Seamless multicolor printing process and quick-drying printing ink formula employing same

A multi-color printing, seamless technology, applied in printing, ink, printing devices, etc., can solve the problems of slow ink release, poor quick-drying of printing ink, oxygen resistance and aging resistance, mildew resistance and poor chemical stability, etc. Achieve the effects of avoiding waste of time and materials, good oxygen resistance and aging resistance, and simplifying operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

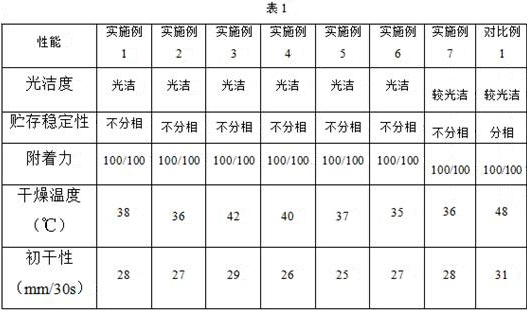

Examples

Embodiment 1

[0053] A quick-drying ink formula, by weight percentage, comprising: cyclic dimethyl polysiloxane 80%, inhibitor 3%, kerosene 2%, toner 10%, resin 30%, solvent 35%, linking material 15%, titanium dioxide powder 2%, quick-drying agent 0.1%, organohydrogen polysiloxane 1%.

[0054] Preferably, the inhibitor is 1-ethynyl-1-cyclohexanol. The resin is polyacrylate. The solvent is composed of ethanol, isopropanol, ethyl acetate, ether, dichloromethane, acetone. The linking material is composed of unsaturated fatty acid ester, asphalt oil, epoxy resin and polymerized polyiron-silicon flocculant. The quick-drying agent is cobalt type, lead type, manganese type.

Embodiment 2

[0056] A quick-drying ink formula, by weight percentage, comprising: cyclic dimethyl polysiloxane 90%, inhibitor 5%, kerosene 4%, toner 20%, resin 30%, solvent 50%, linking material 30%, titanium dioxide powder 4%, quick-drying agent 0.5%, organohydrogen polysiloxane 5%.

[0057] Preferably, the inhibitor is, methyl butynol and. The resin is phenolic resin. The solvent is composed of ethanol, isopropanol, ethyl acetate, ether, dichloromethane, acetone. The linking material is composed of unsaturated fatty acid ester, asphalt oil, epoxy resin and polymerized polyiron-silicon flocculant. The quick-drying agent is cobalt type, lead type, manganese type, iron type.

Embodiment 3

[0059] A quick-drying ink formula, by weight percentage, comprising: cyclic dimethyl polysiloxane 81%, inhibitor 4%, kerosene 3%, toner 12%, resin 30%, solvent 37%, linking material 18%, titanium dioxide powder 3%, quick-drying agent 0.2%, organohydrogen polysiloxane 2%.

[0060] Preferably, the inhibitor is 3,5-dimethyl-1-hexynyl-3-ol. The resin is polyamide. The solvent is composed of ethanol, isopropanol, ethyl acetate, ether, dichloromethane, acetone. The linking material is composed of unsaturated fatty acid ester, asphalt oil, epoxy resin and polymerized polyiron-silicon flocculant. The quick-drying agent is zirconium type, zinc type, calcium type quick-drying agent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap