Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Wet grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

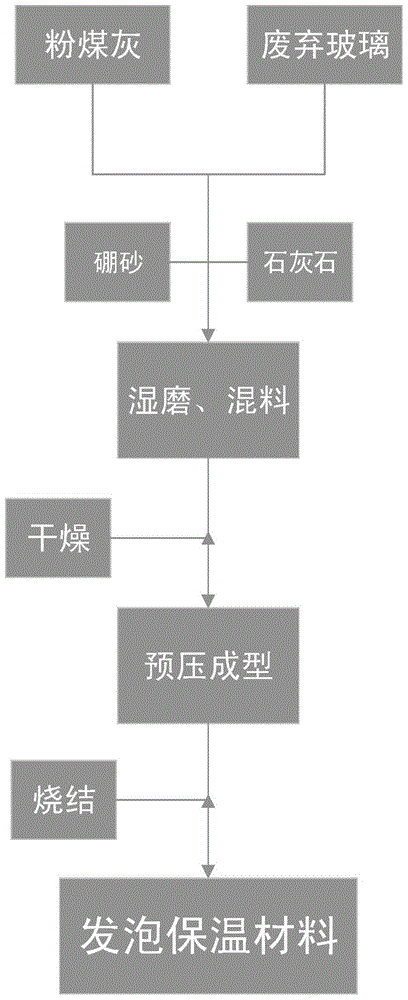

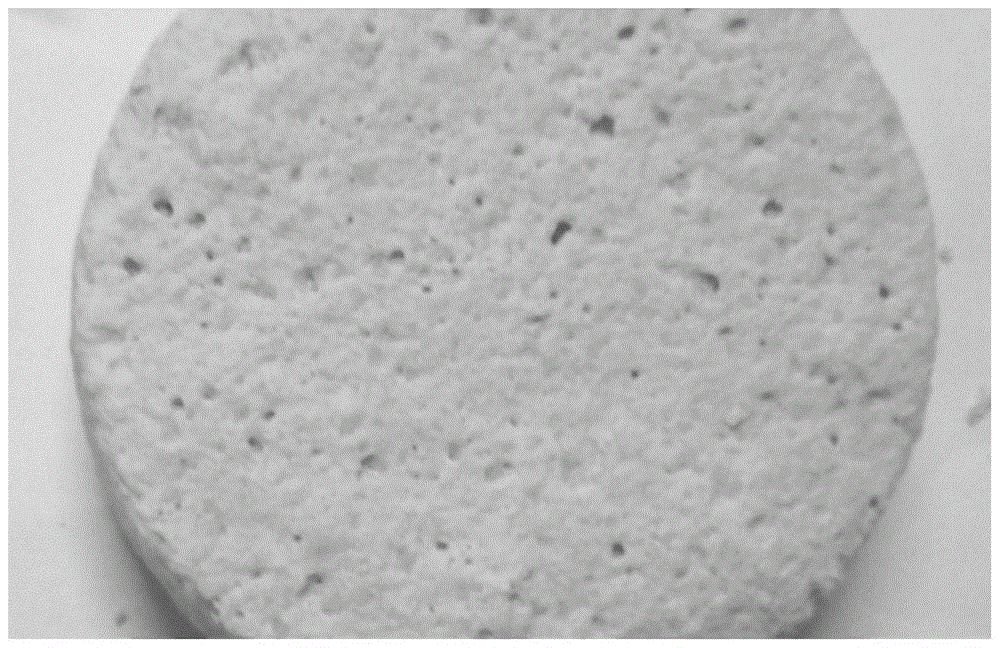

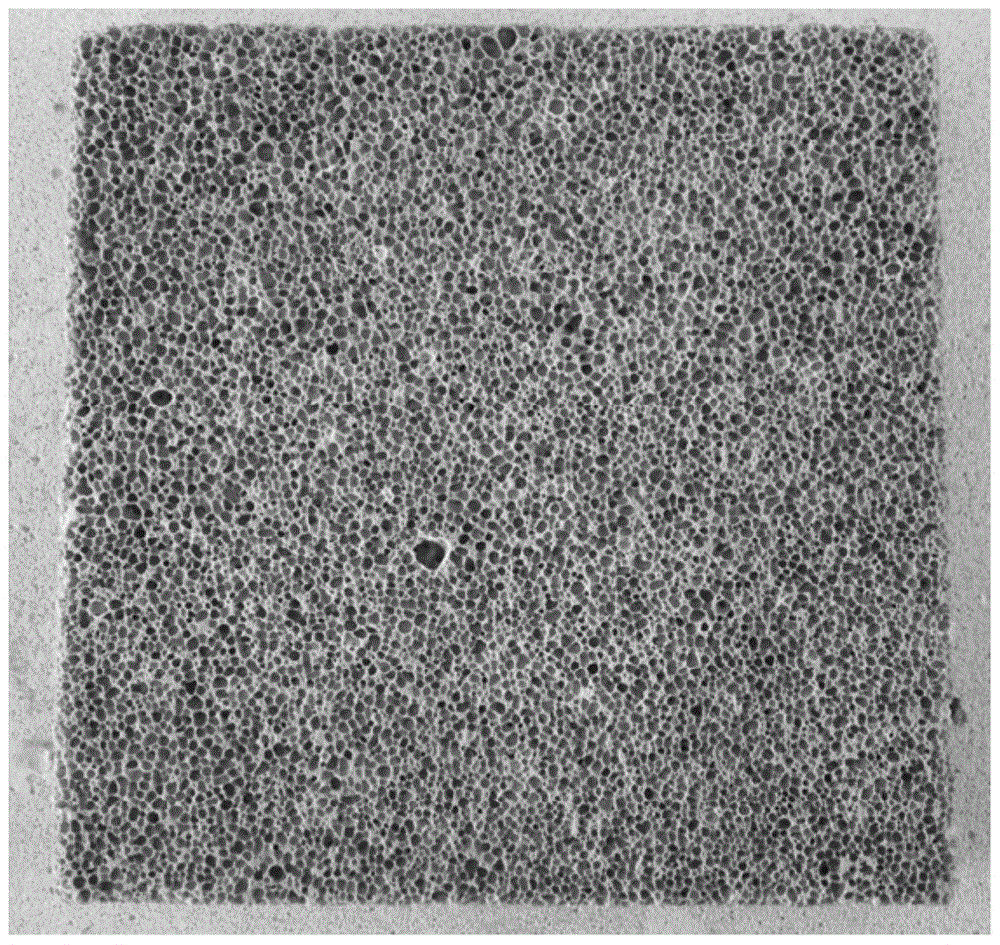

Foamed heat insulation material and preparation method thereof

InactiveCN105800945AIndustrial wasteWet grinding

Owner:PEKING UNIV

Method for preparing composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide

InactiveCN102718493AImprove microstructureOvercoming brittlenessSolid waste disposalFluid removalZirconium hydrideExpanded clay aggregate

The invention discloses a method for preparing a composite type fracturing propping agent by utilizing gold ore tailings and zirconium oxide. The method comprises the steps of mixing the gold ore tailings, alumina powders and high-temperature zirconium oxide chopped fibers, then adding gum water solution, mixing uniformly, conducting wet grinding and then pelleting; putting particles into alumina crucible and arranging into a silicon carbide rod resistor furnace, heating to 1230 DEG C from the room temperature at the heating speed being 5 DEG C / min-10 DEG C / min, keeping the temperature for 0.5h-1h, heating to 1350 DEG C-1400 DEG C at the heating speed being 5 DEG C / min-7 DEG C / min, keeping the temperature for 2h-3h; and cooling the particles in the furnace and then taking out the particles, and screening the particles by a 20-40 meshes sieve so as to obtain the composite type fracturing propping agent. According to the method, fibers (crystal whiskers) necessary for enhancing the strength and toughness is provided by integrating the concept of composite materials integrated with a non-compact ceramic propping agent and adopting the high-temperature reaction self generation mode, and the composite type fracturing propping agent with high strength, high toughness, low density and low damage rate is prepared by two measures, namely fiber reinforcement and particle reinforcement.

Owner:SHAANXI UNIV OF SCI & TECH

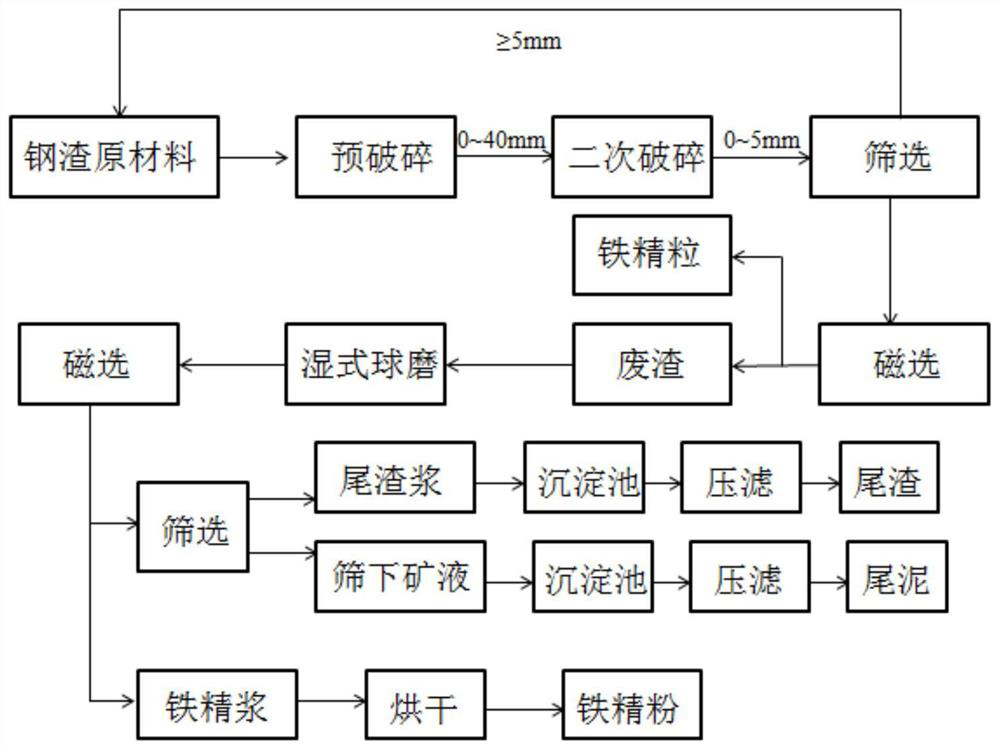

Treatment method for gradient utilization of steel slag

Owner:HUBEI POLYTECHNIC UNIV +1

Stabilizing agent for PCB and preparation method thereof

PendingCN111171584AUniform and stable performanceImprove releaseAnoxomerWet grinding

Owner:安徽华文塑胶科技有限公司

Nickel hydroxide and preparation method thereof

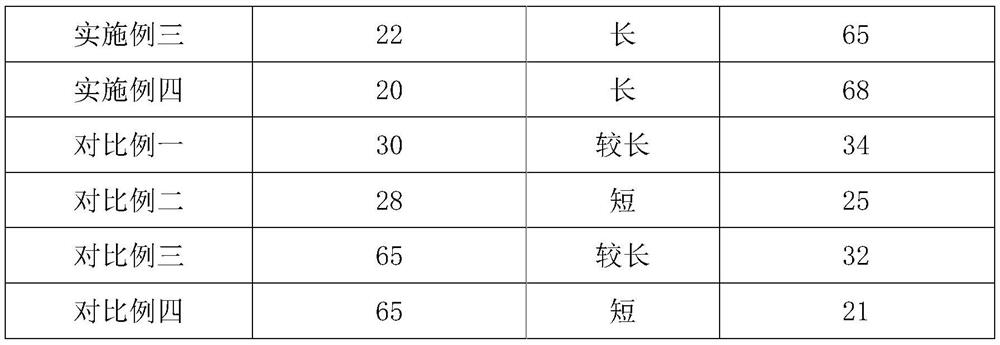

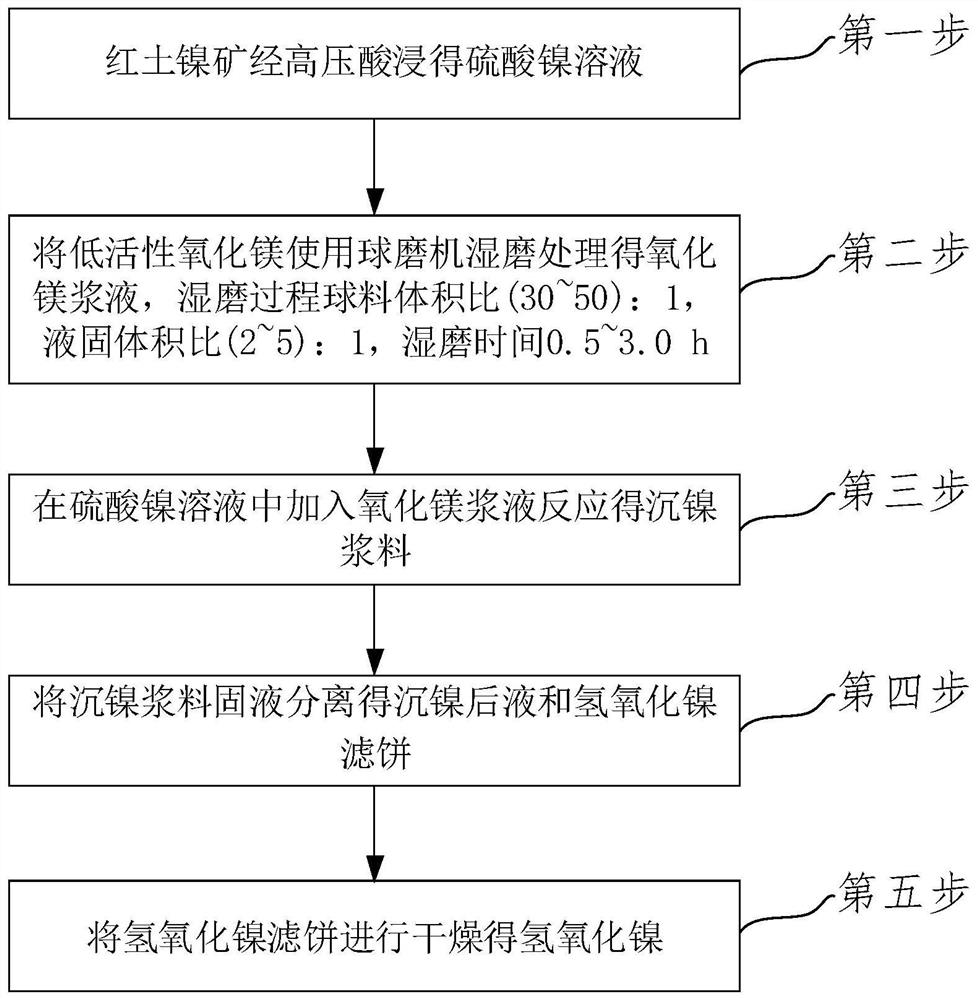

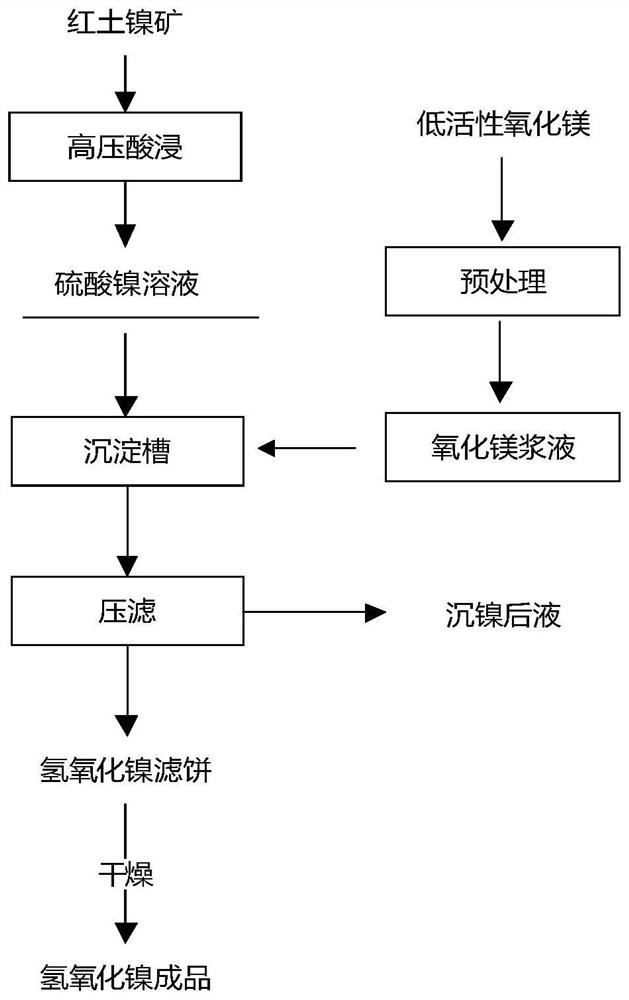

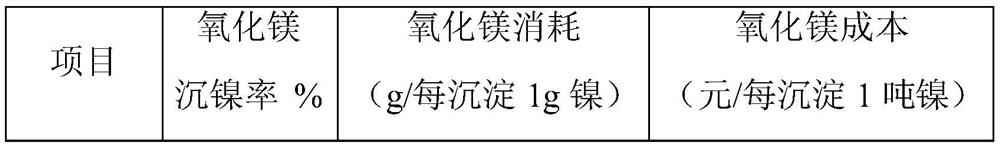

The invention provides nickel hydroxide and a preparation method thereof. According to the preparation method of the nickel hydroxide, heavy-burned magnesia is adopted as a nickel precipitation alkali source auxiliary material, the heavy-burned magnesia is subjected to wet grinding pretreatment through the ball-material volume ratio of (30-50): 1, the liquid-solid volume ratio of (2-5): 1 and the wet grinding time of 0.5-3.0 h, the activity of the heavy-burned magnesia is improved, and the nickel precipitation effect of high-activity magnesium oxide can be achieved; and compared with a high-activity magnesium oxide auxiliary material, the heavy-burned magnesia is low in cost, the technological process is simple, and the product is high in nickel content.

Owner:贵州中伟资源循环产业发展有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap