Controlling cable and manufacturing method thereof

A technology for controlling cables and manufacturing methods, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of lack of cable wiring flexibility, low service life, and small bending Long service life, enhanced flex and softness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

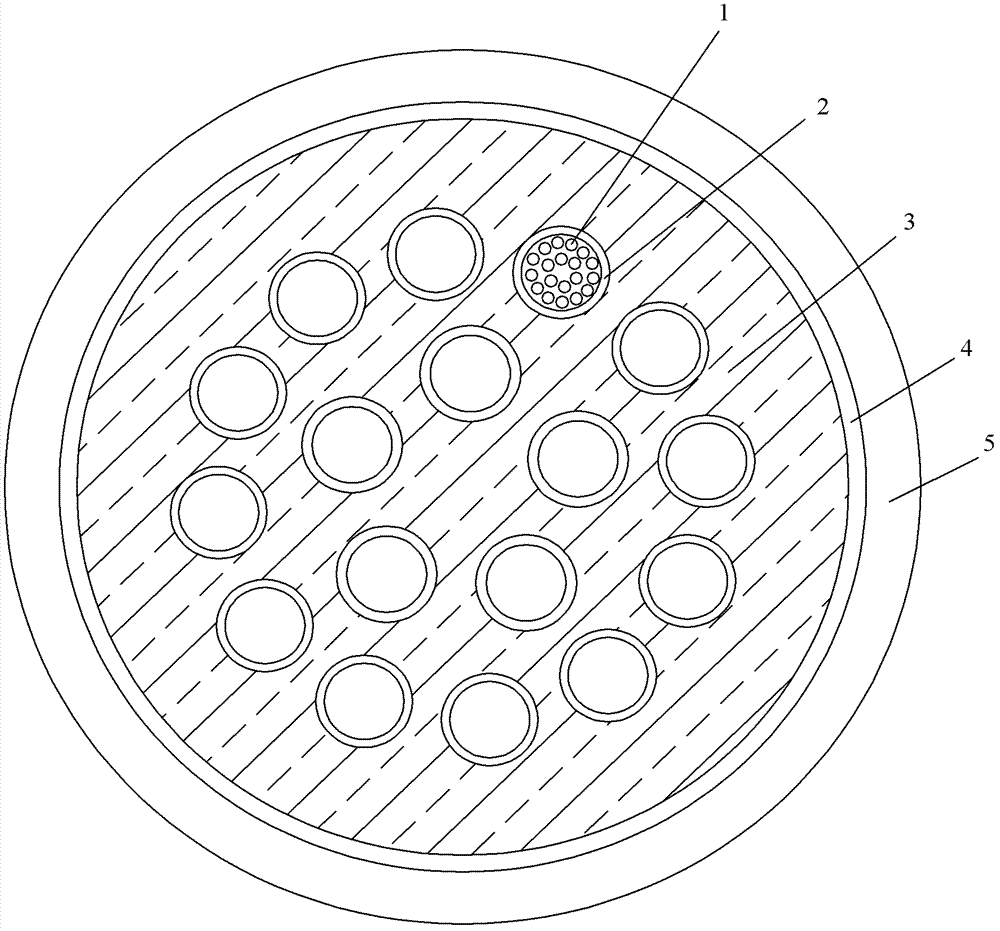

[0023] Such as figure 1 As shown, the control cable of the present invention includes a cable conductor formed by twisting a bundle of multiple copper single wires, and an insulating layer 2 is extruded outside the cable conductor, and the insulating layer 2 adopts JR-70 type soft polychlorinated Vinyl insulating material, the JR-70 type soft polyvinyl chloride insulating material is a commercially available product, and its Shore hardness is 10-85 degrees. In this embodiment, the Shore hardness is 40 degrees. The pitch-to-diameter ratio of the cable conductors ranges from 1:1 to 9:1, and the pitch-to-diameter ratio in this embodiment is 5:1.

[0024] A layer of tape 4 is wrapped around the outside of the cable conductor. The wrapping tension of the wrapping tape 4 during the wrapping pr

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap