High-adhesion wear-resistant UV-LED ink and preparation method thereof

A UV-LED, high-adhesion technology, applied in ink, household utensils, applications, etc., can solve the problems of UV-LED ink wear resistance and poor adhesion, achieve low cost, improve service life, and good friction resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of high adhesion wear-resistant UV-LED ink, comprising the following steps:

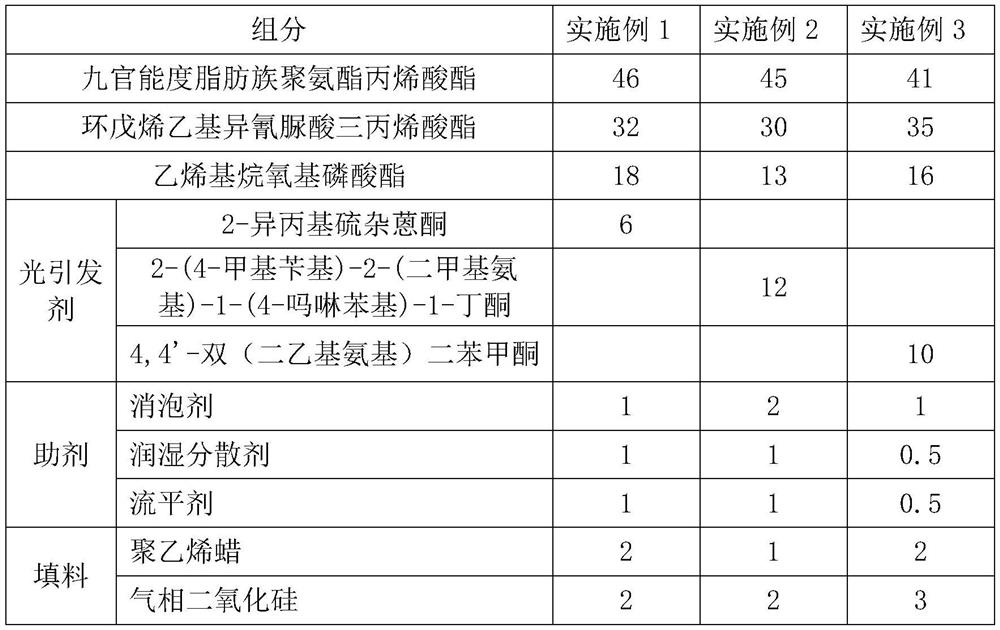

[0024] S1, prepare each component by weight part in Table 1;

[0025] S2. Add high-functionality urethane acrylate, adhesion promoter, cyclopentene ethyl isocyanurate triacrylate, and photoinitiator into the reaction kettle in sequence for mixing and stirring. The stirring speed is 800r / min, and the stirring time is 15 minutes. ;

[0026] S3, then add fillers and additives for mixing and stirring, the stirring speed is 800r / min, and the stirring time is 30 minutes;

[0027] S4. Carry out sufficient grinding on a three-roll machine until the ink fineness is below 5 microns.

Embodiment 2

[0029] S1, prepare each component by weight part in Table 1;

[0030] S2. Add high-functionality urethane acrylate, adhesion promoter, cyclopentene ethyl isocyanurate triacrylate, and photoinitiator into the reaction kettle in sequence for mixing and stirring. The stirring speed is 1000r / min, and the stirring time is 10 minutes. ;

[0031] S3, then add fillers and additives for mixing and stirring, the stirring speed is 1000r / min, and the stirring time is 15 minutes;

[0032] S4. Carry out sufficient grinding on a three-roll machine until the ink fineness is below 5 microns.

Embodiment 3

[0034] S1, prepare each component by weight part in Table 1;

[0035] S2. Add high-functionality urethane acrylate, adhesion promoter, cyclopentene ethyl isocyanurate triacrylate, and photoinitiator into the reaction kettle in sequence for mixing and stirring, the stirring speed is 1200r / min, and the stirring time is 20 minutes ;

[0036] S3, then add fillers and additives for mixing and stirring, the stirring speed is 1200r / min, and the stirring time is 25 minutes;

[0037] S4. Carry out sufficient grinding on a three-roll machine until the ink fineness is below 5 microns.

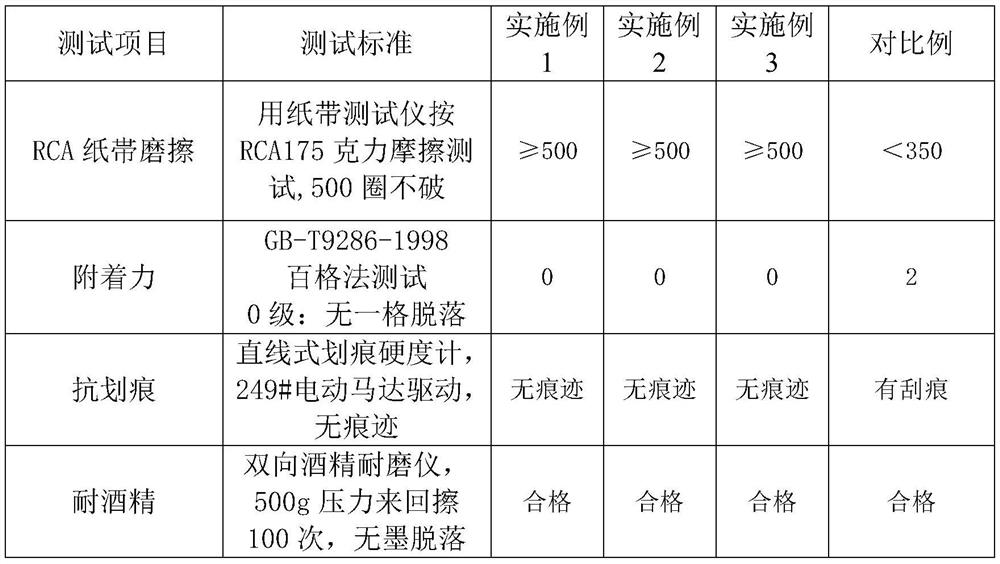

[0038] Table 1: The weight ratio of the high adhesion and wear-resistant UV-LED inks of Examples 1-3

[0039]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap