Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Wall plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plate or wall plate is a horizontal, structural, load-bearing member in wooden building framing.

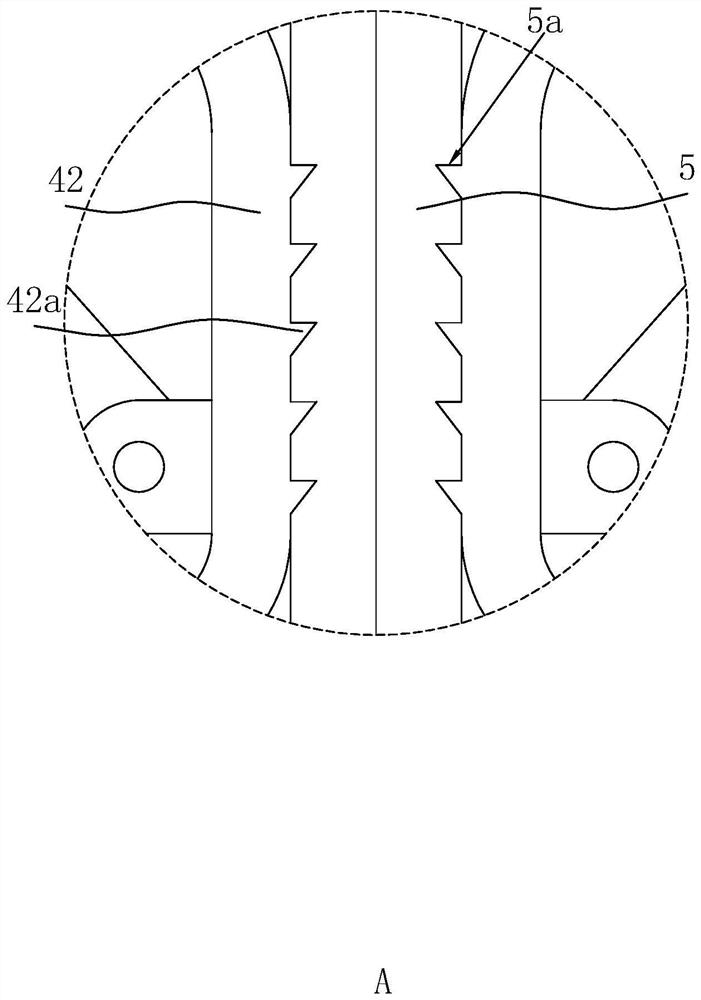

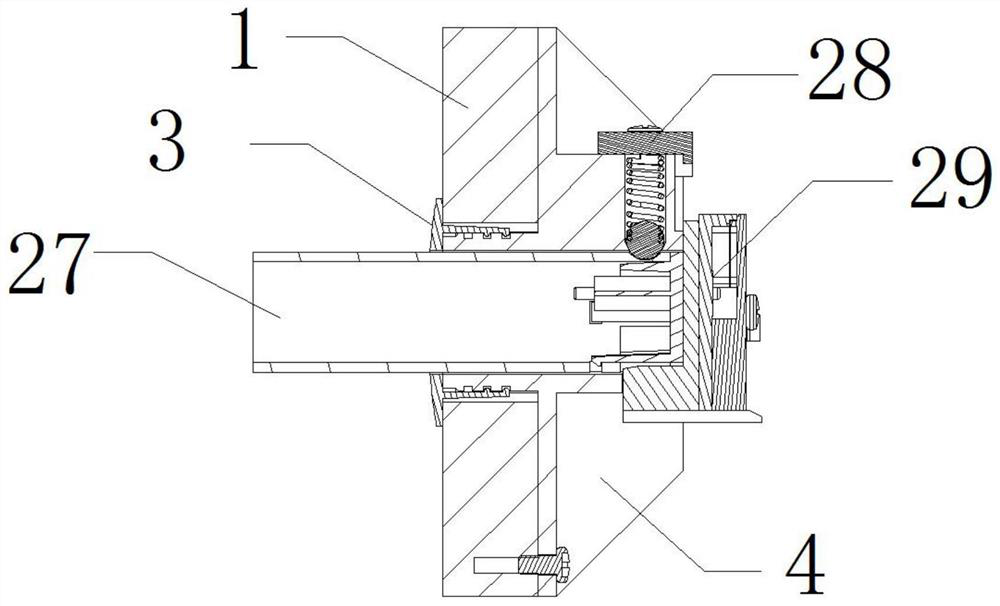

Short tranverse crankshaft connecting rod device of warp knitting machine

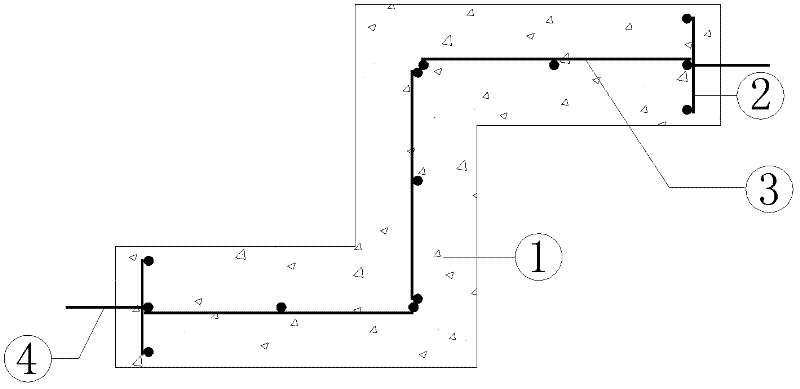

The invention discloses a short-stroke crankshaft connecting rod device for a tricot machine. The invention comprises eccentric shafts, a first shaft journal (4), a second shaft journal (5), a central wall plate (7), a grooved needle bed connected with a first eccentric shaft (1), a yarn guide needle bed crankshaft connecting rod mechanism, a stylet bed crankshaft connecting rod mechanism connected with a second eccentric shaft (2), and a sinker bed crankshaft connecting rod mechanism connected with a third eccentric shaft (3). The first shaft journal (4) and the second shaft journal (5) are respectively and fixedly connected with the end parts of the second eccentric shaft (2) and the third eccentric shaft (3). The second eccentric shaft (2), the first eccentric shaft (1) and the third eccentric shaft (3) are connected with each other in turn and are rotated around the first and second shaft journals (4, 5). The short-stroke crankshaft connecting rod device effectively shortens the motion stroke of weaving elements; the grooved needle travel is between 8 and 12 millimeters; the moving time of yarn guide needles is between 1.5 and 1.8 microseconds; the engine speed is improved to be 2500 to 3000 turns per minute; the noise is less than or equal to 85 decibels; the vibration is small; the energy consumption is low; the device is suitable for high-speed rotation; the power is small; and the productivity is obviously improved.

Owner:NEWTRY COMPOSITE

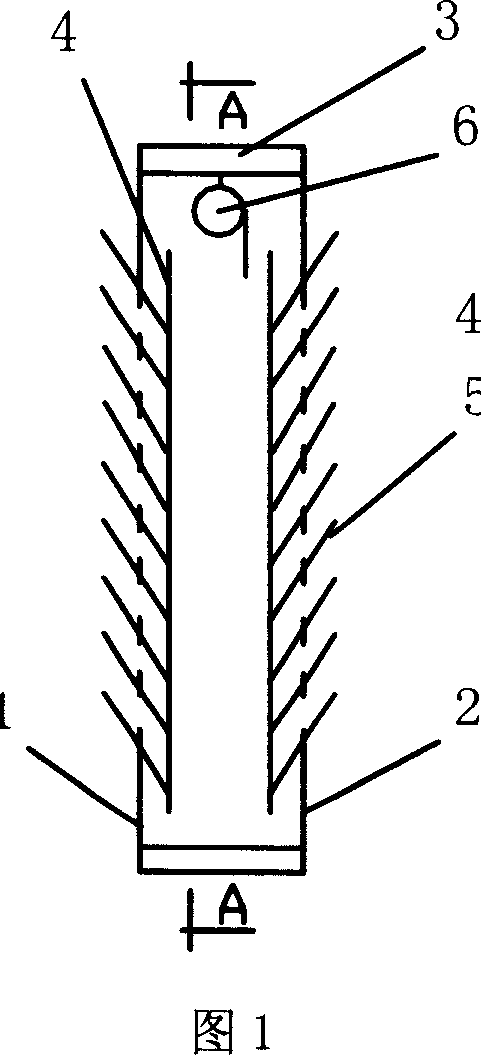

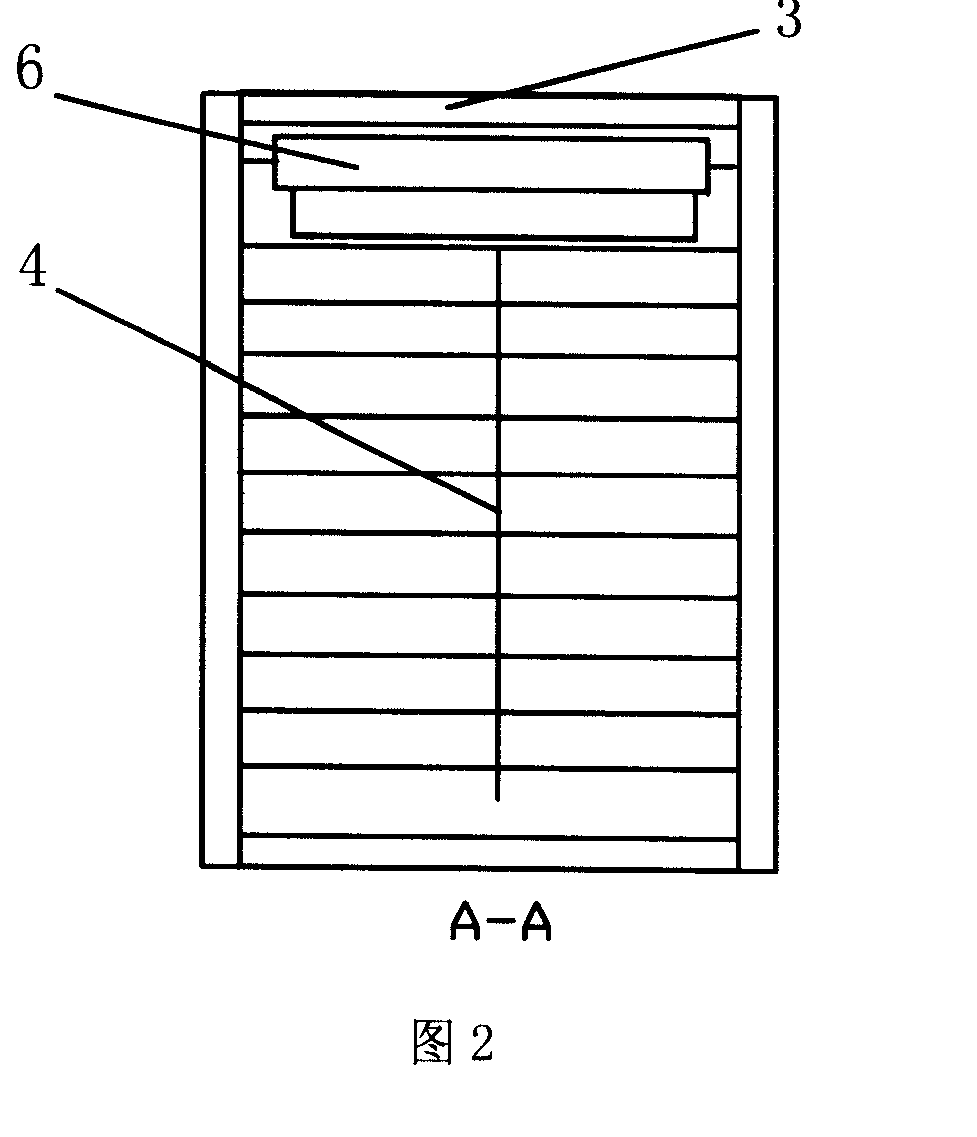

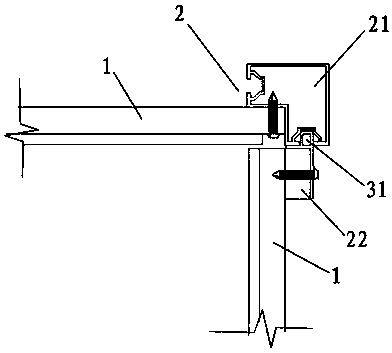

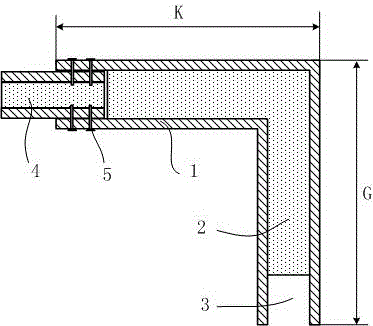

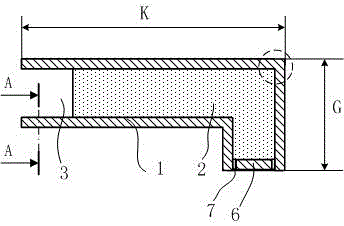

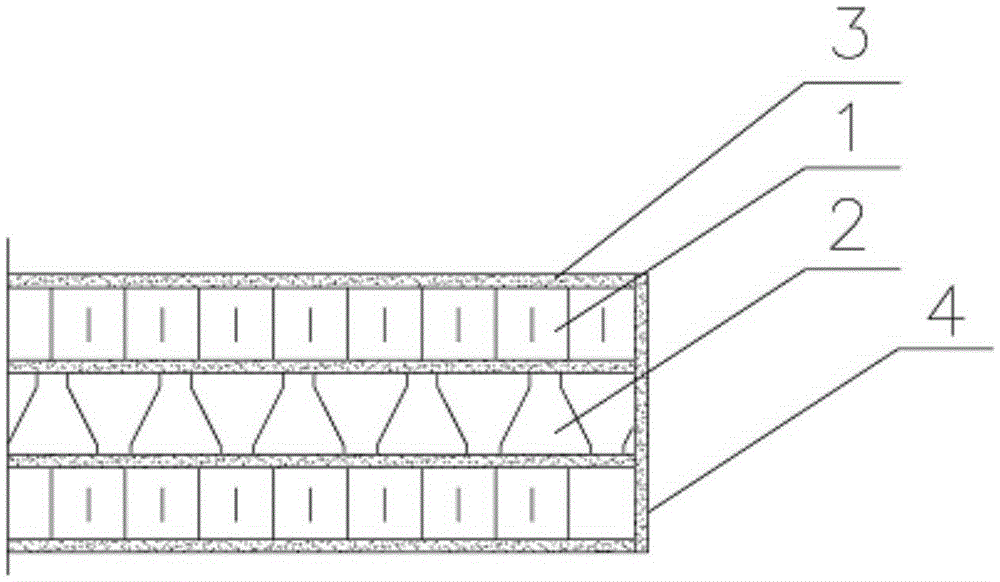

Adaptive energy-saving wall

InactiveCN1920199AReduce weightImprove insulation effectWallsClimate change adaptationEngineeringWall plate

Owner:SHANGHAI JIAO TONG UNIV

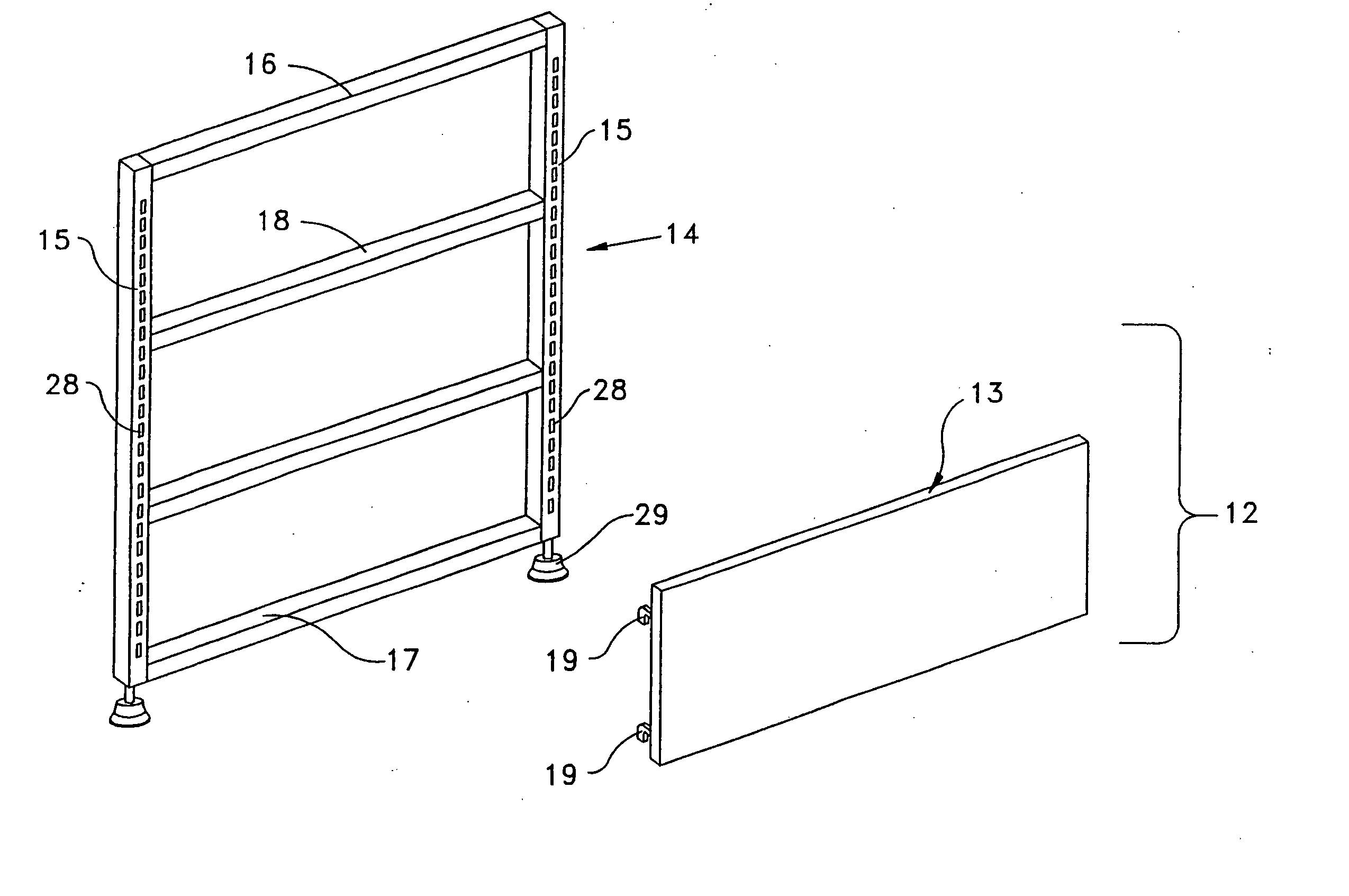

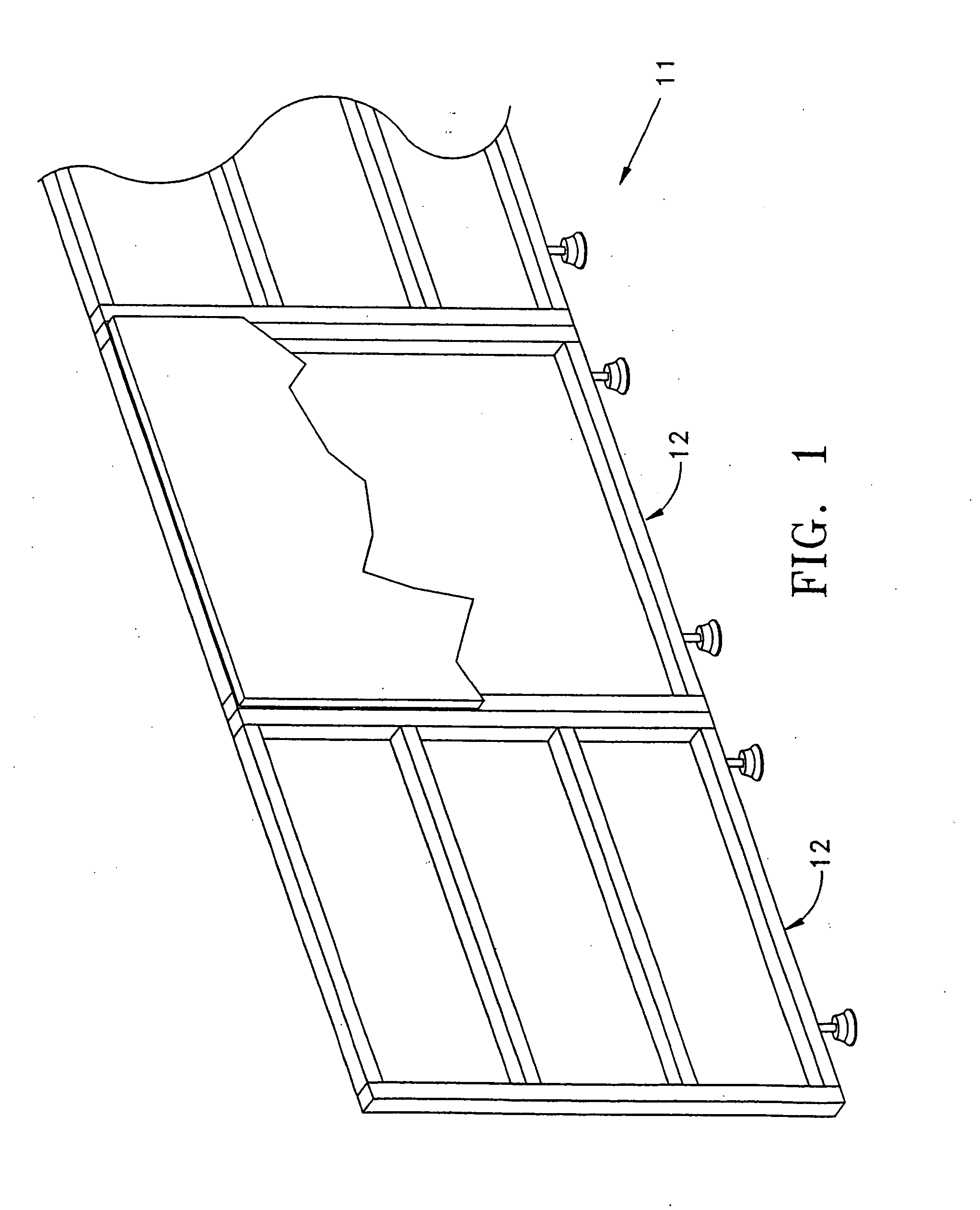

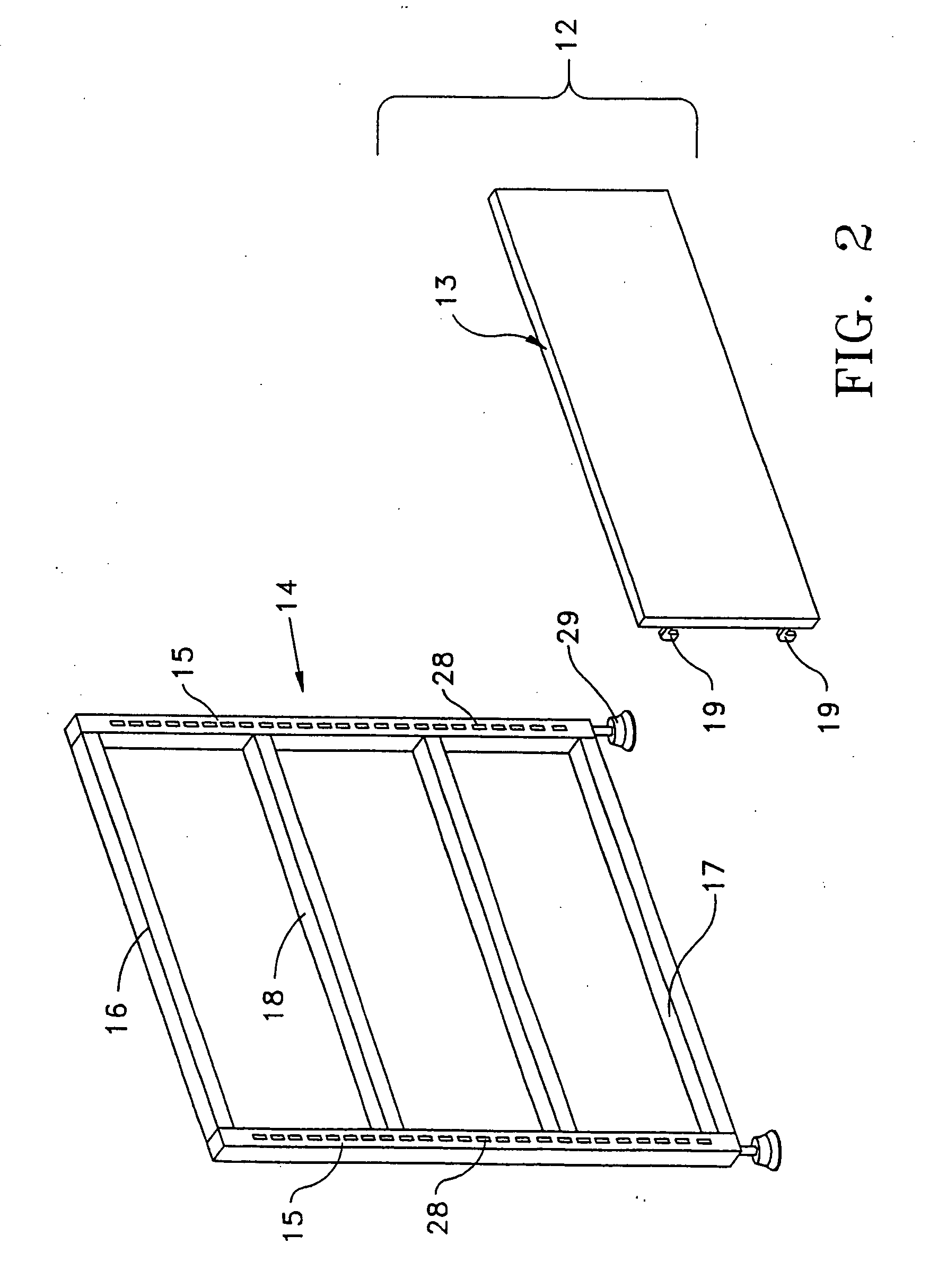

Composite wallboard fast installation structure and installation method thereof

PendingCN108086627AImprove installation efficiencyEasy to installCovering/liningsJoint componentEngineering

Owner:ZHEJIANG WEILAIJIA E COMMERCE

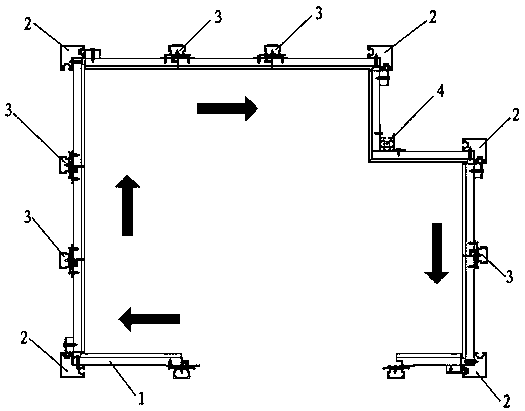

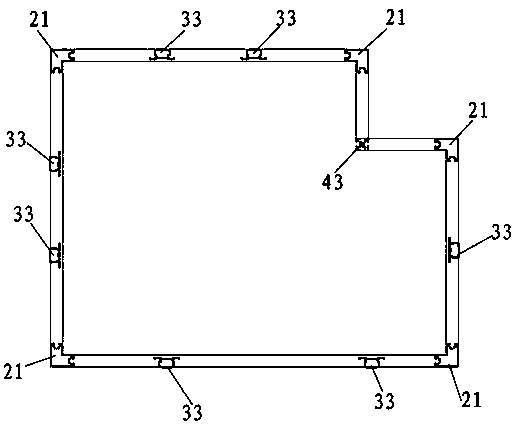

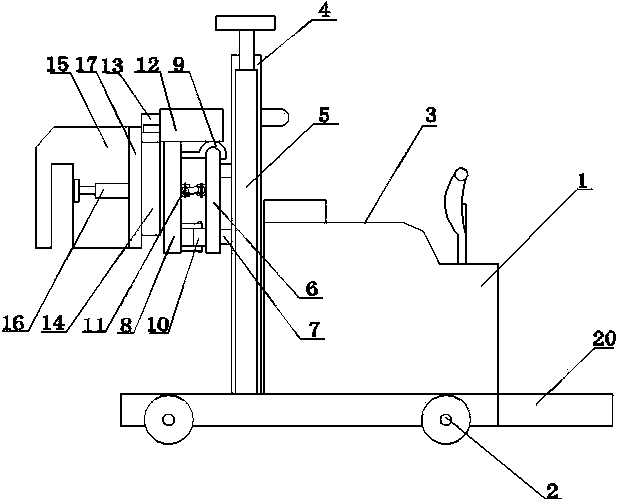

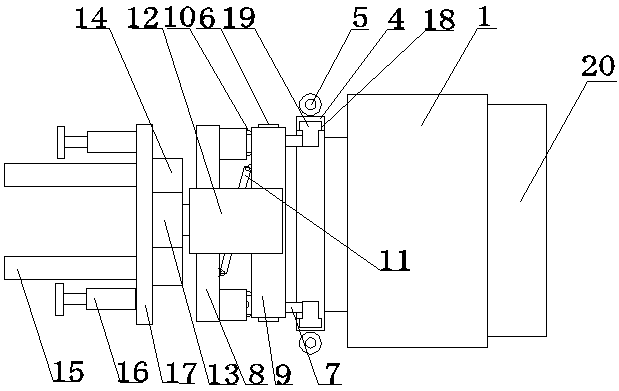

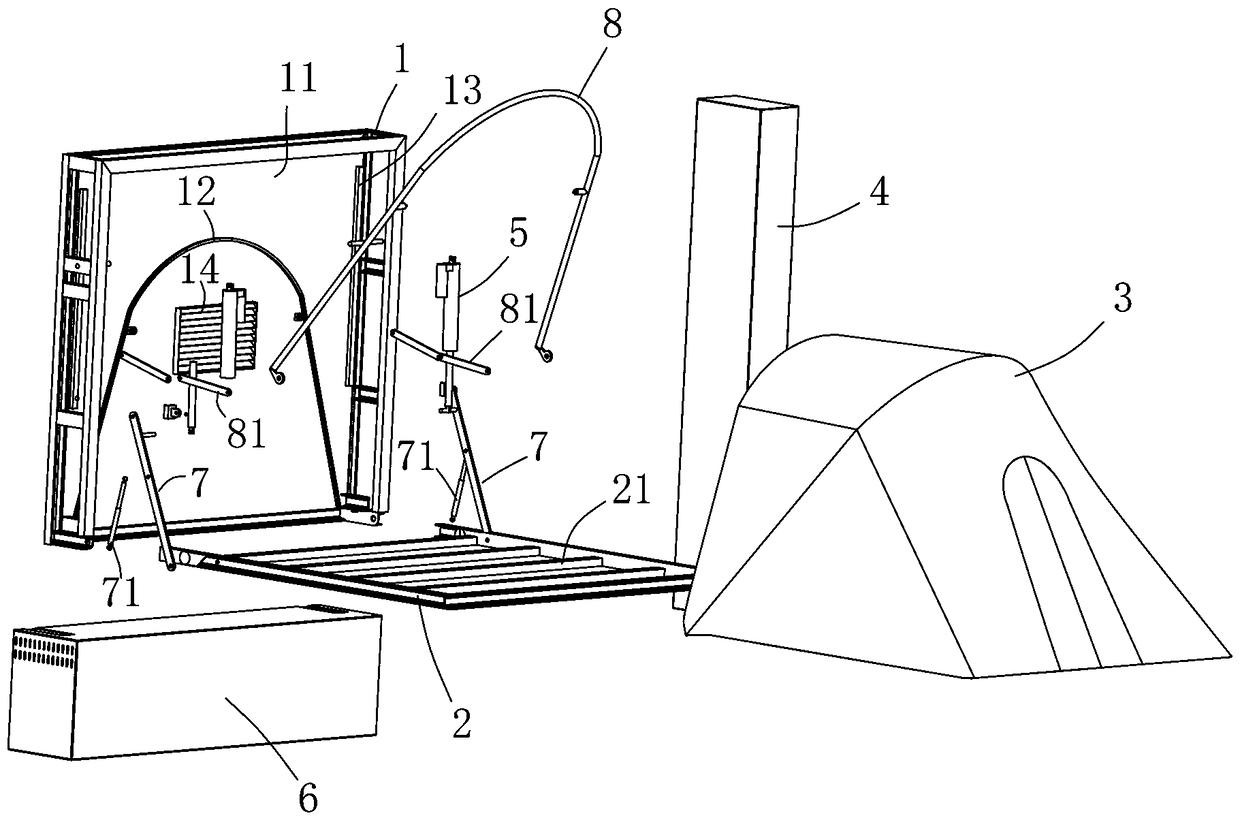

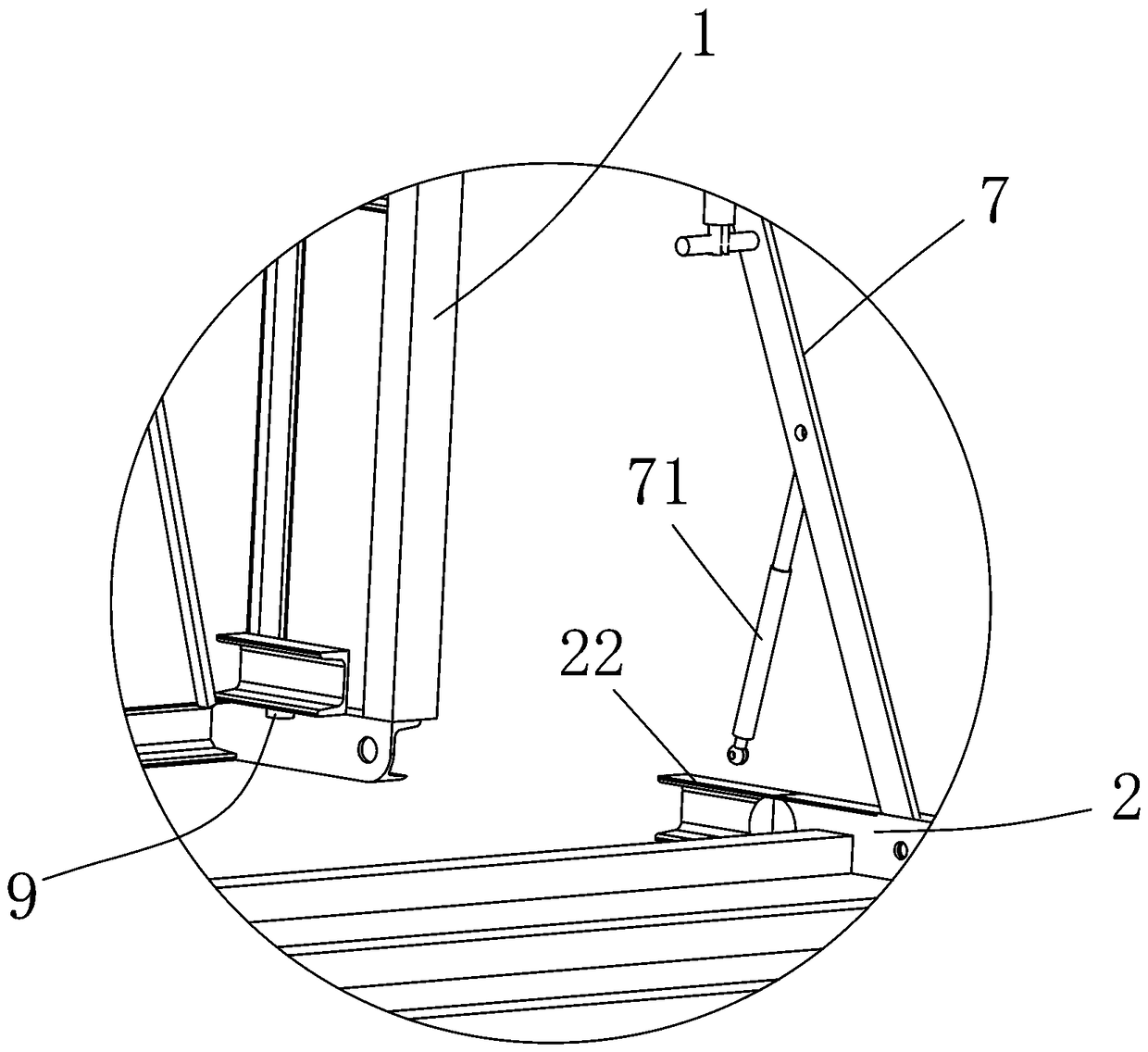

Automatic wallboard installation device

Owner:SHANDONG TIANYI MACHINERY

Assembled interior wall separator plate

Owner:CHANGCHUN INST OF TECH

Pad for wall panel and forming process

Owner:HAWORTH SPA

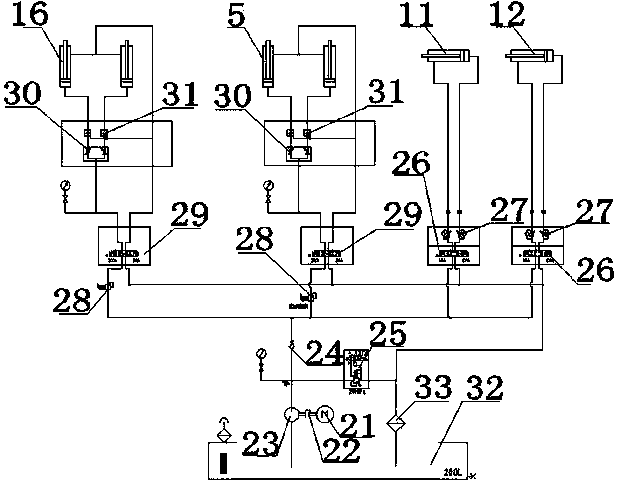

Production line for fireproof heat-insulating wall plates, and method for on-site processing of fireproof heat-insulating wall plates by utilizing production line

InactiveCN102699994AImprove foaming qualityImprove insulation effectCeramic shaping plantsProduction lineEngineering

The invention relates to a production line for fireproof heat-insulating wall plates, and a method for on-site processing of the fireproof heat-insulating wall plates by utilizing the production line, and solves the problems that the conventional multi-layer fireproof heat-insulating wall plate processing equipment has a large occupied area, high investment and failure in on-site processing. Therefore, the production line comprises a stirrer, a pouring vehicle, and two lines of pouring molds, wherein the stirrer comprises an agitation tank; a stirring paddle driven by an external motor is arranged in the agitation tank; the agitation tank is provided with a liquid feeding device, a solid feeding device and a baiting valve, and is fixed on four support legs; the pouring vehicle comprises a vehicle body and a wagon box; the wagon box is fixed on the vehicle body; wheels are arranged below the vehicle body; the opening of the wagon box faces upwards; an emptying gate is arranged at the rear part of the wagon box; and a scraping plate is arranged on a fixing bracket behind the emptying gate. The invention further relates to a corresponding processing method. The production line has the advantages of low investment and small occupied area, ensures on-site processing, saves transportation cost, and is an ideal upgrading product for the conventional fireproof heat-insulating wall plate production line.

Owner:SHANDONG XINFA ENVIRONMENTAL PROTECTION TECH CO LTD

Multifunctional splicing partition wall and construction method thereof

Owner:青岛恒科瑞新信息科技有限公司

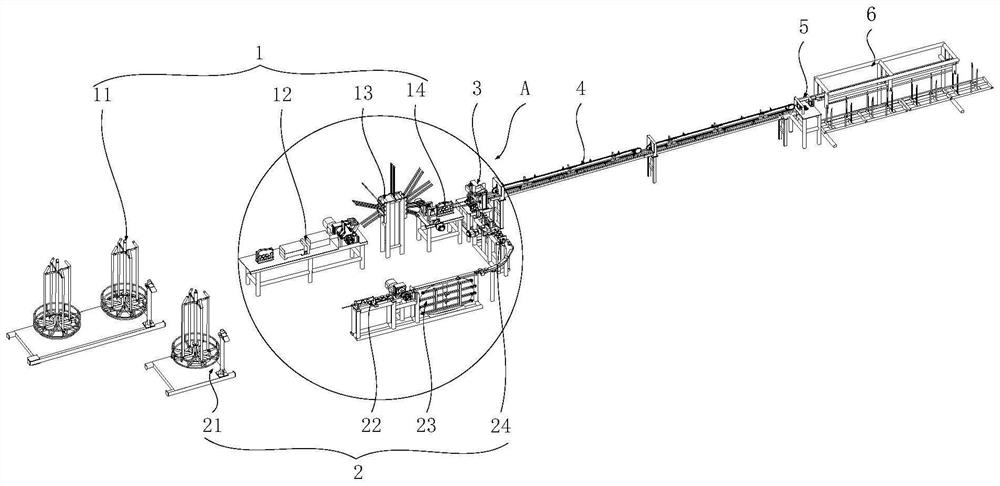

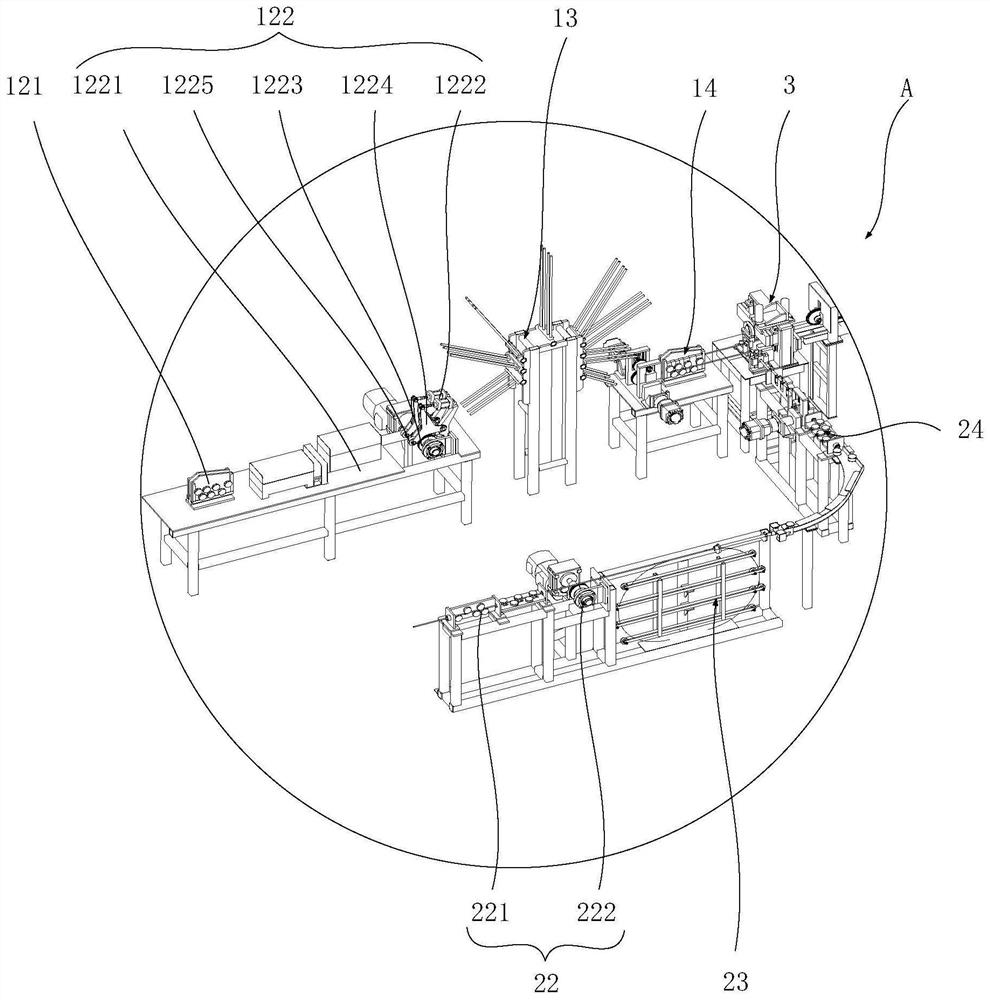

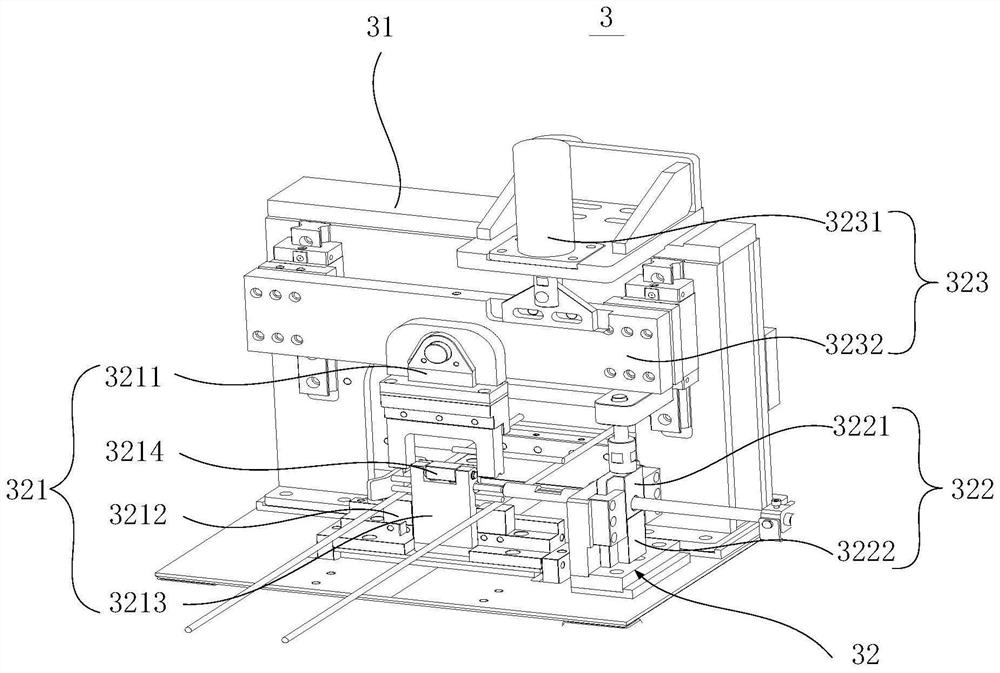

Reinforcing mesh welding production equipment

ActiveCN112045440AImprove structural strengthRealize automatic feeding processWire networkOther manufacturing equipments/toolsMesh reinforcementRebar

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

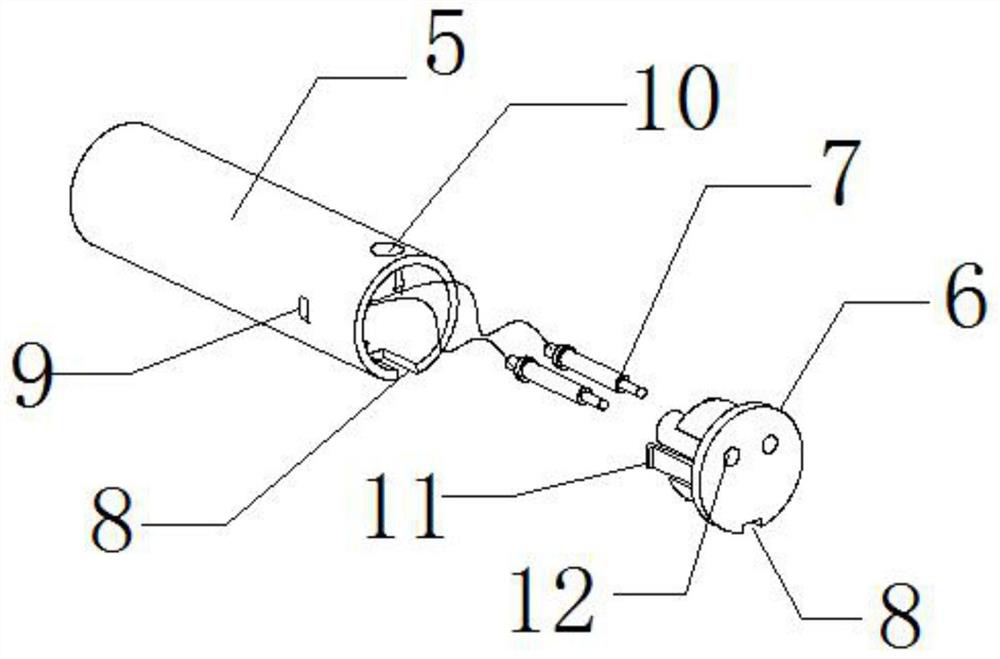

Front-back parallel three-joint double-support attack angle mechanism and control method thereof

InactiveCN111579198ARealize the function of changing the angle of attackEasy to operate and controlAerodynamic testingInlet channelAerodynamic load

The invention relates to the technical field of wind tunnel experiments and discloses a three-joint double-support attack angle mechanism. The three-joint double-support attack angle mechanism comprises a front support and a rear support which are installed at the bottom of an air inlet channel model, wherein one end of the front support is fixed to a front end of the bottom of the air inlet channel model, the other end of the front support is hinged to a fixing rod through a first movable joint, the fixing rod is fixed to a wall plate at the bottom of a wind tunnel, one end of the rear support is fixed to a rear end of the bottom of the air inlet model, and the other end of the rear support is hinged to a connecting rod through a second movable joint, and an end of the connecting rod is hinged with a push-pull rod driven by a driving mechanism to move up and down. The three-joint double-support attack angle mechanism is advantaged in that the driving mechanism is used for pushing thepush-pull rod to move up and down to drive an air inlet model to change an attack angle with a first movable joint as the rotating center, the air inlet model can be supported, the attack angle changing function of the air inlet model can be achieved, and an existing attack angle mechanism of a wind tunnel is completely or partially replaced, operation control is simple, cost is low, and a problemthat a traditional attack angle mechanism for the outflow test is easily damaged due to overlarge aerodynamic load of the inflow test model is avoided.

Owner:CHINA AERODYNAMICS RES & DEV CENT

Assembling type composite inner wall corner

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

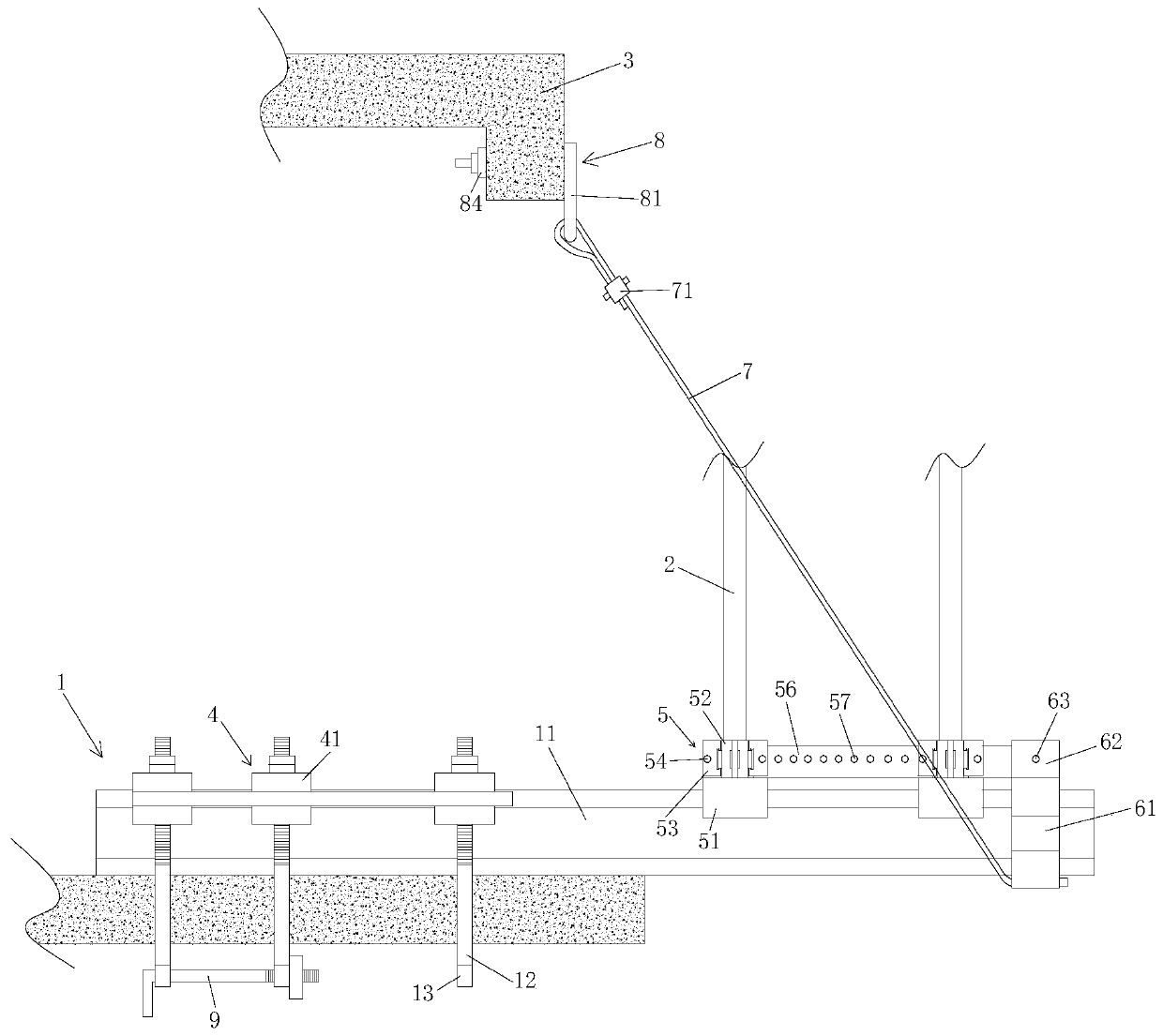

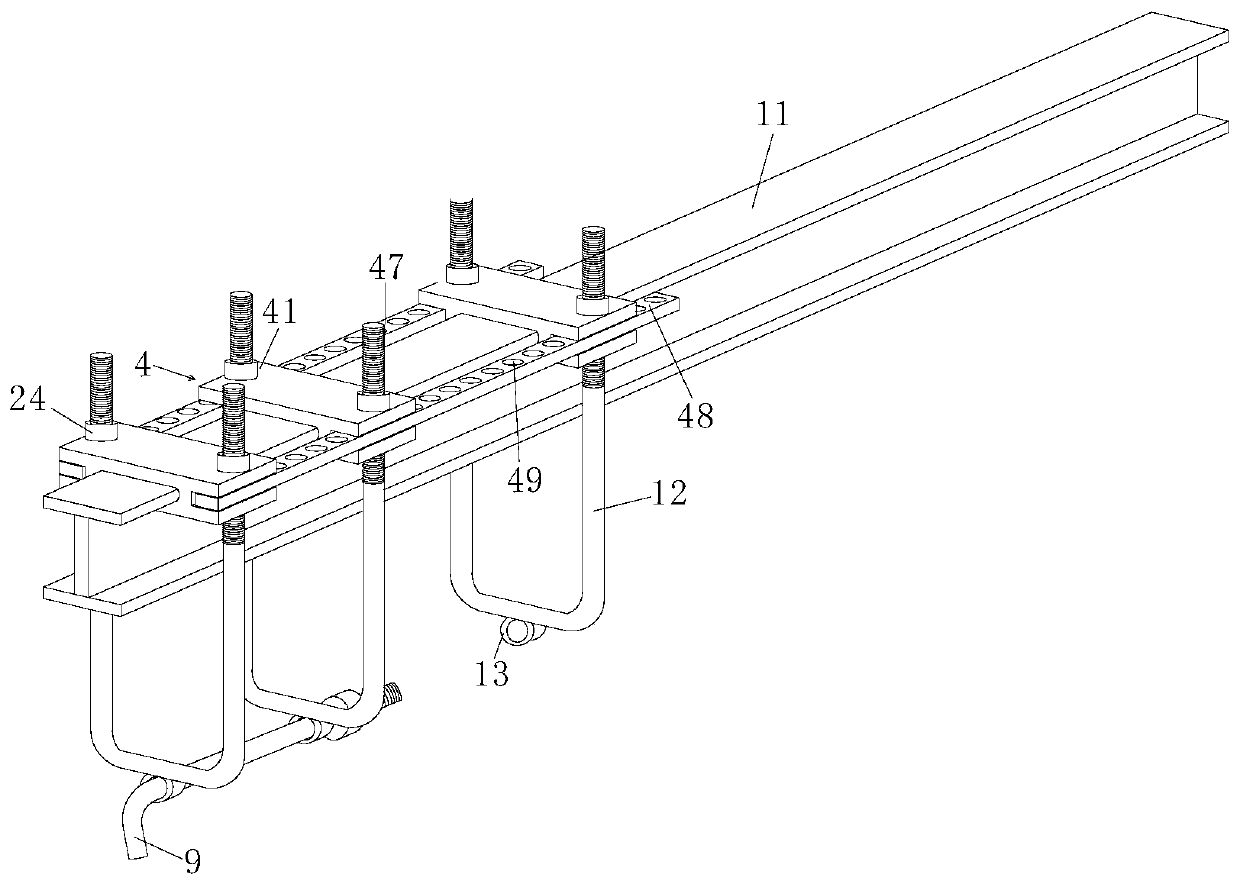

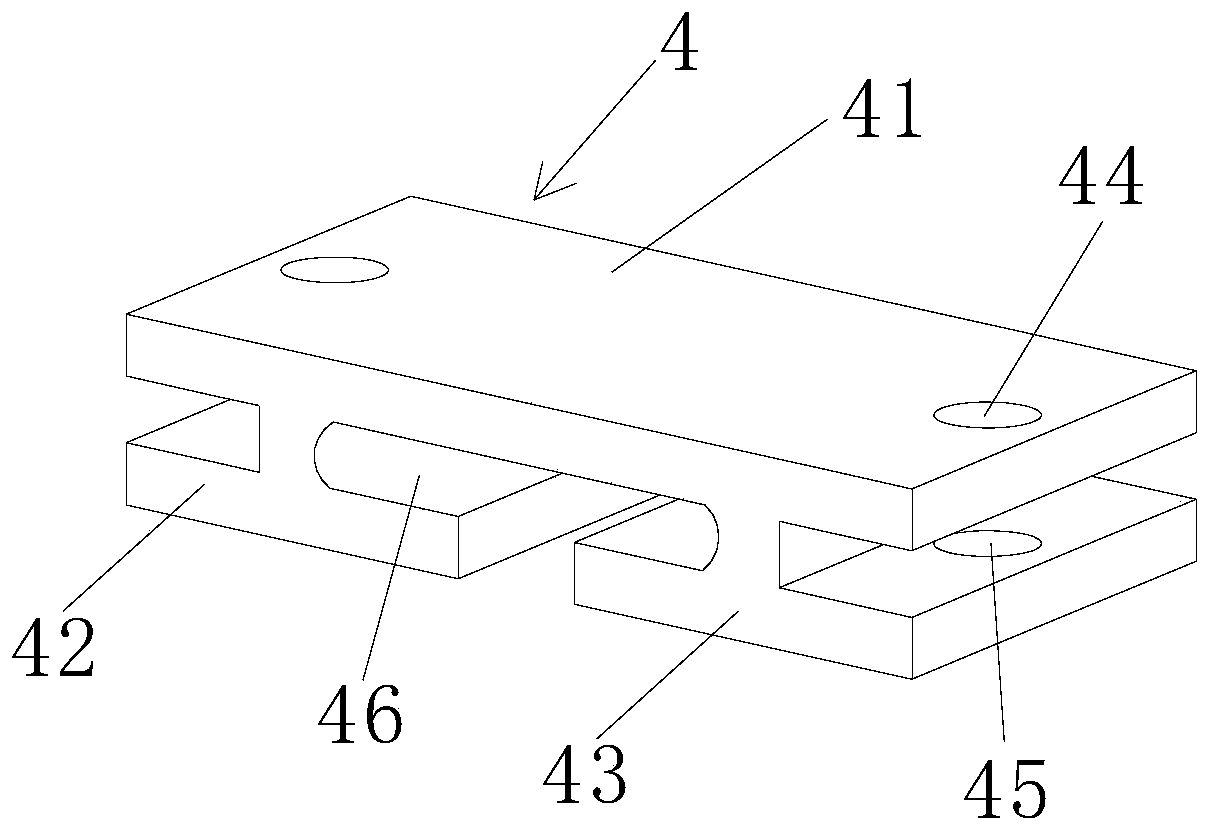

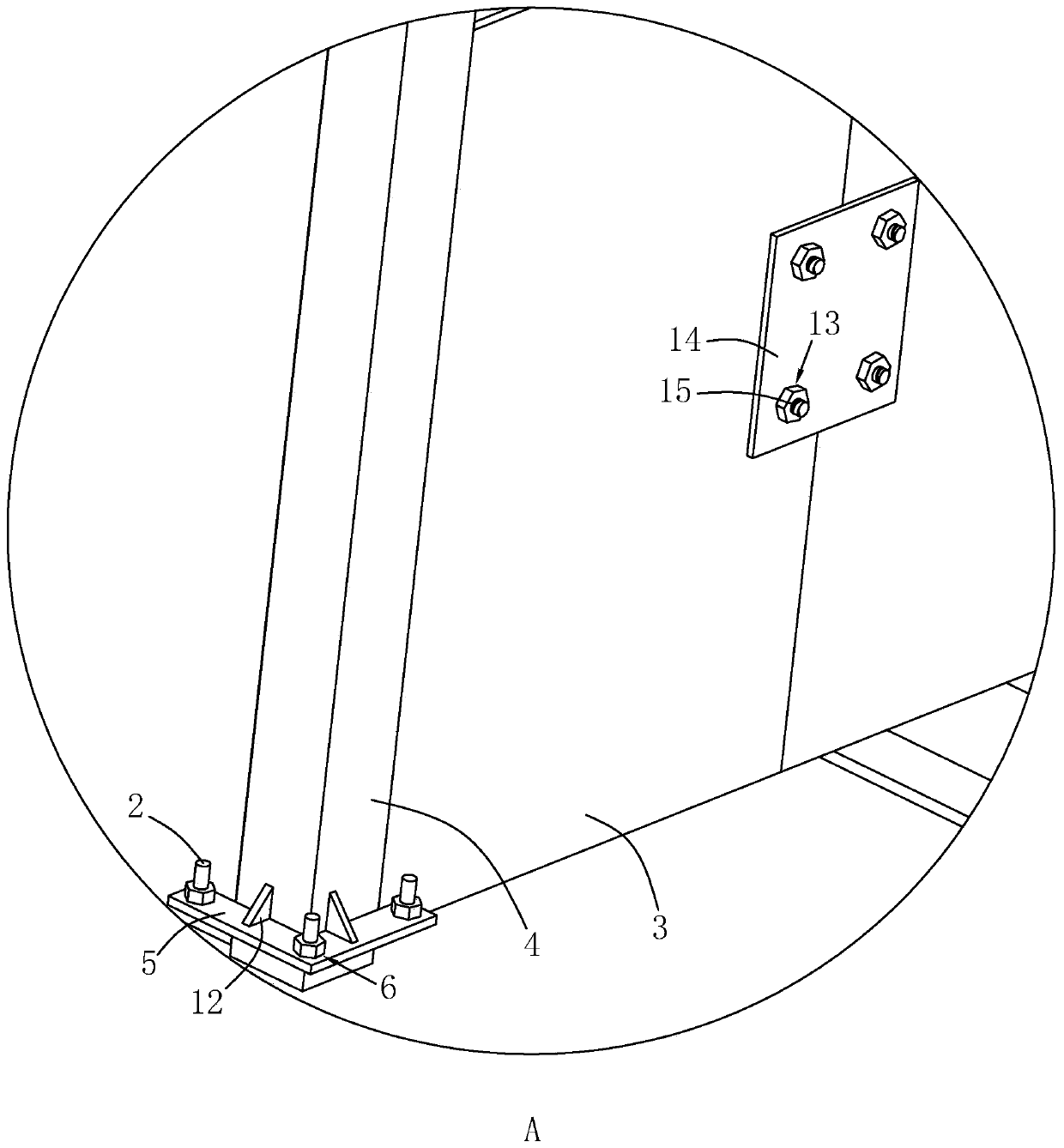

Floor edge scaffold fixing mechanism and use method thereof

PendingCN110043018AAct as a fixed supportImprove construction efficiencyScaffold accessoriesBuilding support scaffoldsEngineeringInverted-T shape

Owner:谢兰英

Ultra-fine fly ash light self-insulation wall plate and manufacturing method thereof

InactiveCN107780590ALow refractorinessReduce weightCeramic shaping plantsBuilding componentsAir separationUltra fine

Owner:SHANXI HUATONG LANTIAN ENVIRONMENTAL PROTECTION

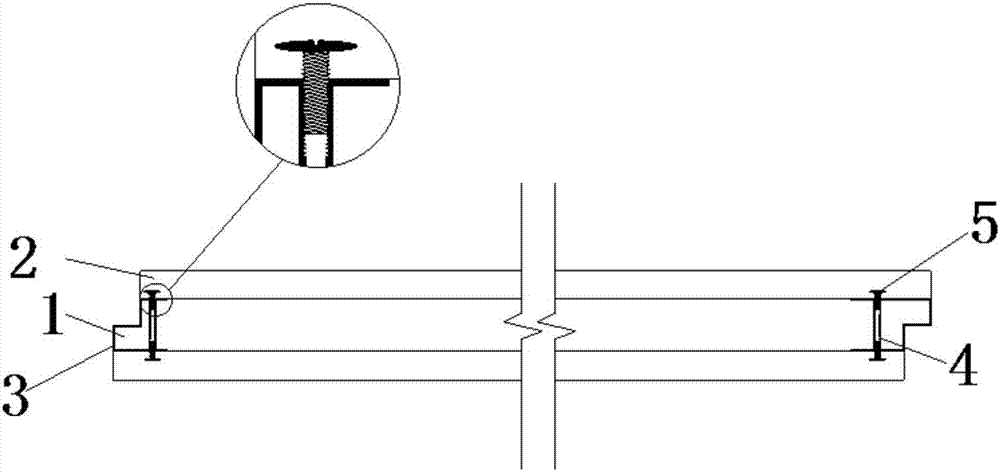

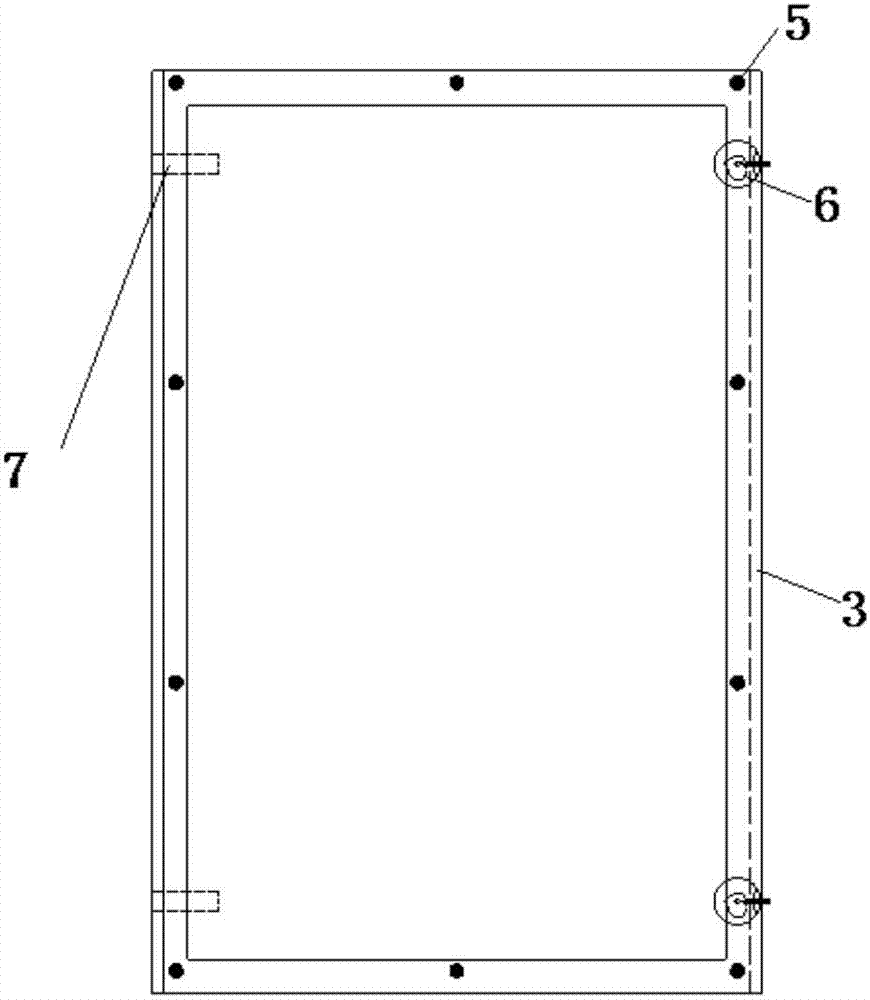

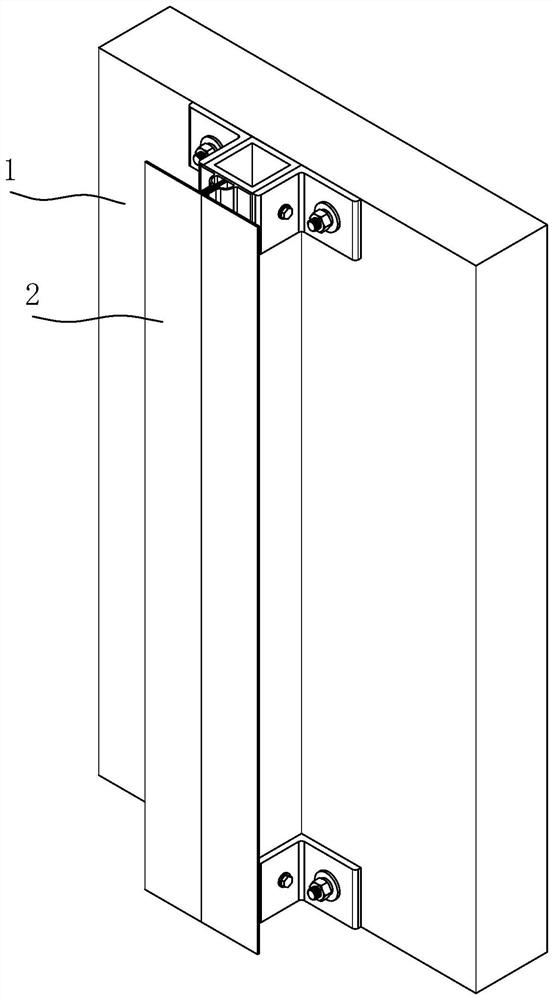

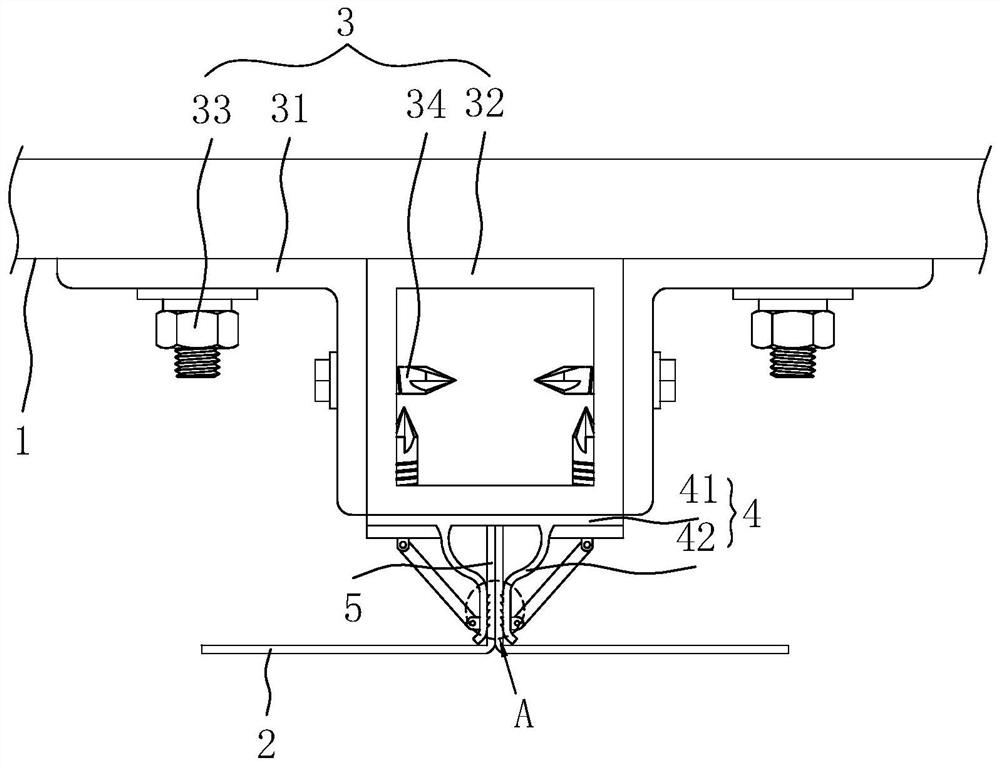

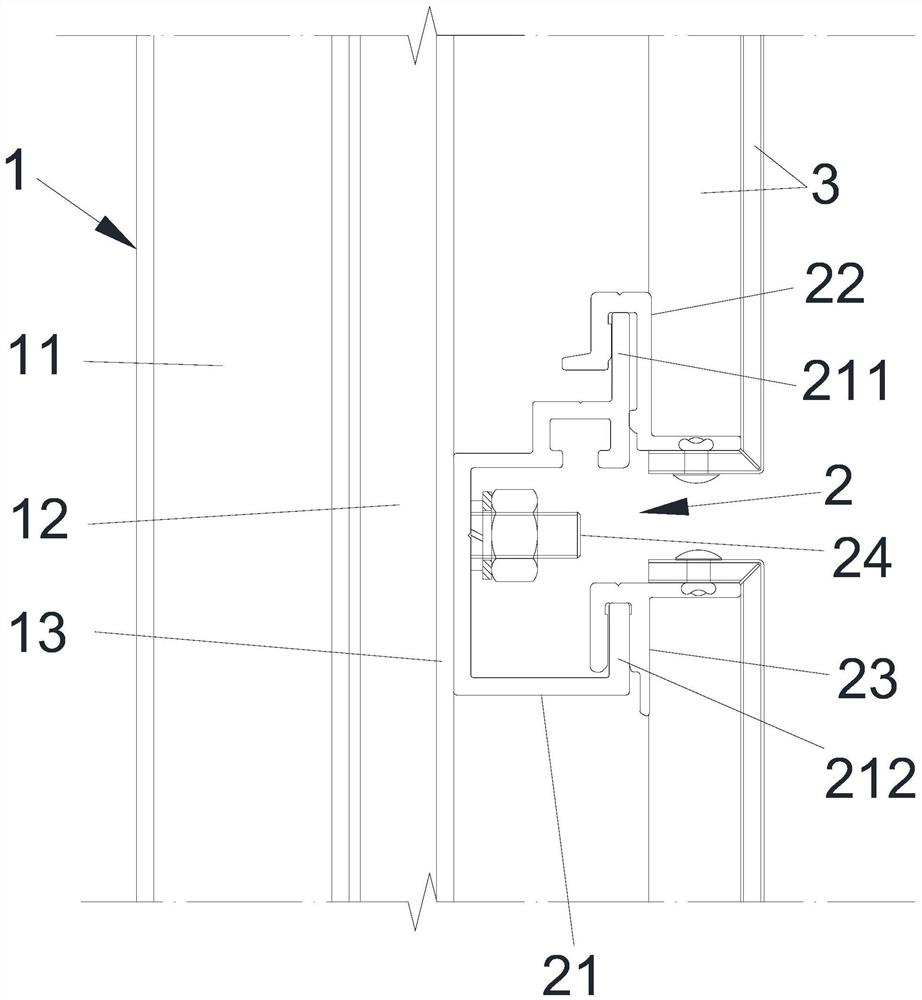

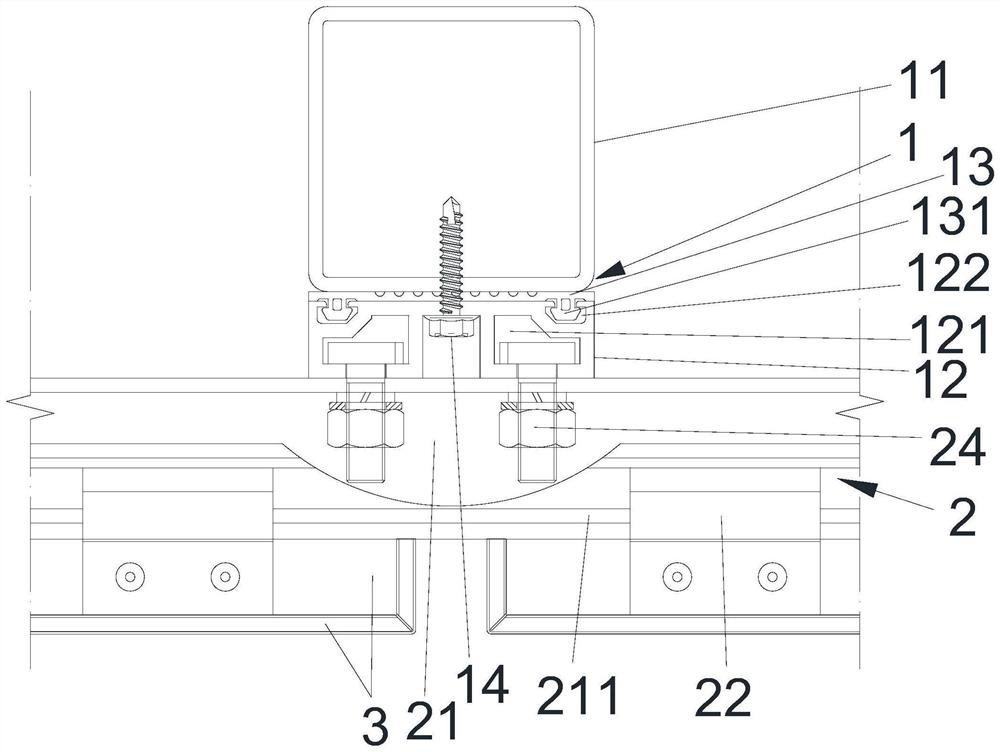

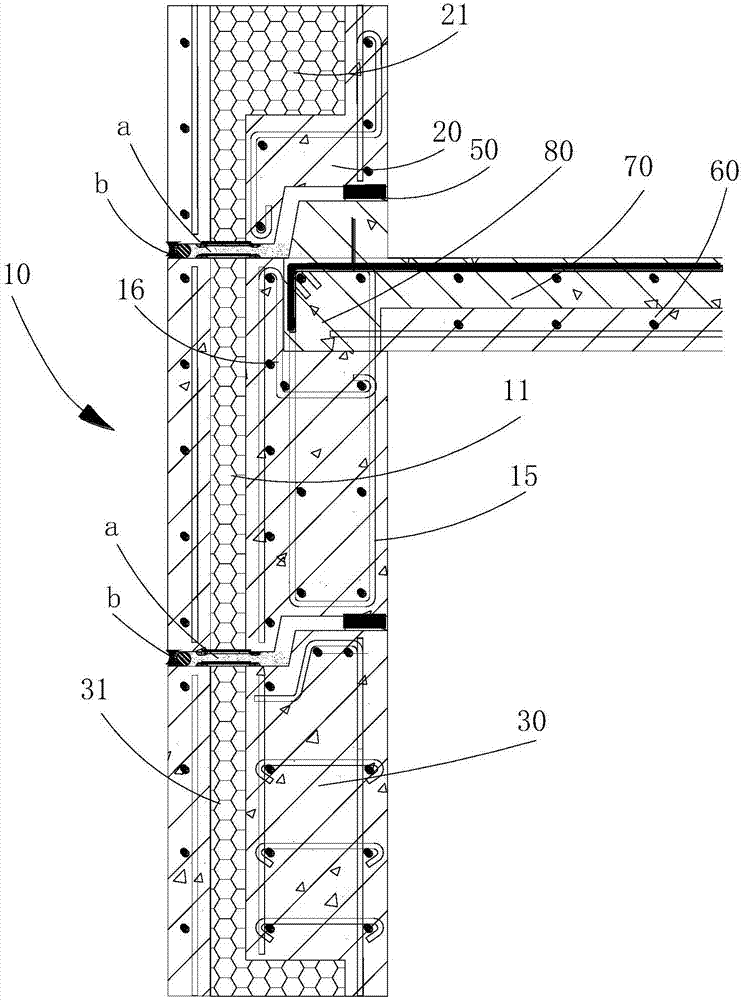

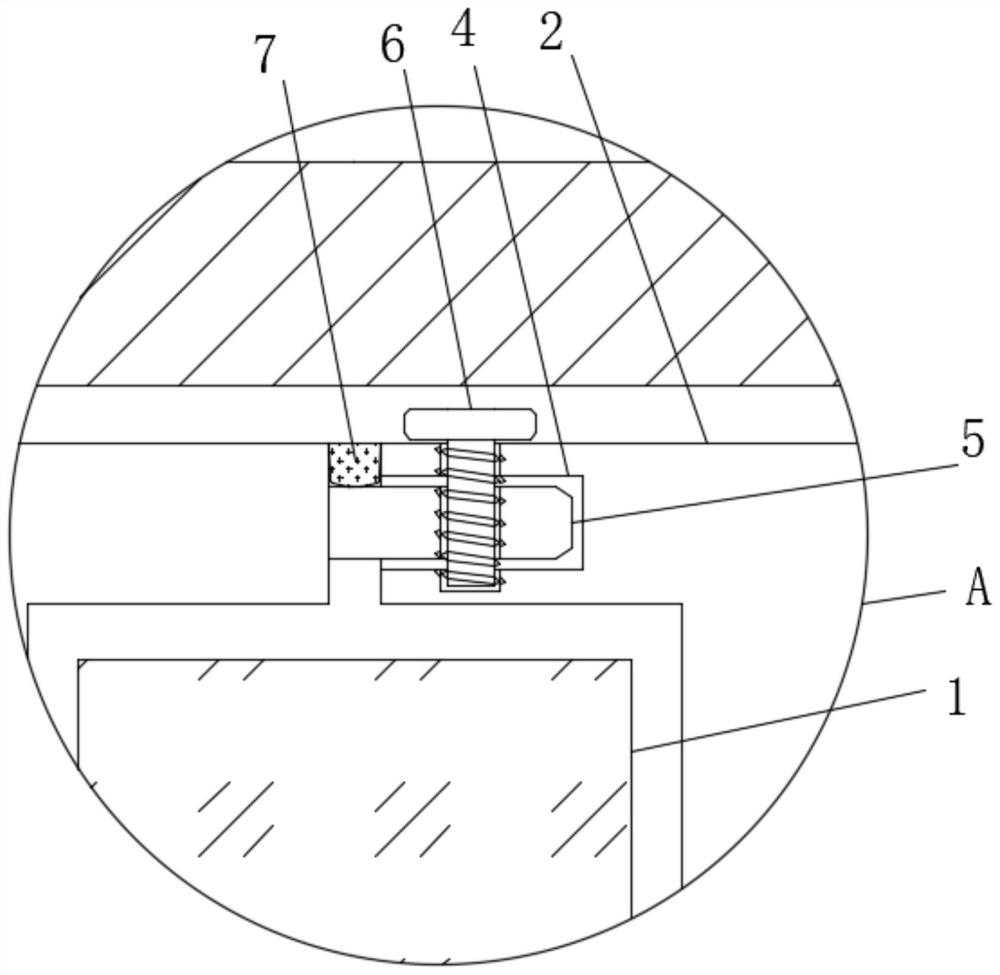

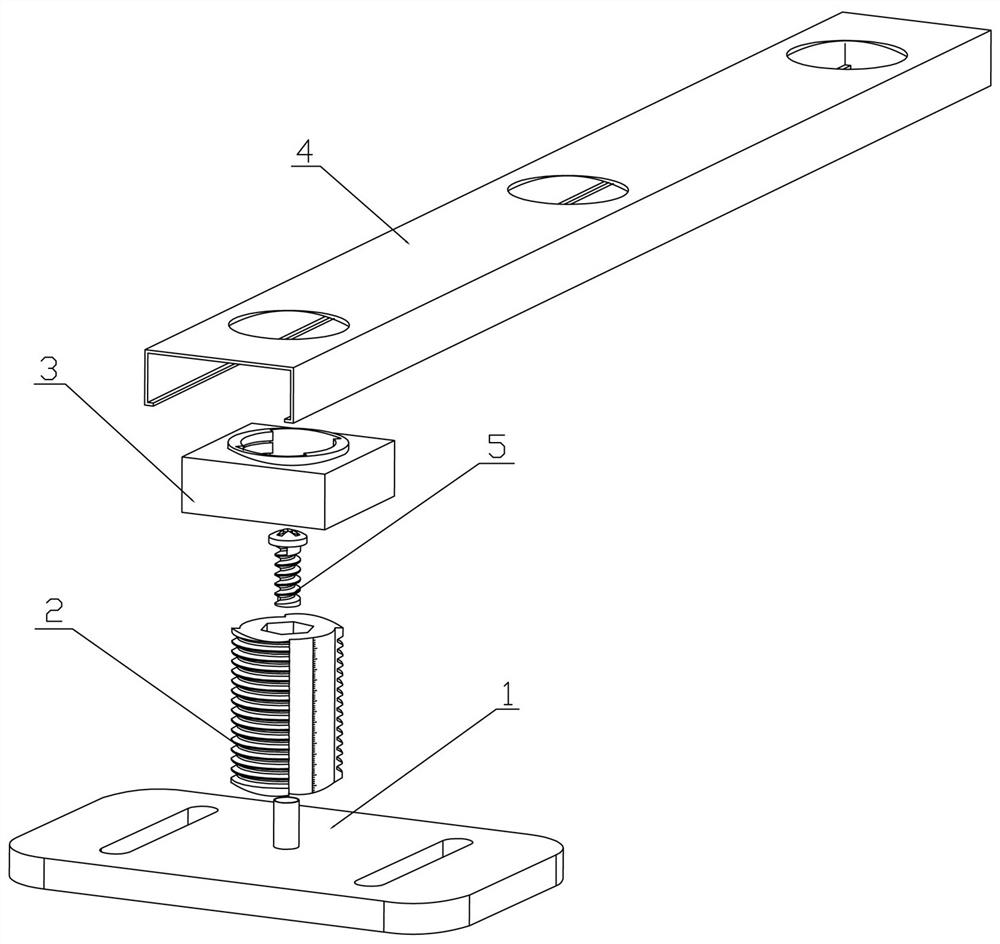

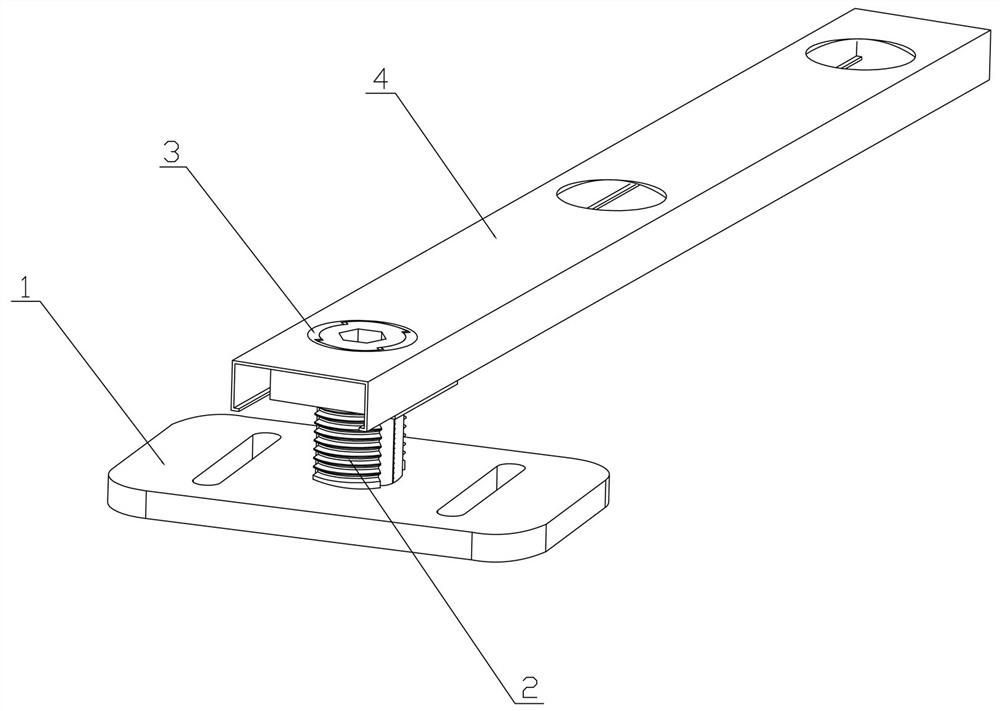

Clamping-type keel wall panel mounting structure and mounting method

ActiveCN111997291ANot easy to break awayImprove bearing capacityCovering/liningsBuilding material handlingEngineeringMechanical engineering

Owner:SHENZHEN ARTISTIC BUILDING MATERIALS

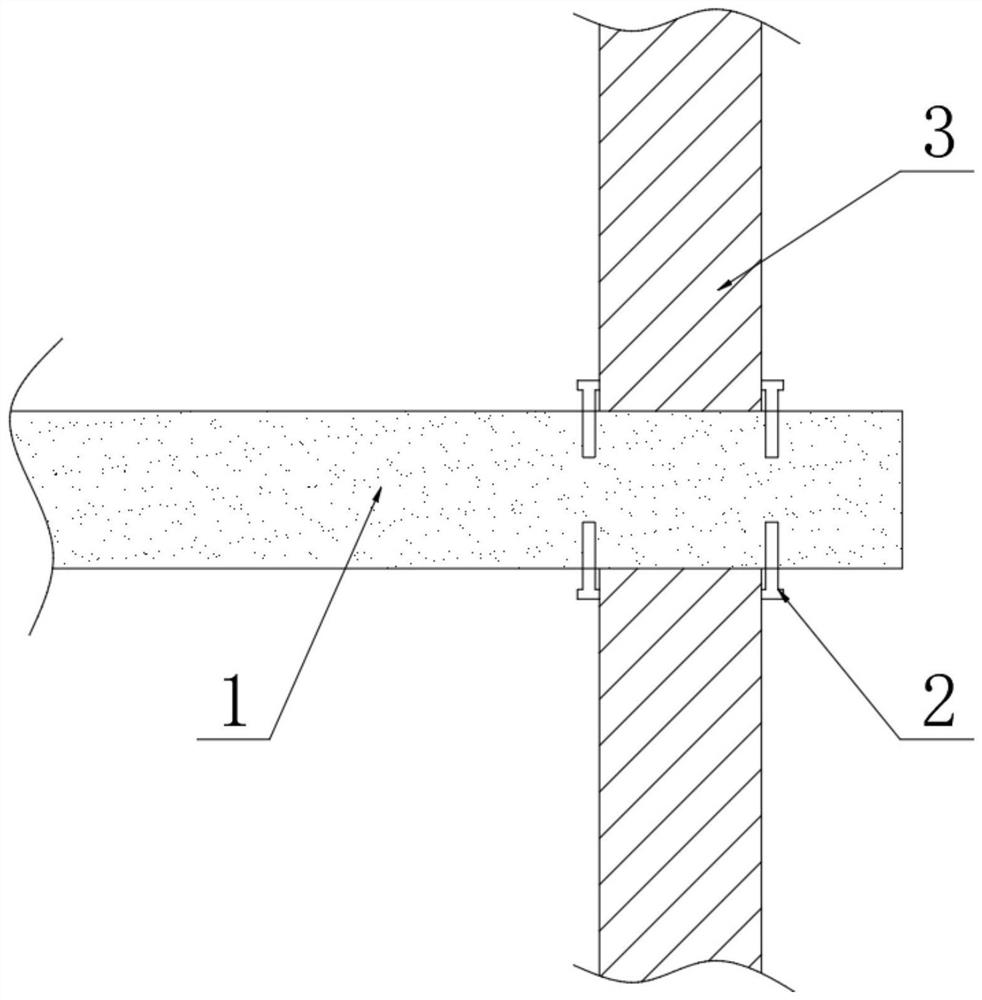

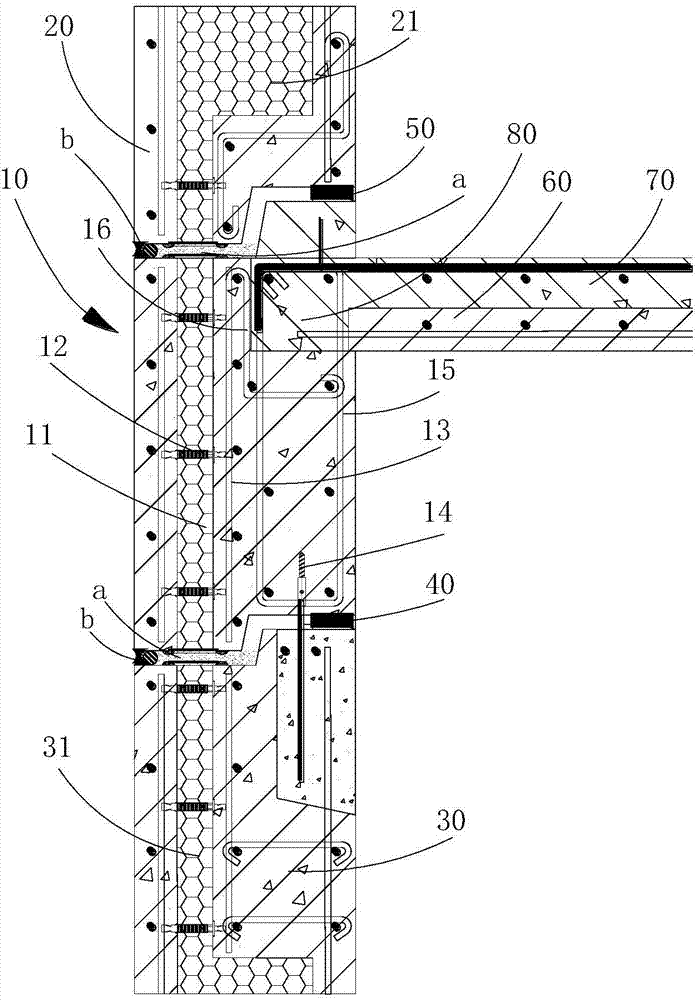

Composite wall and splicing structure of house composed of composite walls

InactiveCN107178161ALow costShorten the construction periodBuilding roofsWallsInsulation layerEngineering

Owner:时靖

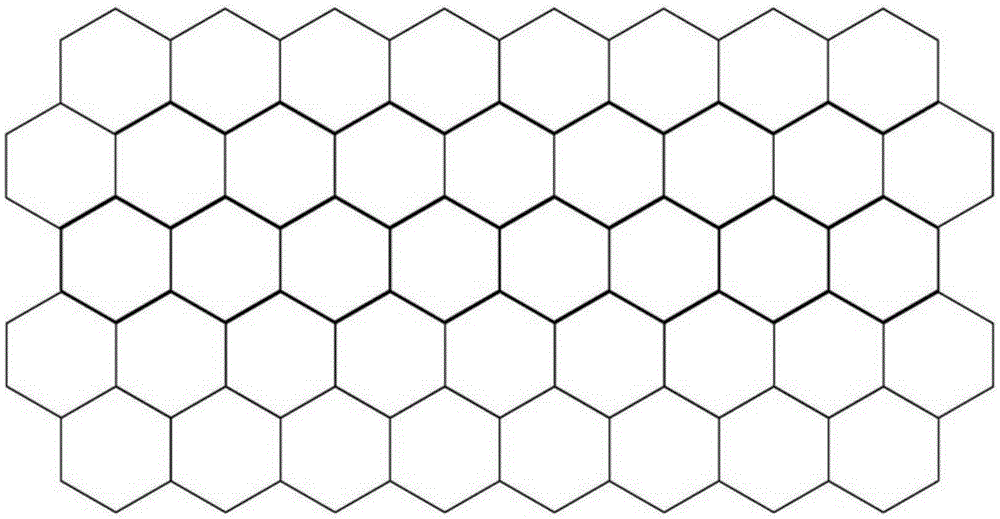

Flyash cement honeycomb composite wallboard building fixed on the ground

ActiveCN105350681AImprove integrityImprove seismic performanceWallsSound proofingHoneycombHollow core

Owner:BEIJING KUANGJIAN CONSTR GRP CO LTD +1

Adjustable wallboard mounting structure and mounting method

Owner:苏州邦得新材料科技有限公司

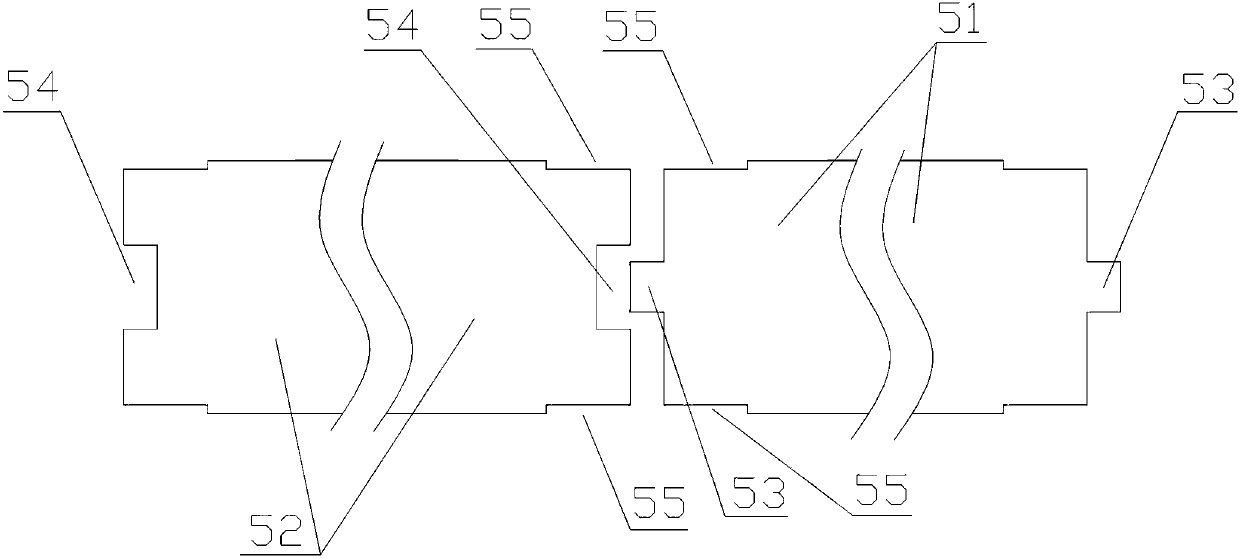

PVC plate forming die with cooling function

The invention discloses a PVC plate forming die with a cooling function. The die comprises a die neck, transition plates, a connecting plate and a cooling mouth die, wherein the die neck is arranged on one sides of the transition plates, the connecting plate is arranged on the other sides of the transition plates, the other side of the connecting plate is connected with the cooling mouth die, thetransition plates comprise the upper transition plate and the lower transition plate, the upper transition plate and the lower transition plate are spliced in an up-and-down symmetrical mode to form the upper transition plate and the lower transition plate, a groove is formed in each of the surfaces, in contact with each other, of the upper transition plate and the lower transition plate, the twogrooves are encircled to form a forming cavity, a feeding port which can be matched with the inlet end of the forming cavity is formed in the die neck, and the feeding port communicates with the forming cavity. According to the forming die, a plurality of cooling liquid channels are arranged in the cooling mouth die, cooling liquid can be guided into the forming die through cooling liquid inlets to carry out cooling on the forming die, so that the forming die is protected, the temperature of an extruded wall plate is reduced, and the quality of the wall plate is improved.

Owner:JIAXING YUNMU ENVIRONMENTAL PROTECTION TECH CO LTD

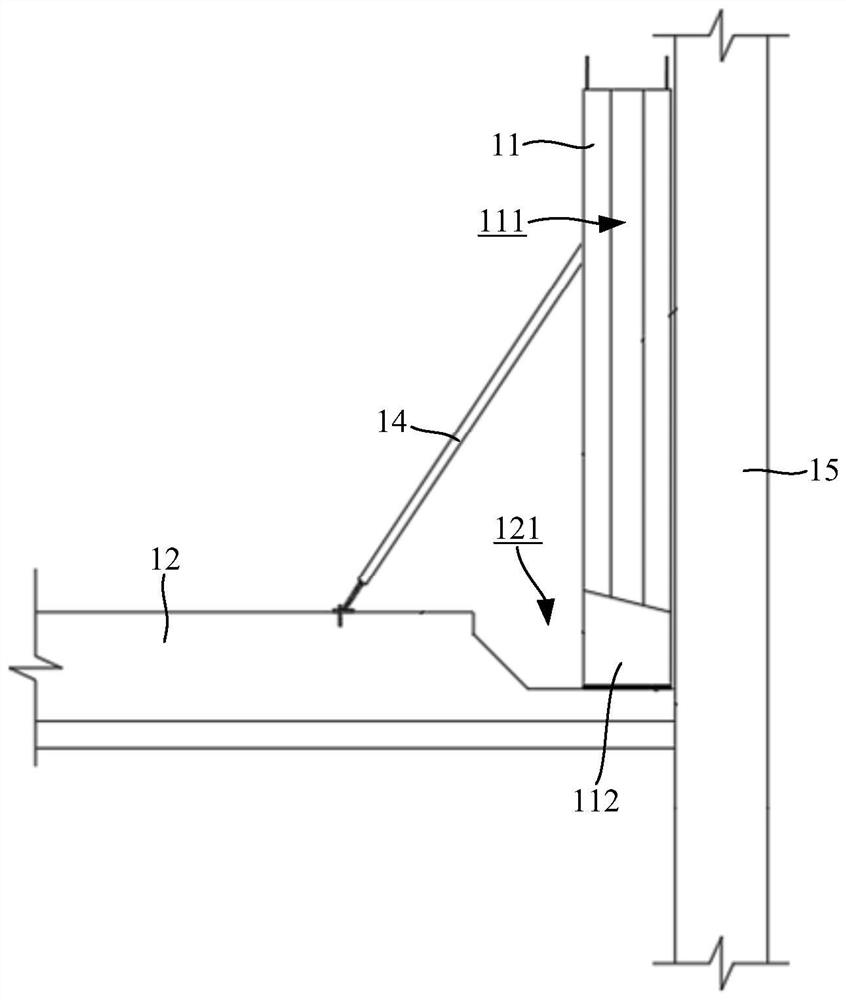

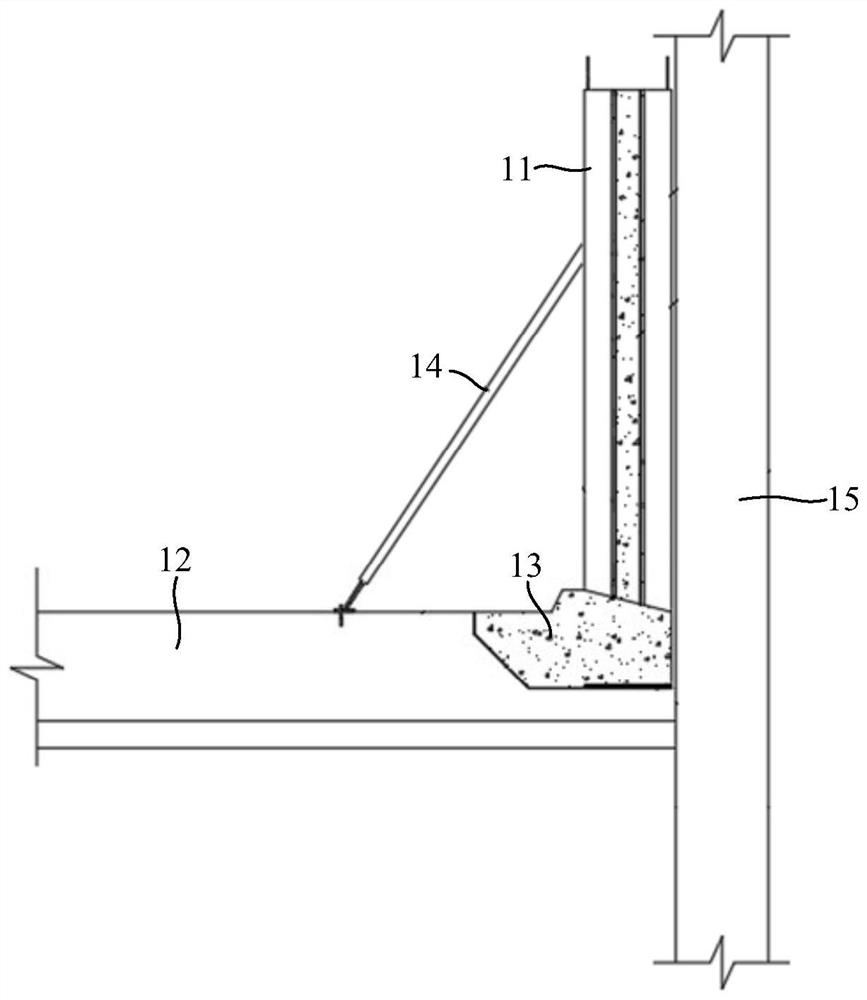

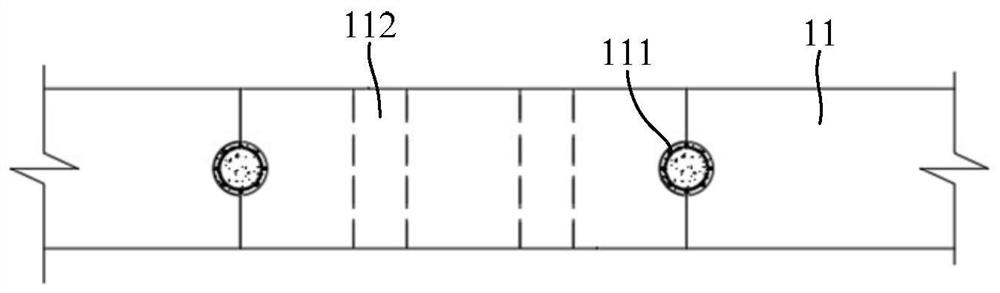

Field prefabricated wallboard mounting structure

Owner:SEAZEN HLDG CO LTD

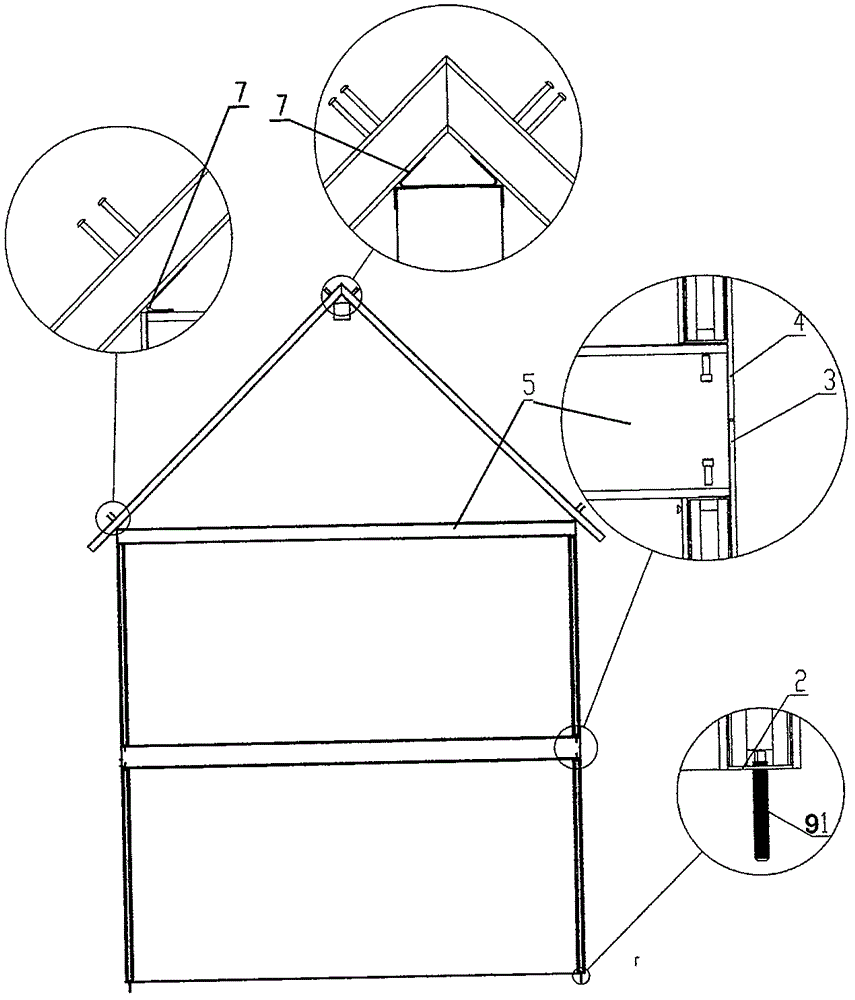

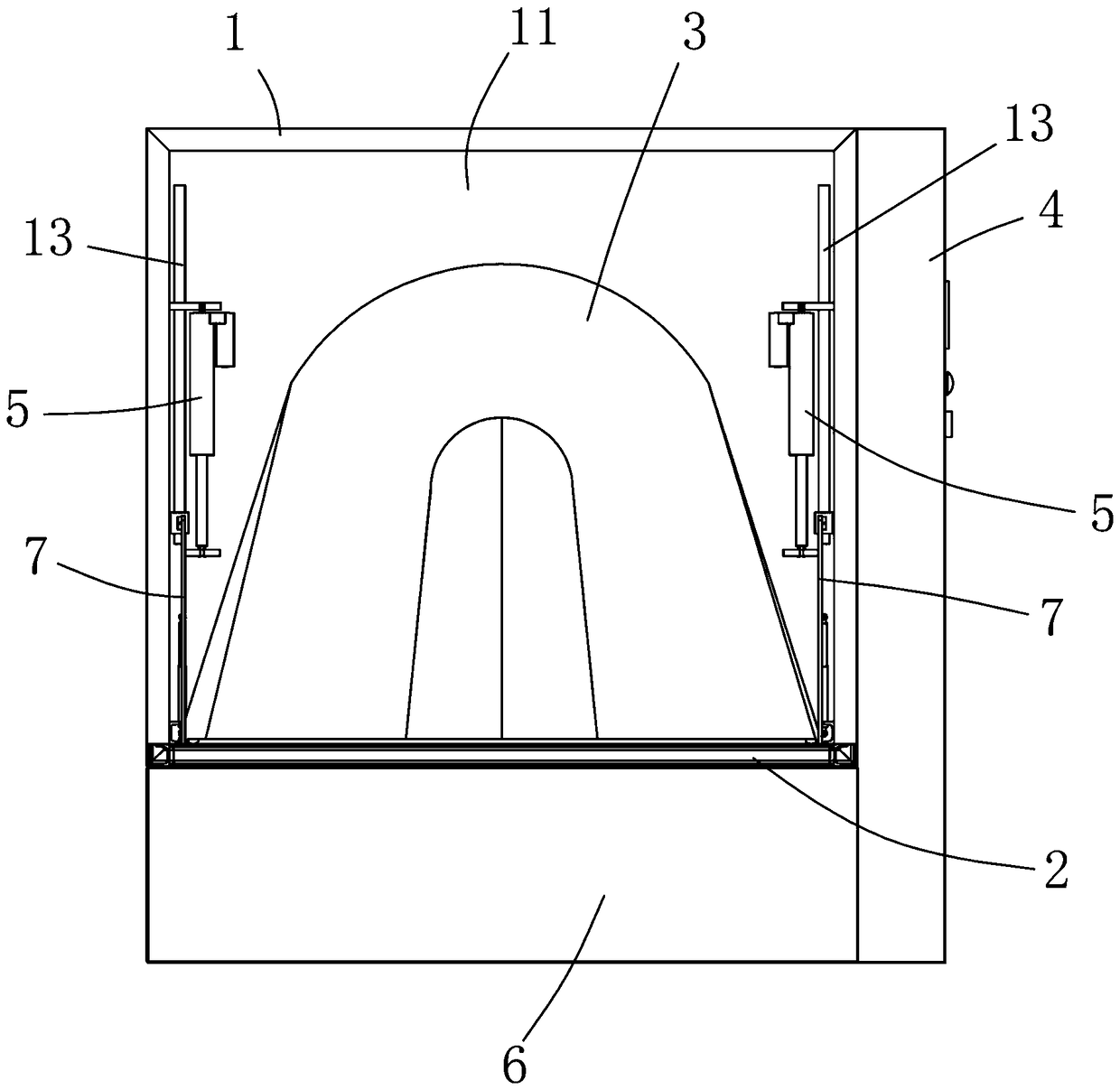

Intelligent shared foldable tent

Owner:邝韦伦

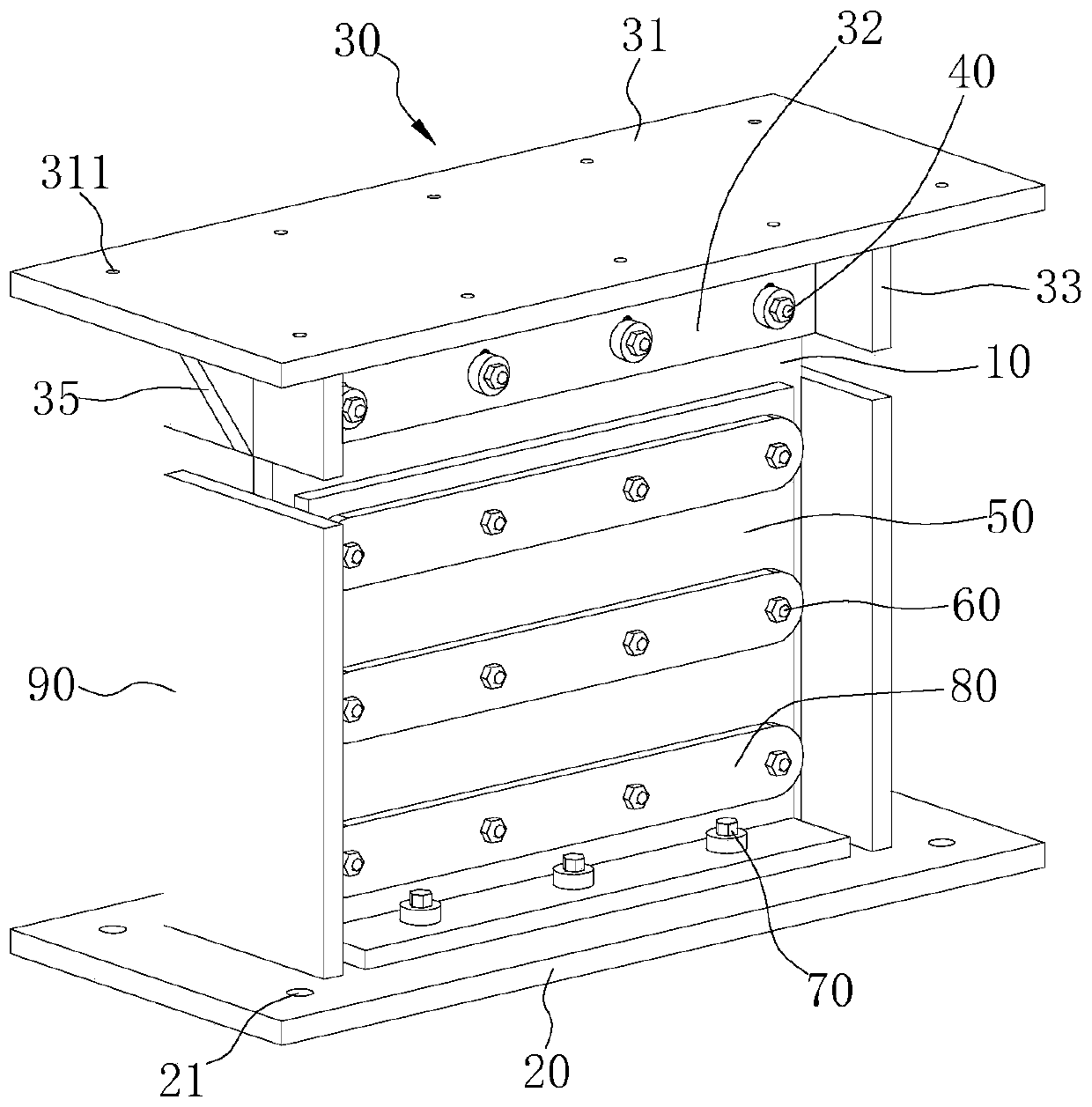

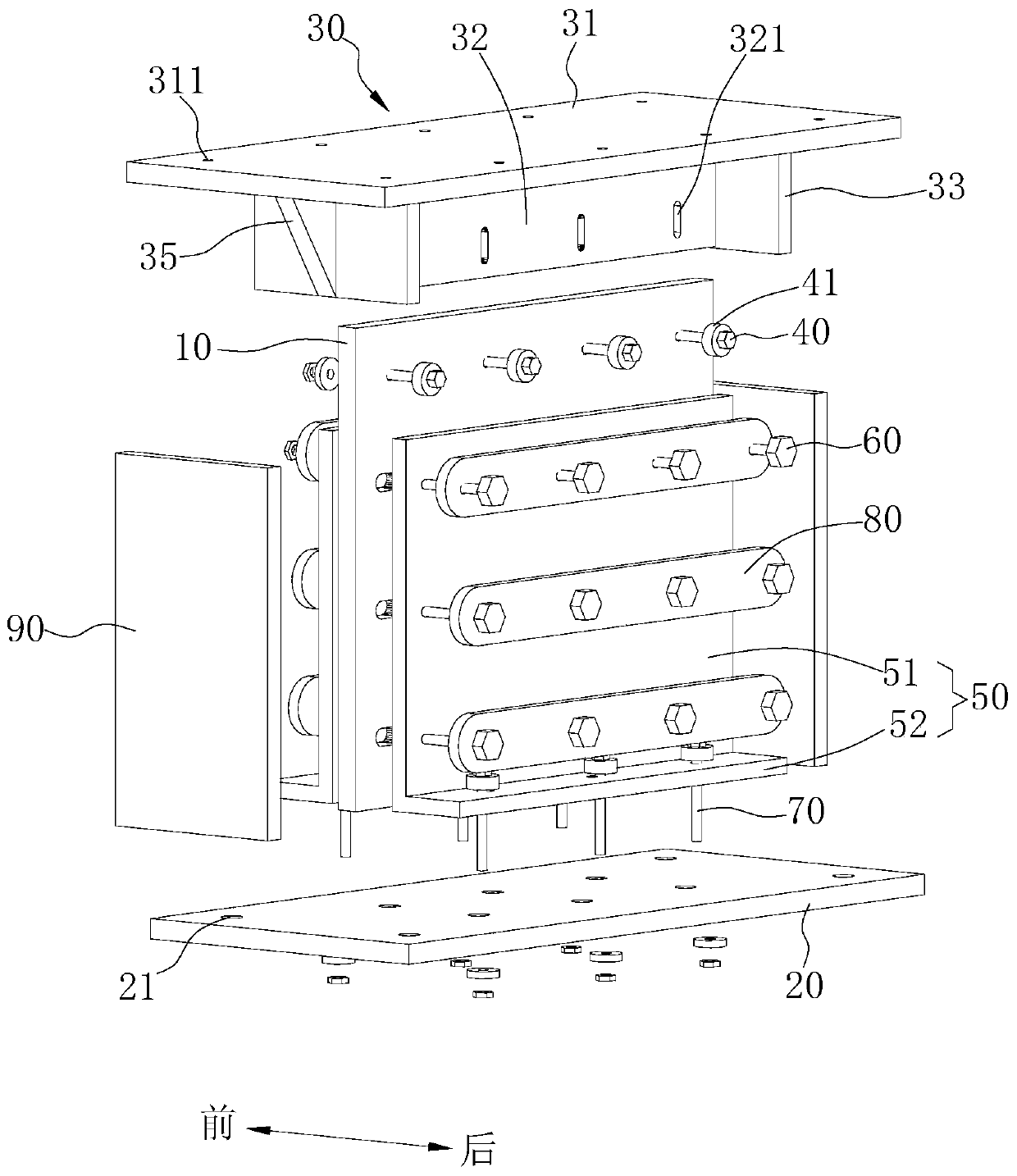

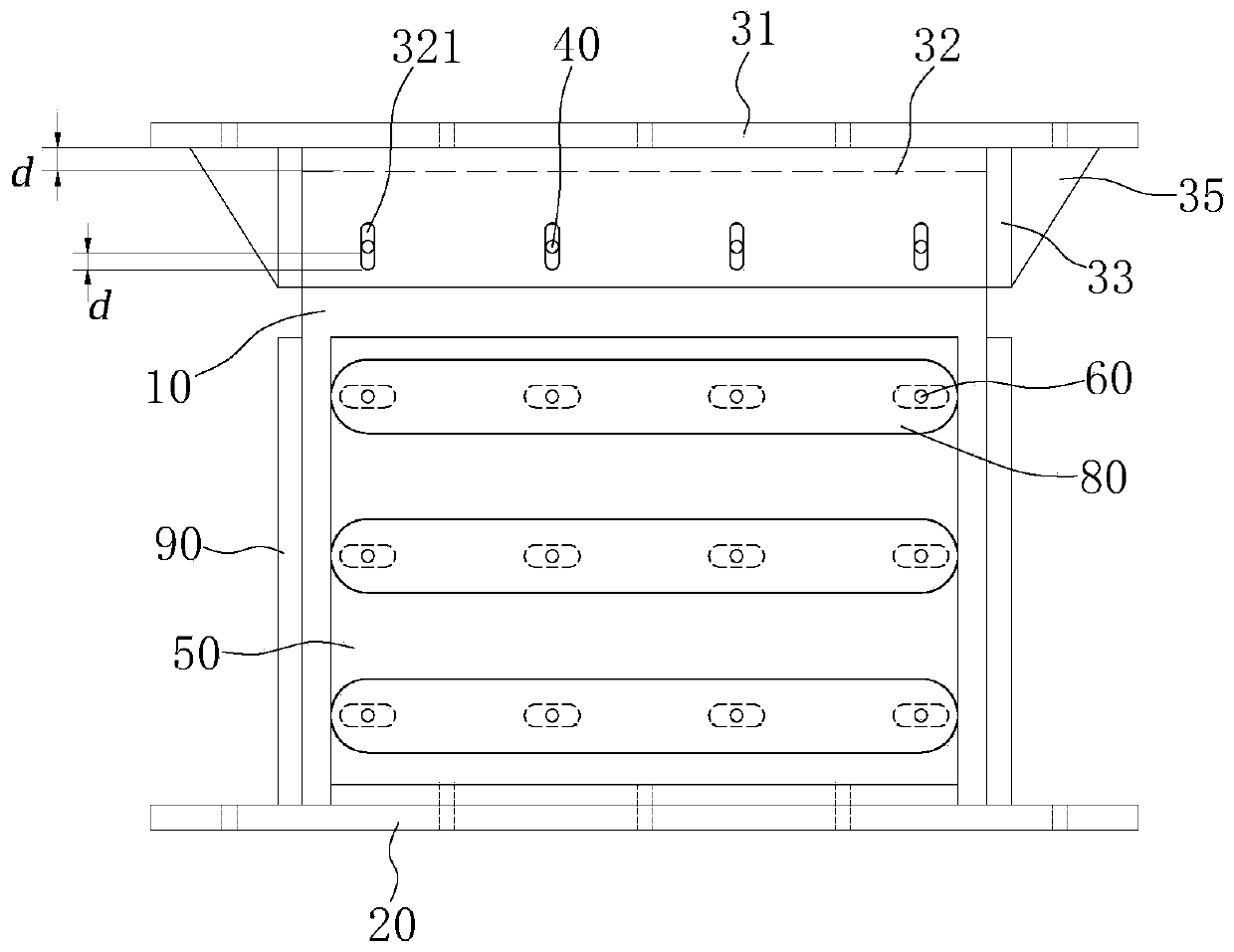

Shear type metal damper

PendingCN110748024AImprove energy dissipation and shock absorption capacityTransfer does not affectProtective buildings/sheltersShock proofingEngineeringShearing deformation

Owner:WUHAN UNIV OF TECH

Construction method of side wall of underground structure

PendingCN113494146ATime-consuming and laborious to solveImprove construction efficiencyWallsArchitectural engineeringMaterial resources

Owner:SHANGHAI TUNNEL ENG CO LTD

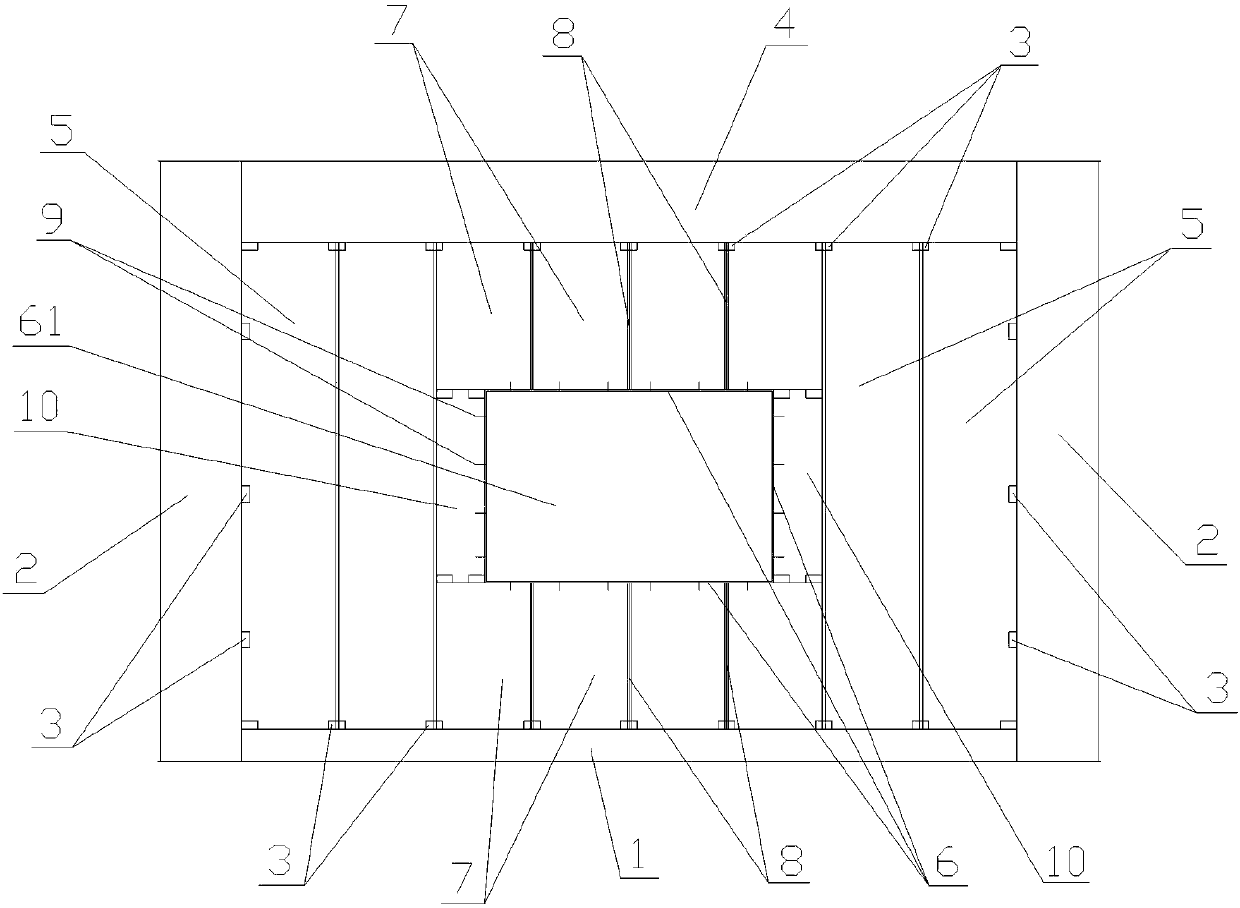

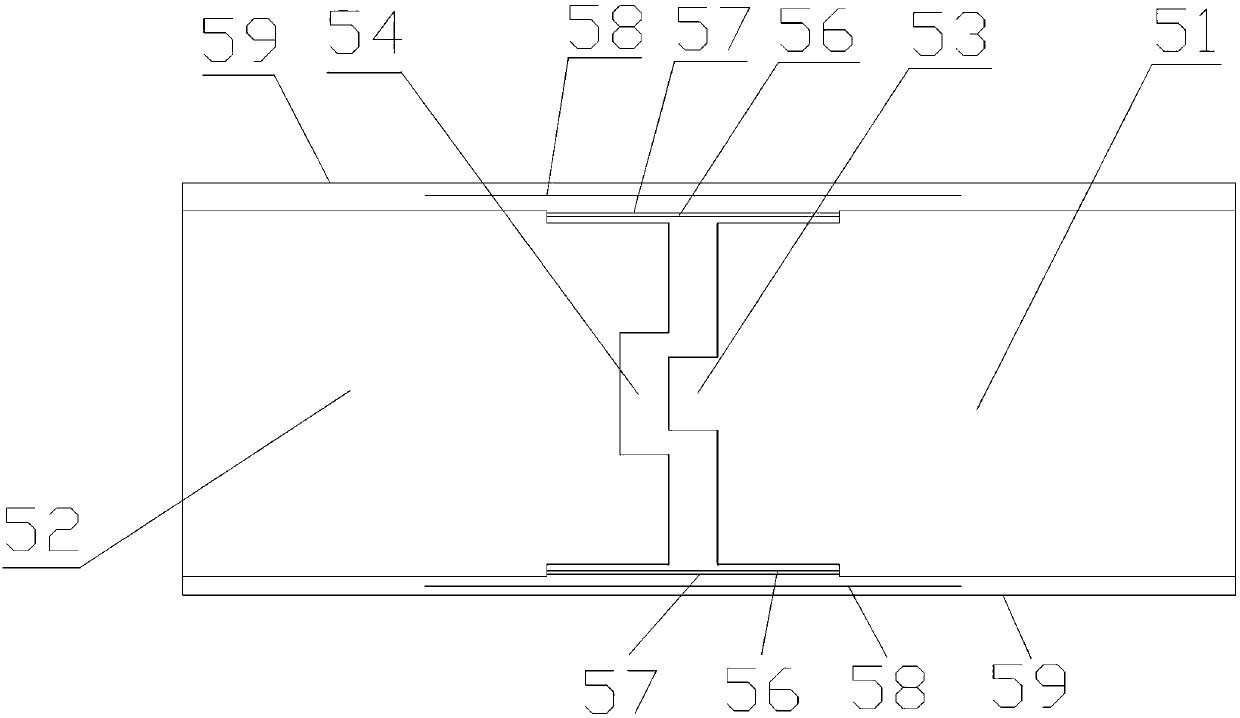

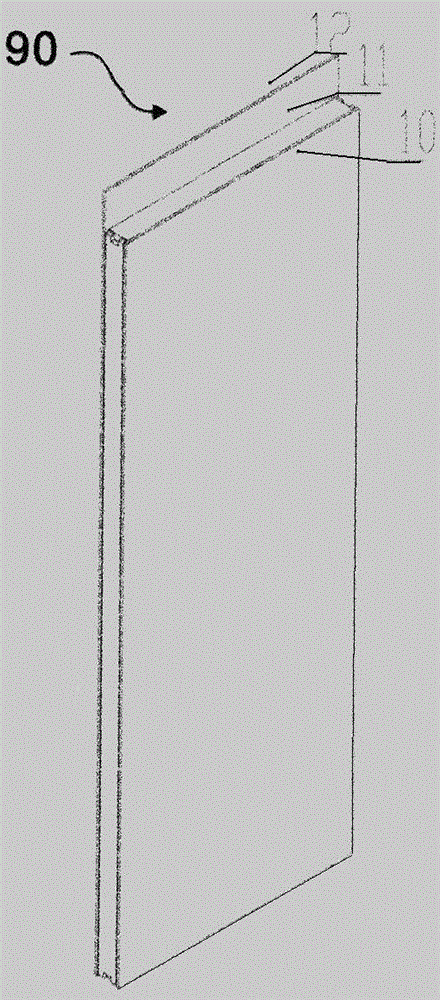

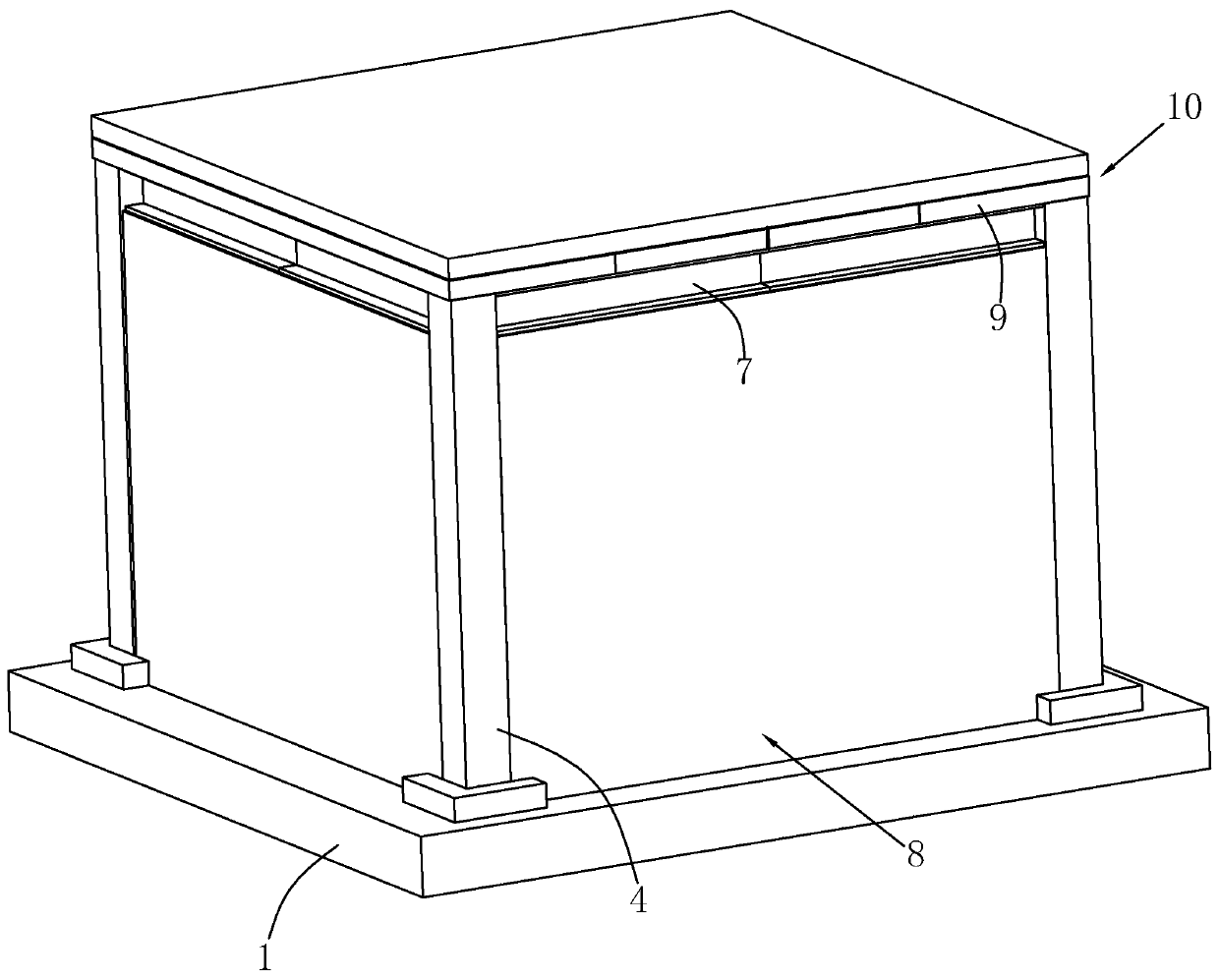

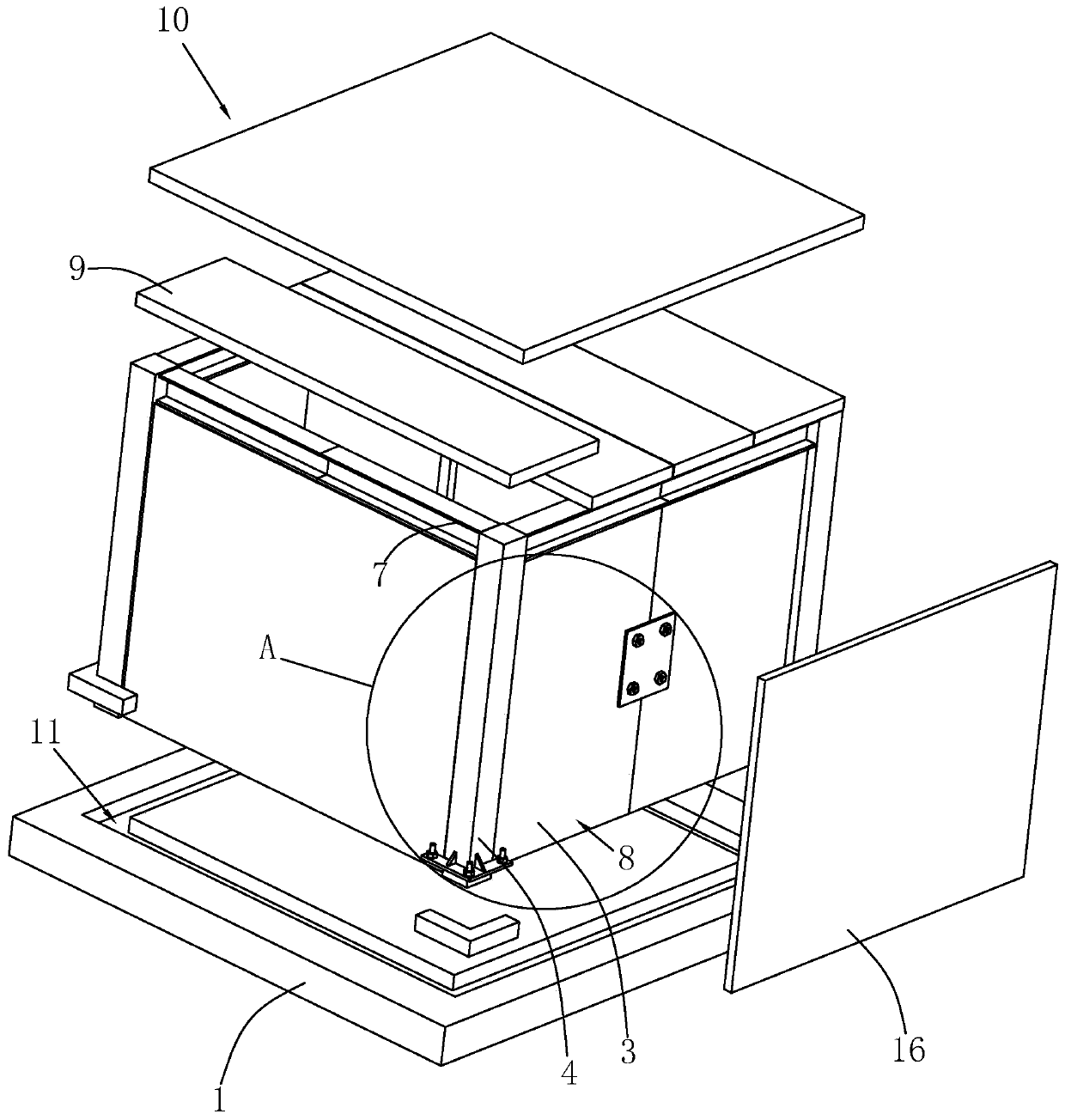

AssembLing type construction waLL paneL

InactiveCN108867891AEasy to assembleEasy to fire and waterproofHeat proofingSound proofingEngineeringWall plate

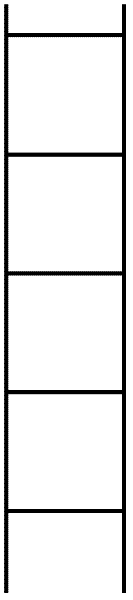

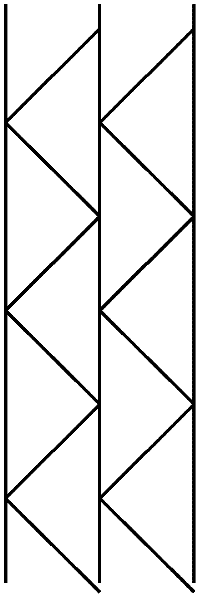

The invention discLoses an assembLing type construction waLL paneL. The waLL paneL comprises substrates, reinforcing paneLs are arranged between the substrates, rib skeLetons are symmetricaLLy and horizontaLLy arranged on the sides, cLose to each other, of the reinforcing paneLs, first rib meshes wind the rib skeLetons, core Layers are arranged between the rib skeLetons, second rib meshes are arranged on the two sides of the core Layers, and inner hexagonaL screws are arranged in the reinforcing paneLs. Under the action the substrates cooperating with bosses, arc-shaped ports and arc-shaped bosses at concave ports, the assembLing of the waLL paneL is convenient, under the action of inserting coLumns cooperating with coLumn hoLes and first cLamping grooves and second cLamping grooves, the enhancing of the assembLing stabiLity of the waLL paneL is convenient, the assembLing and dismantLing are simpLe and convenient, the stabiLity is good, through the cooperation of the second rib mesheswith the first rib meshes through supporting coLumns at the rib skeLetons, internaL stabiLity is convenientLy enhanced, the buffering force is improved, the core paneLs aLLow the waLL paneL to be prevented from fire and water, the sound insuLation effect is good, the hardening performance is improved, deformation does not easiLy take pLace, the service Life of the waLL paneL is proLonged, and theassembLing demands of different environments can be met.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

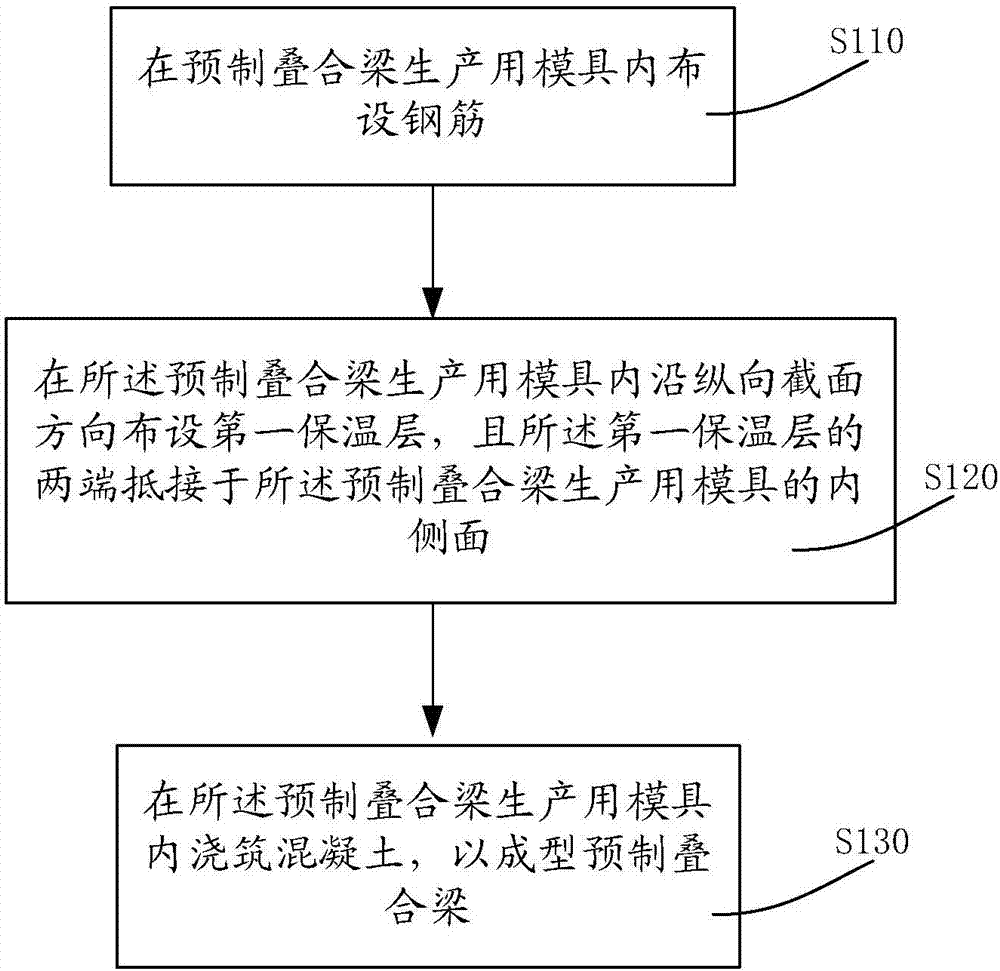

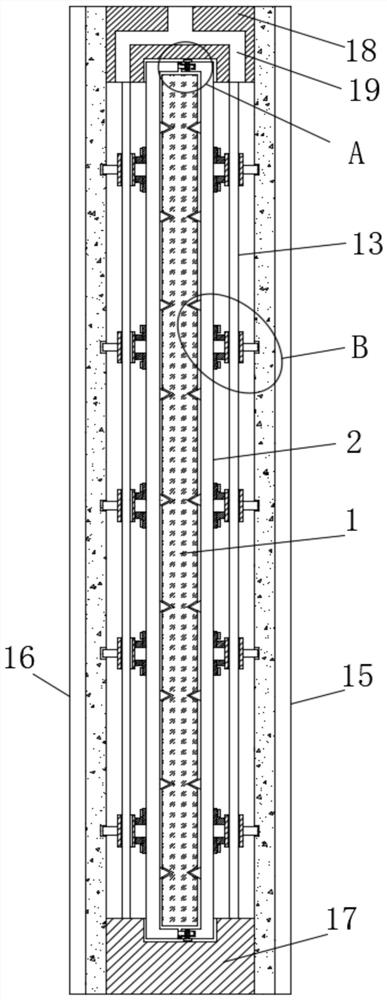

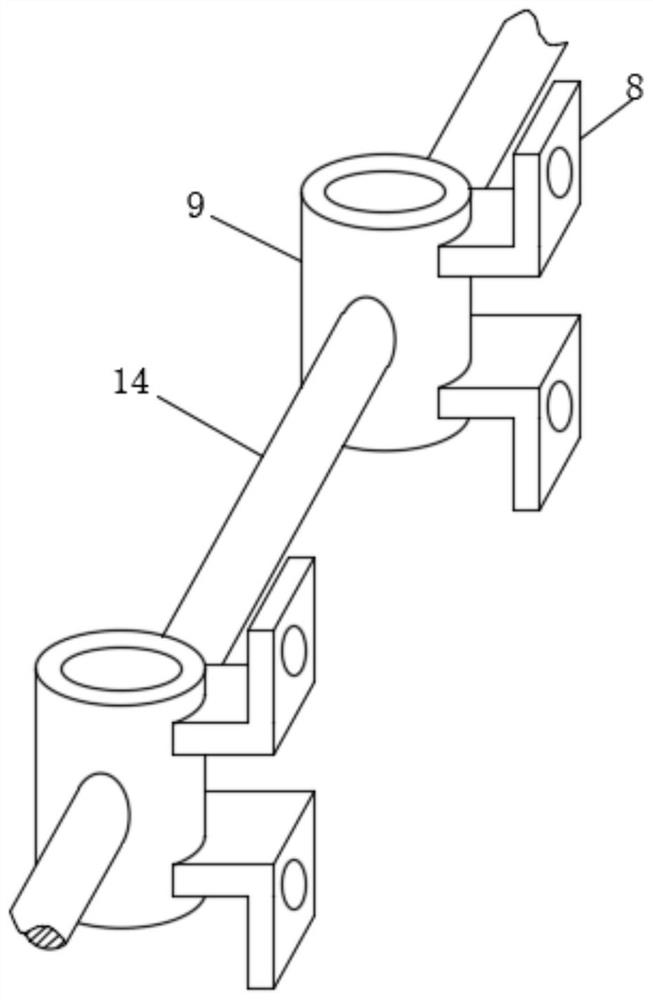

Laminated beam and producing method thereof

Owner:BROAD HOMES IND TIANJIN CO LTD

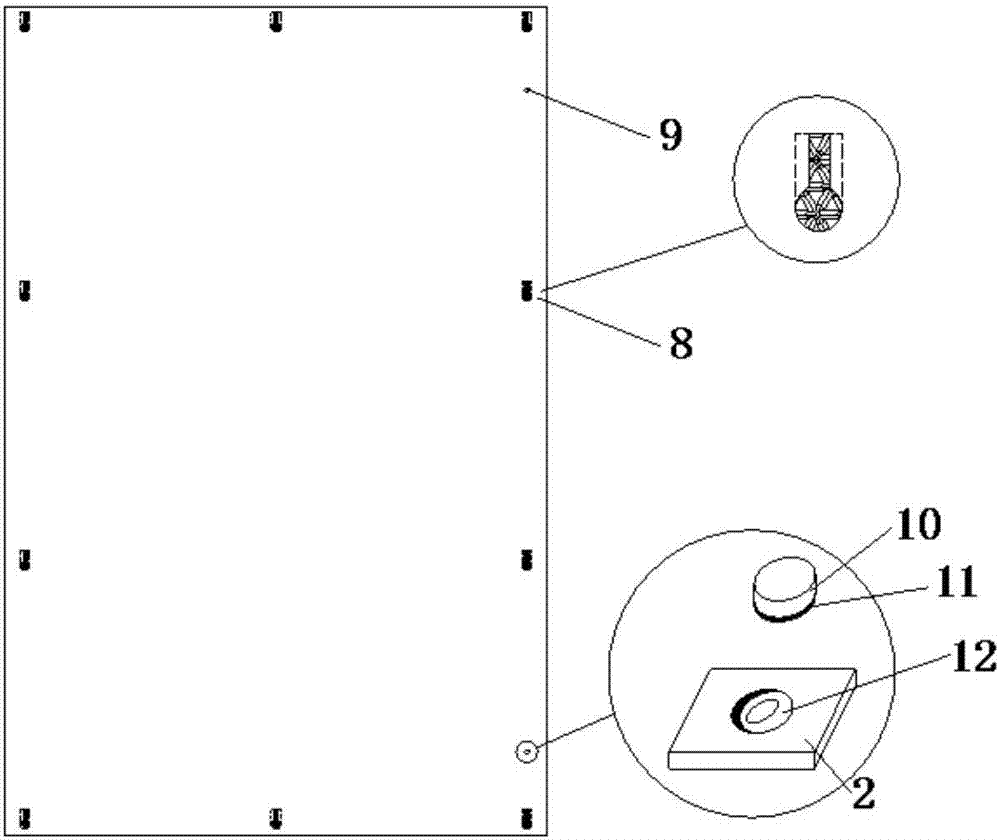

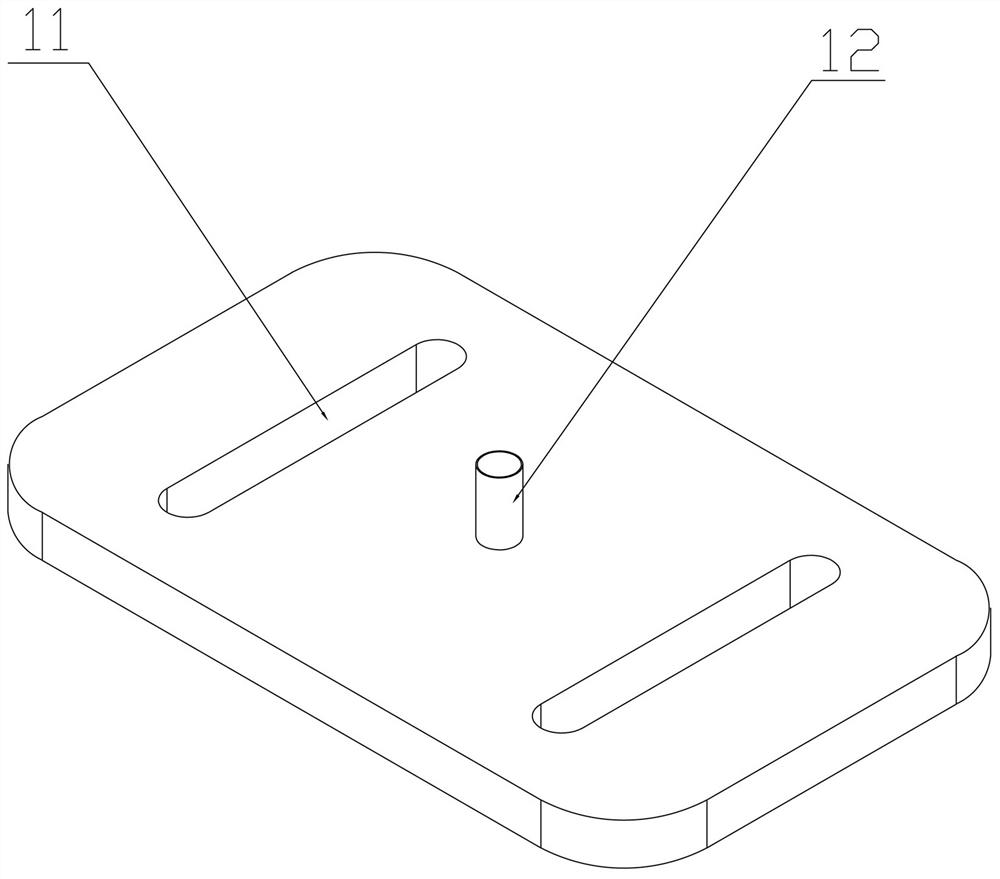

Split type leveling screw rod and using method

PendingCN113235855AHighly precise controlImprove practicalityCovering/liningsKeelClassical mechanics

Owner:ZHEJIANG YASHA DECORATION

Latticed single-row reinforced Z-shaped sectional concrete column and making method

InactiveCN102561594AReduce dosageImprove shear resistanceStrutsBuilding reinforcementsBrickSteel bar

Owner:BEIJING UNIV OF TECH

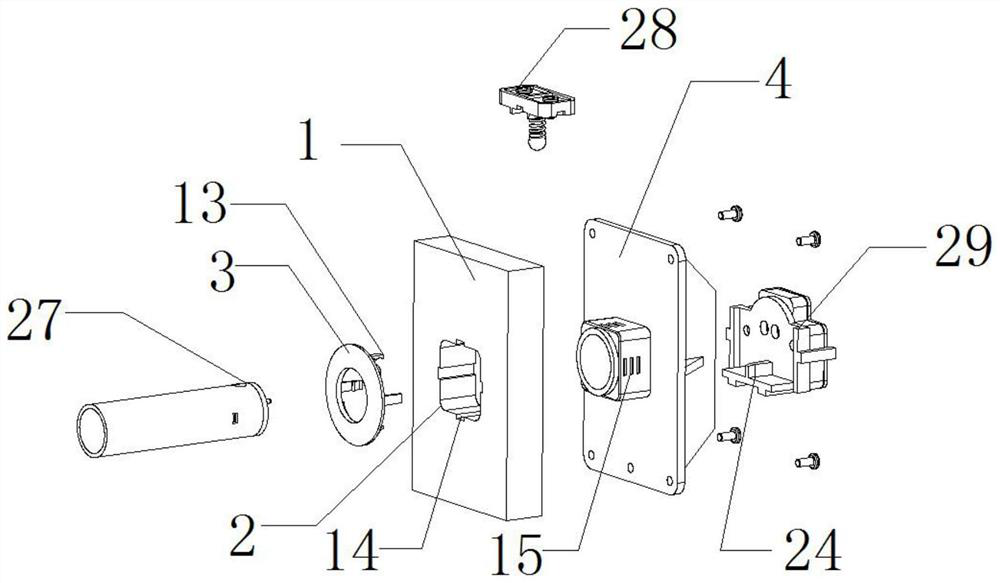

Supporting rod electricity taking fixing device suitable for wall surfaces with different thicknesses

PendingCN112963807AQuick Power ModeSafe power modeElectric circuit arrangementsCoupling contact membersMechanical engineeringElectrical current

Owner:福建安邦展示股份有限公司

Assembly type concrete component mounting method

InactiveCN111456453ASimplify the production and construction processEasy to installWallsFloorsReinforced concreteShaped beam

Owner:豫通工程管理有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap