Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Zirconium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium oxide. n. A hard white amorphous powder, ZrO 2, derived from zirconium and also found naturally, used chiefly in pigments, refractories, and ceramics and as an abrasive. n. (Elements & Compounds) a white amorphous powder that is insoluble in water and highly refractory, used as a pigment for paints, a catalyst, and an abrasive.

Preparation method of zirconium oxide-silicon oxide composite aerogel

ActiveCN103214034ALow densityLow thermal conductivitySilicon compoundsZirconium oxidesAlcoholSilicon oxide

The invention relates to a preparation method of zirconium oxide-silicon oxide composite aerogel. The method comprises the following steps of: dissolving siloxane in alcohol and uniformly stirring the solution to obtain alcohol solution of the siloxane; titrating concentrated nitric acid with 65-68% of mass concentration, titrating deionized water after stirring uniformly and continuously stirring; titrating the concentrated nitric acid to the pre-hydrolyzed siloxane solution, titrating zirconium alkoxide after mixing uniformly, adding the deionized water after stirring uniformly and stirring continuously to obtain clear and transparent gel; transferring the gel to a mould, and still standing and aging the gel to obtain the zirconium oxide-silicon oxide composite wet gel; soaking the wet gel by using aging solution; and finally soaking the gel by using absolute ethyl alcohol or isopropanol solvent. The blocky zirconium oxide-silicon oxide composite aerogel featured with low density and low thermal conductivity prepared by the invention basically keeps the former microcosmic undefined structure after thermal treatment at 1000 DEG C, and has specific area up to 353m<2> / g and good high-temperature stability.

Owner:LINXIAO (TIANJIN CHINA) TECH CO LTD

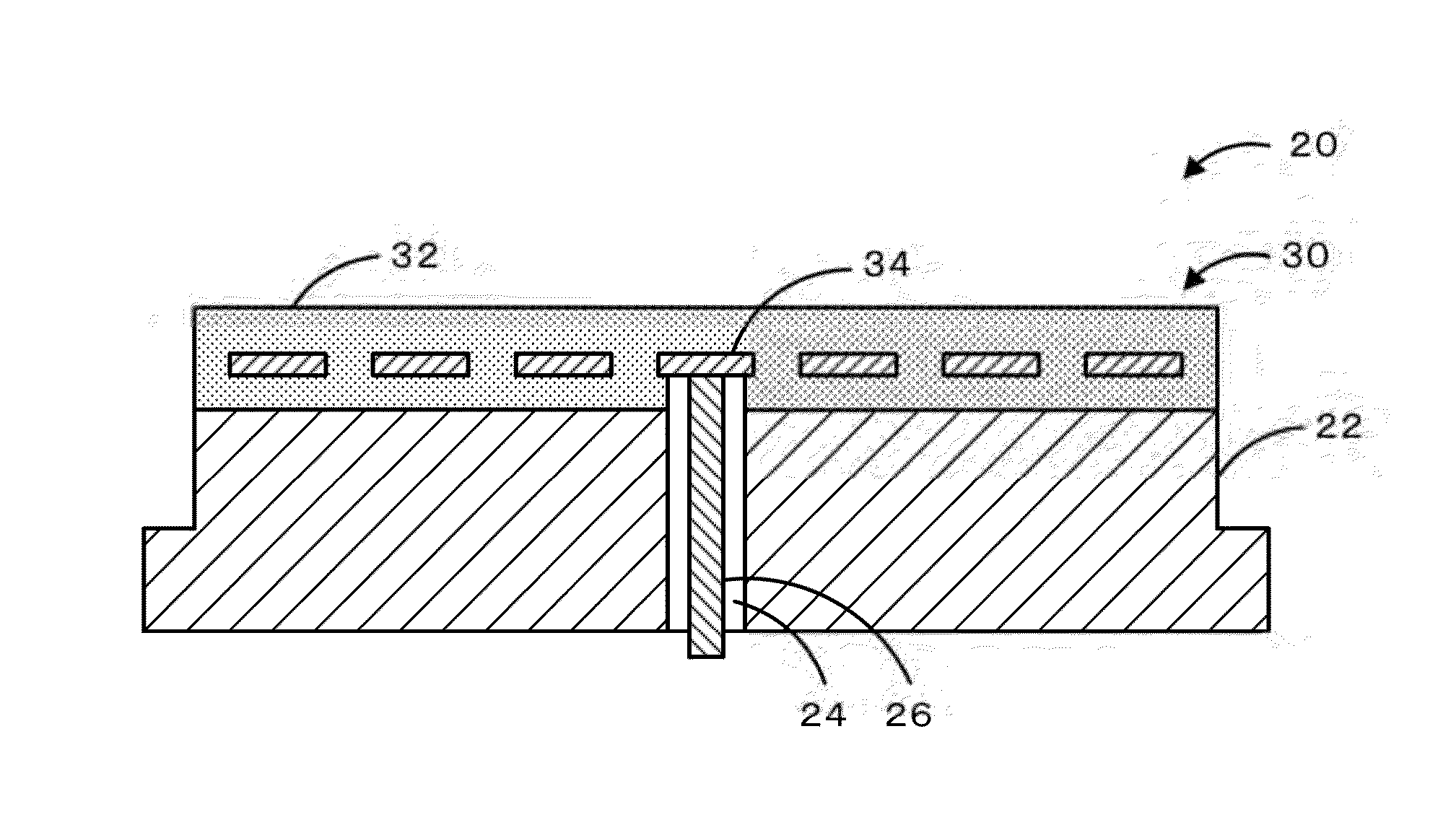

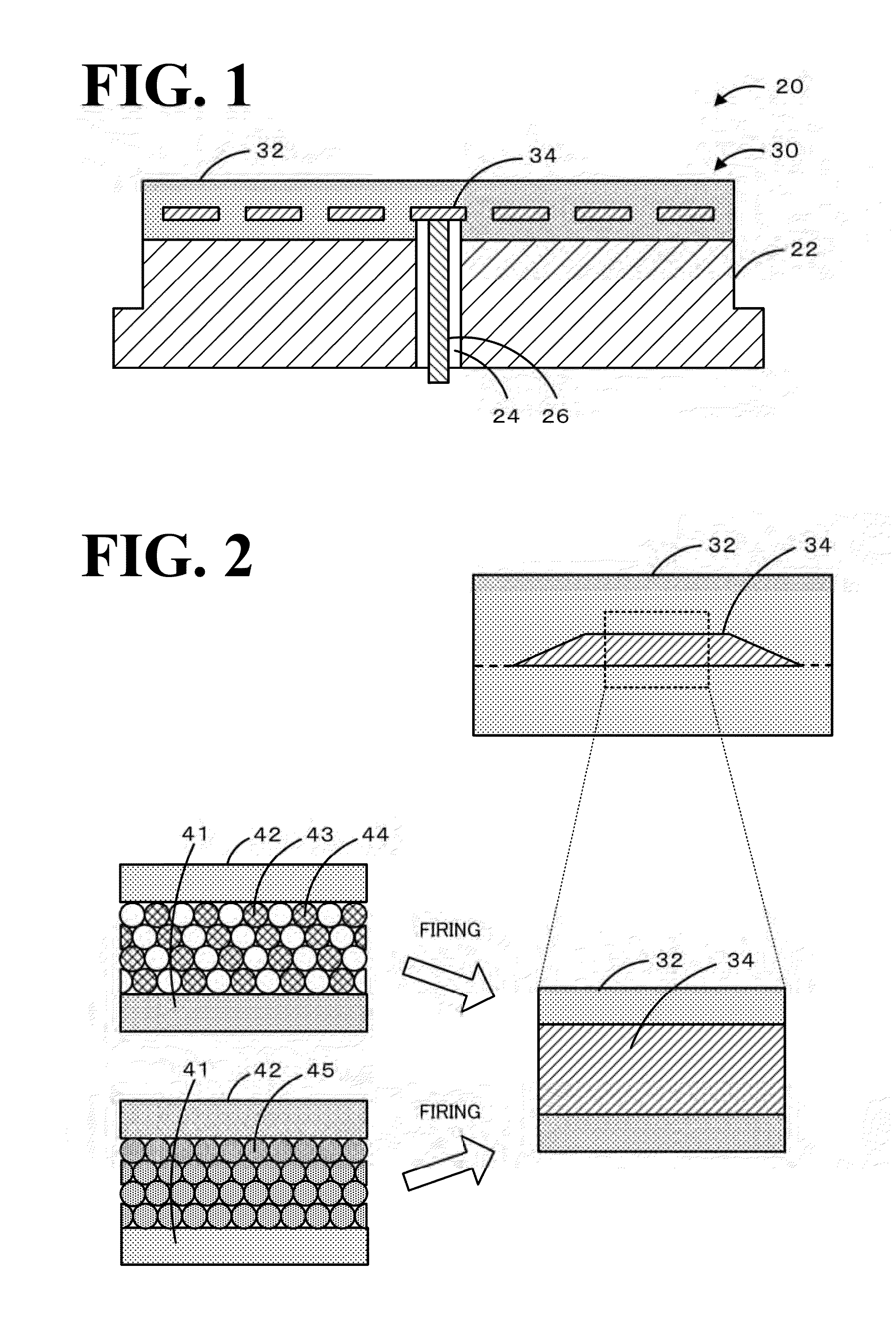

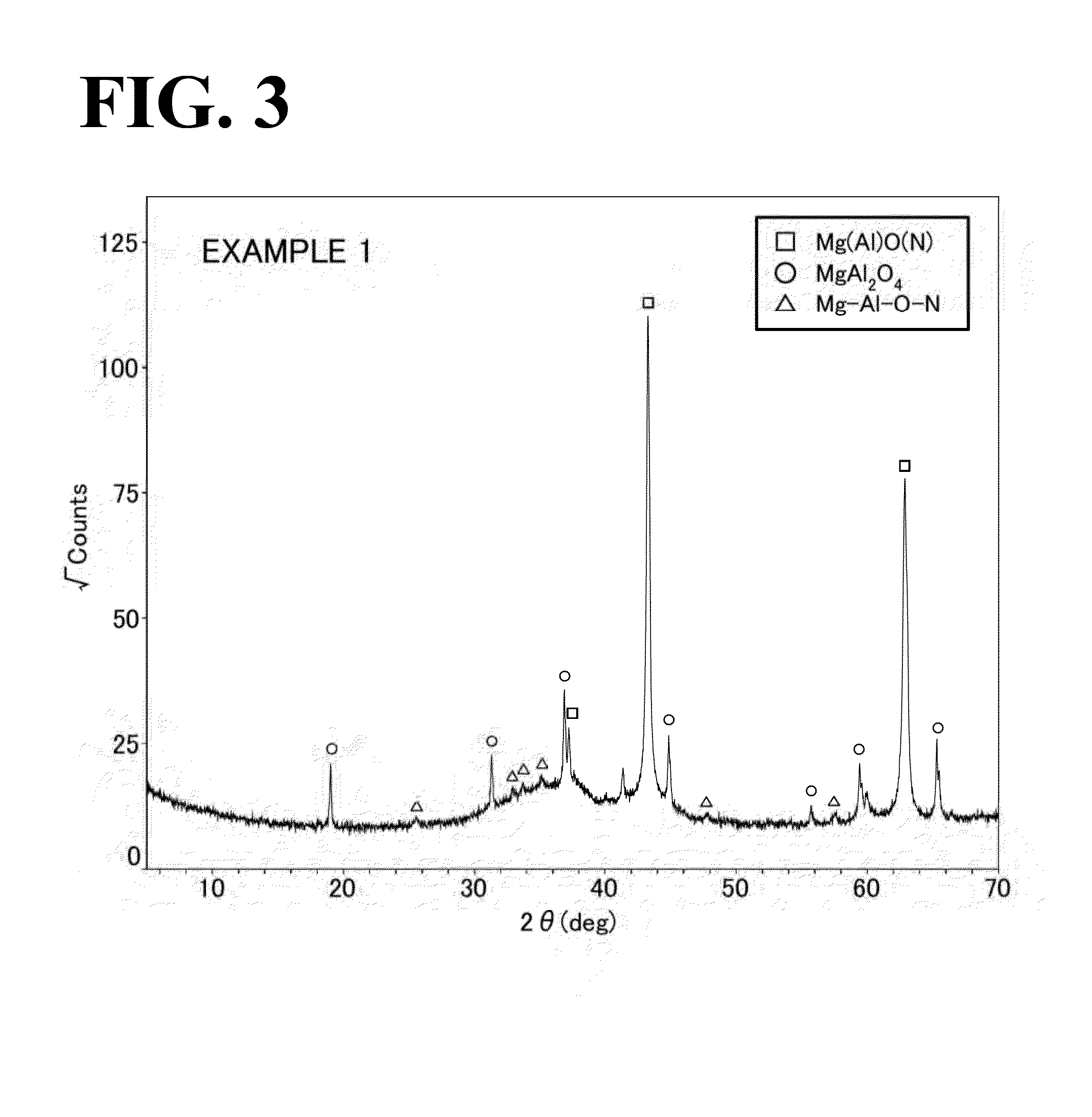

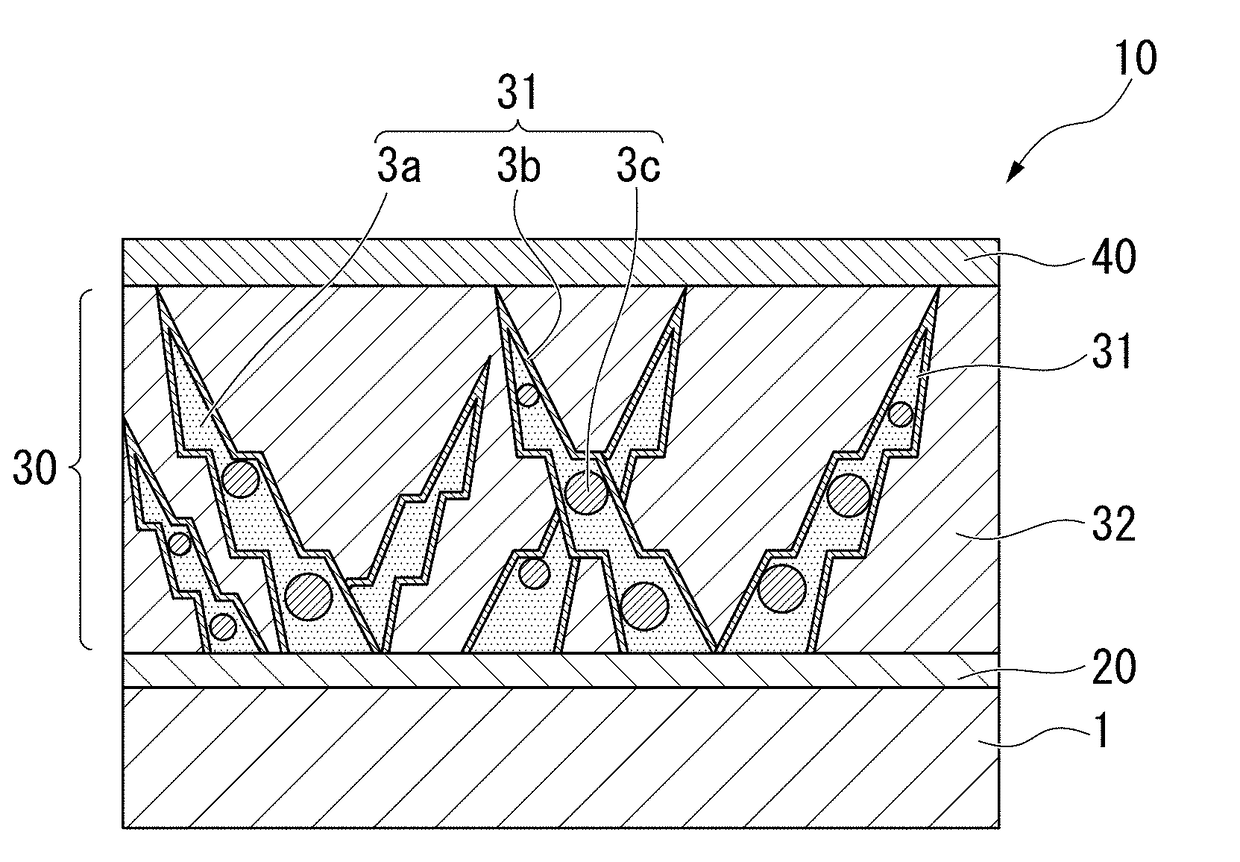

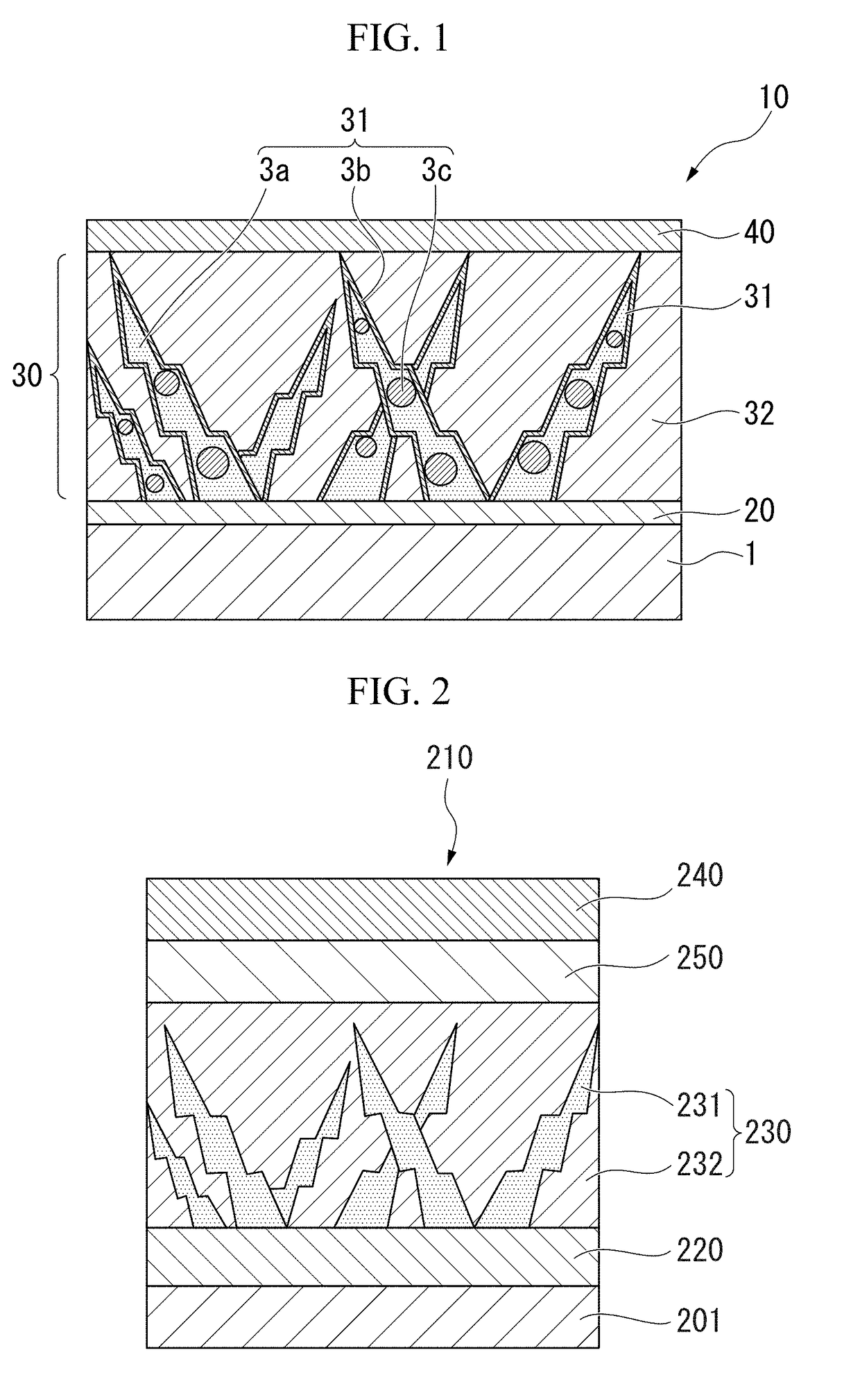

Ceramic member and member for semiconductor manufacturing equipment

ActiveUS20140285943A1Avoid crackingLow resistivitySemiconductor/solid-state device manufacturingPositioning apparatusRutheniumAlloy

Owner:NGK INSULATORS LTD

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

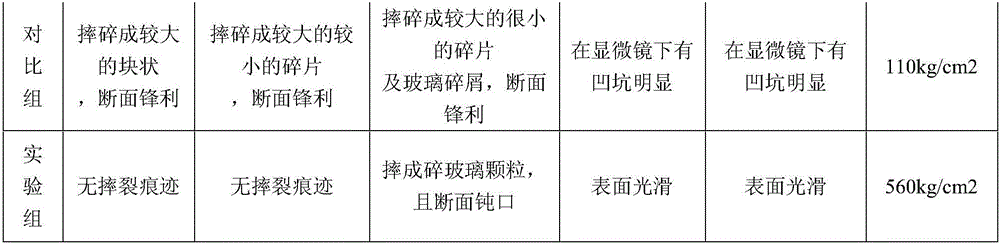

Anti-smashing glass bottle and production method thereof

InactiveCN106587605AGood chemical stabilityIncrease surface tensionGlass blowing apparatusGlass tempering apparatusManufacturing technologyBreak the glass

Owner:柳州市昌泉贸易有限公司

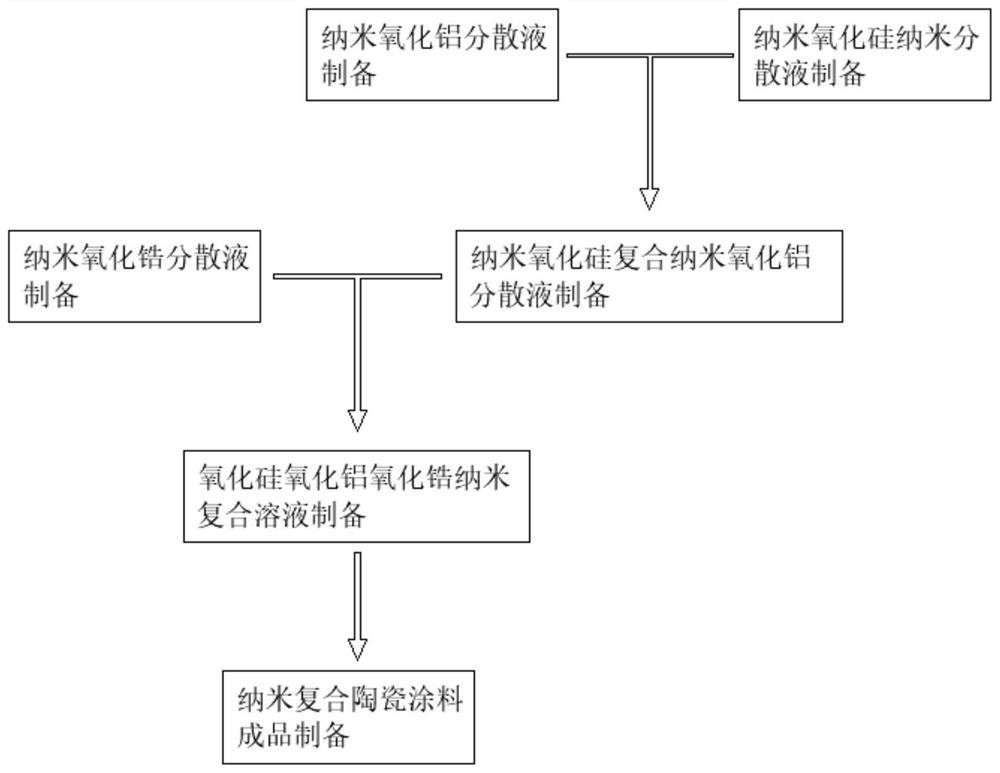

Transparent high-temperature-resistant anti-corrosion nano composite ceramic coating suitable for welding part

InactiveCN112898806AEasy to useGood value for moneyFireproof paintsAnti-corrosive paintsNano siliconComposite ceramic

Owner:薛国旺

Surface-treated steel sheet

InactiveUS20180100244A1Good film adhesionElectrolytic inorganic material coatingDendriteVanadium oxide

Owner:NIPPON STEEL CORP

Method for preparing composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide

InactiveCN102718493AImprove microstructureOvercoming brittlenessSolid waste disposalFluid removalZirconium hydrideExpanded clay aggregate

The invention discloses a method for preparing a composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide. The method comprises the steps of mixing the gold ore tailings, alumina powders and high-temperature zirconium oxide chopped fibers, then adding gum water solution, mixing uniformly, conducting wet grinding and then pelleting; putting particles into alumina crucible and arranging into a silicon carbide rod resistor furnace, heating to 1230 DEG C from the room temperature at the heating speed being 5 DEG C / min-10 DEG C / min, keeping the temperature for 0.5h-1h, heating to 1350 DEG C-1400 DEG C at the heating speed being 5 DEG C / min-7 DEG C / min, keeping the temperature for 2h-3h; and cooling the particles in the furnace and then taking out the particles, and screening the particles by a 20-40 meshes sieve so as to obtain the composite type fracturing propping agent. According to the method, fibers (crystal whiskers) necessary for enhancing the strength and toughness is provided by integrating the concept of composite materials integrated with a non-compact ceramic propping agent and adopting the high-temperature reaction self generation mode, and the composite type fracturing propping agent with high strength, high toughness, low density and low damage rate is prepared by two measures, namely fiber reinforcement and particle reinforcement.

Owner:SHAANXI UNIV OF SCI & TECH

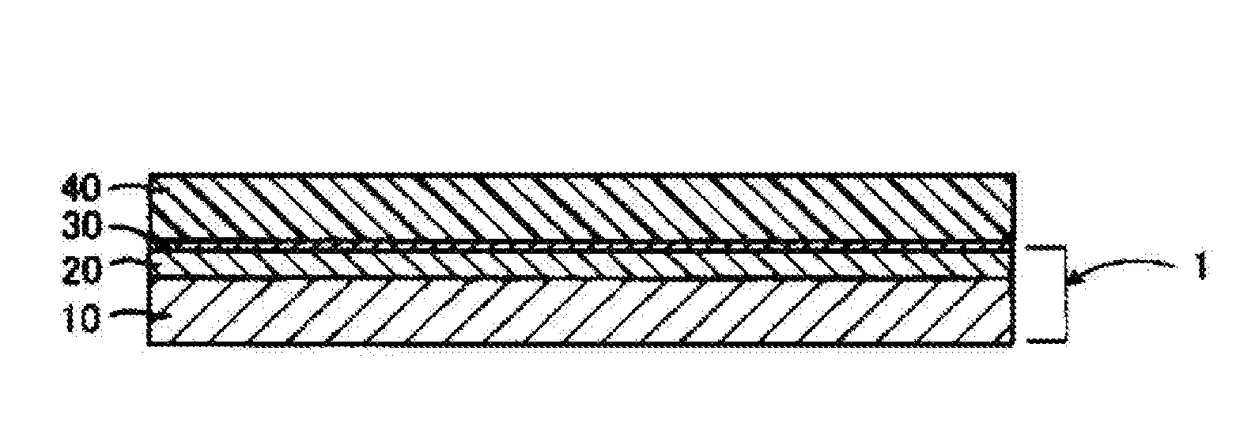

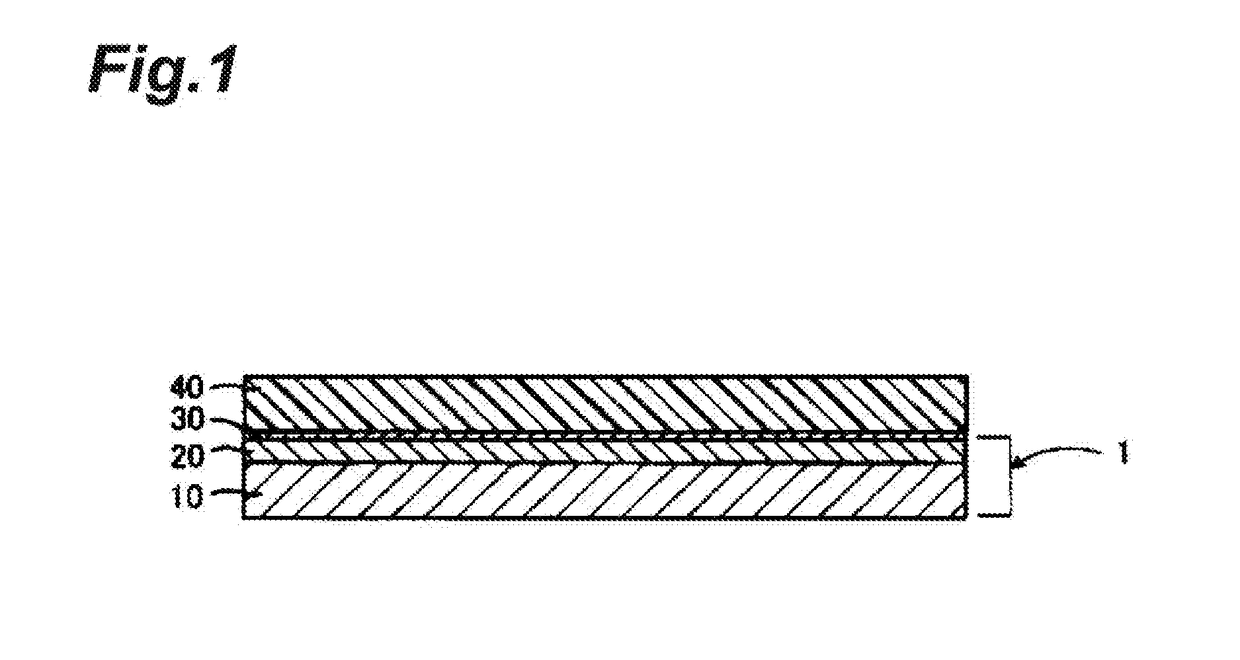

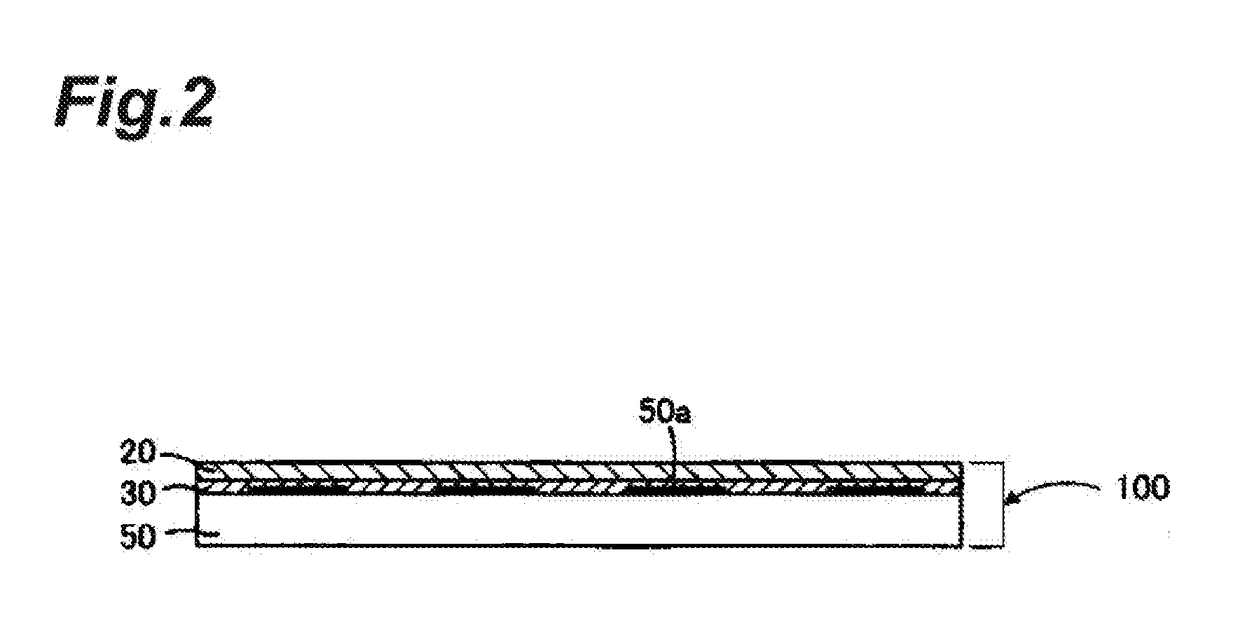

Solid oxide electrolytic cell and preparation method thereof

ActiveCN114016063AAvoid harmful reactionsSuppress internal leakage problemsCellsElectrodesElectron blocking layerMaterials science

The invention discloses a low-temperature solid oxide electrolytic cell and a preparation method thereof. The electrolytic cell comprises a hydrogen electrode layer, an electrolyte layer, an electron barrier layer, an interlayer and an oxygen electrode layer, wherein the hydrogen electrode layer is a composite material composed of NiO and doped cerium oxide LnxCe<1-x>O2, the electrolyte layer is a doped cerium oxide-based material LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, the electron barrier layer is a doped zirconia-based material MyZr<1-y>O2, M is one or more of Y, Sc, Ce, Yb, La, Gd and Sm, y is greater than or equal to 0 and less than or equal to 0.5, the interlayer is doped cerium oxide LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Y, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, and the oxygen electrode is a composite material composed of a perovskite oxide, a perovskite-like oxide or a perovskite oxide and doped cerium oxide or a perovskite-like oxide and doped cerium oxide. The electrolytic cell disclosed by the invention has excellent performance of producing hydrogen by electrolyzing water at low temperature and supplying electrolytic water and carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

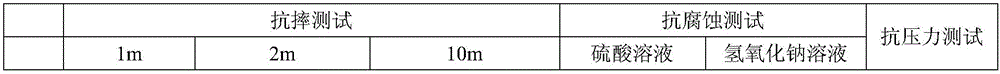

ZrO2 ceramic surface electric conduction method

ActiveCN113004060AScreen printingGlaze

The invention provides a ZrO2 ceramic surface electric conduction method. The ZrO2 ceramic surface electric conduction method comprises the steps: (1) processing a plurality of grooves in the surface of a ZrO2 ceramic finished product; (2) ball-milling glaze powder, electrically conductive ceramic powder and gloss oil to obtain electric conductive slurry, wherein the glaze powder comprises Al2O3 and SiO2 and further comprises at least one of Na2O, K2O, CaO, MgO, B2O3 and ZnO; (3) carrying out silk-screen printing on the electric conductive slurry at the grooves of the ZrO2 ceramic finished product, and drying to obtain a zirconium oxide blank; and (4) carrying out sintering treatment on the zirconium oxide blank at the sintering temperature of 600 DEG C-1200 DEG C, and then carrying out polishing treatment to prepare the zirconium oxide ceramic with the electrically conductive surface. According to the method, the surface electrically conductive zirconium oxide ceramic is obtained at a relatively low sintering temperature and is resistant to acid and alkali corrosion; and moreover, good electrical conductivity is achieved, a metalized layer is firmly combined with a zirconia ceramic matrix, is not easy to crack and fall off, has a mirror surface effect and does not have macroscopic pores.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Wear-resistant engineering plastic

InactiveCN107082933AImprove wear resistanceGood mechanical propertiesWear resistantEngineering plastic

Owner:东至县科创塑料制品有限公司

Medical aluminum oxide ceramic compound material and preparation method thereof

InactiveCN109574634AAdd lessImprove flexural strengthBiocompatibility TestingCooling down

Owner:周琪

Explosion-proof glass

Owner:湖南创安防爆电器有限公司

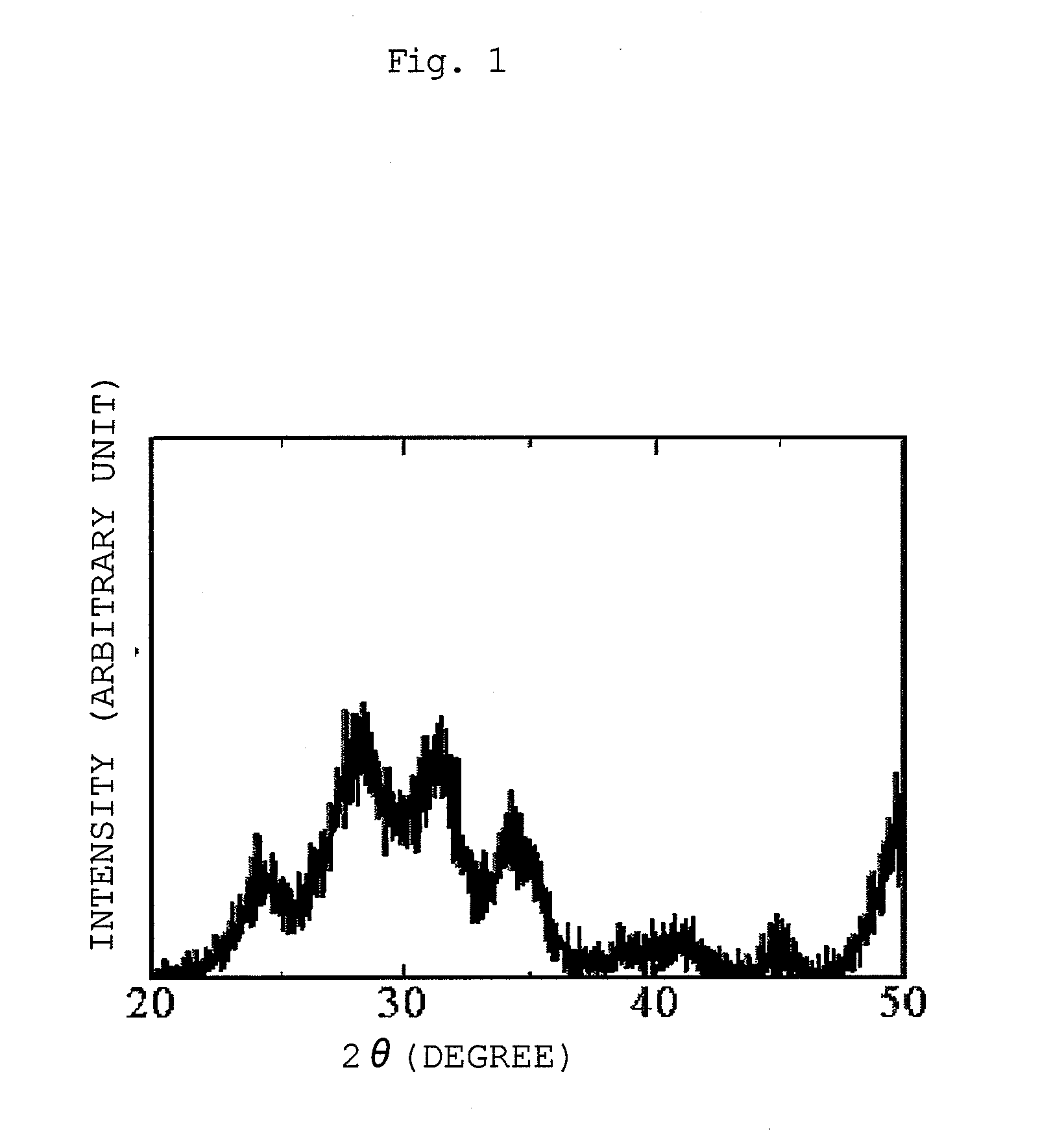

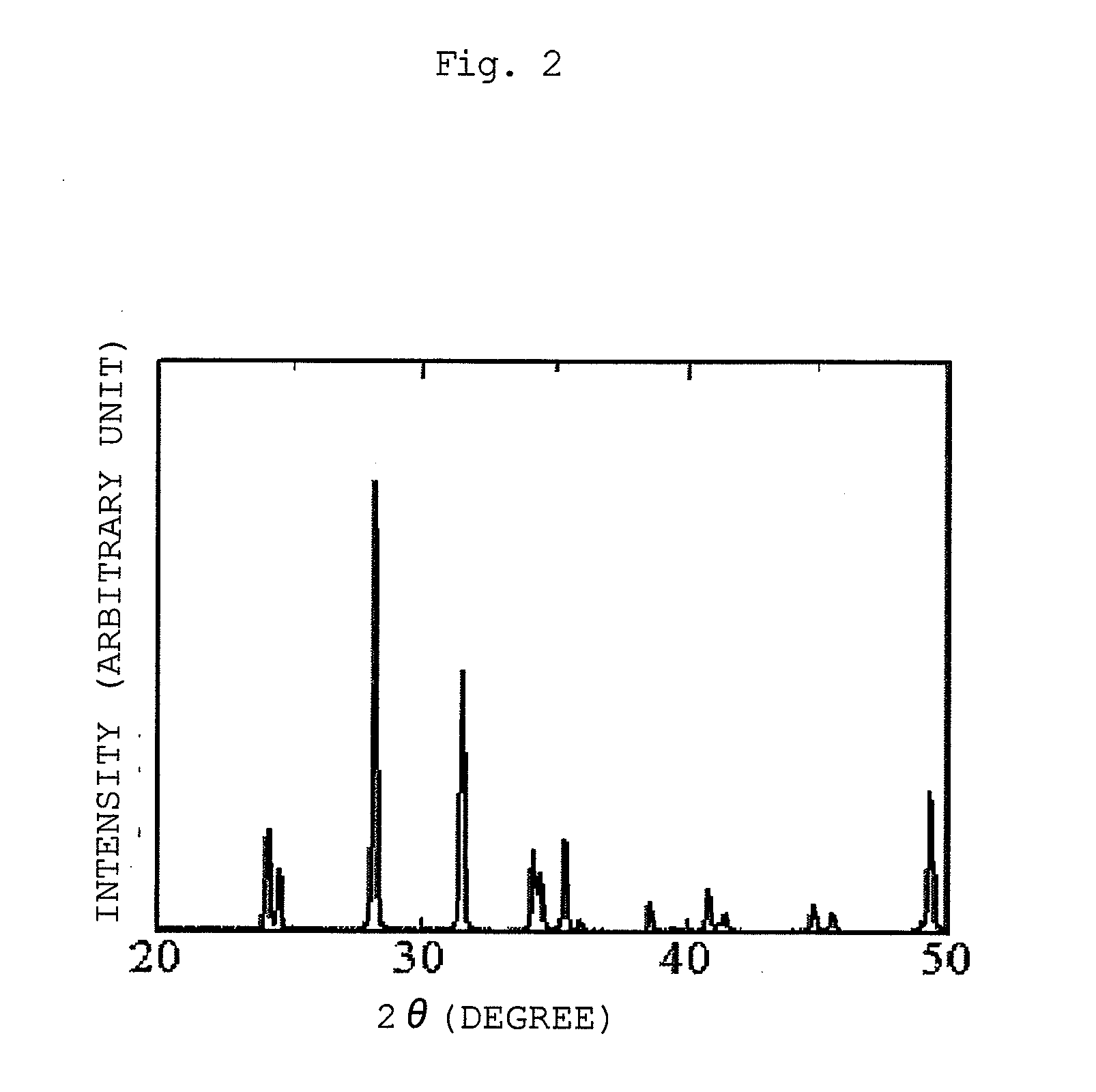

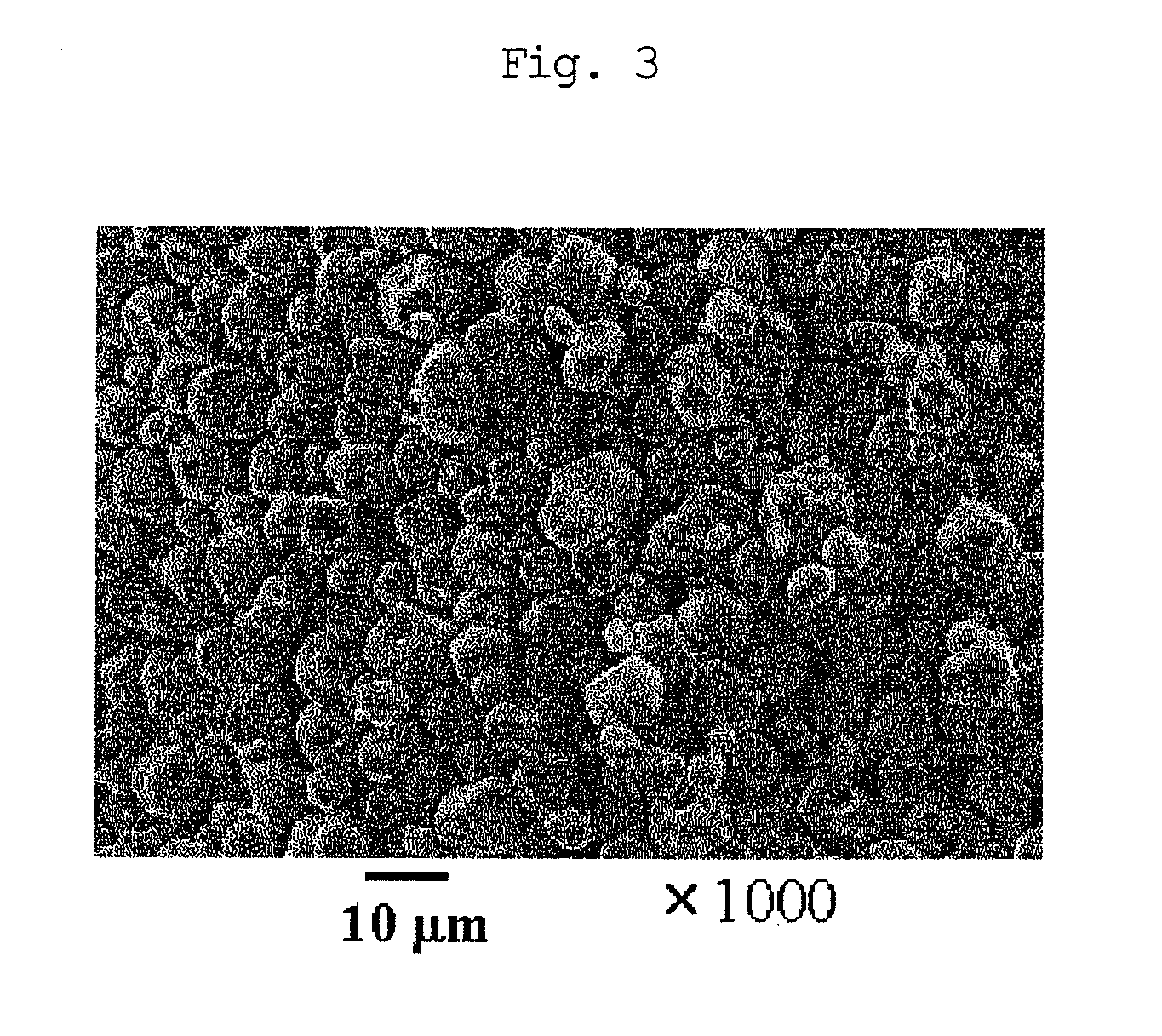

Zirconium Oxide Powder, Process For Producing The Same, And Material For Thermal Spraying

InactiveUS20090308283A1Easy to produceMolten spray coatingSynthetic resin layered productsThermal sprayingMetallurgy

Owner:SUMITOMO CHEM CO LTD

Transfer-type photosensitive film for refractive-index modulation

InactiveUS20180284920A1Improve transmittanceGood developing propertiesSynthetic resin layered productsPhotomechanical apparatusZirconium oxideChemistry

Owner:HITACHI CHEM CO LTD

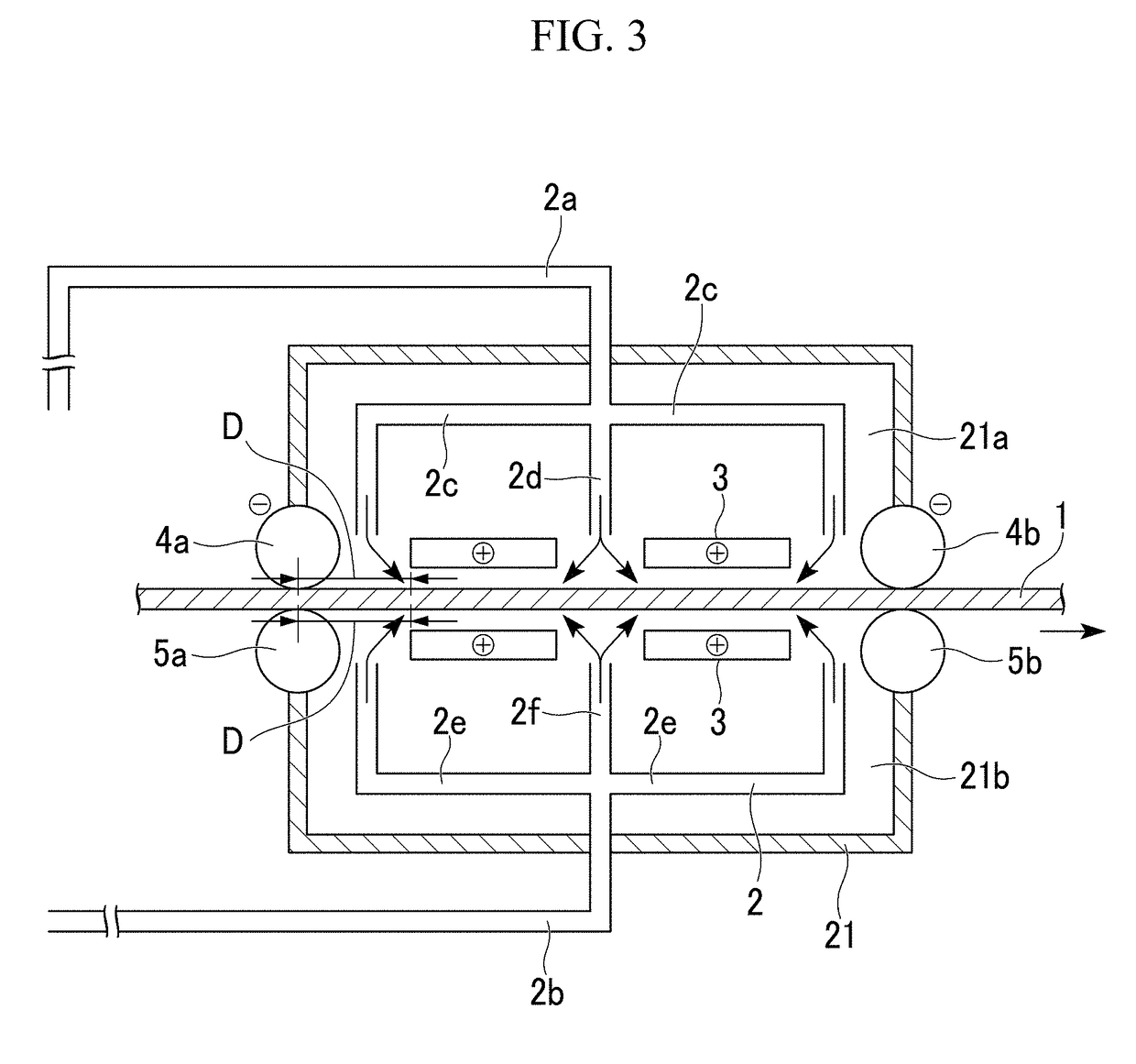

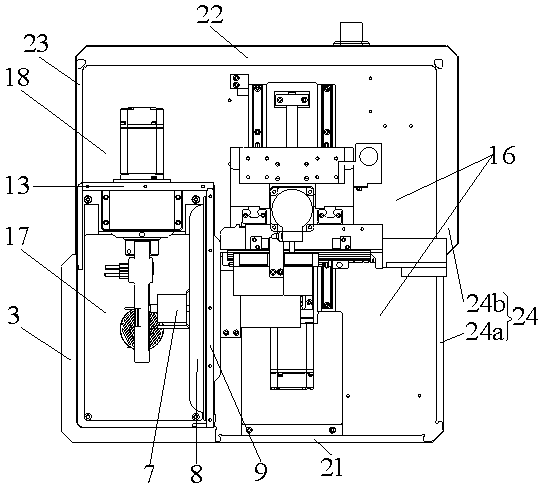

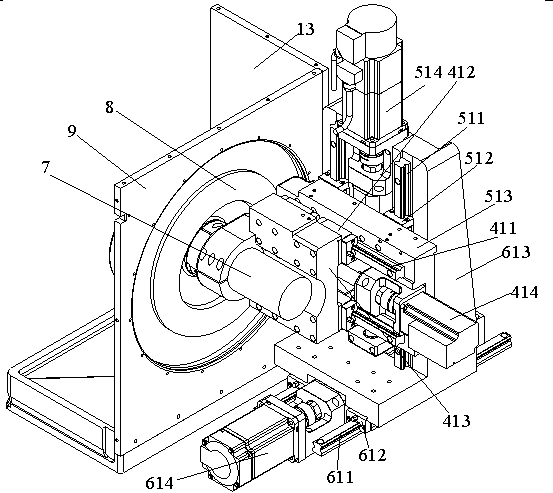

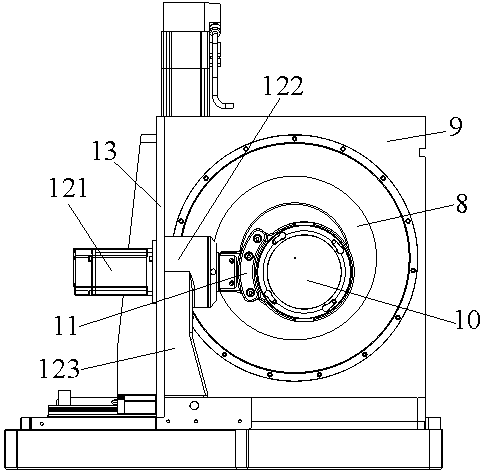

Zirconium-oxide processing equipment and four-axis processing structure

PendingCN107738110ASimple structureSimplify complexityLarge fixed membersPositioning apparatusEngineeringMechanical engineering

Owner:沈阳机床(东莞)智能装备有限公司

Anti-corrosive glass fiber reinforced plastic used for sewage treatment

InactiveCN109988403AHigh compressive strengthImprove corrosion resistanceWater/sewage treatmentFiberEpoxy

Owner:宜兴市恒邦环保有限公司

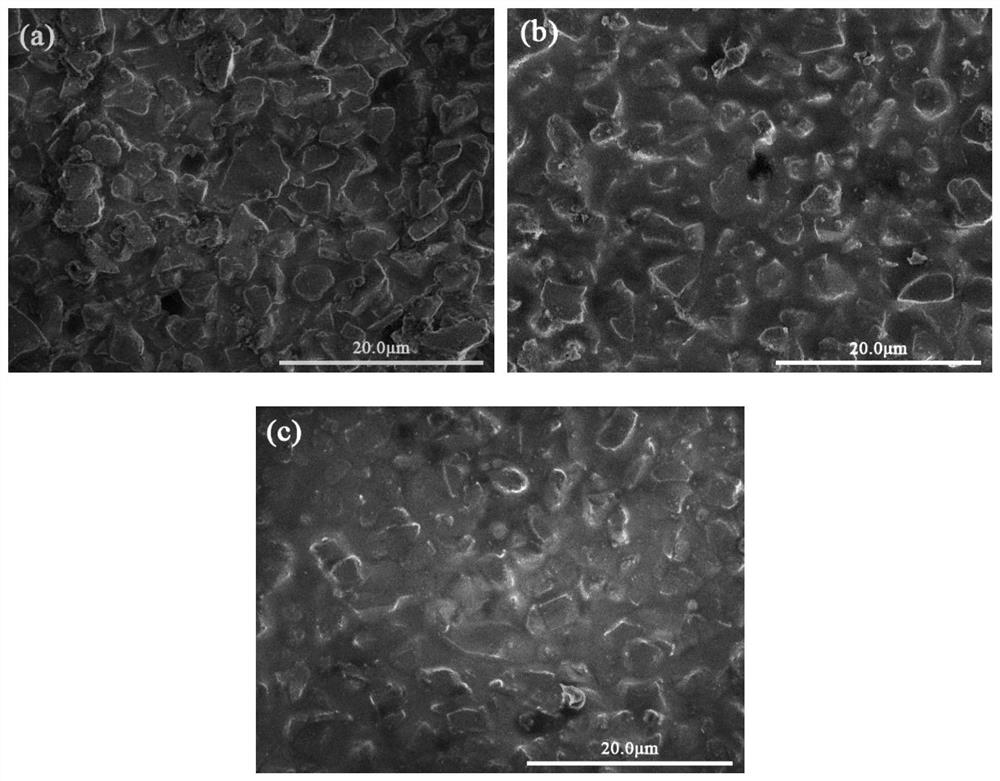

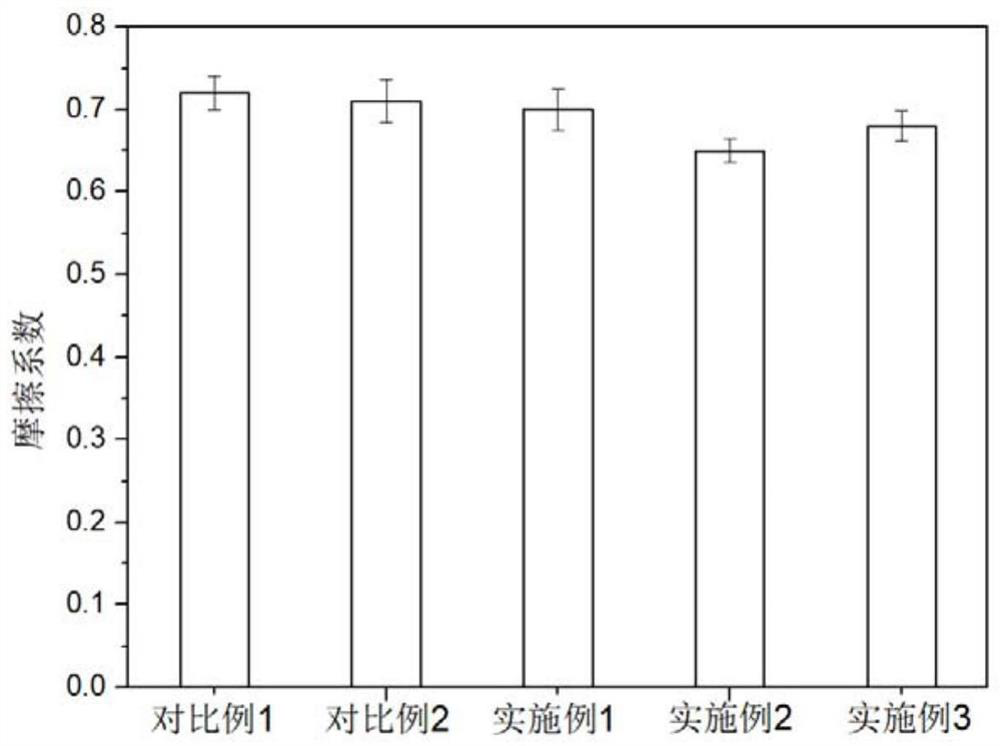

Nickel-coated graphite reinforced wear-resistant antifriction corrosion-resistant ceramic coating material, coating, and preparation method and application thereof

ActiveCN113564574AImprove wear resistance, friction reduction and corrosion resistanceImprove the lubrication effectHeat inorganic powder coatingSodium molybdateMetal coating

Owner:CHANGZHOU UNIV

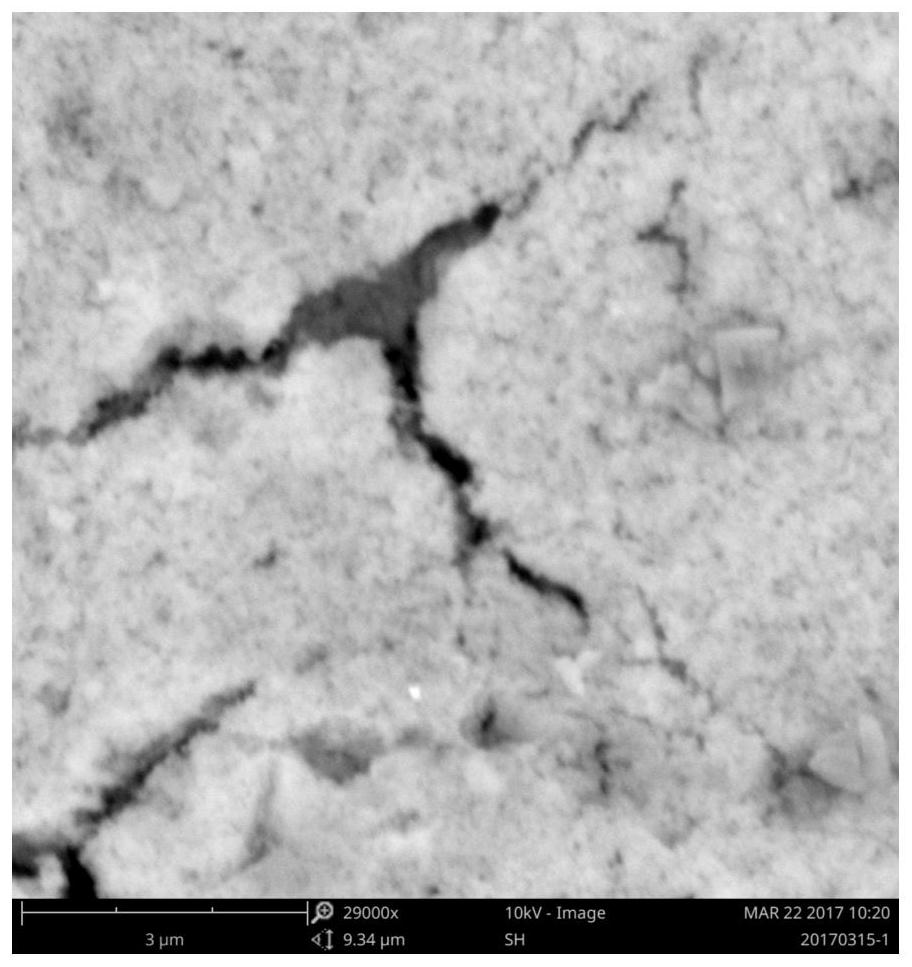

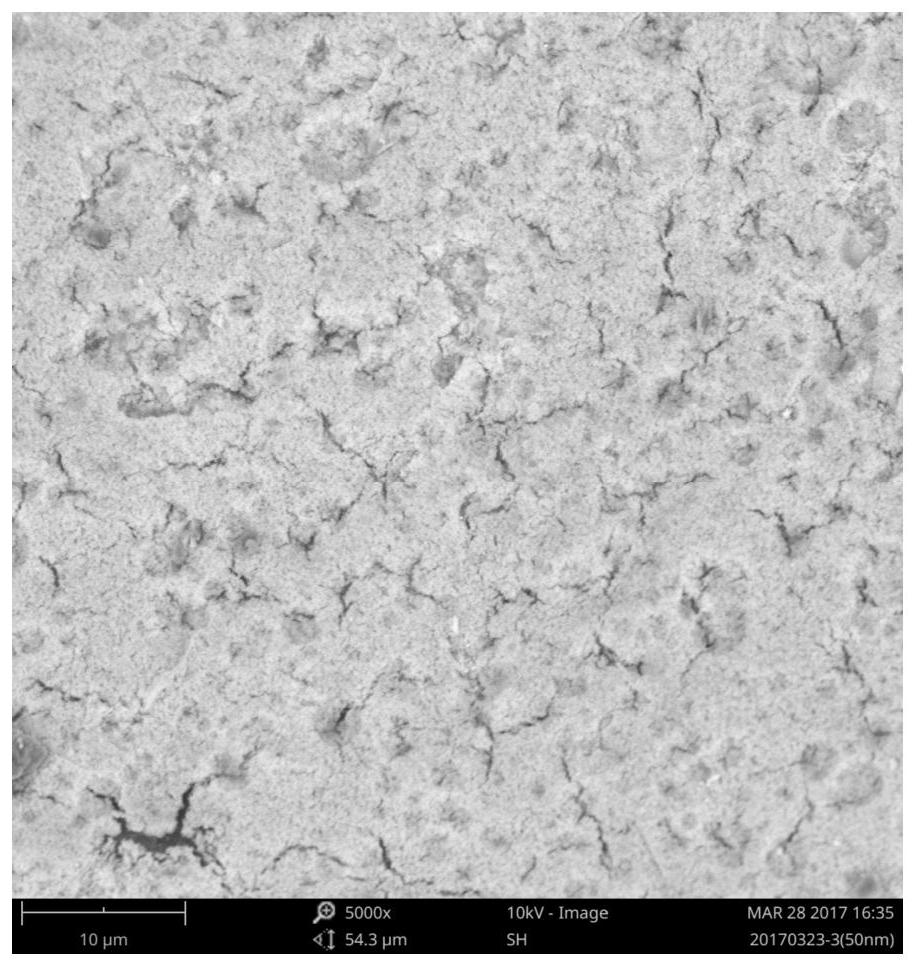

Preparation method of zirconia ceramic ultrafiltration membrane

Owner:SANDA FILM SCI & TECH XIAMEN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap