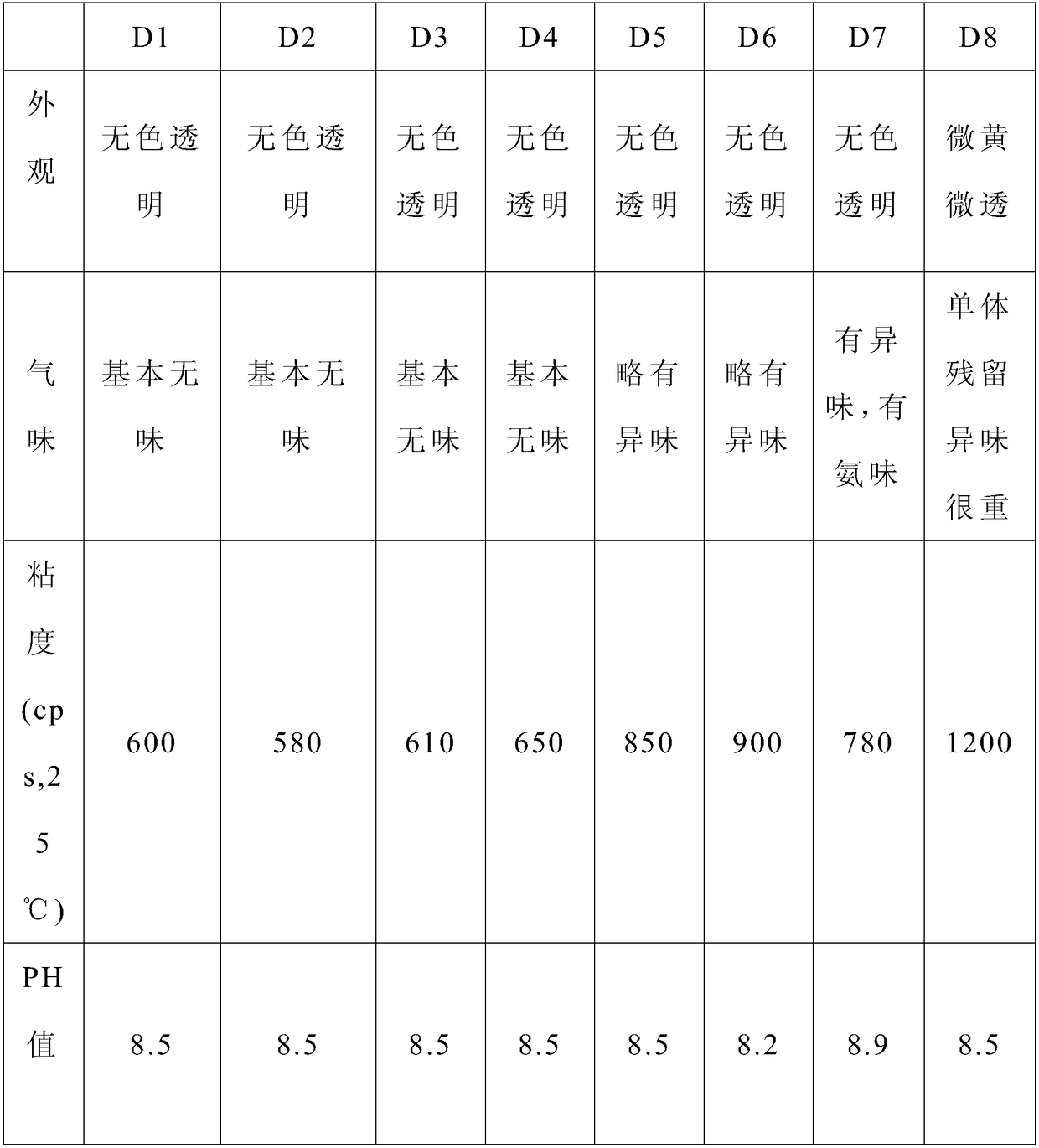

Method for improving stability of organic silicon emulsion

The invention relates to a method for improving the stability of an organic silicon emulsion, raw materials for preparing the emulsion comprise polysiloxane, polyether modified polysiloxane, a cross-linking agent, a basic catalyst, silicon dioxide, an emulsifier, a thickener, water and a preservative, and the emulsion is obtained by polymerization, cross-linking, grinding and dispersion. Compared with an emulsion prepared by a common method, the organic silicon emulsion has more excellent high-temperature resistance, low-temperature resistance, dilution resistance and shear resistance, and can be used in the fields of buildings, electronics and electrics, textiles, automobiles, machinery, leather, papermaking, metal processing, printing ink, coatings and the like.

Owner:NANJING RUISI CHEM TECH CO LTD

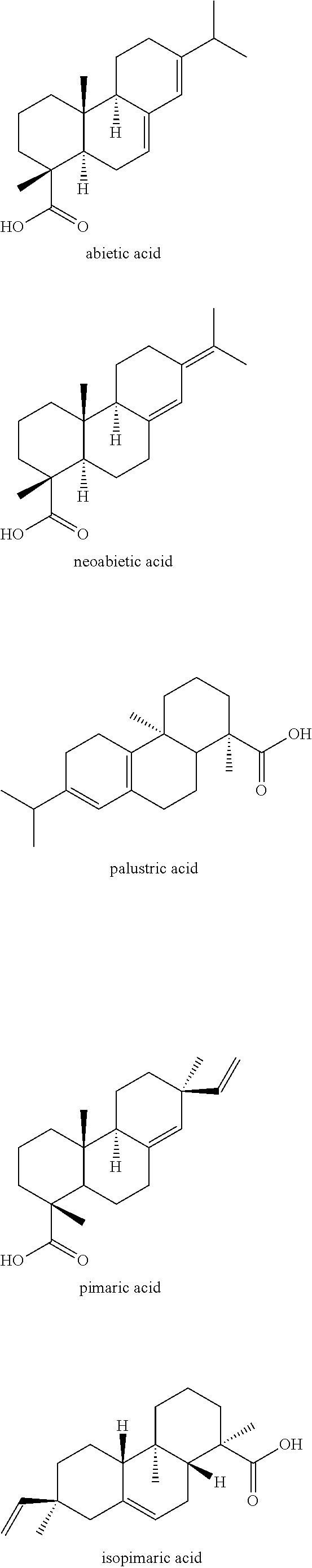

High bio-renewable content printing inks

Owner:SUN CHEM CORP

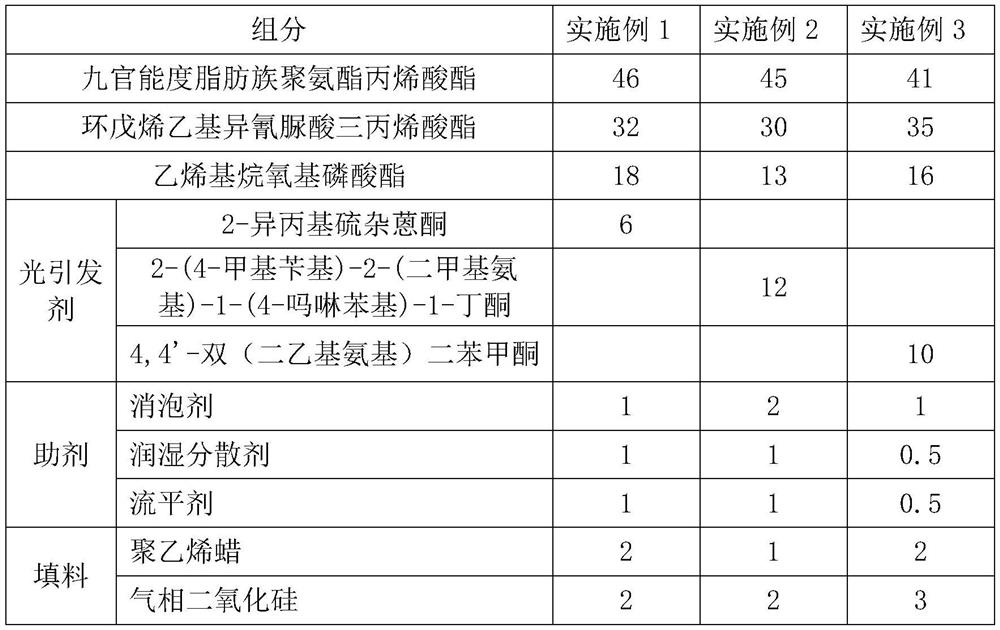

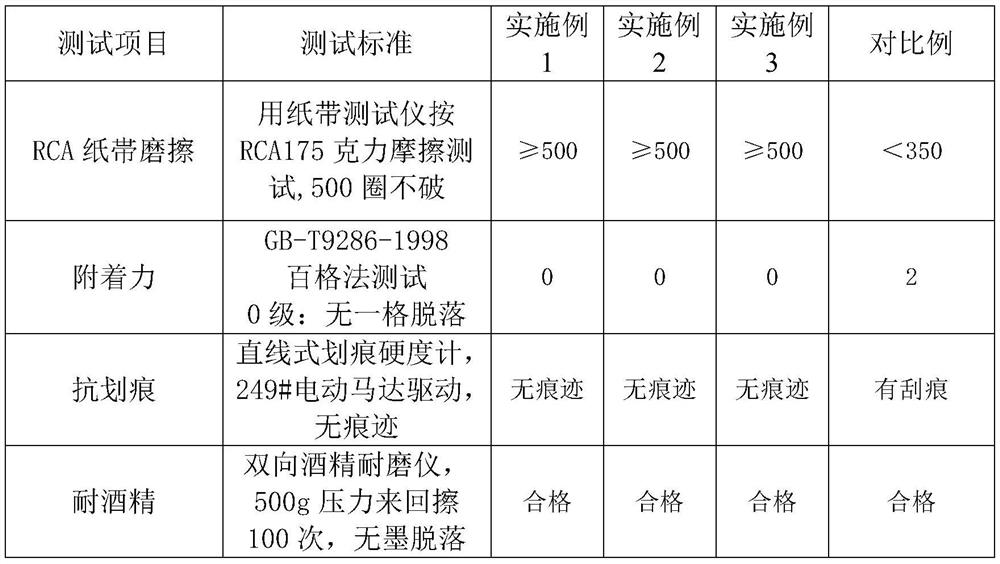

High-adhesion wear-resistant UV-LED ink and preparation method thereof

Owner:中山市中益油墨涂料有限公司

Antistatic foaming tipping paper printing ink

Owner:江苏卫星新材料股份有限公司

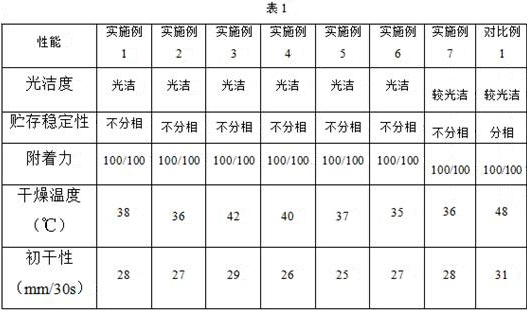

Seamless multicolor printing process and quick-drying printing ink formula employing same

PendingCN113002206AIncrease printing speedImprove qualityInksOther printing apparatusColor printingPrinting ink

Owner:DONGGUAN MEMTECH ELECTRONICS MEMTECH ELECTRONICS PRO

Efficient and accurate daily porcelain 3D soft silica gel transfer printing ink and application thereof

The invention provides efficient and accurate daily porcelain 3D soft silica gel transfer printing ink and application thereof. The printing ink is prepared from 100 parts of stamp-pad ink and 60-120 parts of ceramic toner, the stamp-pad ink is prepared from the following components: 80 to 120 parts of sodium polyacrylate-aluminum sol composite liquid, 10 to 15 parts of thermocuring phenolic resin, 3 to 5 parts of guar gum, 5 to 10 parts of tripolyglycerol, 3 to 6 parts of Span 60 and 1.5 to 3 parts of castor oil. The printing ink has balanced plate-sticking, glue-sticking and ceramic-sticking performance and plate-separating and glue-separating performance, the transfer printing speed is high, the precision is high, the adaptability to the performance of domestic porcelain glaze is good, and the transfer printing effect is basically not affected by environment temperature and humidity fluctuation; and the printed and fired ornamentation is accurate in color, fine in line and clear in edge.

Owner:ZIBO CREATE NEW MATERIAL TECH CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap