Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Inkjet printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper, plastic, or other substrates.

Water-based ink for ink-jet recording

InactiveUS6758559B1Improve light resistanceImprove water resistanceMeasurement apparatus componentsDuplicating/marking methodsCarbon blackInkjet printing

Owner:KAO CORP

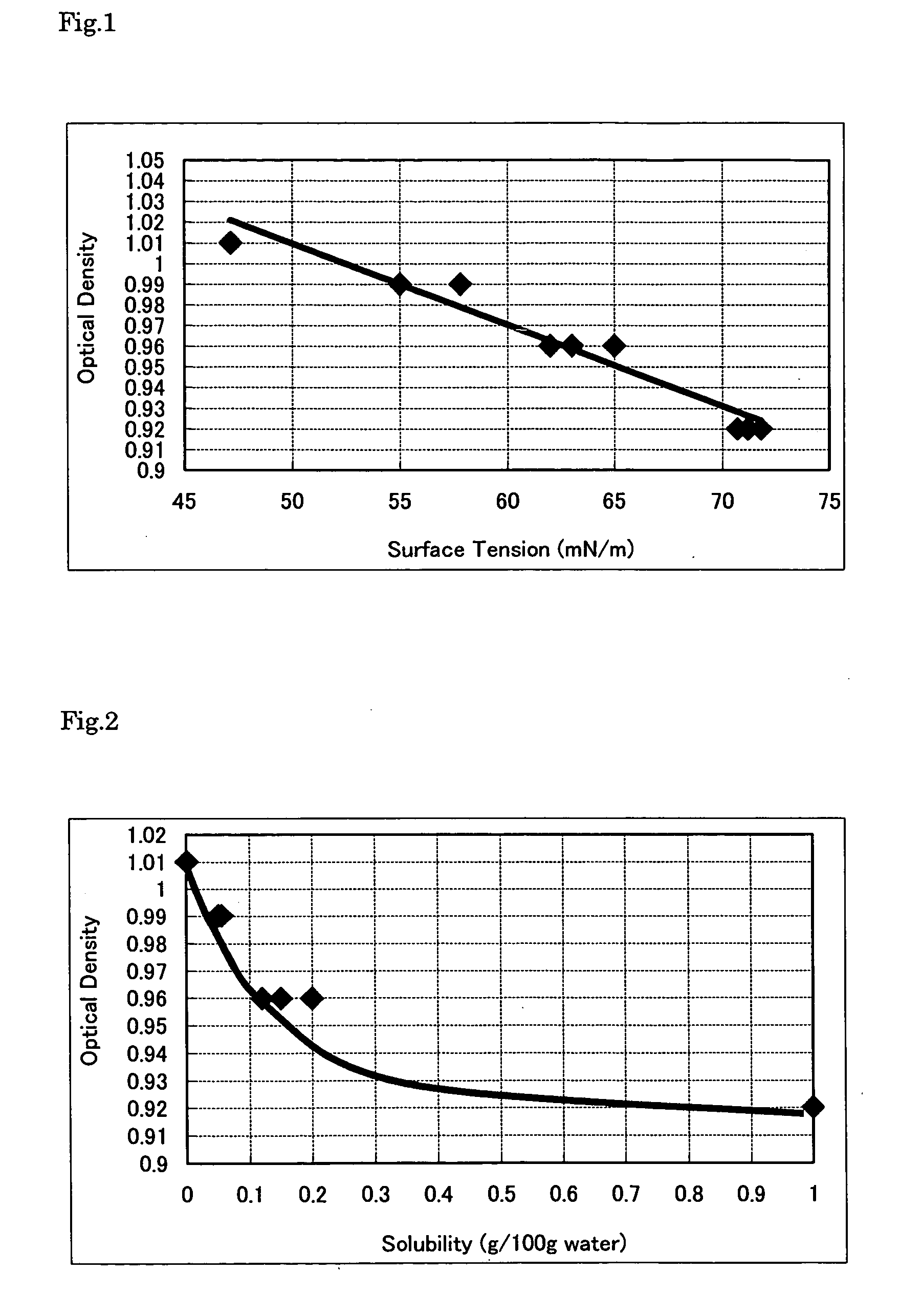

Inkjet printing fluid

InactiveUS20120277366A1High optical densityPolyurea/polyurethane coatingsWater dispersiblePolymer science

An inkjet printing fluid composition comprising water, colorant, acrylic latex polymer, and a water dispersible polyurethane additive having an acid number greater than 50, preferably between 50 and 150, more preferably from 60 to 100, and most preferably from 60 to 90. The invention provides inkjet printing fluid compositions, such as pigment-based inkjet printing inks, which contain an acrylic latex polymer which provides increased optical density for printed images, and a water dispersible polyurethane additive that enables the latex-containing printing fluid to be recirculated for extended periods in a recirculating printing fluid printing system without significant fluid destabilization or pressure build up or filter clogging. The invention further provides a method for printing an inkjet image comprising: I) providing an inkjet printing fluid according to the invention; and II) jetting the inkjet printing fluid in the form of ink drops onto a recording element to form a printed image.

Owner:EASTMAN KODAK CO

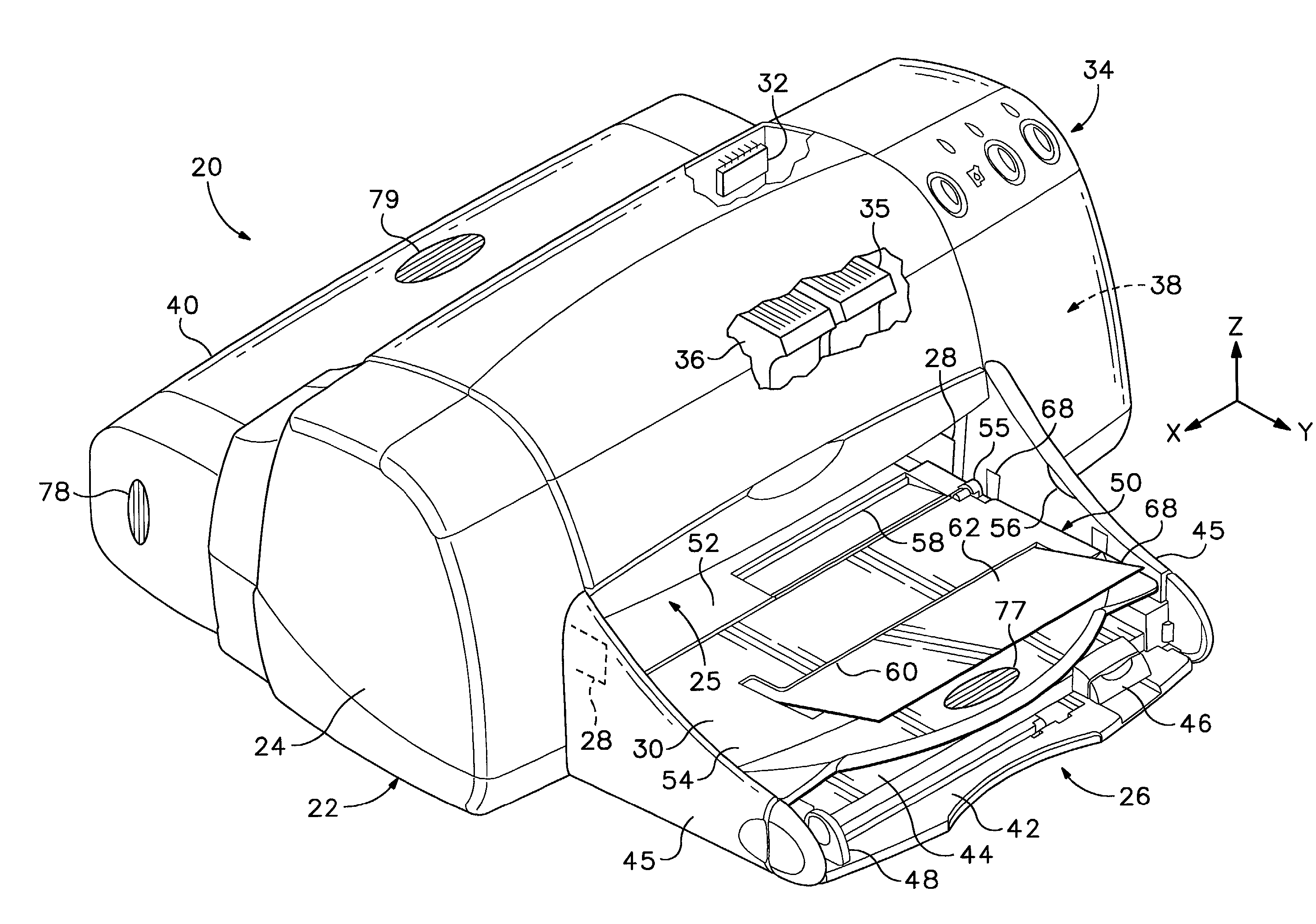

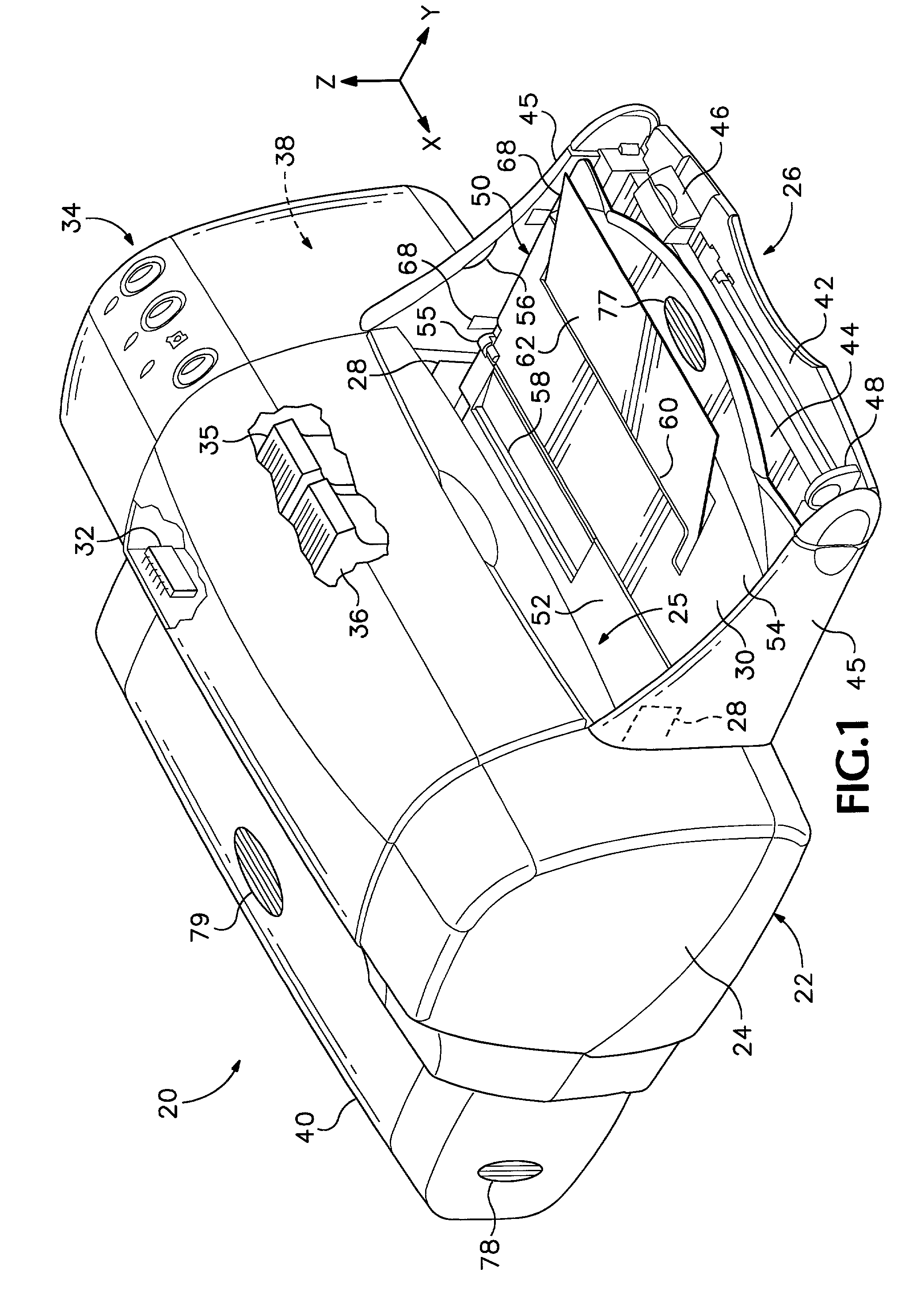

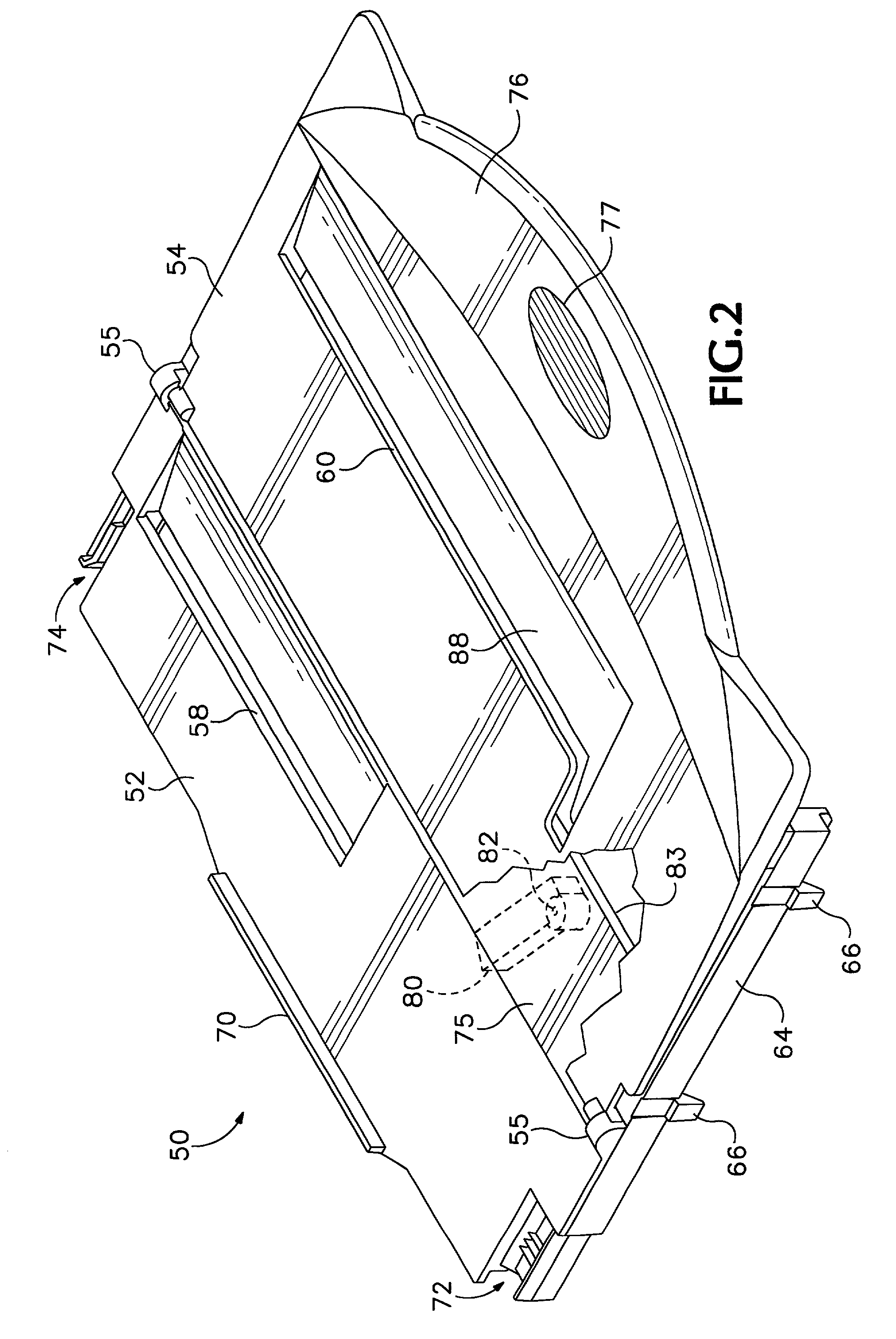

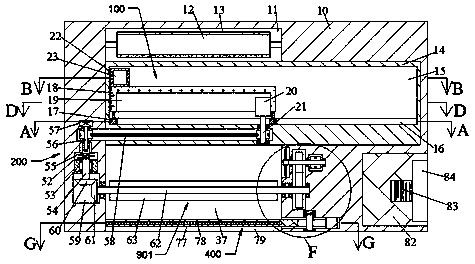

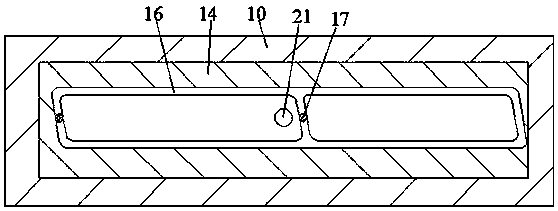

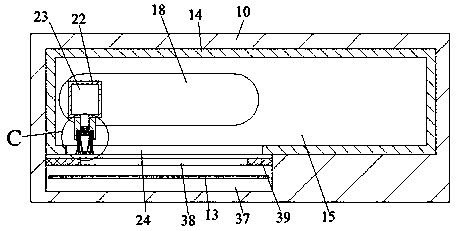

Greeting card feeder module for inkjet printing

InactiveUS20020127043A1Easy to useClear imagingPrinting mechanismsRegistering devicesEngineeringInkjet printing

Owner:HEWLETT PACKARD DEV CO LP

Method of manufacturing display panel

InactiveUS20080299315A1Reducing projection and depressionSimple designDuplicating/marking methodsIndication apparatusColor printingEngineering

In a method of manufacturing a display panel that includes a base and a printed layer printed on the base by inkjet printing, a color UV curable ink is deposited on a predetermined portion of the base for forming a color printed portion of the printed layer, and a transparent UV curable ink is deposited in at least one of a first depression provided by the color printed portion on a surface of the base and a second depression formed on a surface of the color printed portion for forming a transparent printed portion.

Owner:DENSO CORP

Cellulosic fiber fabric ink jet transfer printing method

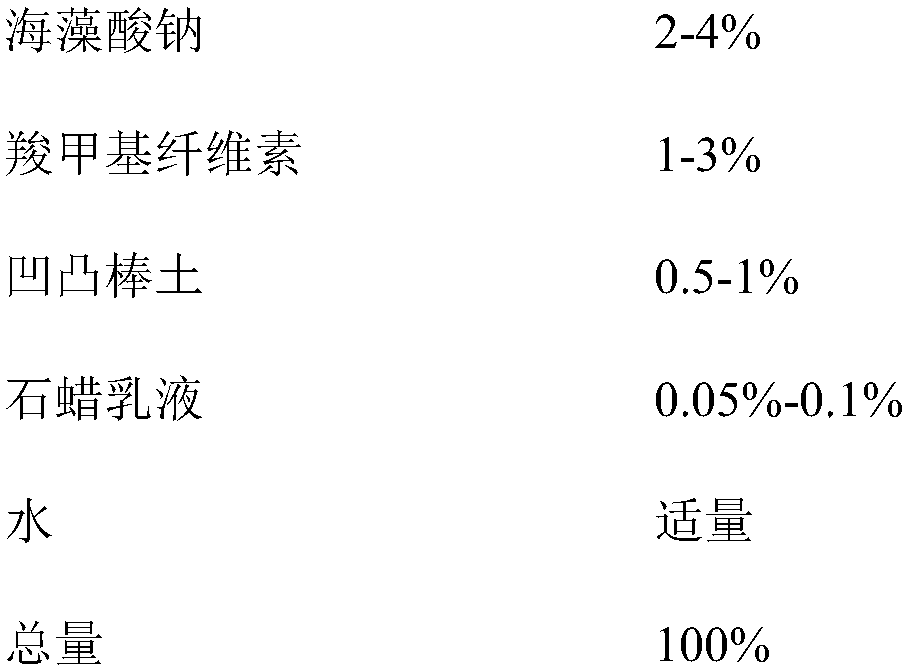

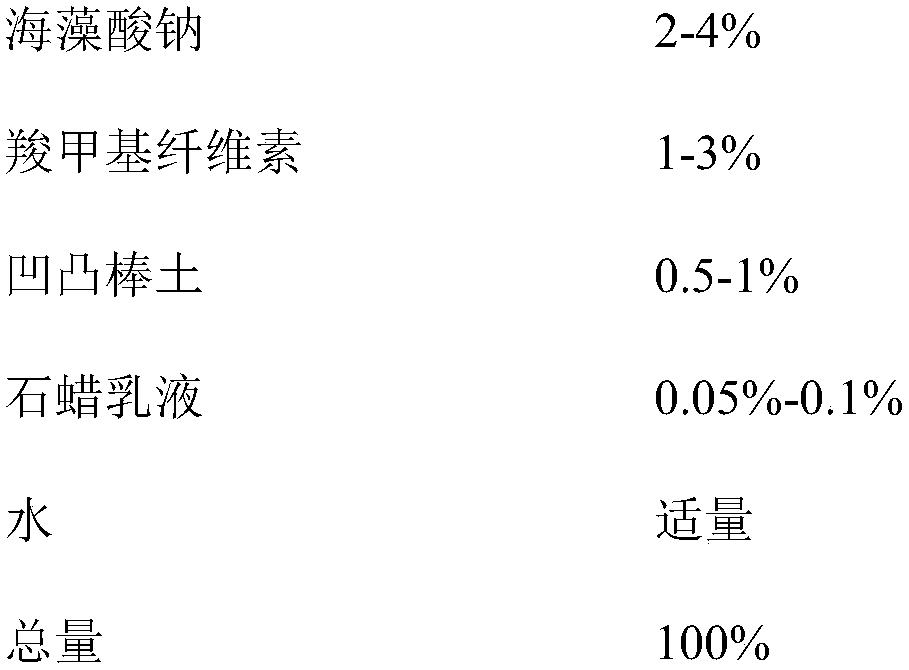

ActiveCN107780264APrevent seepageImprove bindingTransfer printing processDyeing processColour fastnessPolyethylene terephthalate

Owner:CHANGZHOU UNIV

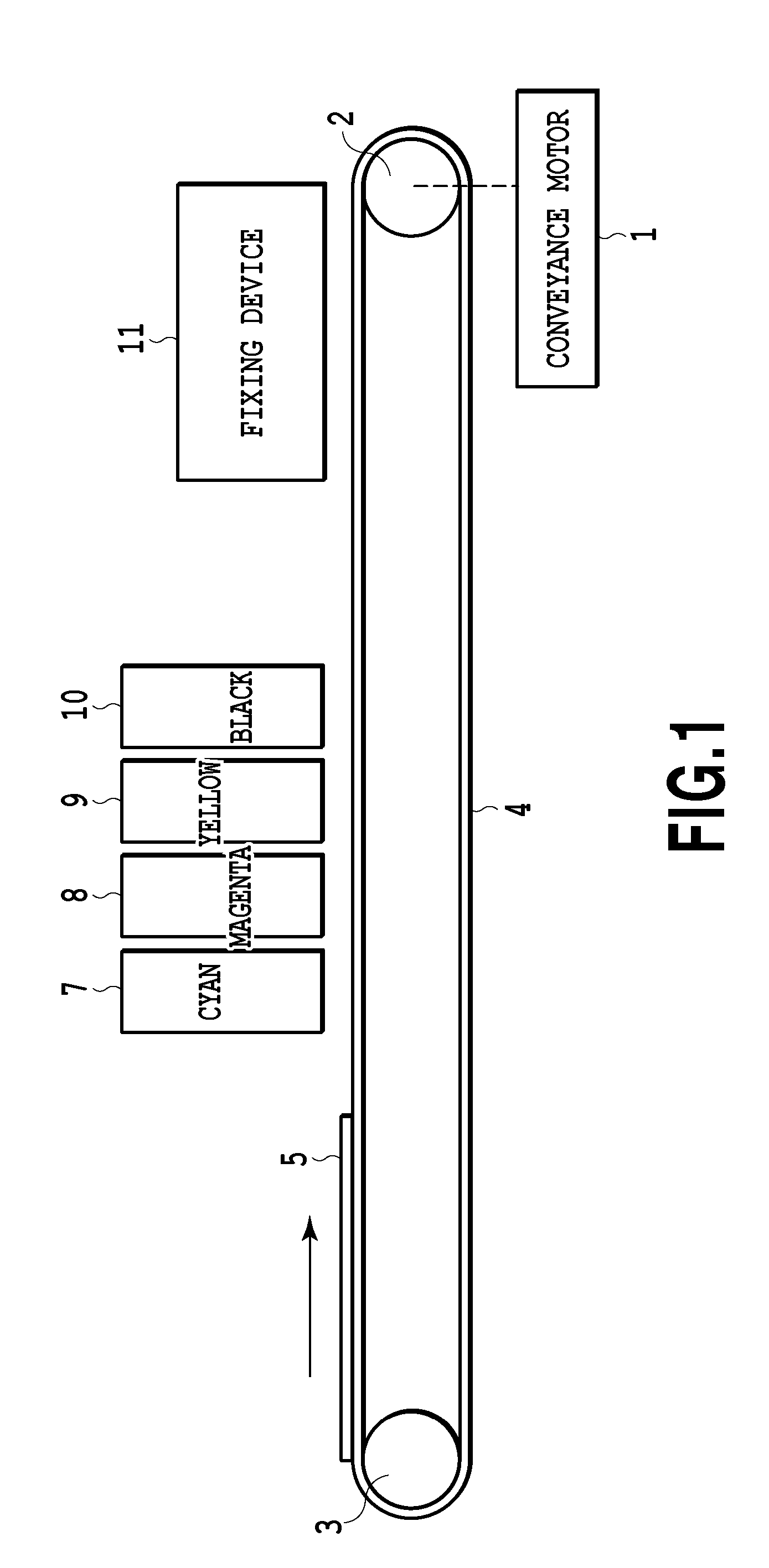

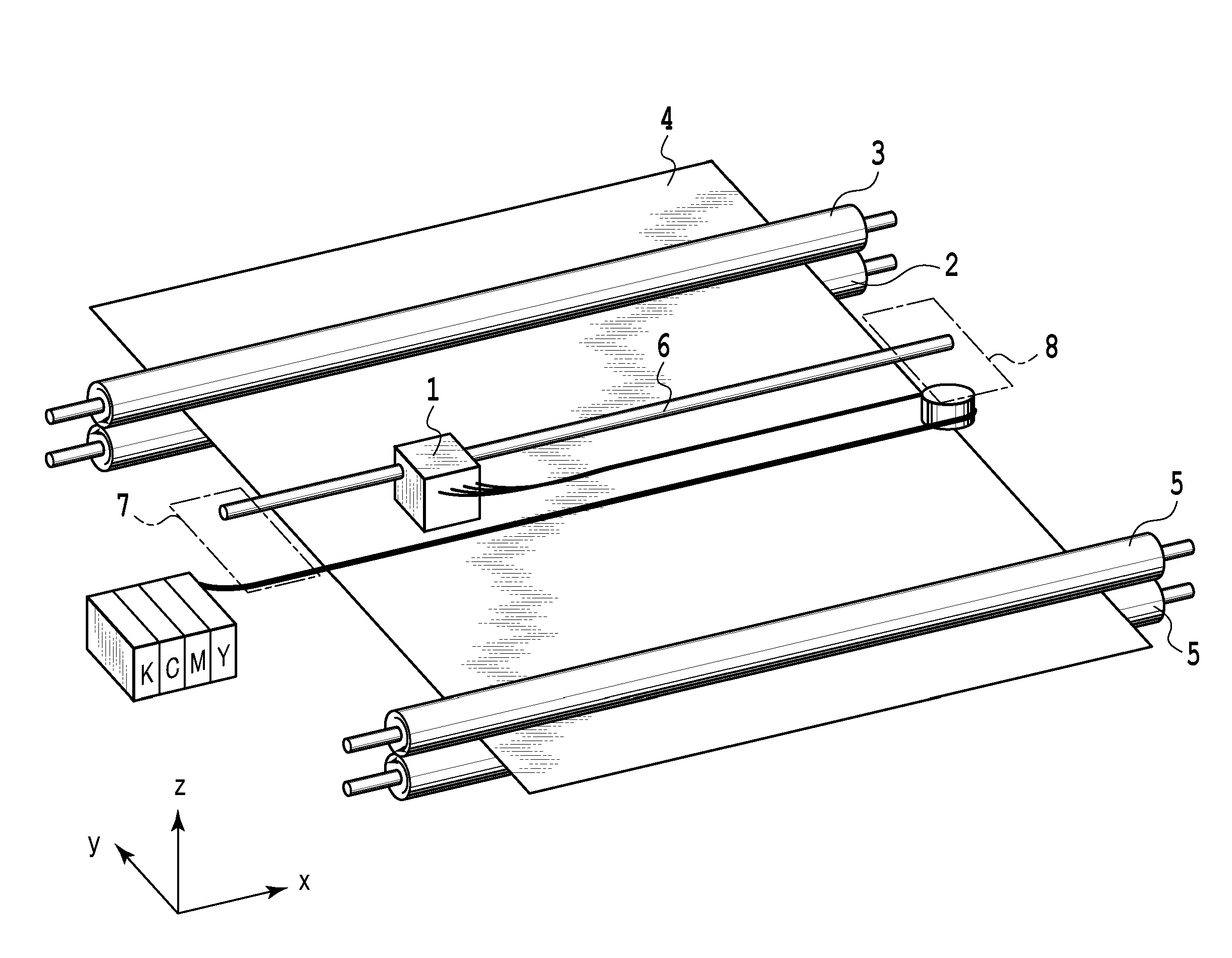

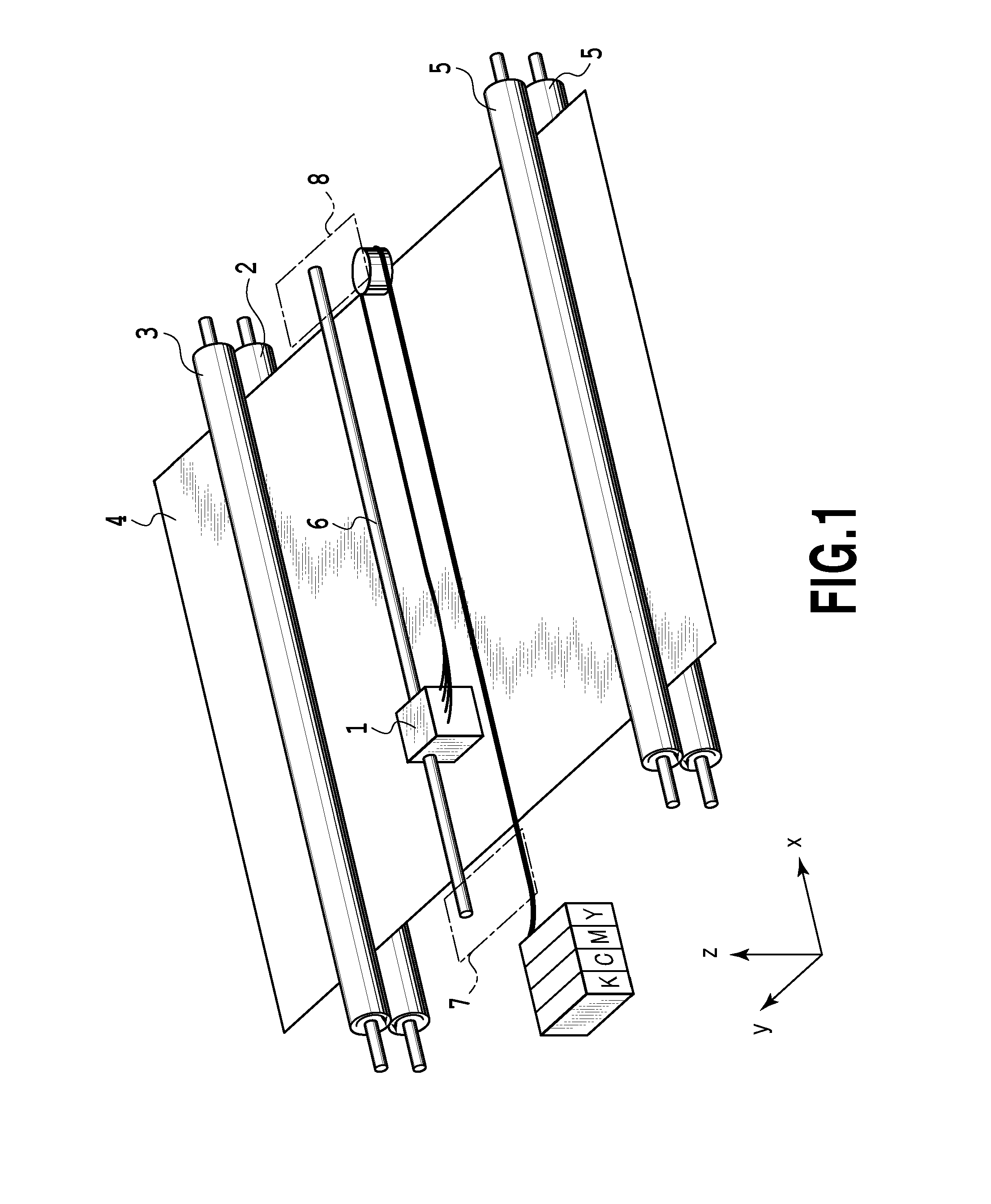

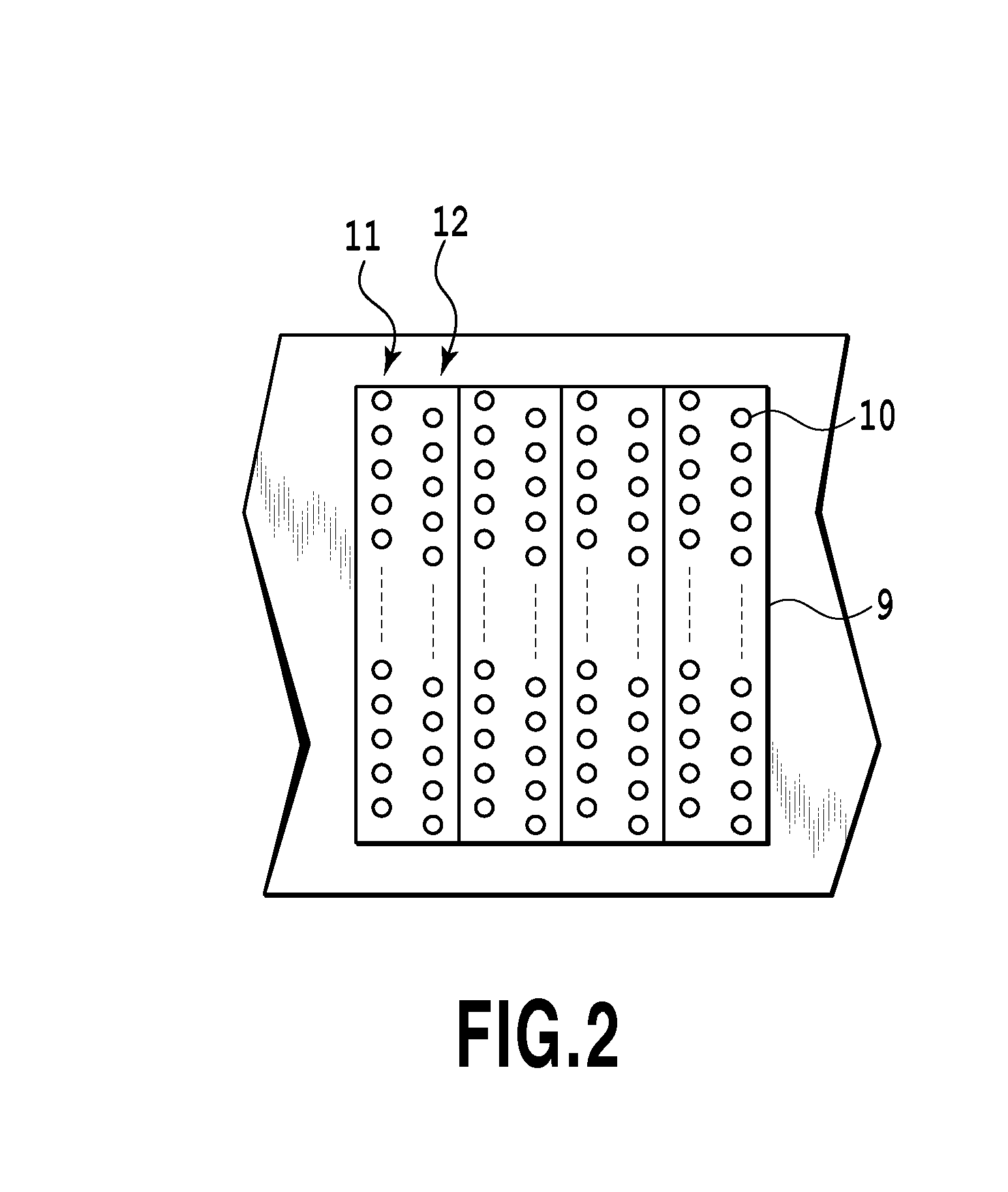

Inkjet printing apparatus and inkjet printing method

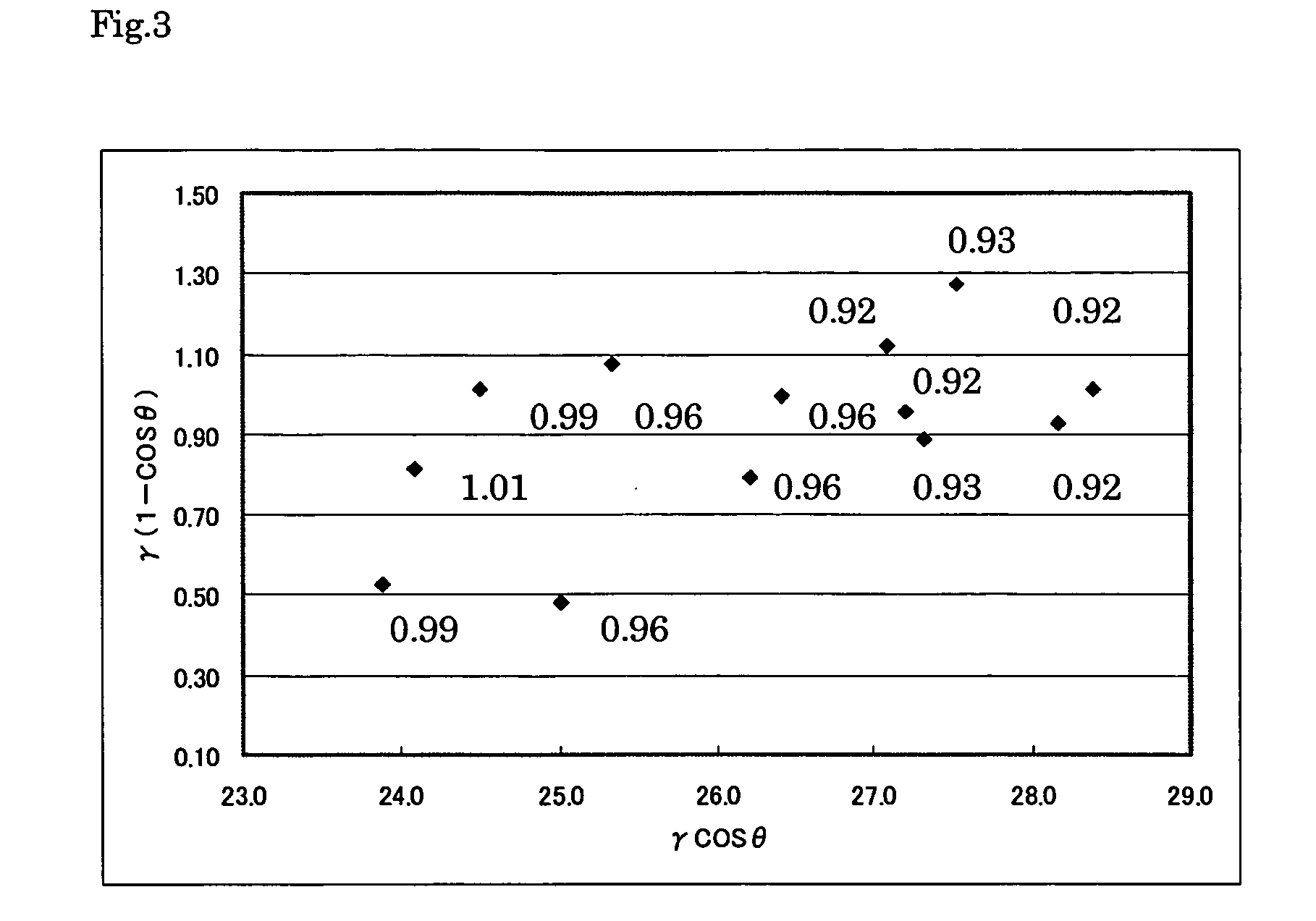

In an inkjet printing apparatus, the colors of ink dots are controlled to make it possible to change the colors of an image to be printed. More specifically, ink temperatures, ink permeation speeds, and the capillary occupancy rates of inks in a print medium are used to control a permeation area formed by performing printing with preceding cyan and subsequent magenta, thereby controlling the colors realized by the inks which are ejected in an overlapping manner.

Owner:CANON KK

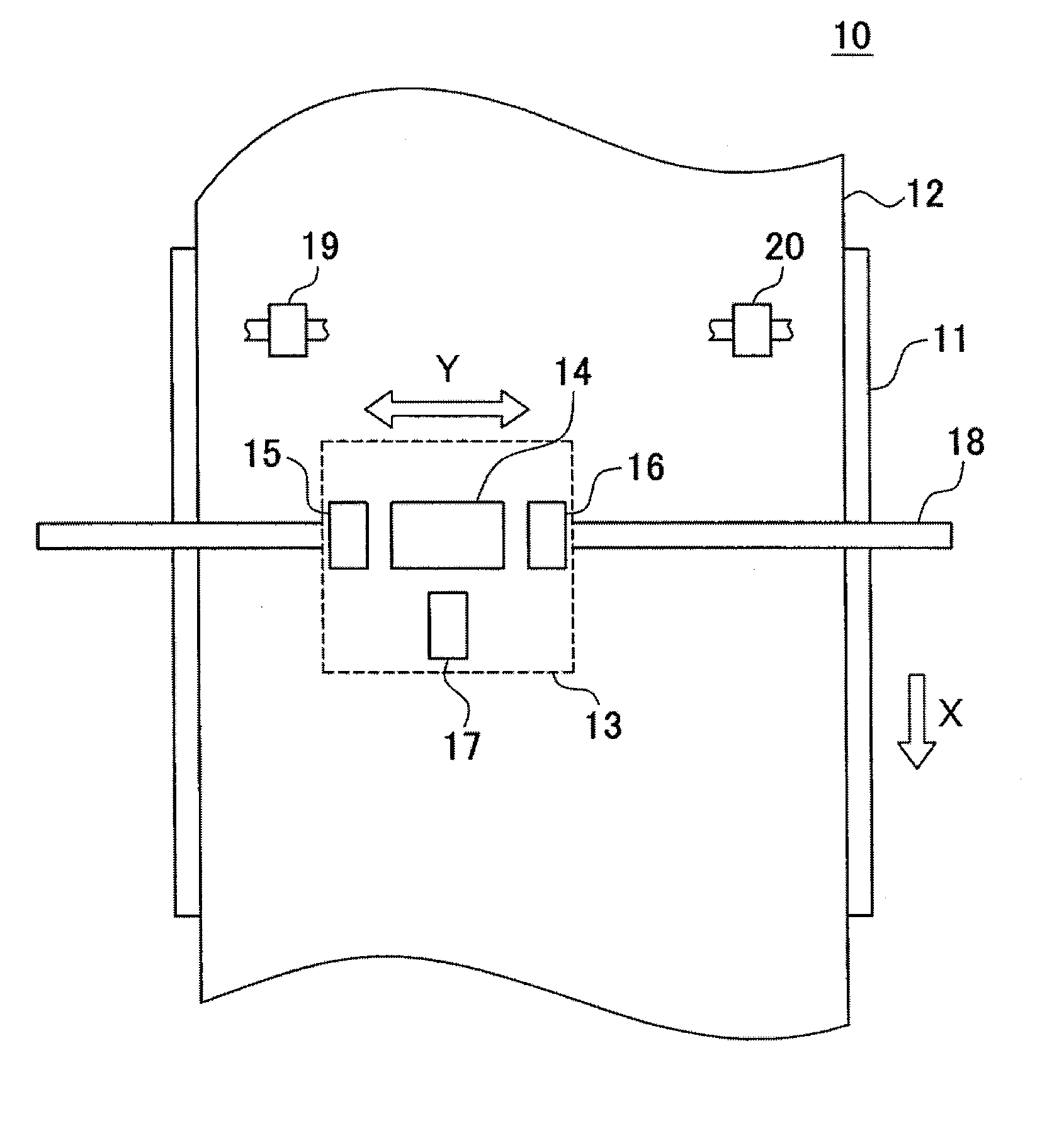

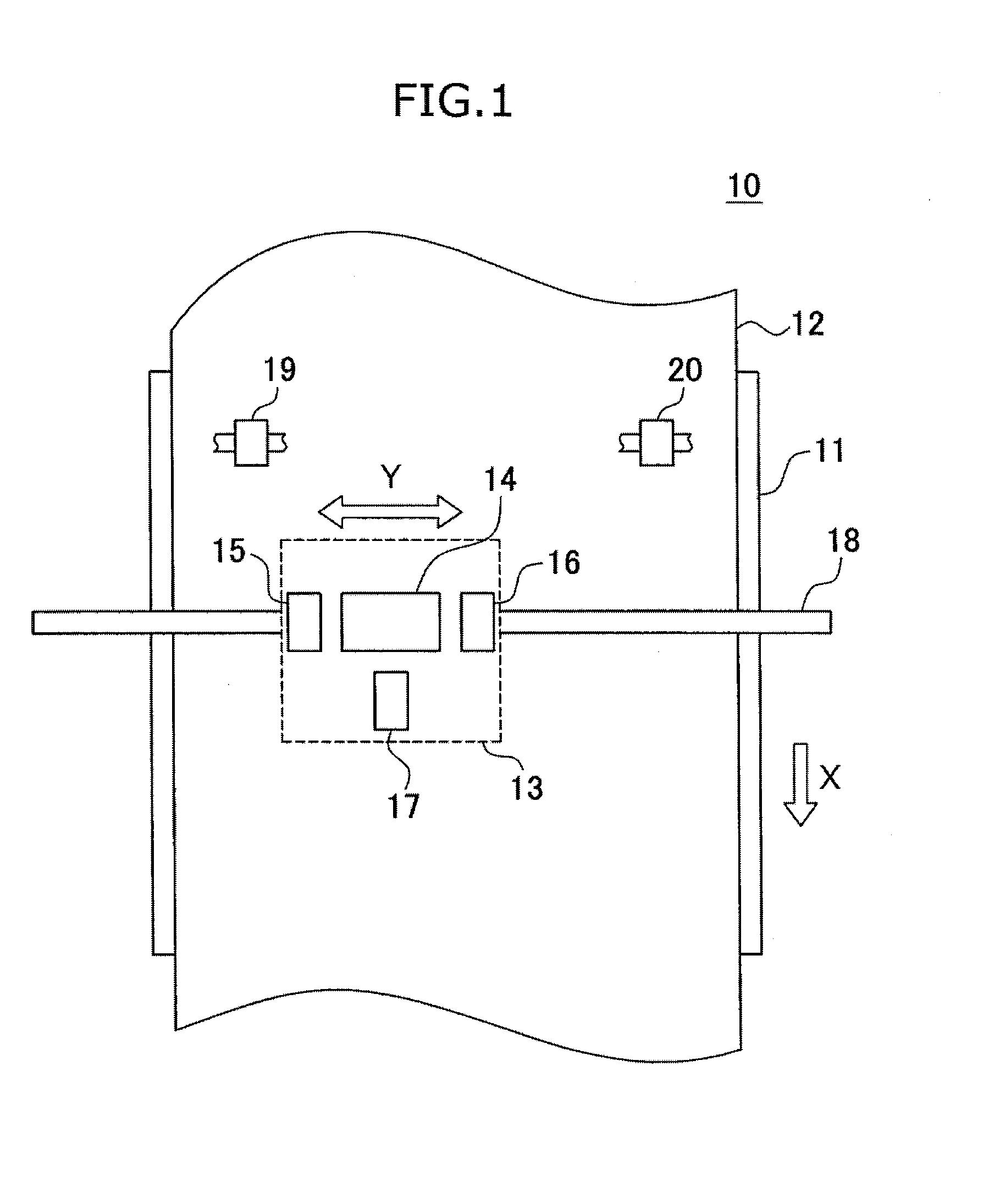

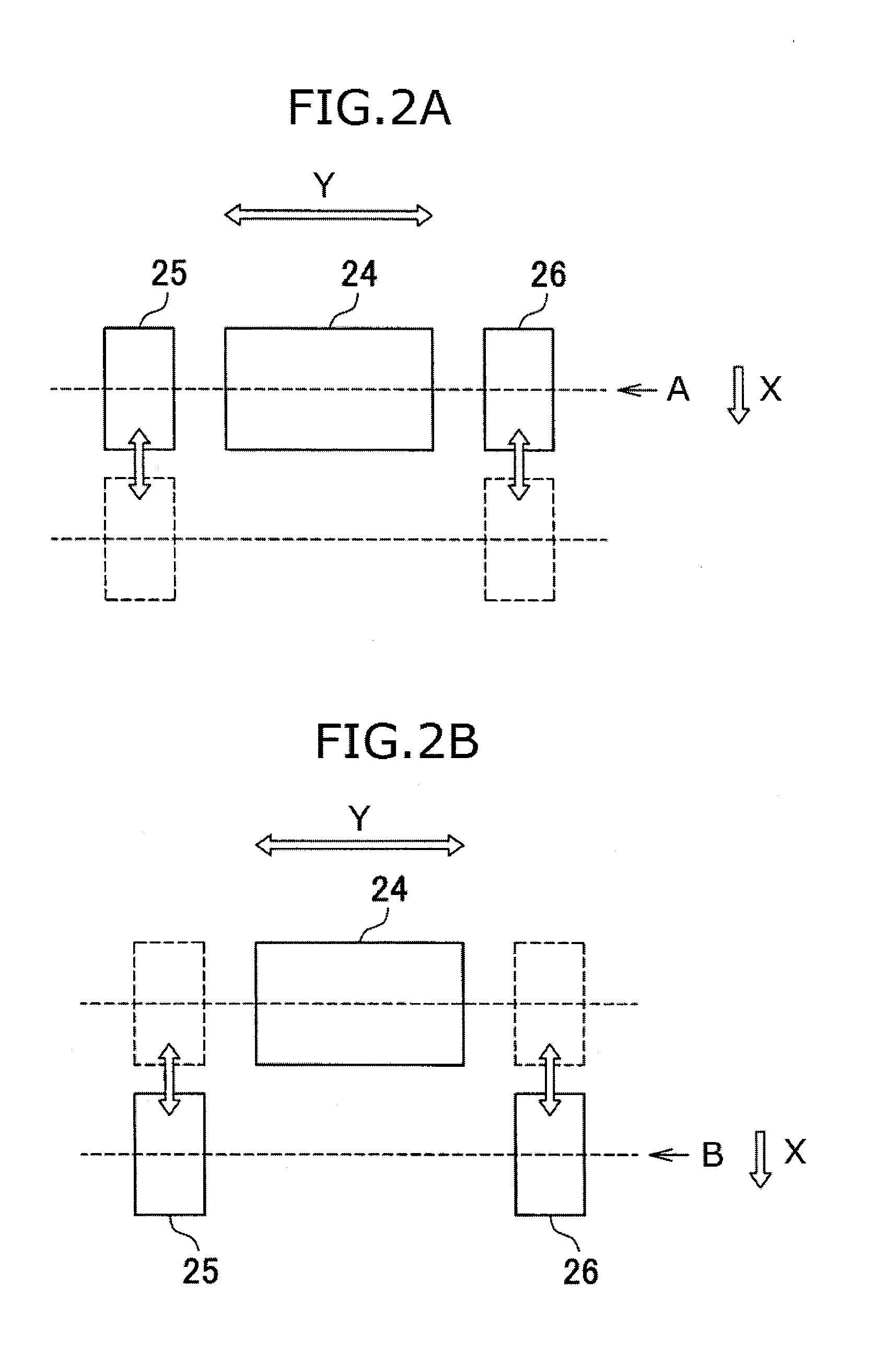

Inkjet printer and inkjet printing method

ActiveUS20120147109A1Improve clarityAvoid runningInking apparatusOther printing apparatusEngineeringIrradiation

Owner:MIMAKI ENG

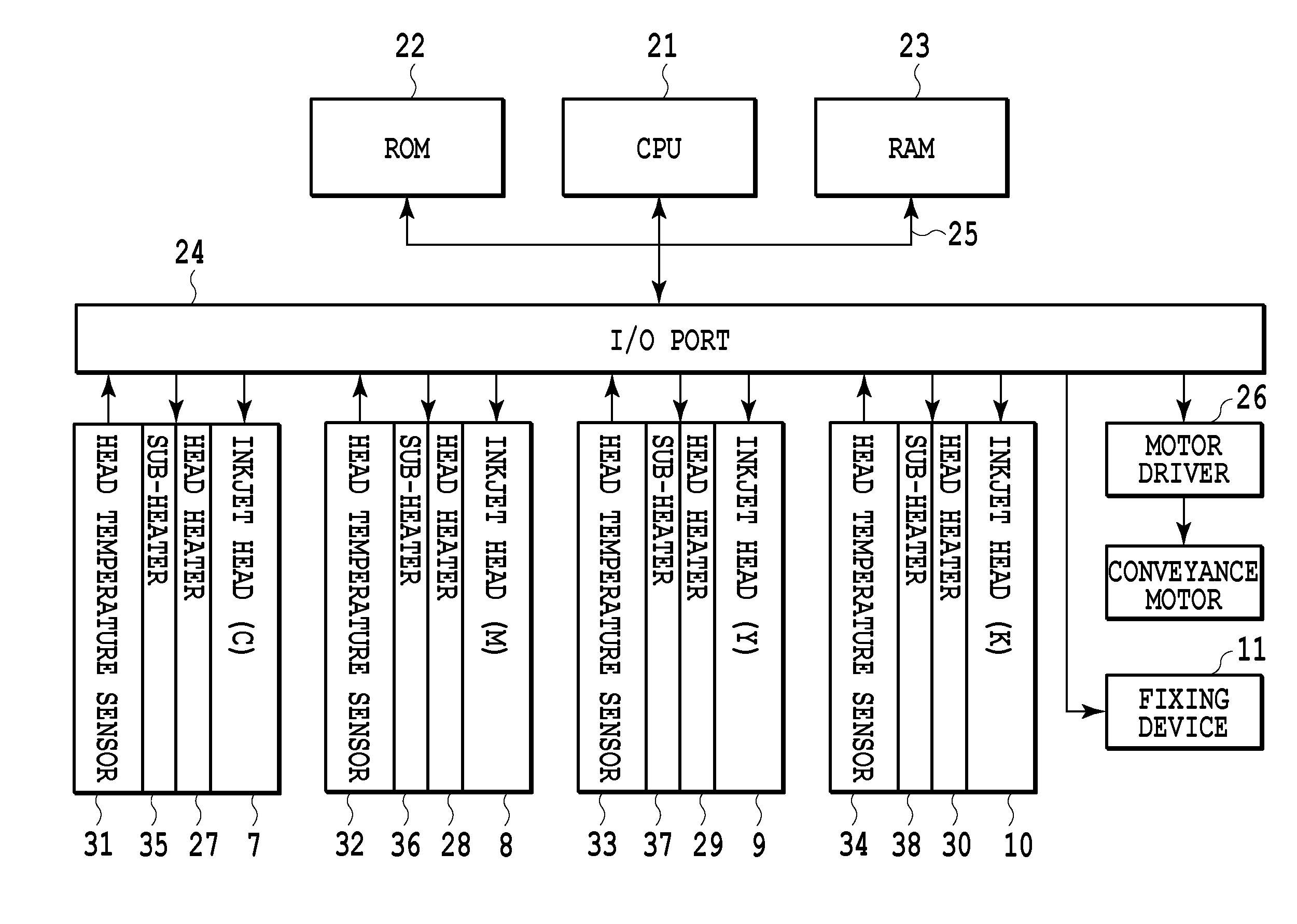

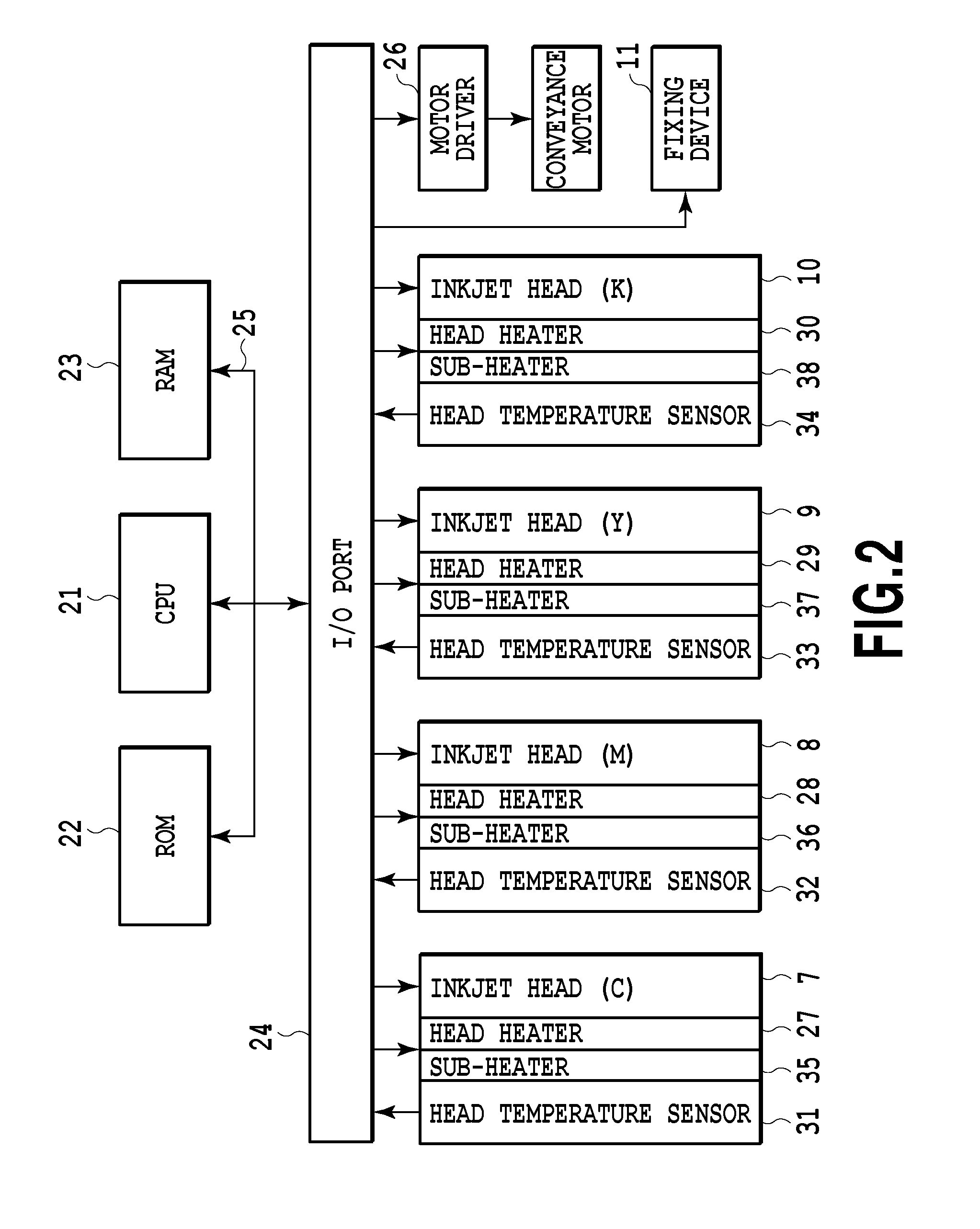

Inkjet printing apparatus and control method thereof

InactiveUS20130307889A1Stable ejectionIncrease speedOther printing apparatusEngineeringMechanical engineering

Owner:CANON KK

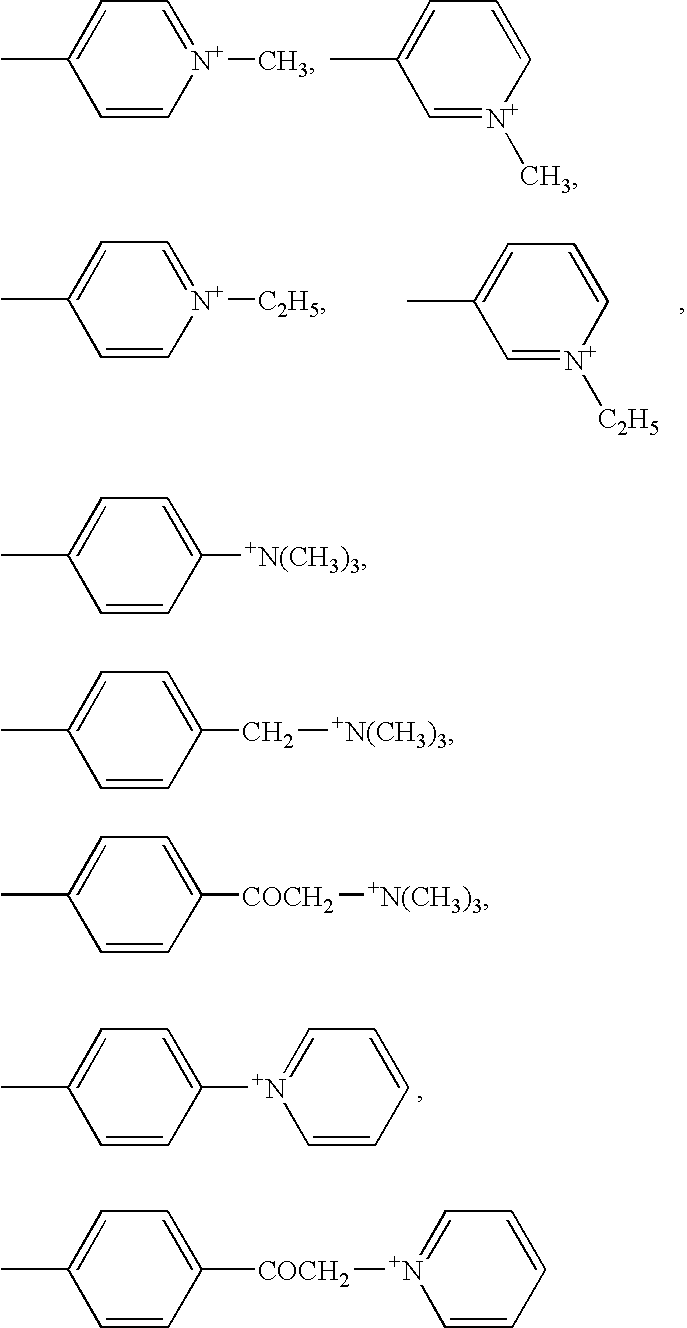

Water-based inks for ink-jet printing

Owner:KAO CORP

Aerosol jet printed flexible graphene circuits for electrochemical sensing and biosensing

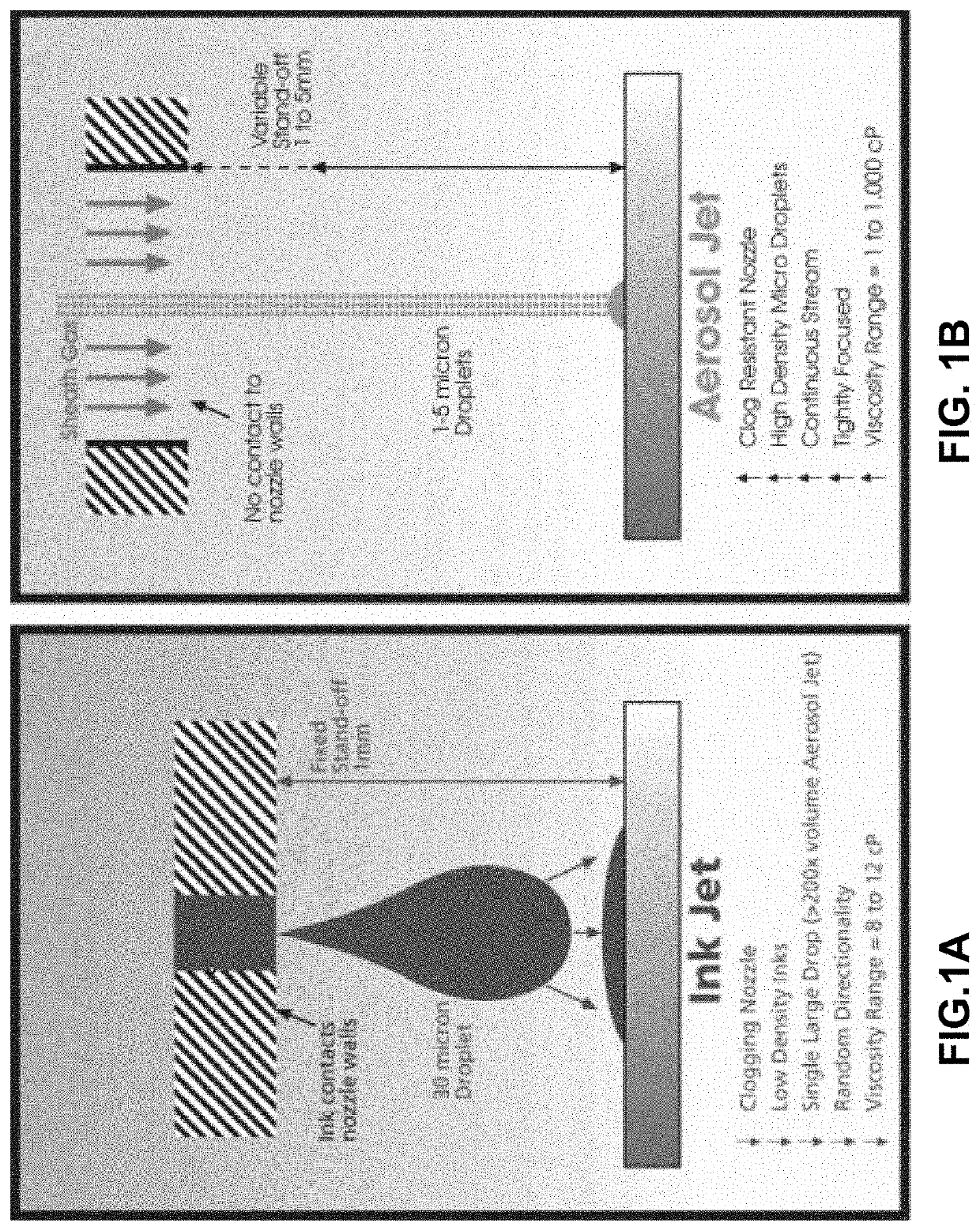

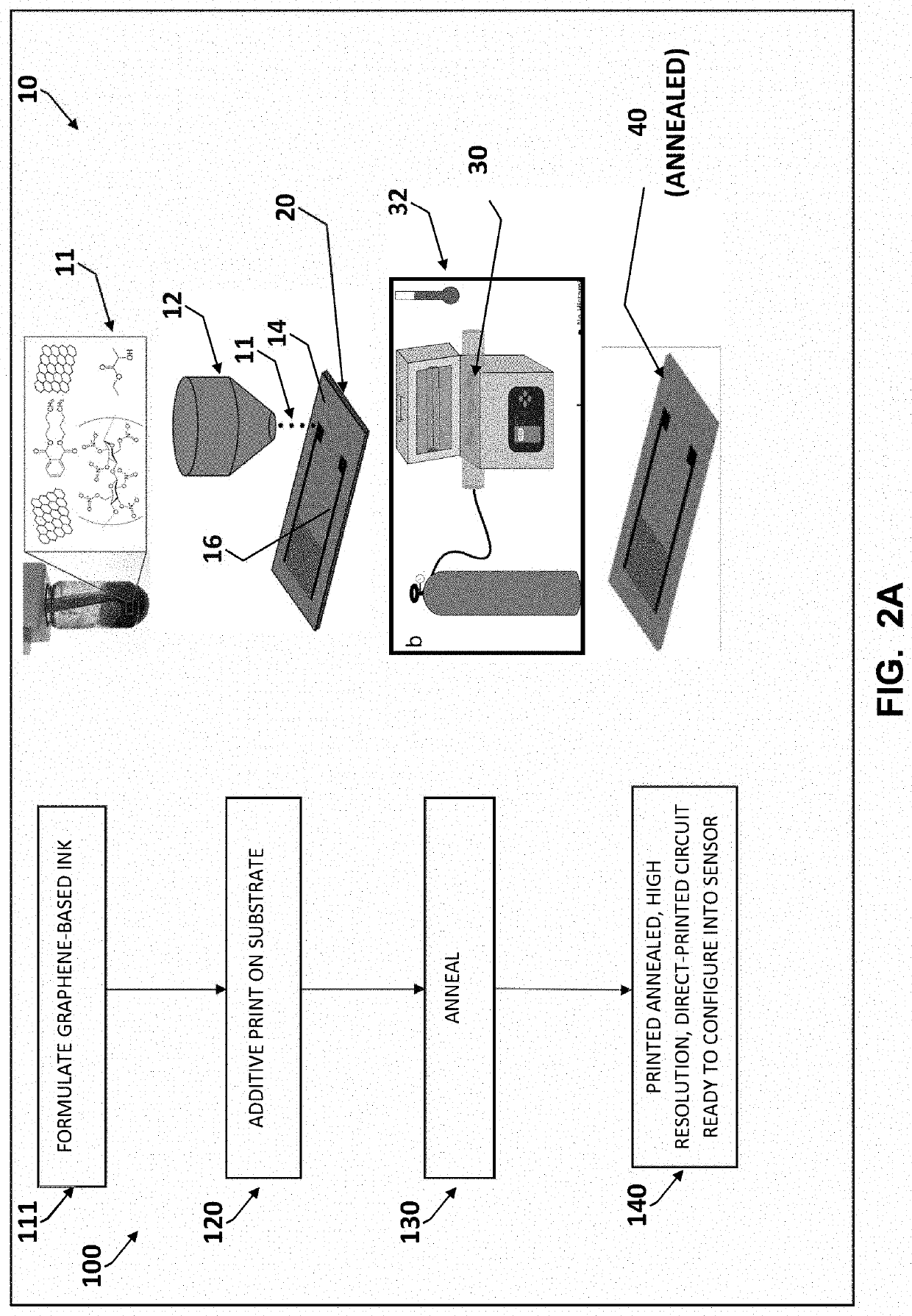

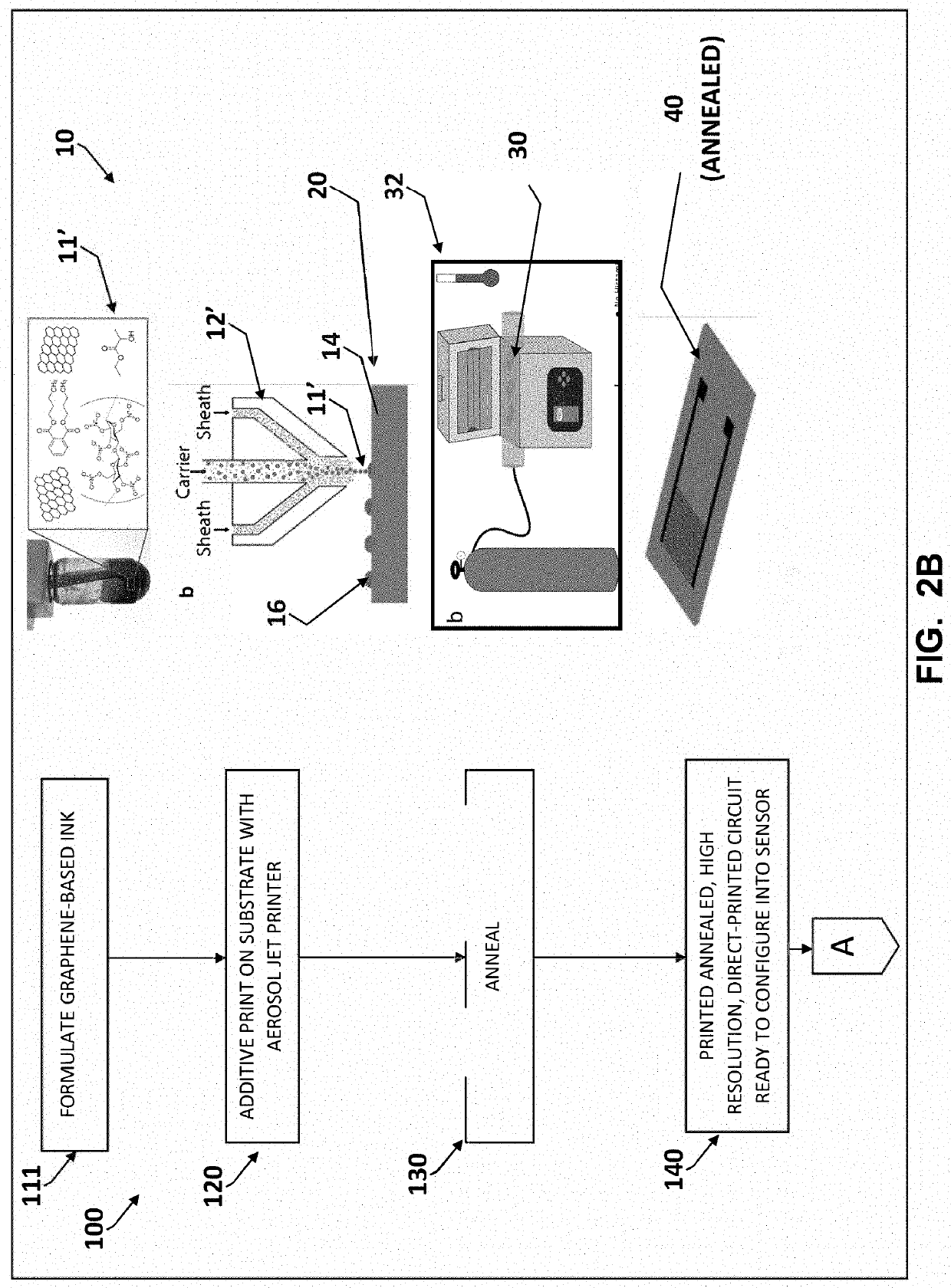

PendingUS20210215636A1High resolutionInexpensive to fabricateAdditive manufacturing apparatusDuplicating/marking methodsInkjet printingAerosol jet printing

Owner:IOWA STATE UNIV RES FOUND +1

Electric meter data printing device

Owner:PUJIANG HUIYI INTELLIGENT TECH CO LTD

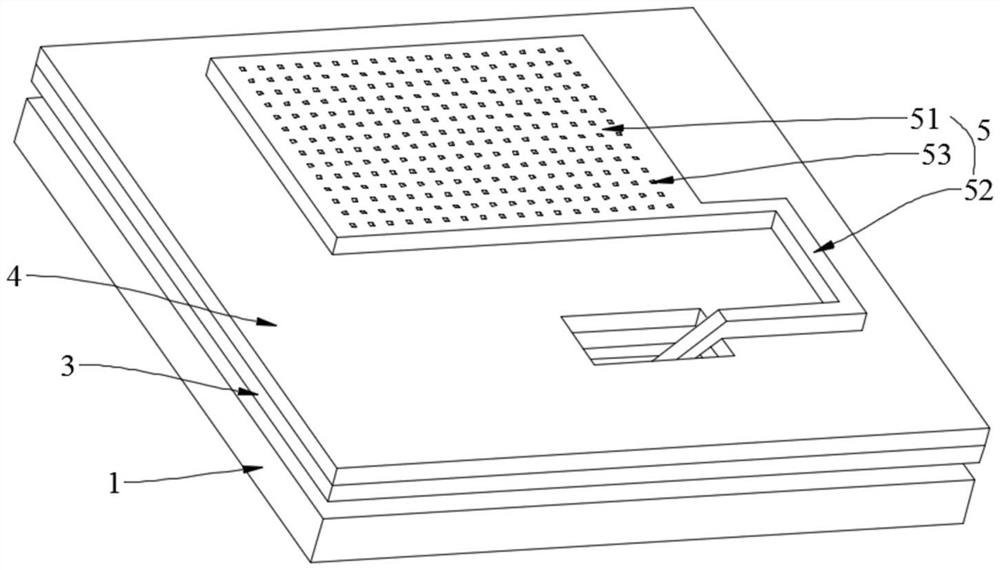

Synchronous plate registration based on silk-screen printing technology and synchronous registration system and method for plates

ActiveCN113815304AImprove adhesionServes as an initial coverScreen printersFinal product manufactureScreen printingTextile printer

The invention discloses a synchronous plate registration method based on a silk-screen printing technology. The synchronous plate registration method comprises the following steps: establishing an embossing digital model, embossing a base material by matching an upper pressing plate engraved with concave-convex patterns with a lower pressing plate below the base material, then carrying out silk-screen printing on the base plate by using a prepared silk-screen printing plate type, and printing a preset pattern on the surface of the base plate. The invention further discloses a synchronous plate registration system based on the silk-screen printing technology and the synchronous registration plate. The concave-convex patterns and the patterns are established by adopting the same digital model, and the matching degree of the concave-convex patterns and the patterns is high. A distance sensor or a scanning mode is adopted, strict cutting of a base material can be achieved, patterns can be aligned with patterns through a positioning frame, and a high-quality product is obtained. The patterns are pressed on the surface of the base material in a continuous embossing mode, the pressure maintaining time is long, the indentation depth is far higher than that of the patterns pressed by a printing roller, the patterns are clearer, the cost of the silk-screen printing mode is only 1 / 10 of that of an ink-jet printing mode, and the cost can be effectively reduced.

Owner:陈竹

Abnormal nozzle compensation method, device, inkjet printing equipment and storage medium

ActiveCN108177442BFix the problem of poor image qualityReduce maintenance costsPrintingImaging qualityImage quality

The embodiment of the invention provides a nozzle abnormity compensation method and device, an inkjet printing device and a storage medium. The method includes the steps that a first printing parameter is acquired, feathering processing is performed on first printing data corresponding to the first printing parameter, and second printing data are obtained; according to abnormal nozzle position information and the first printing parameter, first data corresponding to an abnormal nozzle are acquired from the second printing data, and compensation nozzle position information corresponding to compensation of the first data in a sprayer is determined; according to the compensation nozzle position information and the first printing parameter, corresponding second data during normal printing of acompensation nozzle are acquired from the second printing data, and the second data comprise ink outflow data and ink non-outflow data; and an address of the ink non-outflow data in the second data is determined, the first data are written into the address of the ink non-outflow data in the second data, and compensation data are generated. Due to the technical scheme, the problem that because ofabnormal ink outflow of the abnormal nozzle, the image quality becomes poor is solved, and the sprayer maintaining cost is reduced.

Owner:SENDA SHENZHEN TECH CO LTD

Flexible humidity sensor based on ink-jet printing and preparation process thereof

PendingCN114858872ASimple structureAchieve a single responseDuplicating/marking methodsMaterial capacitanceCapacitanceHemt circuits

Owner:WUHAN UNIV

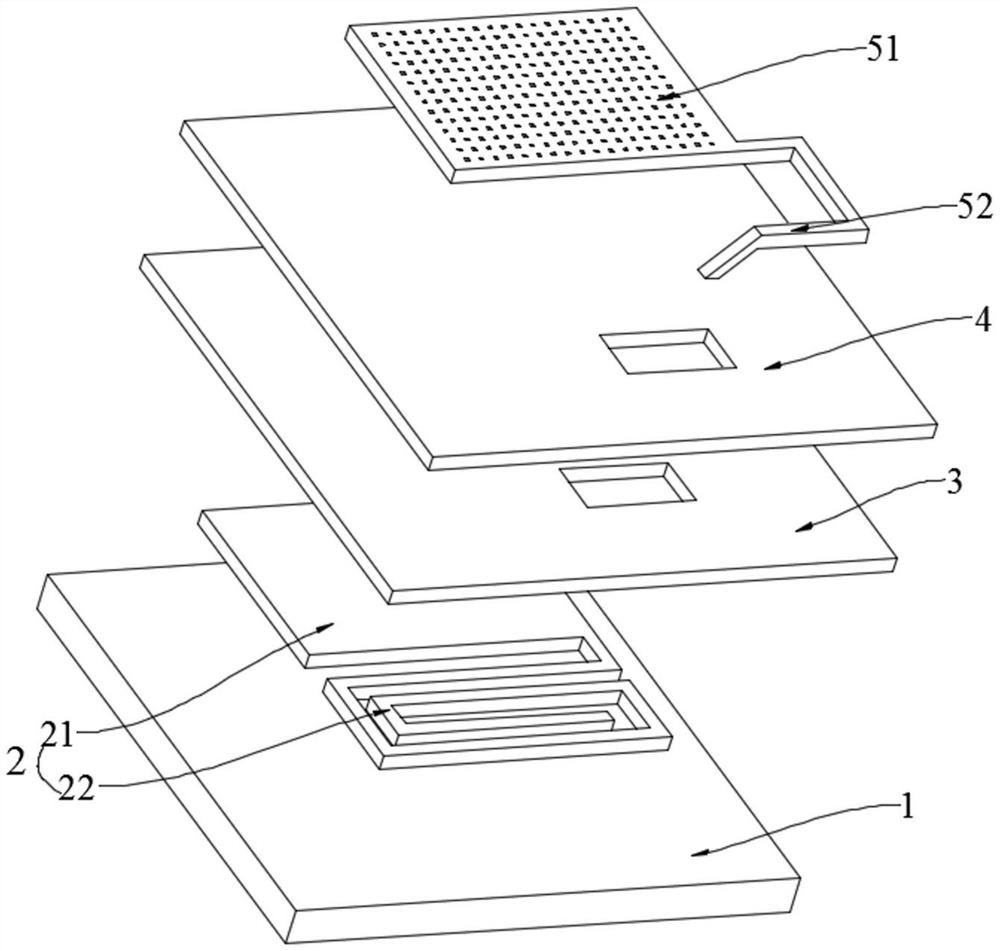

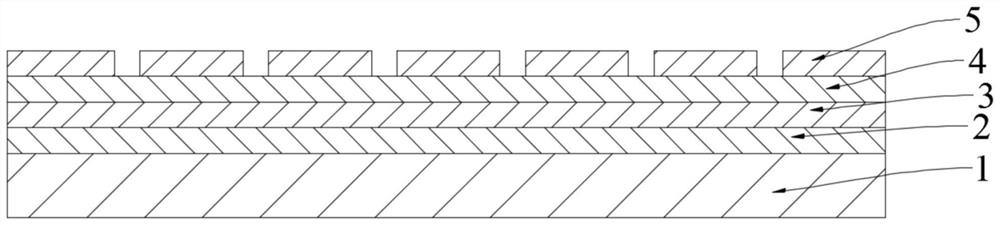

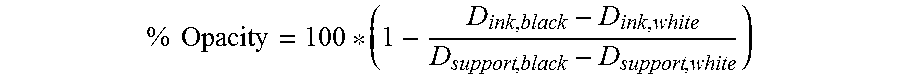

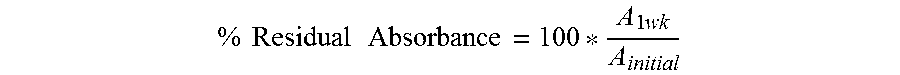

Shading polypropylene base film for photographic paper and preparation method of shading polypropylene base film

PendingCN114381067AGood shading rateIncrease shading rateSynthetic resin layered productsFlat articlesPolymer sciencePhotographic paper

The invention discloses a shading polypropylene base film for photographic paper and a preparation method of the shading polypropylene base film. The shading polypropylene base film for the photographic paper is characterized in that the shading polypropylene base film for the photographic paper is formed by sequentially compounding a surface polypropylene composition layer, a core polypropylene composition layer and a surface polypropylene composition layer, the surface layer polypropylene composition is prepared by mixing, melting and extruding polypropylene resin, an antistatic agent and a dispersing agent; the core layer polypropylene composition is prepared by mixing, melting and extruding polypropylene resin, filler, a coupling agent, an antioxidant, carbon black and a dispersing agent; and respectively putting the core layer polypropylene composition and the surface layer polypropylene composition into a main machine and an auxiliary machine of three-layer co-extrusion casting extrusion equipment, and carrying out melt extrusion, cooling shaping and the like to obtain the shading polypropylene base film for the photographic paper. The shading polypropylene base film for photographic paper has the characteristics of good shading performance, low water vapor transmittance, excellent surface glossiness, high surface energy, excellent antistatic performance and the like, and is suitable for the fields of ink-jet printing, inkjet films and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL CO LTD +1

Pigment dispersions and inkjet ink compositions

ActiveUS20170145233A1High refractive indexDuplicating/marking methodsInksPolymer chemistryInkjet printing

Owner:EASTMAN KODAK CO

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap