Analog printing preprocessing process

A pretreatment and process technology, applied in the direction of printing, printing devices, etc., can solve problems affecting image size reduction, screen elongation deformation, graphic line deformation, etc., to reduce screen deformation, reduce waste products, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

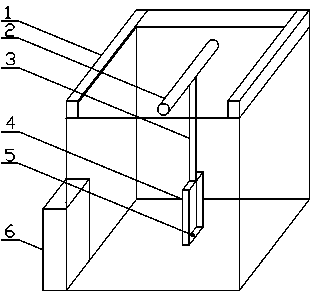

[0015] The invention provides a simulated printing pretreatment process, which uses simulated printing pretreatment equipment. The equipment includes a bearing platform 1 , rollers 2 , a lifting device 3 , universal wheels 5 , a cylinder 4 and a control device 6 . The carrying table 1 is two grooves, the two grooves are respectively located on the left and right sides of the simulated printing pretreatment equipment and are supported by structures such as columns. The roller 2 is connected to the top of the lifting device 3, the lifting device 3 is connected with the cylinder 4, and the cylinder 4 drives the lifting device 3 to move up and down. Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap