Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about "Optically investigating flaws/contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

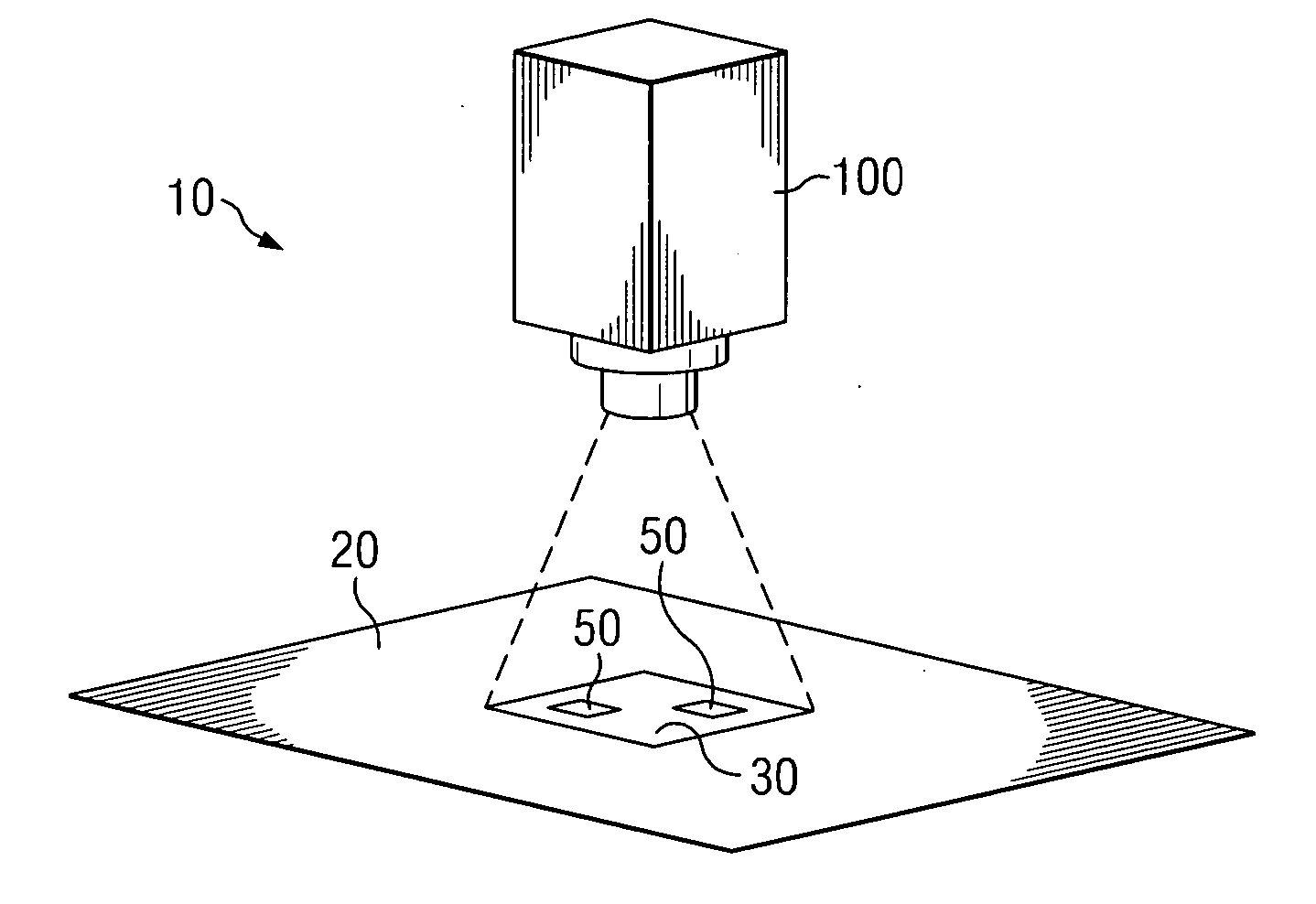

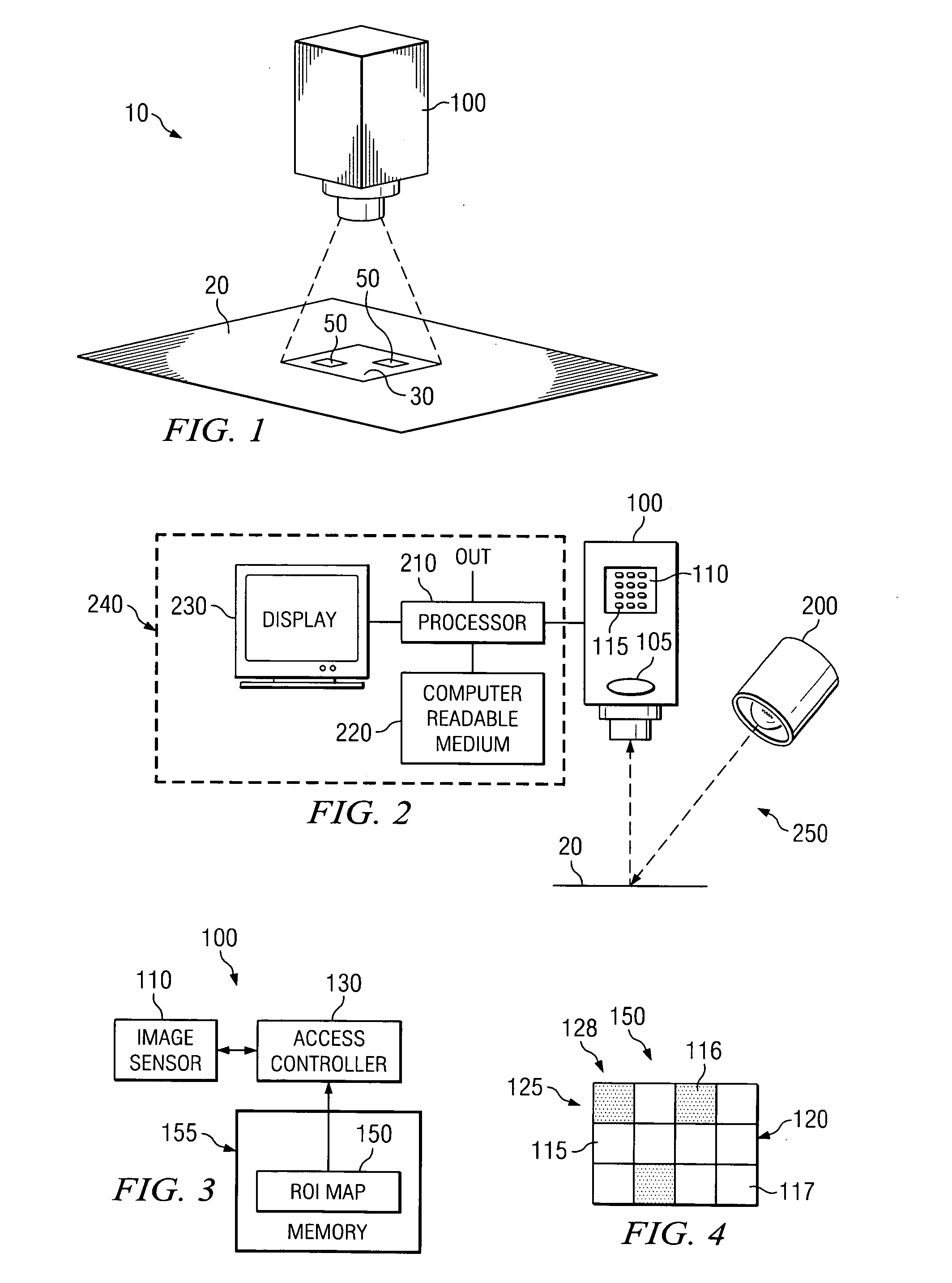

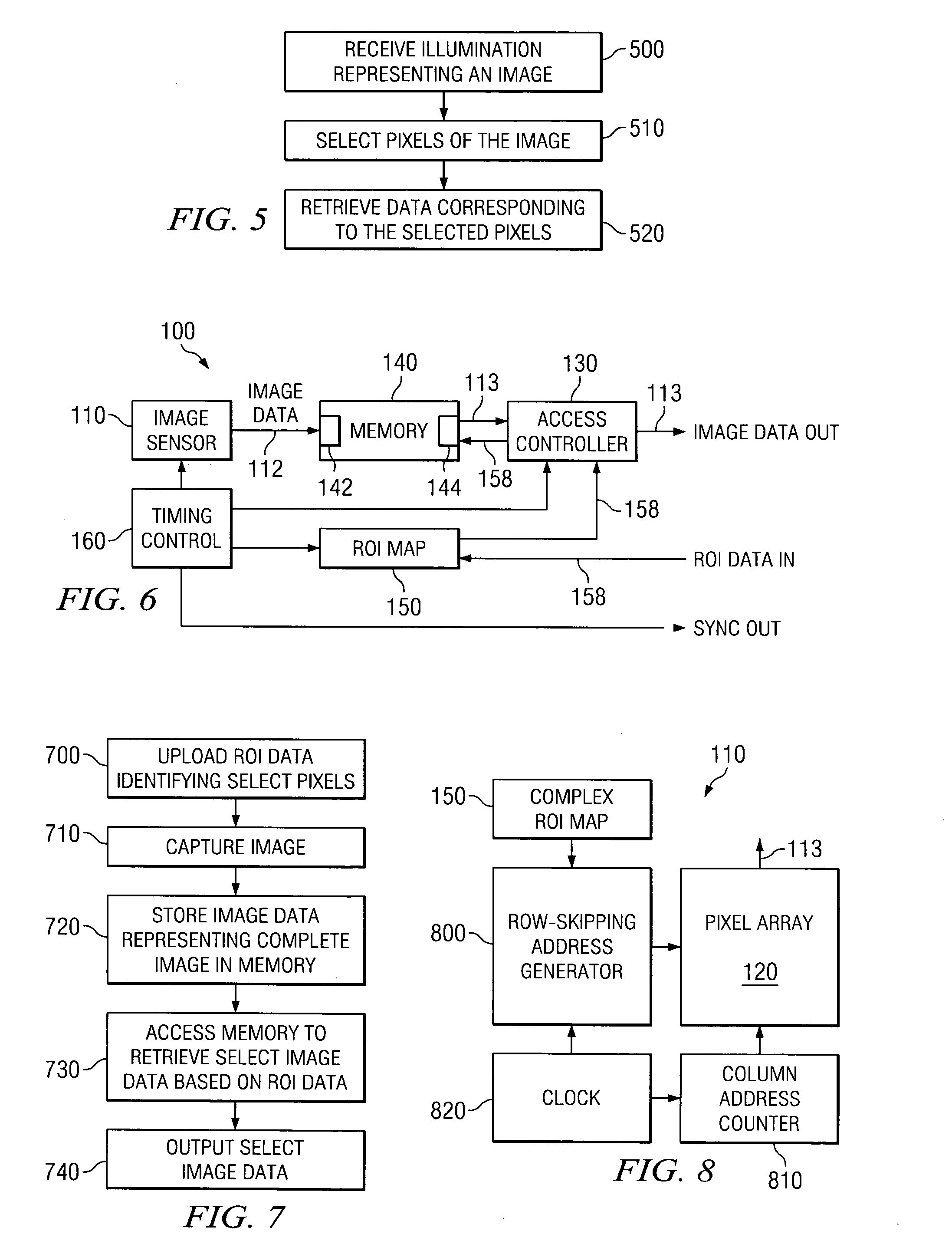

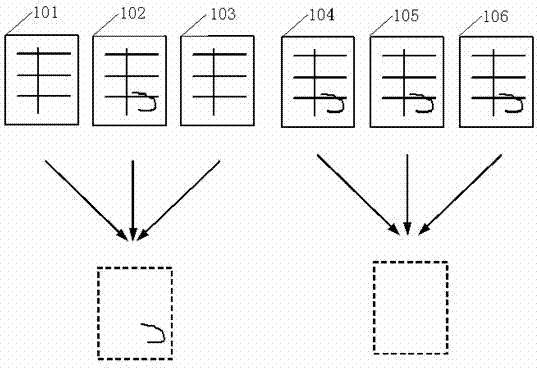

System and method for imaging regions of interest

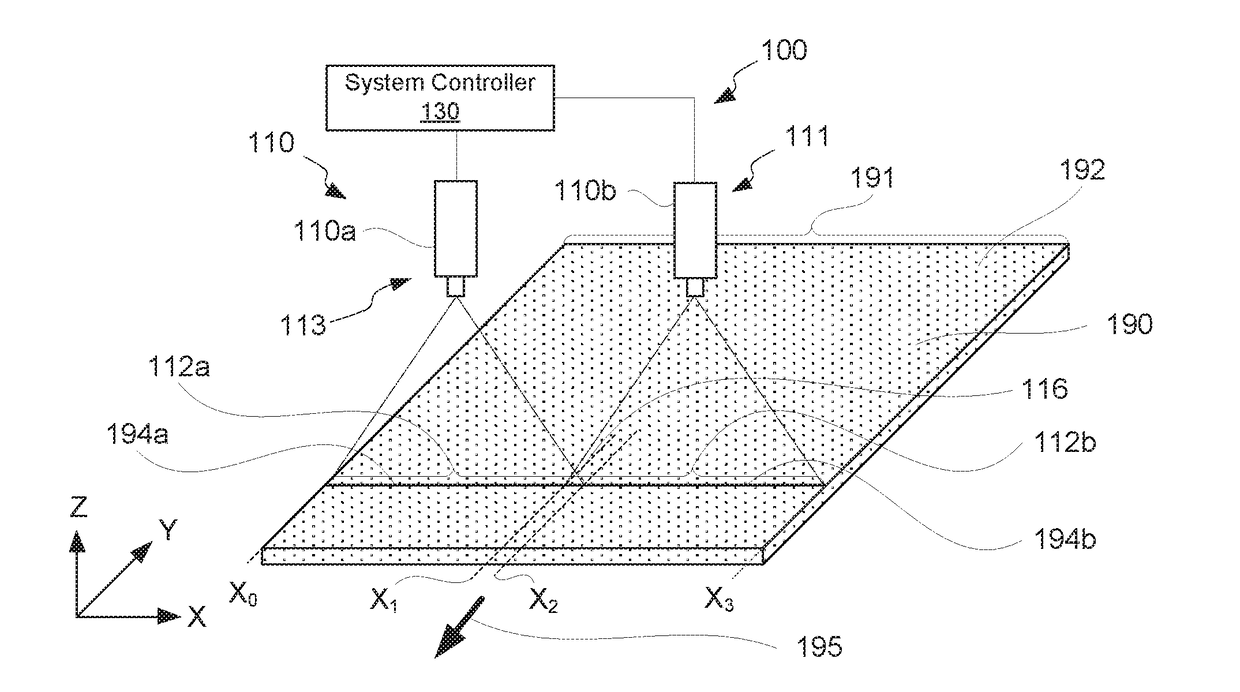

InactiveUS20050117017A1Increase imaging speedImprove data transfer rateColor television detailsOptically investigating flaws/contaminationRegion of interestImage sensor

A camera uses a map to retrieve image data pertaining to two or more region of interest segments (ROI segments) within the field-of-view (FOV) of the camera. The map identifies selected pixels of the image located in the region of interest segments. Image data corresponding to the image can be stored and the image data associated with the selected pixels can be accessed individually. In other embodiments, image data associated with the selected pixels is read off of the image sensor row-by-row or pixel-by-pixel. The camera can be included within an optical inspection system to analyze ROI segments on a target surface by transmitting only the image data associated with the ROI segments from the camera to an image processing system of the optical inspection system.

Owner:AGILENT TECH INC

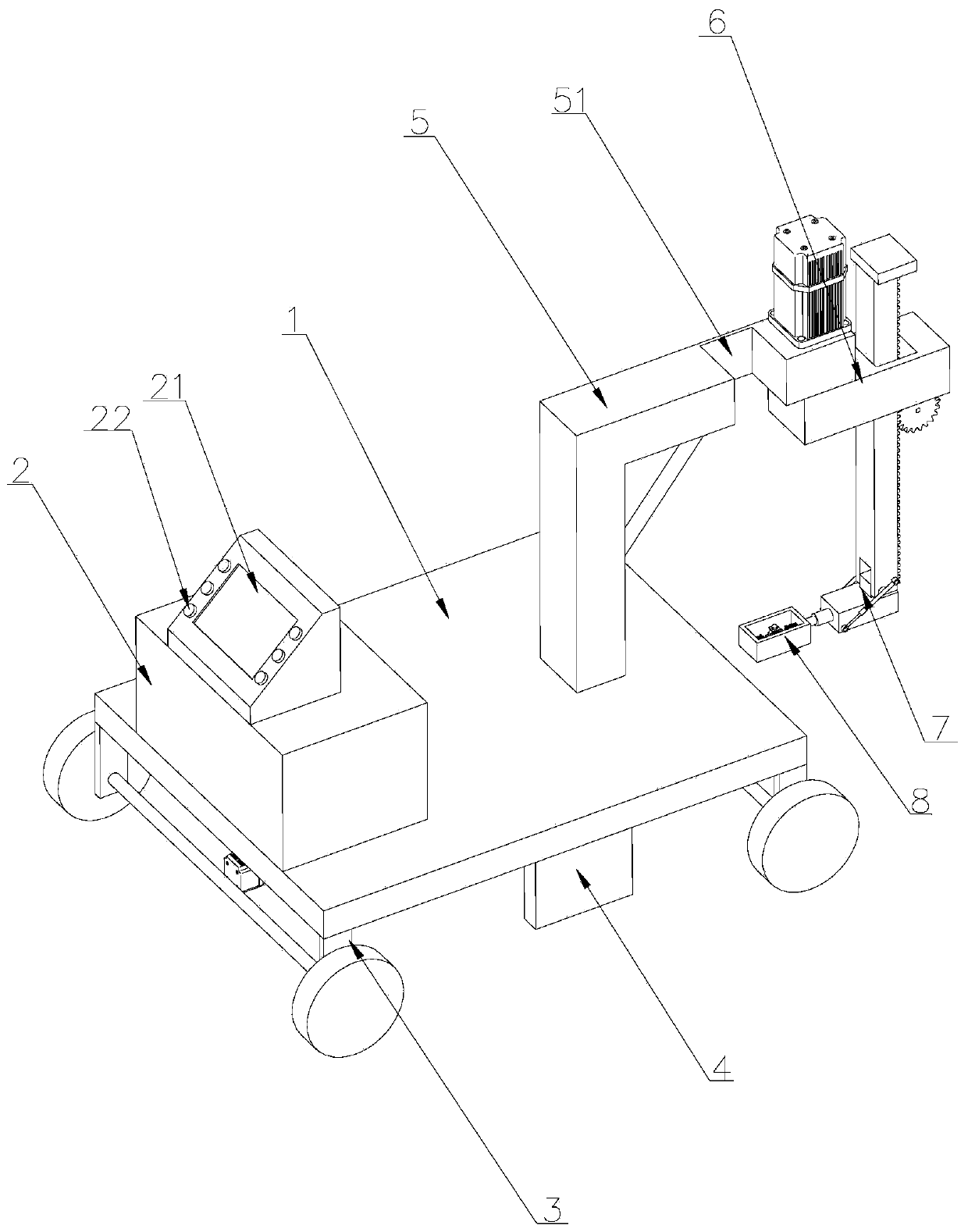

Detection device applied to bridge cracks

ActiveCN111007009ARealize no dead angle detectionReduce production and use costsOptically investigating flaws/contaminationEngineeringStructural engineering

Owner:济南工程职业技术学院

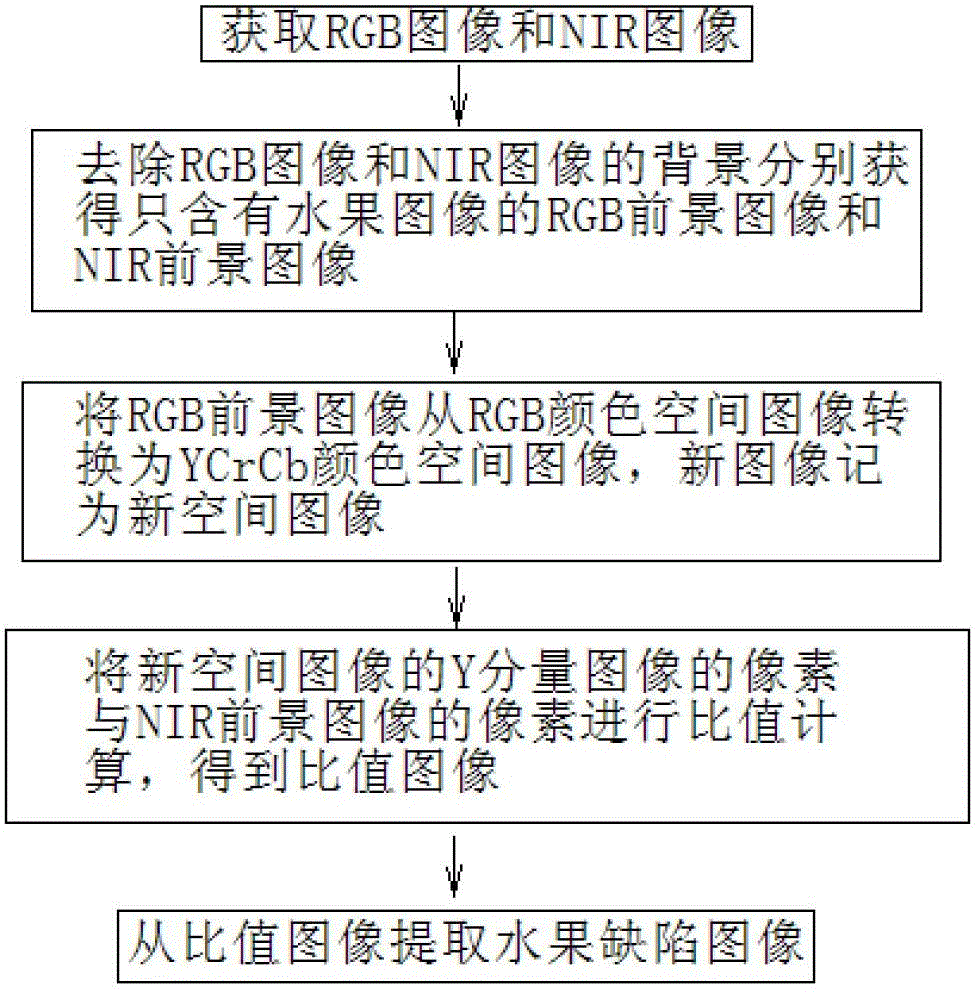

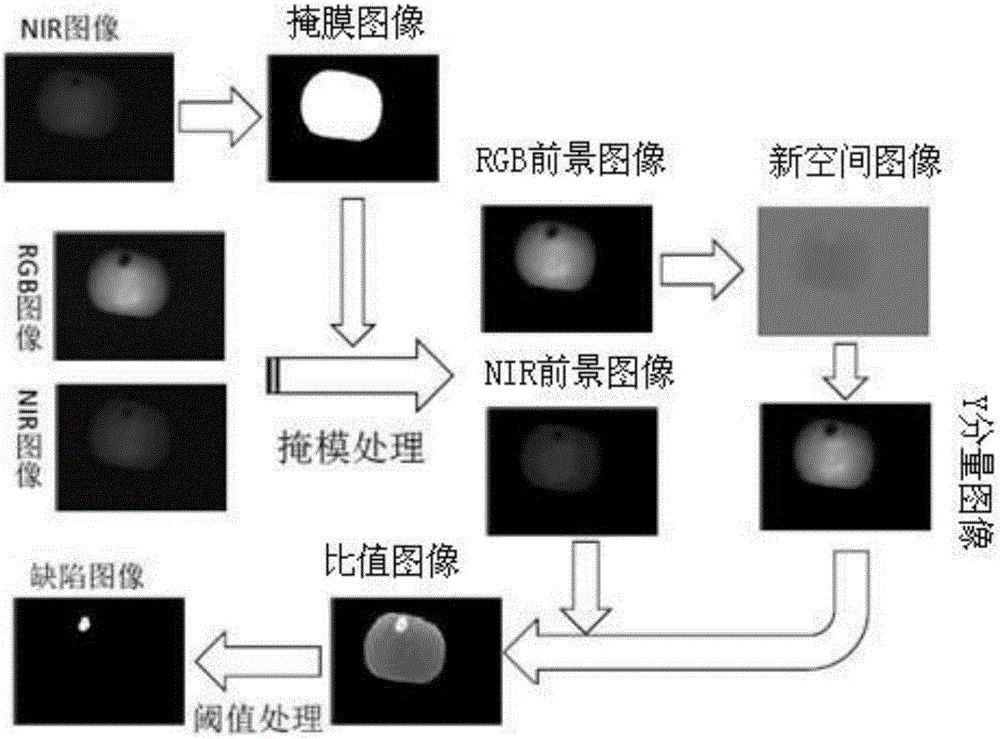

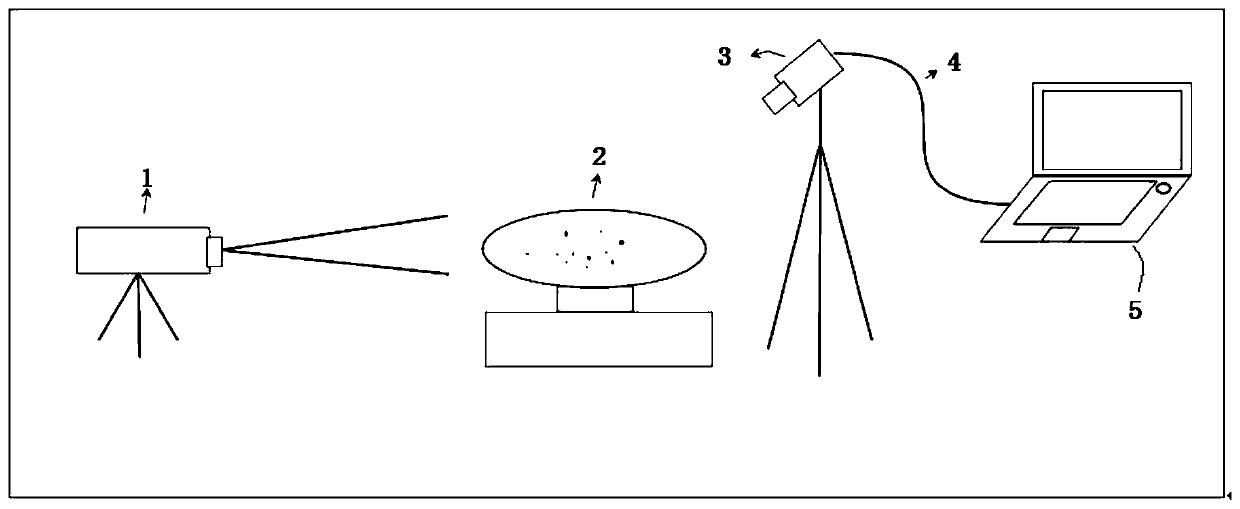

Fruit surface defect detection method based on image marking

InactiveCN105424709AAccurate Defect DetectionStatistically accurateOptically investigating flaws/contaminationImage conversionVisual perception

A fruit surface defect detection method based on image marking includes the following steps that firstly, a surface picture of a to-be-detected fruit is taken and saved, and an original image is obtained; secondly; the original picture is uploaded to a server to be analyzed and processed; processing of the server includes the steps that a, the obtained original image is converted into a space where the visual system of human beings is applied, and an H component and an I component are extracted; b, dynamic threshold segmentation is performed on the H component; c, gray histogram statistics is performed on the I component, segmentation is performed through a fixed threshold method, and a threshold is selected between two wave peaks; d, the H value segmentation result and the I value segmentation result are operated, and a binary image with defect areas is obtained; denoising is performed on the obtained binary image; f, the binary image is enhanced, hole noise may exist in the defect areas, and filling is performed on the noise; g, the obtained binary image is marked, and the number and the area of defects are calculated; a detection result is output; labor intensity of workers is reduced, and production efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Linear frequency modulation ultrasonic excitation-based infrared thermal wave nondestructive testing method and system

ActiveCN103926253AMaterial analysis using acoustic emission techniquesOptically investigating flaws/contaminationUltrasonic generatorTest sample

Owner:HARBIN INST OF TECH

Method for detecting flaw on surface of fruit

Owner:SHANGHAI JIAO TONG UNIV

Multi-angle lighting device and collecting system

InactiveCN108535265AEasy to detectLow costOptically investigating flaws/contaminationGlass coverThree-dimensional space

The invention relates to the technical field of glass cover plate detection, in particular to a multi-angle lighting device. The multi-angle lighting device comprises a light source module and a control module for controlling the on and off and / or brightness of the light source module, the light source module comprises a plurality of light source components which are disposed at different lightingangles in a three-dimensional space and all face the same lighting area. By virtue of the light source module which face the same lighting area and can light at different lighting angles in a three-dimensional space, and the control module controlling the on and off and / or brightness of the light source module, the collection imaging and defect detection at different angles of a product to be detected can be realized. The multi-angle lighting device has the advantages of low cost, stable performance and low omission factor.

Owner:SHENZHEN NANOVISION CORP

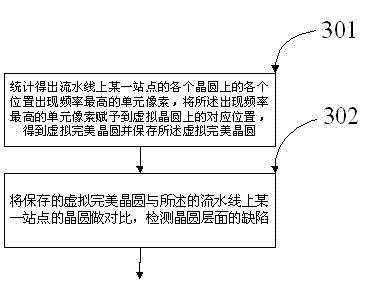

Method and machine for scanning wafer defects, wafer defect scanning machine

ActiveCN102890089AOptically investigating flaws/contaminationEngineeringElectrical and Electronics engineering

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

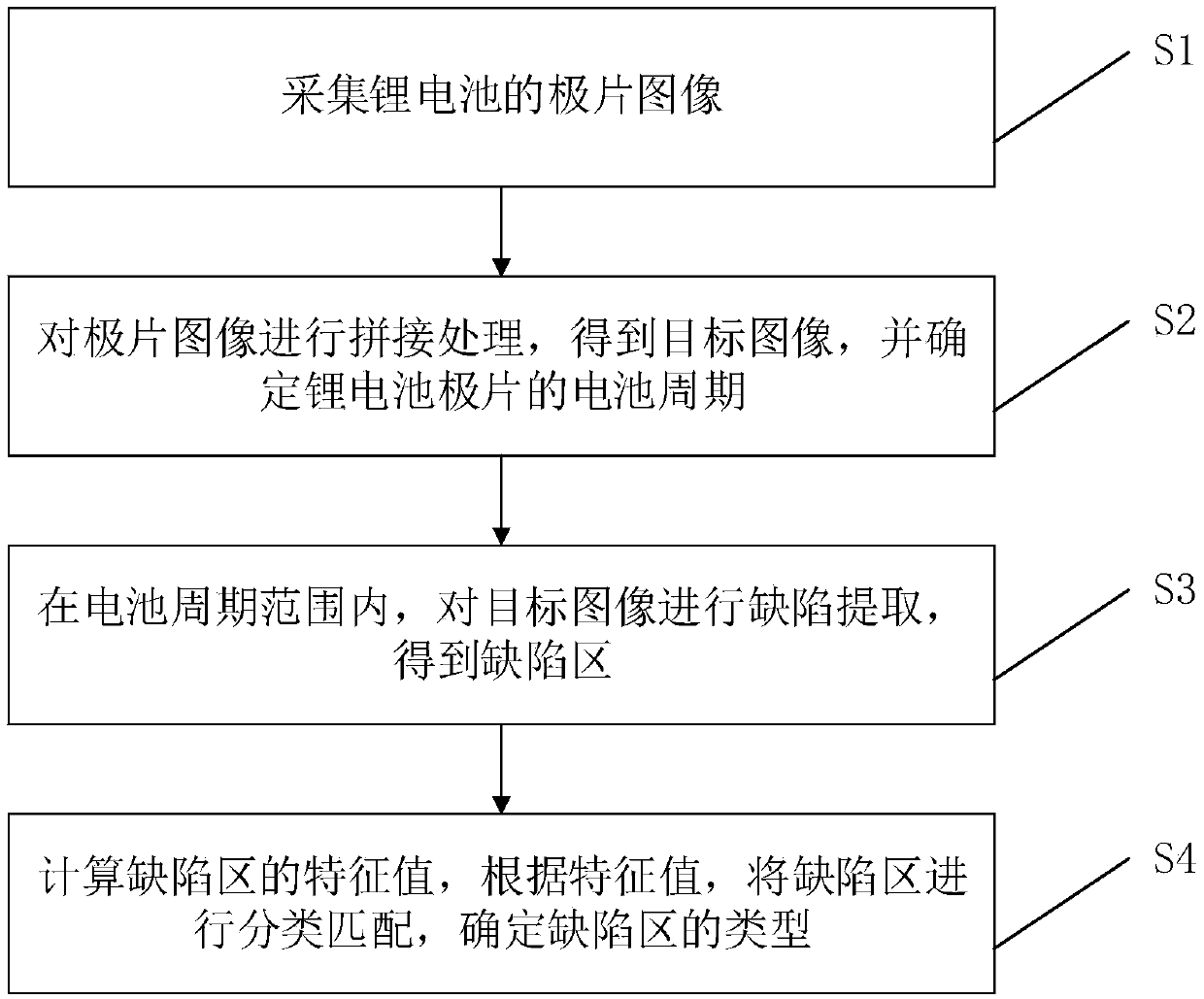

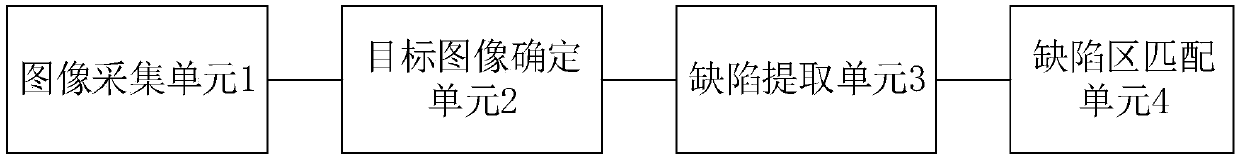

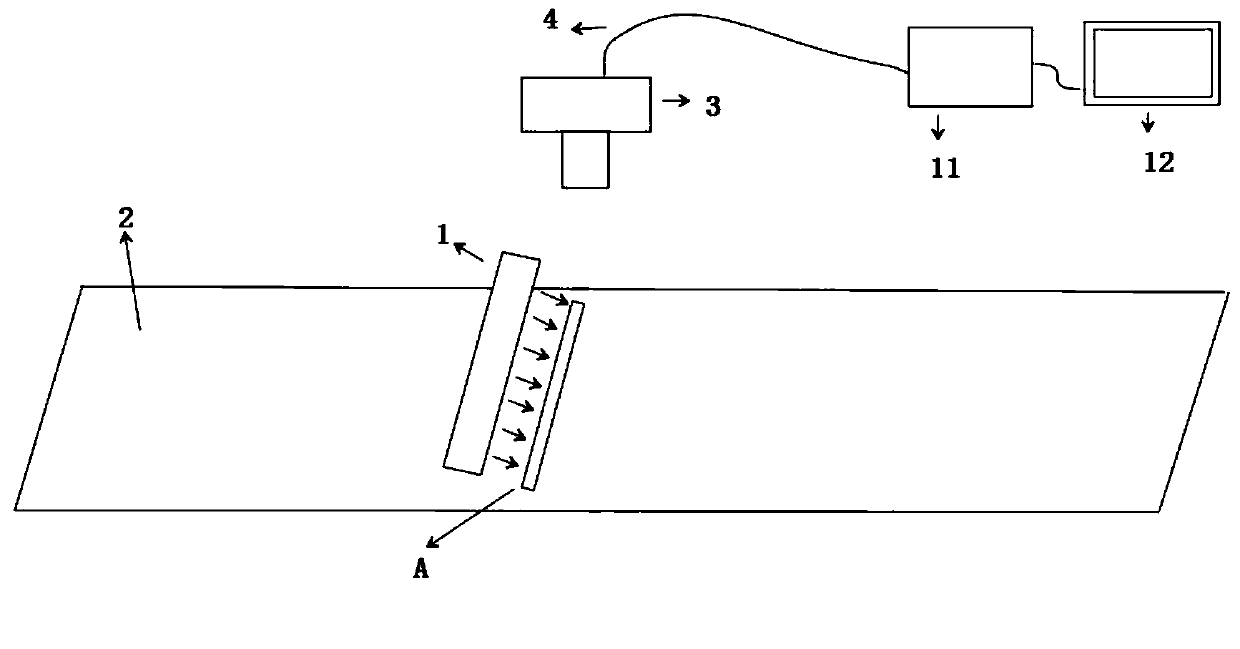

Lithium battery coating defect detection method, system and device and storage medium

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH

Part appearance defect detection method, device and equipment and readable storage medium

InactiveCN109767431AImage analysisOptically investigating flaws/contaminationComputer visionArtificial neural network

Owner:BEIJING LEADERTECH INTELLIGENT EQUIP CORP

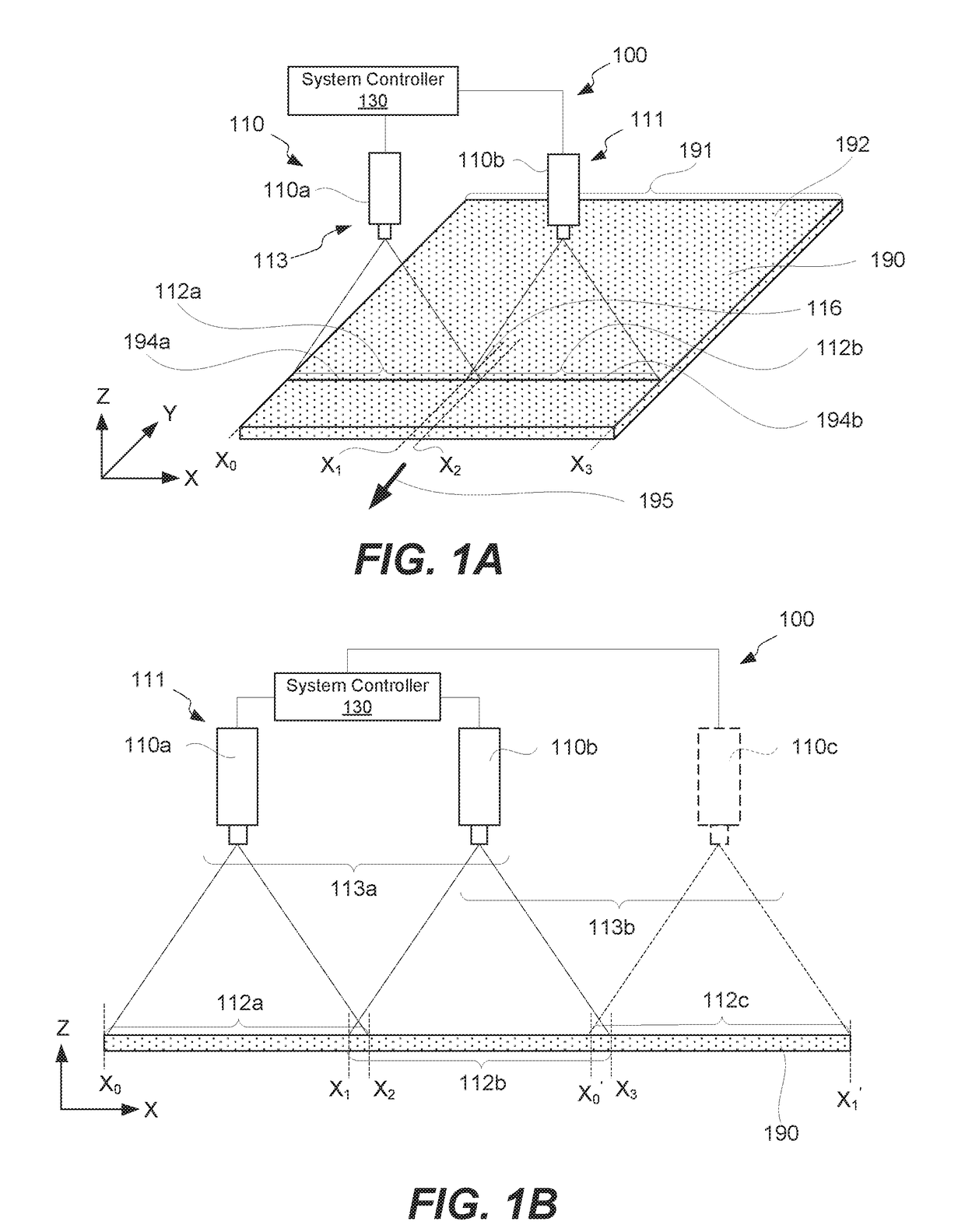

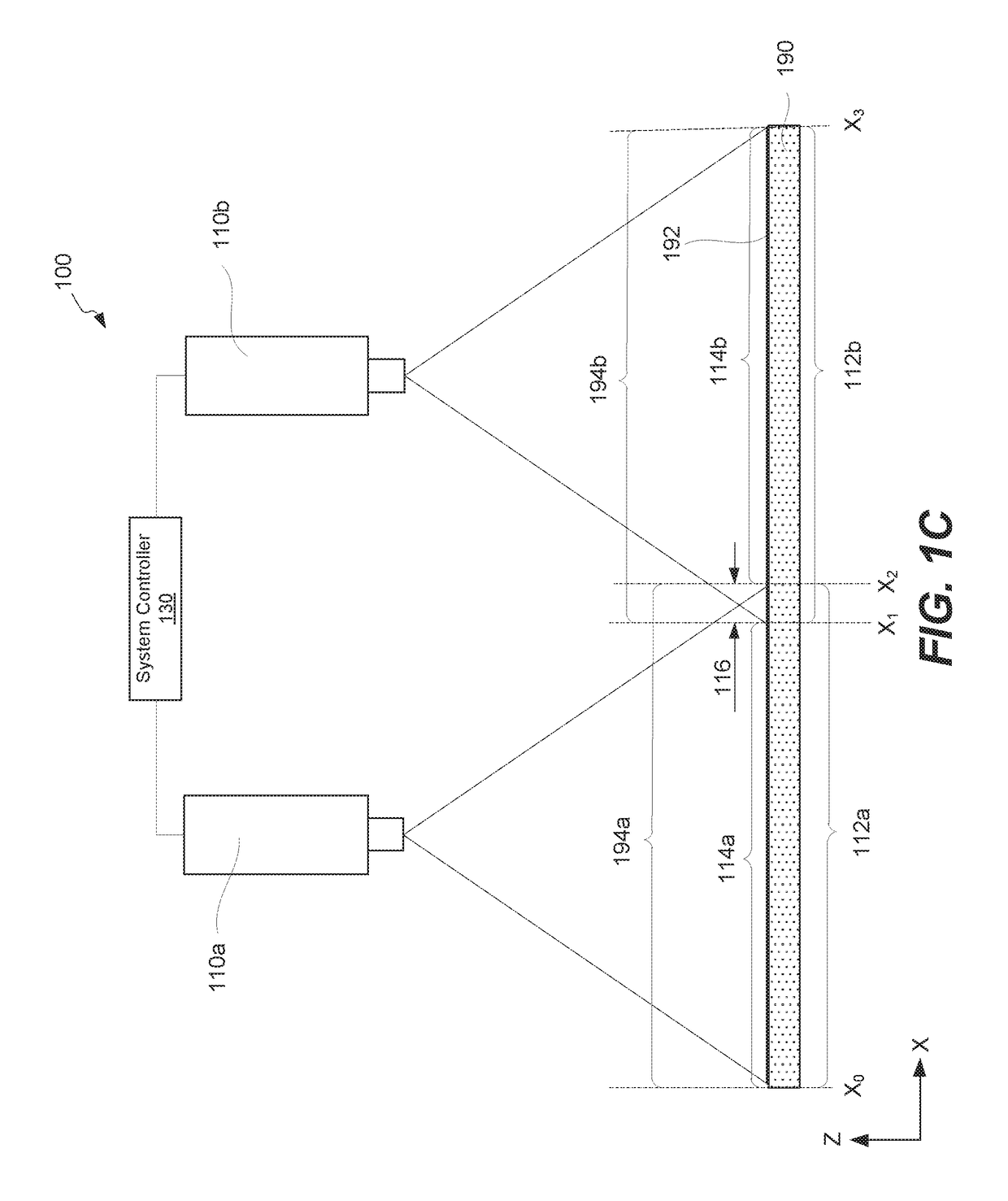

Combined surface inspection using multiple scanners

InactiveUS20180128751A1Avoid interferenceScan accuratelyOptically investigating flaws/contaminationUsing optical meansData setTime segment

Owner:THE BOEING CO

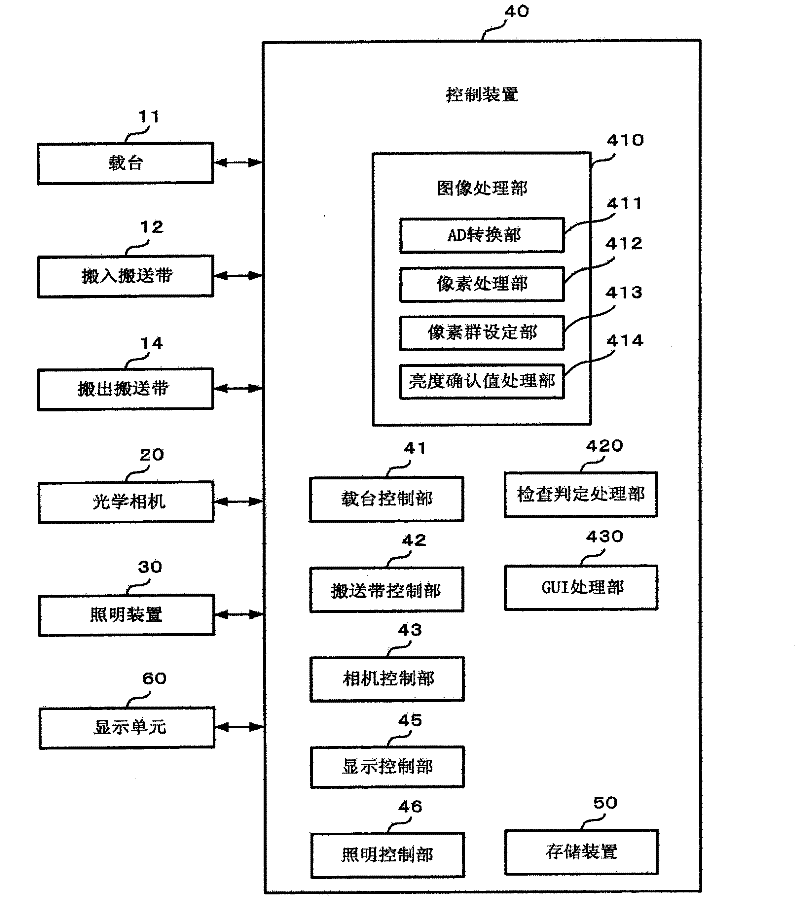

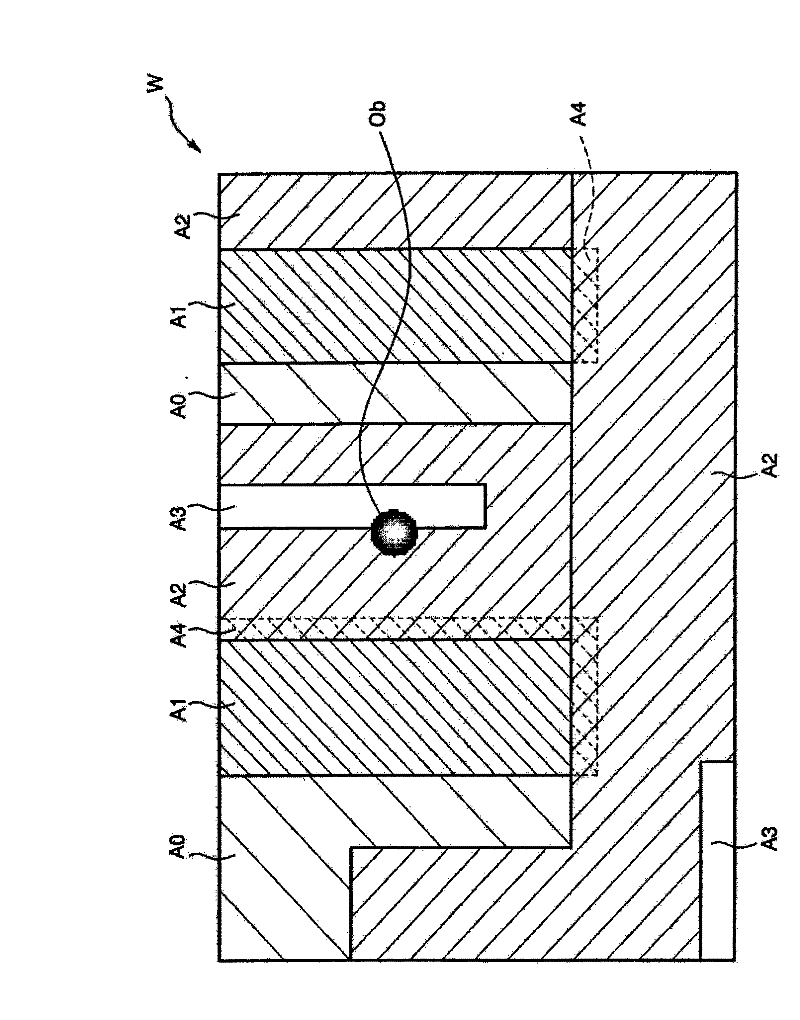

Foreign matter detecting apparatus and method

InactiveCN102539436AEfficient detectionOptically investigating flaws/contaminationForeign matterDigital image

Owner:YAMAHA MOTOR CO LTD

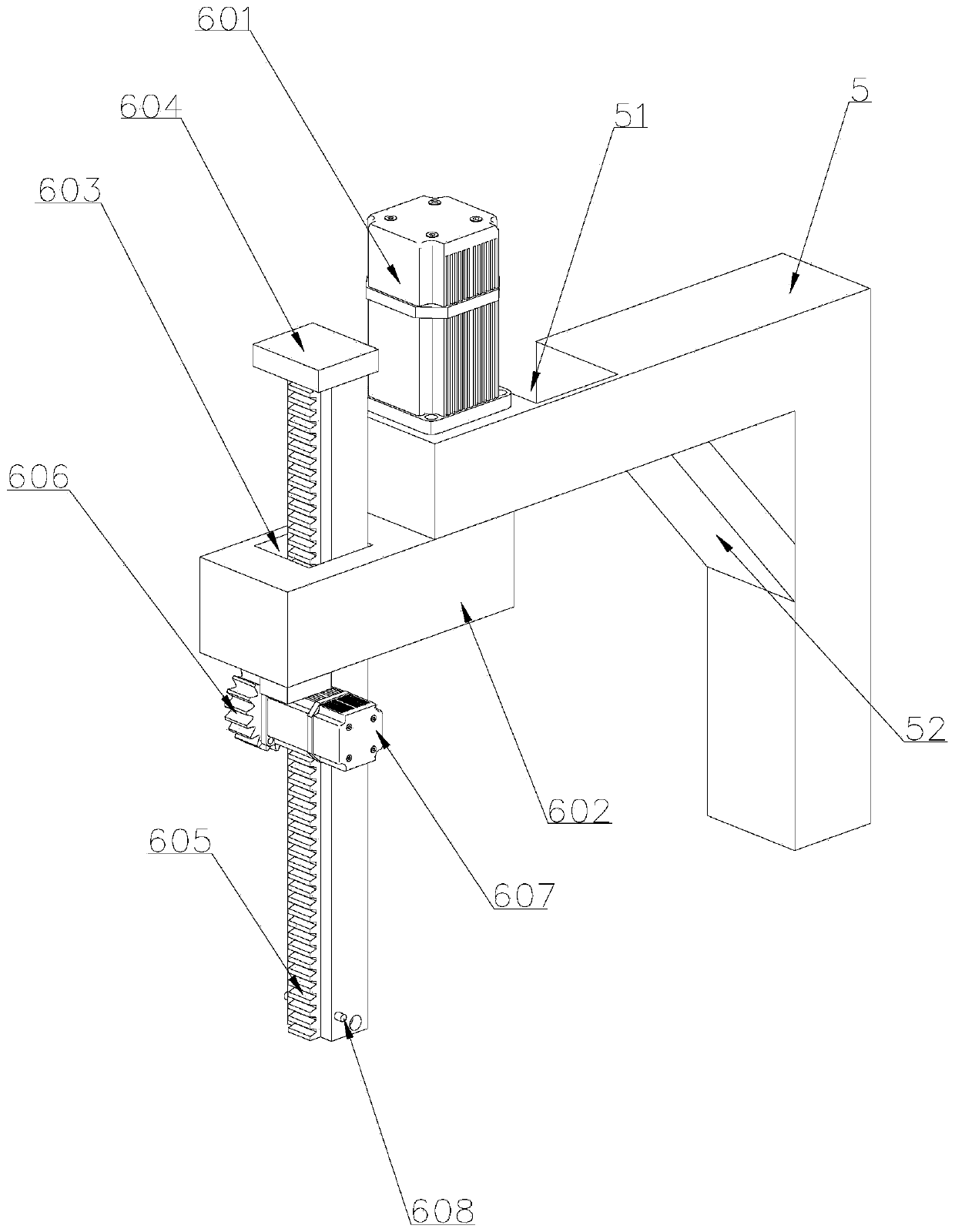

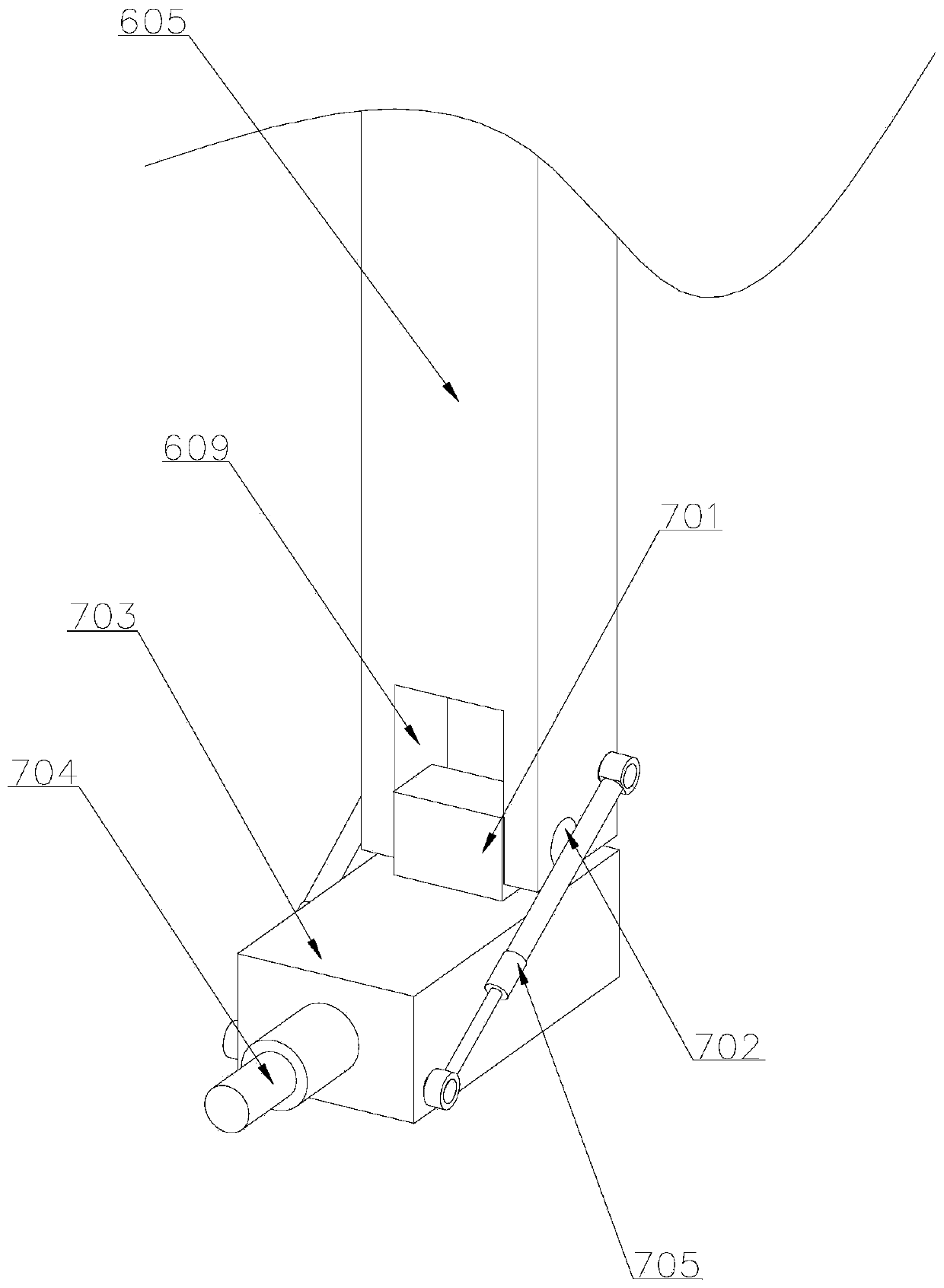

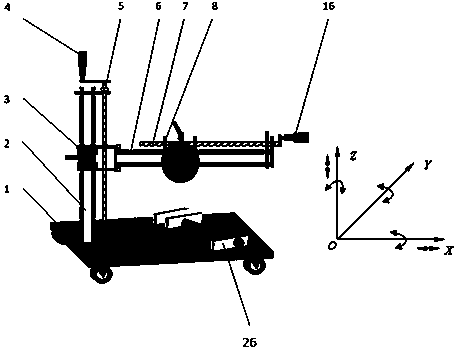

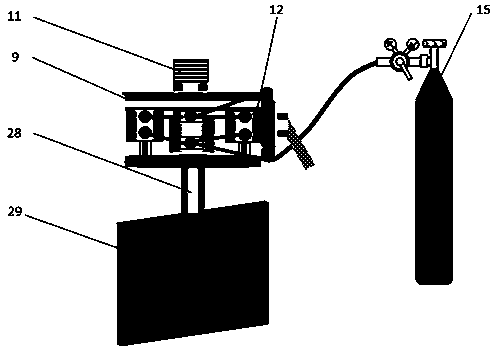

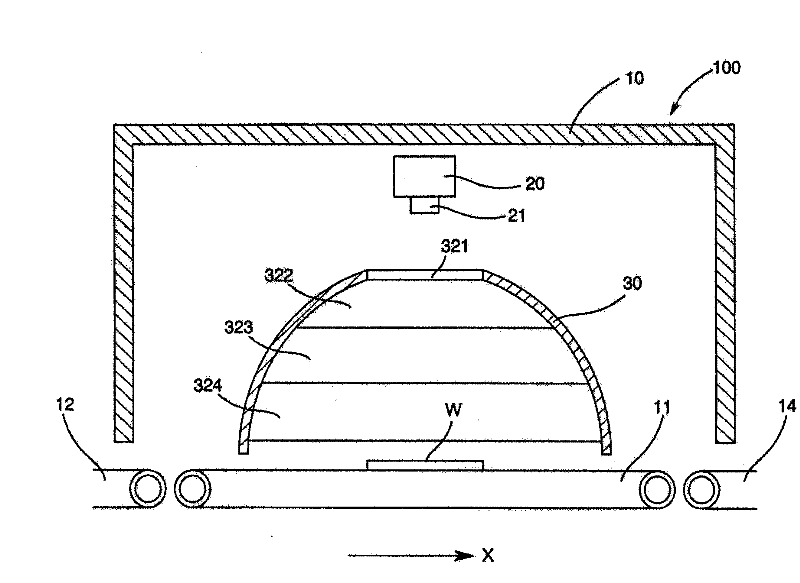

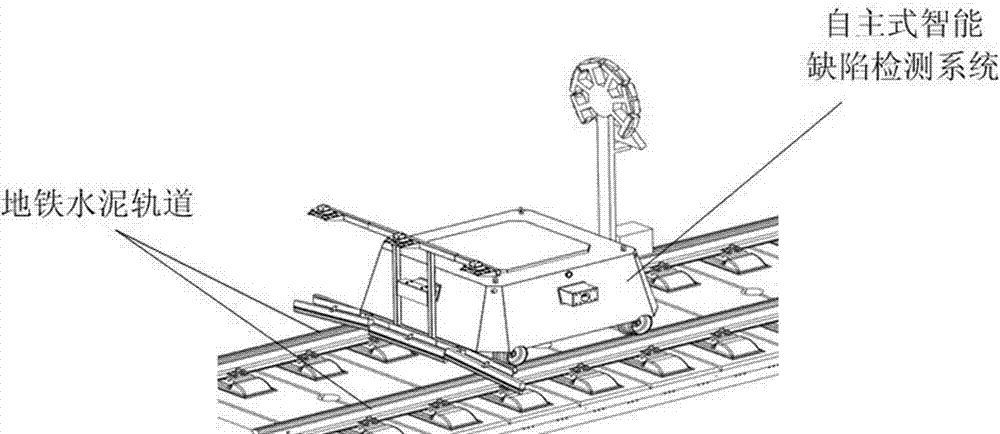

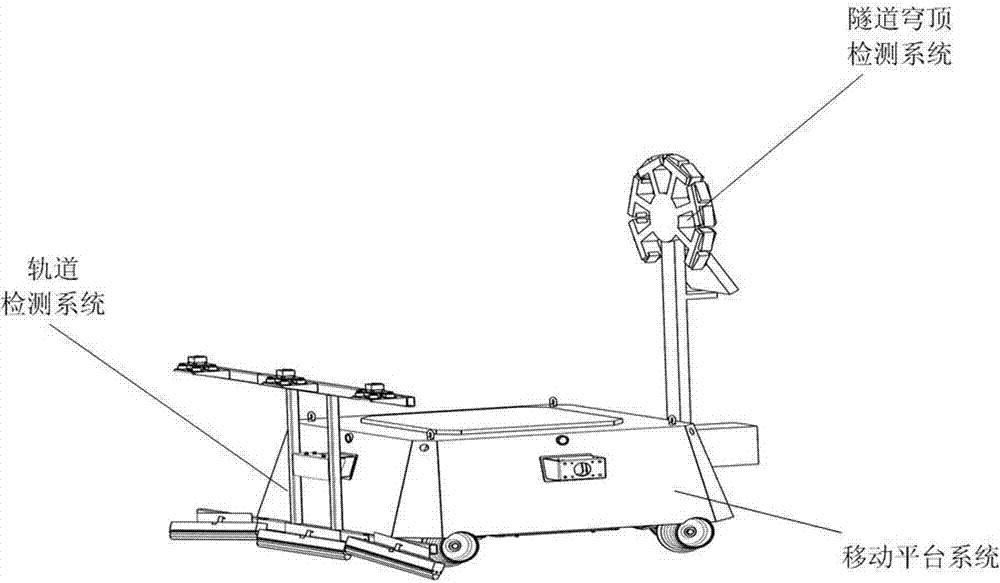

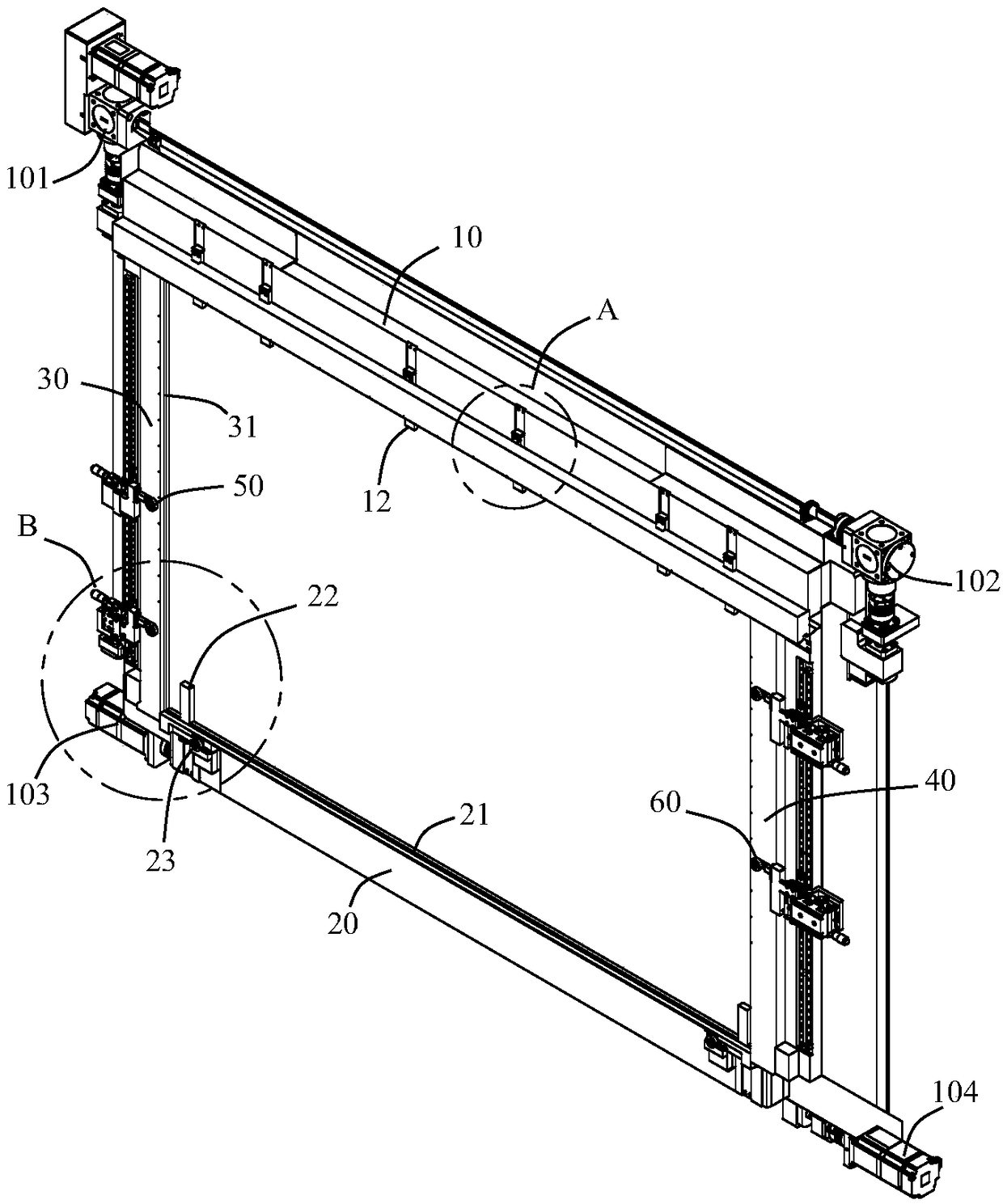

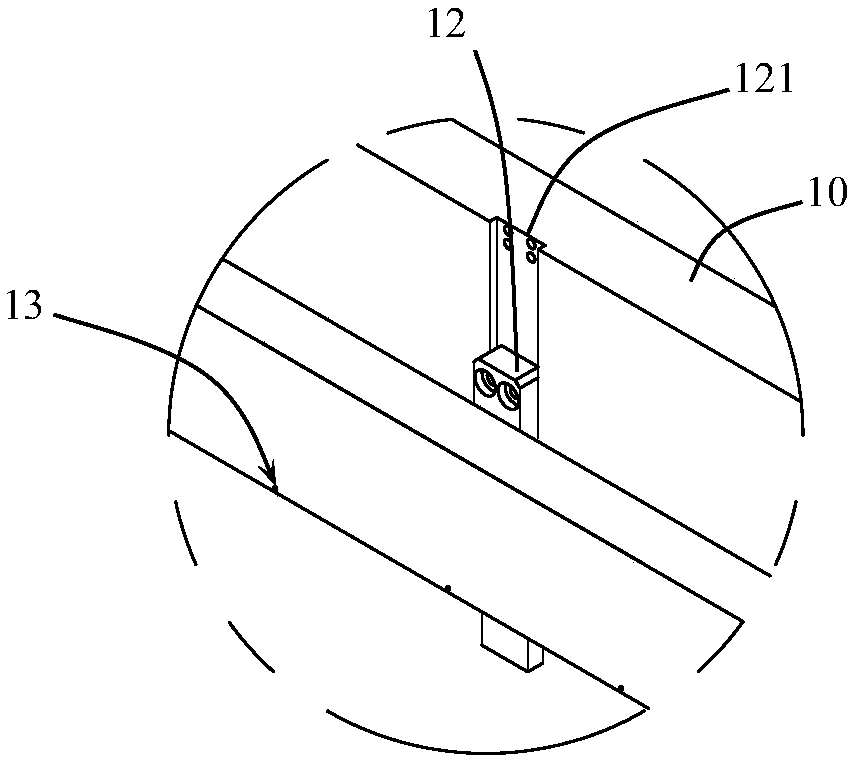

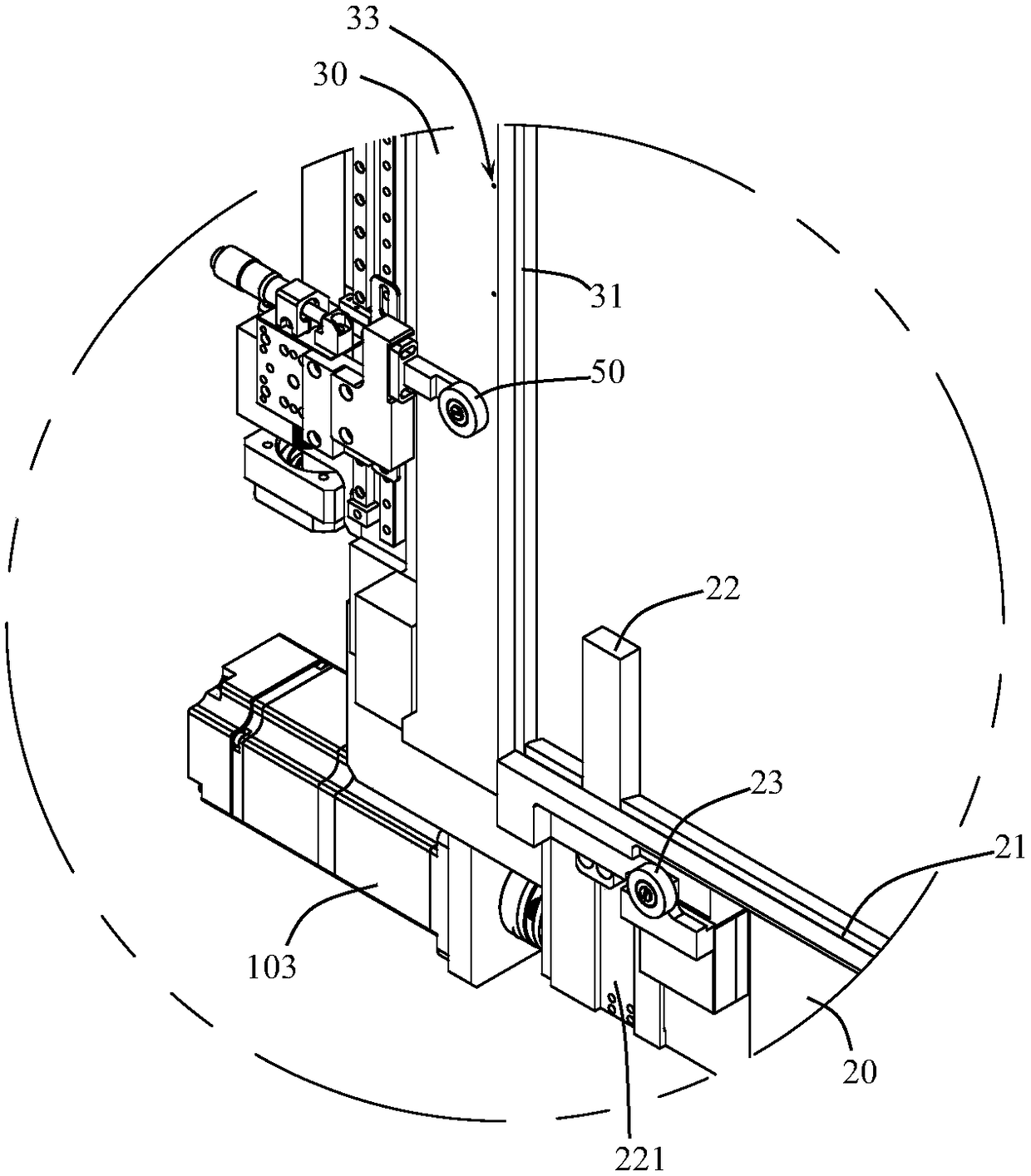

Movable defect detection structure based on double rails

PendingCN107505332AQuick installation kitRealize unmanned inspection work modeOptically investigating flaws/contaminationDistance measurementVehicle frameEngineering

The invention relates to a movable defect detection structure based on double rails. The movable defect detection structure comprises a movable platform system, a rail detection system and a tunnel dome detection system, wherein the movable platform system comprises a frame and a movable wheel train located at the bottom of the frame; the movable wheel train is of a steel rail wheel pair type structure comprising a front wheel train and a rear wheel train; rapid connectors are mounted at the periphery of the frame; the rail detection system and the tunnel dome detection system are mounted on the movable platform system through the rapid connectors. The movable defect detection structure based on the double rails can be rapidly mounted and combined with peripheral equipment and instruments; especially, the movable defect detection structure capable of being adaptive to subway rails and a tunnel dome is provided aiming at the rail detection system and the tunnel dome detection system.

Owner:成都圭目机器人有限公司

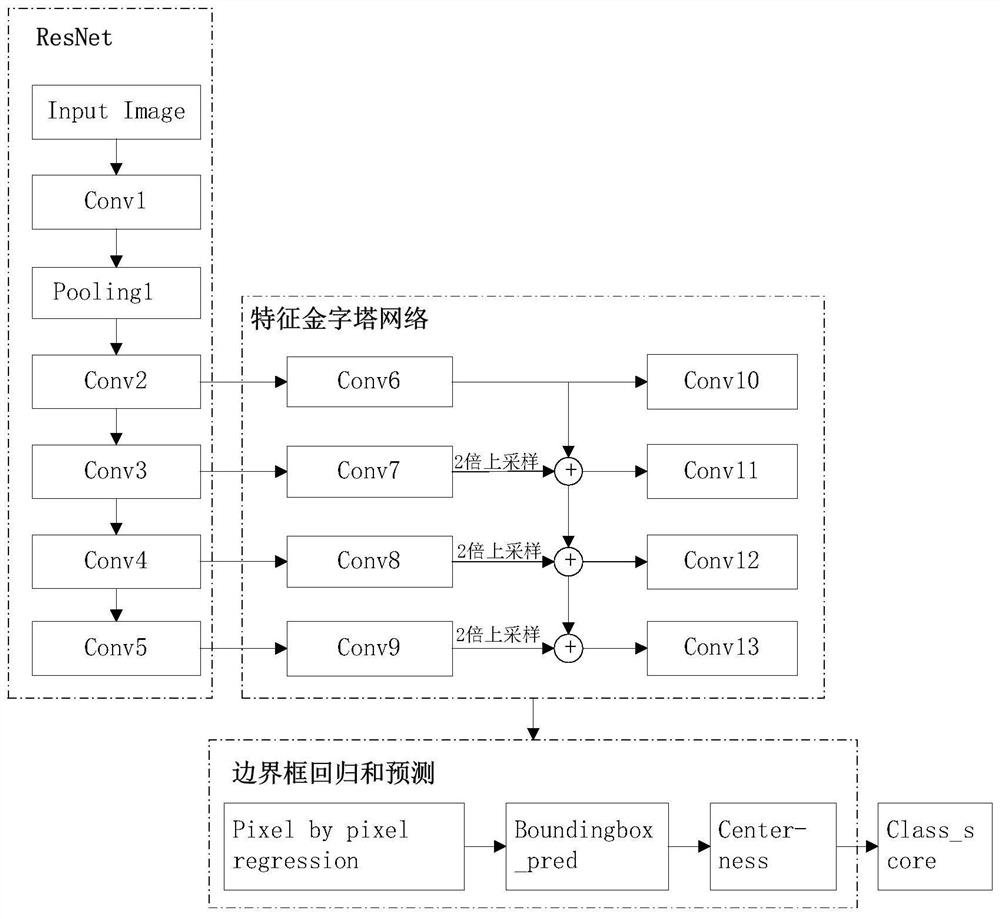

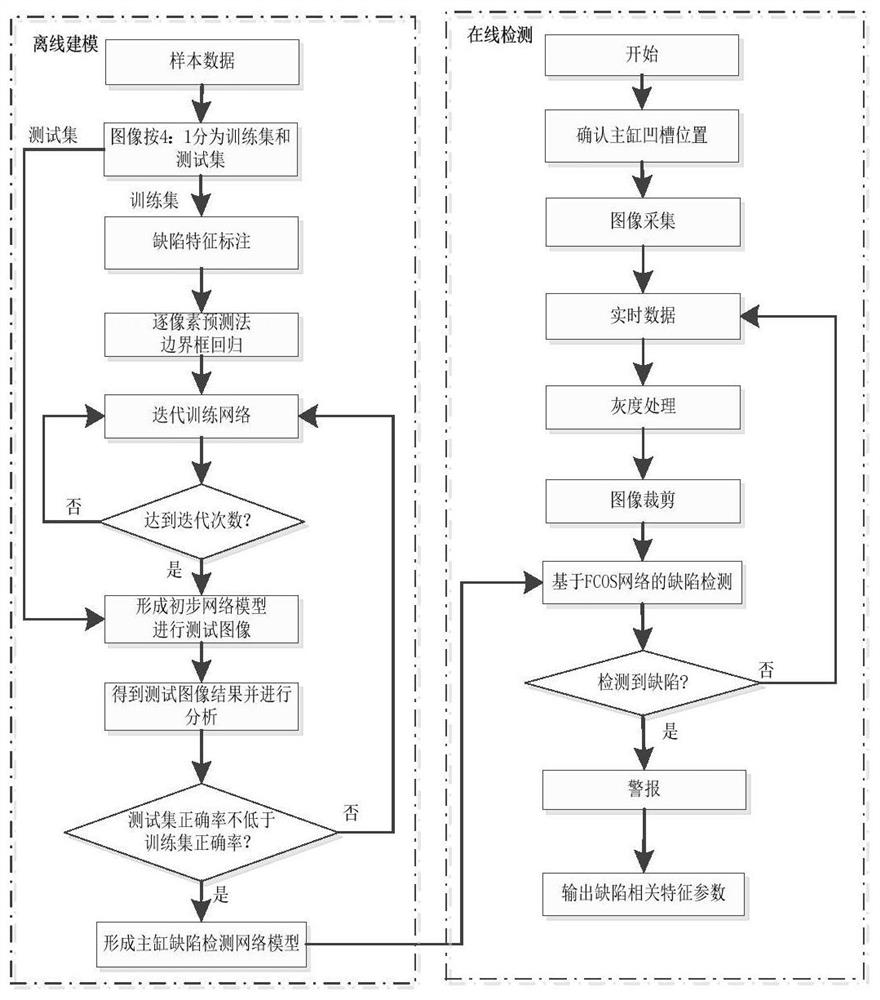

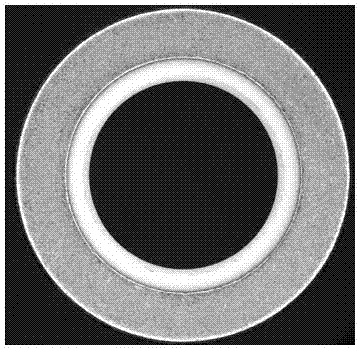

Automobile clutch main cylinder groove surface defect detection method based on deep learning

ActiveCN112419237AEasy to identifyReduce in quantityImage enhancementImage analysisMachine visionAlgorithm

Owner:CHINA JILIANG UNIV

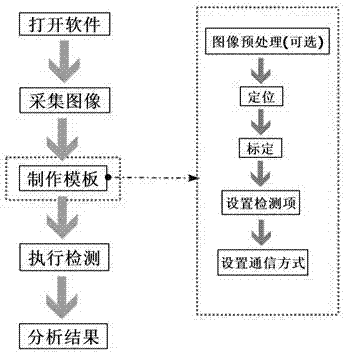

Ceramic defect visual inspection method

InactiveCN107421955AImprove detection rateImprove detection accuracyOptically investigating flaws/contaminationVisual inspectionWork flow

Owner:XIJING UNIV

Product packaging defect detection and identification method based on machine vision

The invention discloses a product packaging defect detection and recognition method based on machine vision. The method comprises steps that firstly, a product packaging processing image without surface defects is extracted; a defect image template feature database is established; feature extraction, detection and identification of the packaging image of the to-be-detected product are carried out;and finally, the unqualified packaged products are blown into the collecting box, and the qualified packaged products are conveyed by the conveying belt to be output. The method is advantaged in thatproblems that in the prior art, the product packaging defect detection error rate is high, and production efficiency is low are solved.

Owner:SHAANXI UNIV OF SCI & TECH

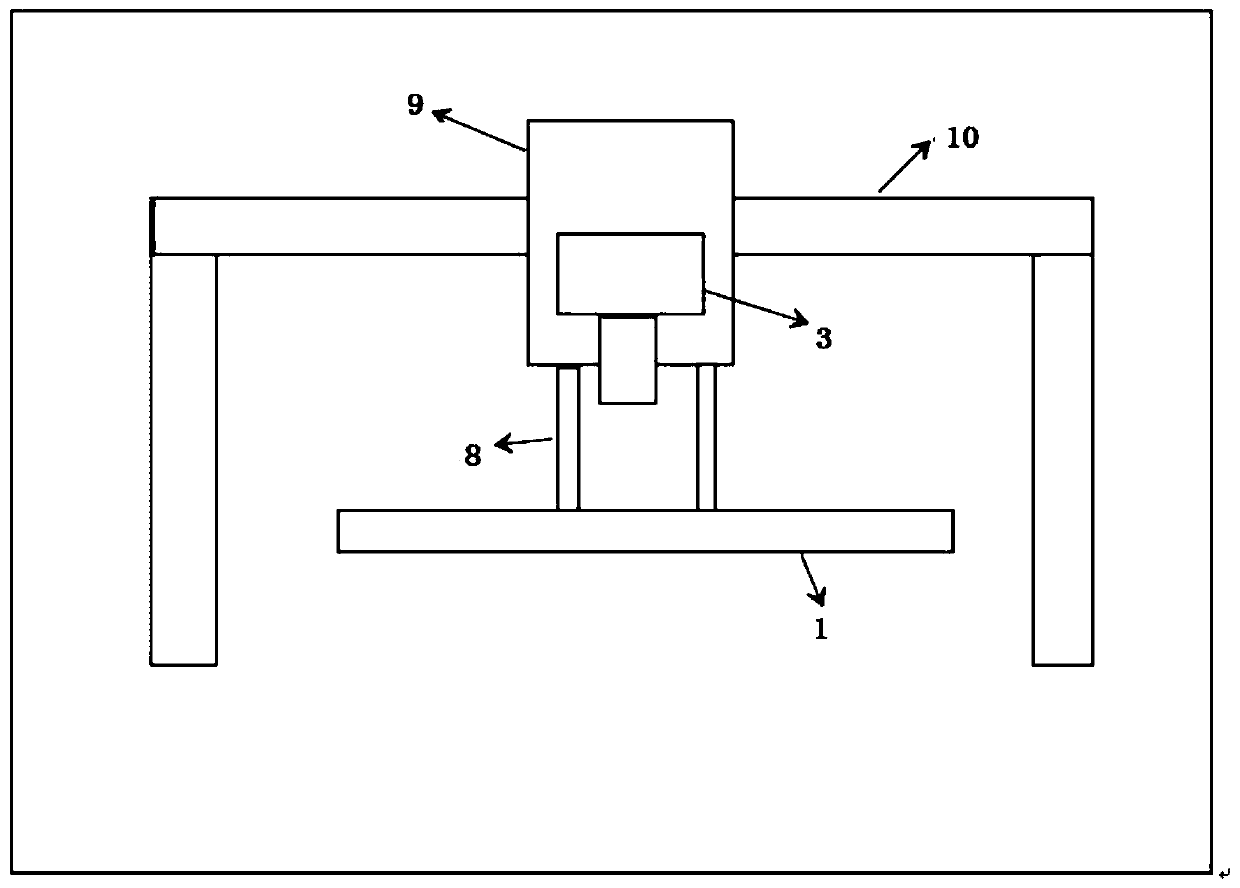

Semiconductor chip test system and method

ActiveCN109827970AReduce downtimeReduce in quantityOptically investigating flaws/contaminationIndividual semiconductor device testingElectrical connectionSemiconductor chip

The present invention provides a semiconductor chip test system. The system comprises: a test circuit; a test interface device comprising a plurality of probes to provide electrical connection betweena semiconductor chip to be tested and the test circuit so as to allow the test circuit to test the semiconductor chip to be tested; an image obtaining device configured to obtain images of the test interface device, wherein the probes are shown in the images; and a processor configured to detect the test interface device based on the obtained image to determine the possible defects in the test interface device and generate output signals based on the determination result of the defects. The detection for the test interface device is provided during the test of the semiconductor chip to prevent the test interface device from being taken out from the semiconductor chip test system as far as possible for detection so as to shorten the downtime of the semiconductor chip test system and save the cost.

Owner:INTEL PROD CHENGDU CO LTD +1

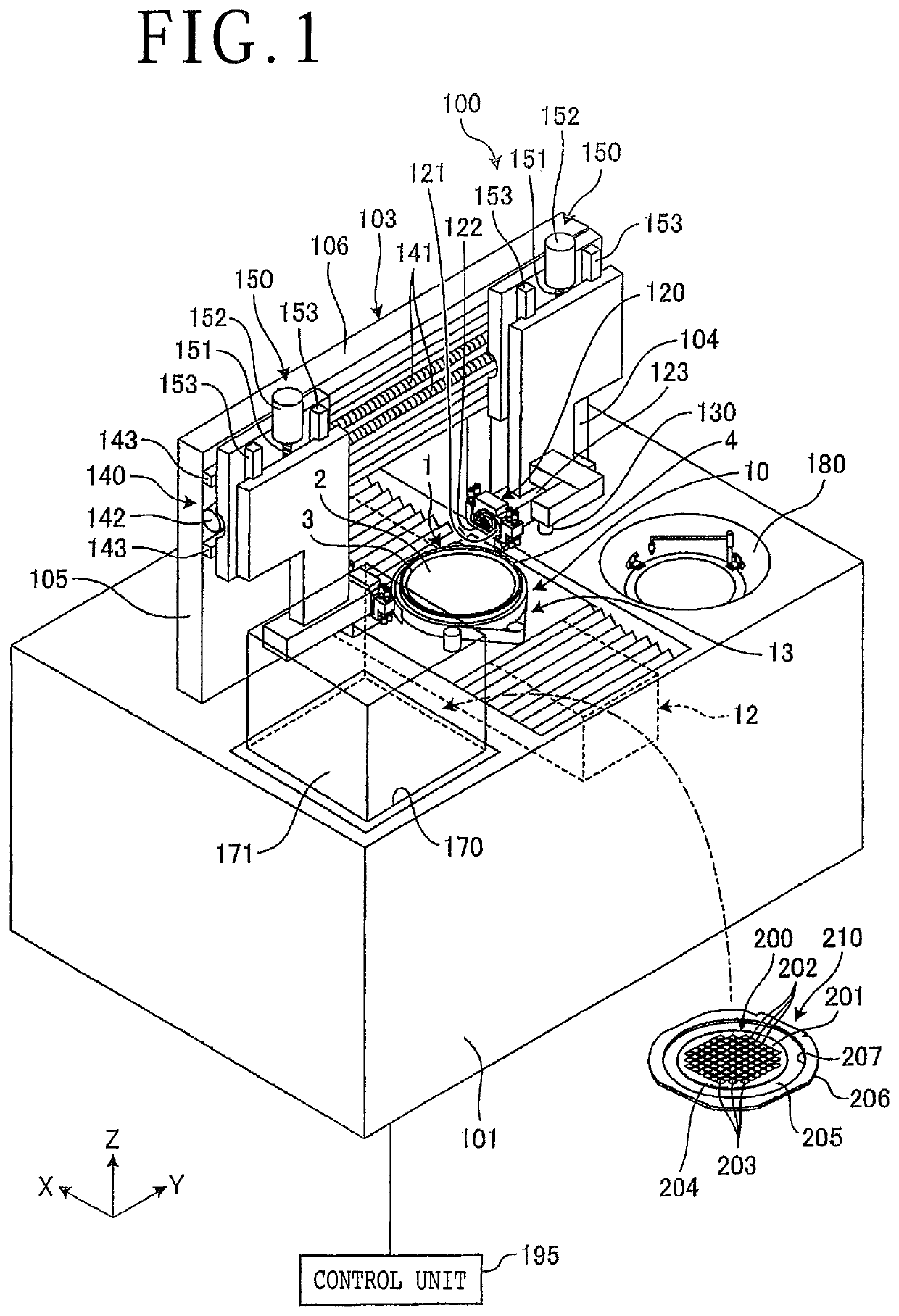

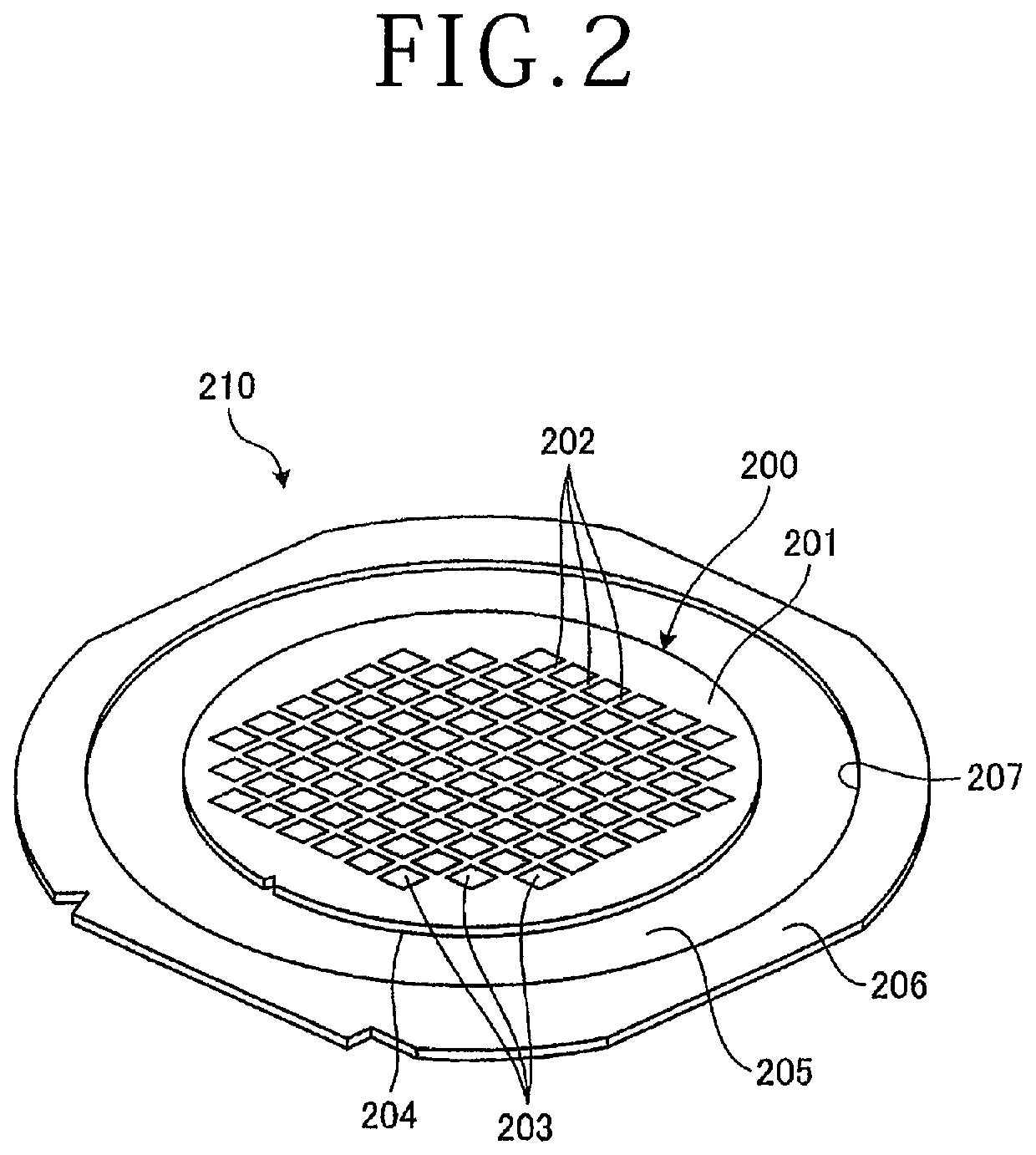

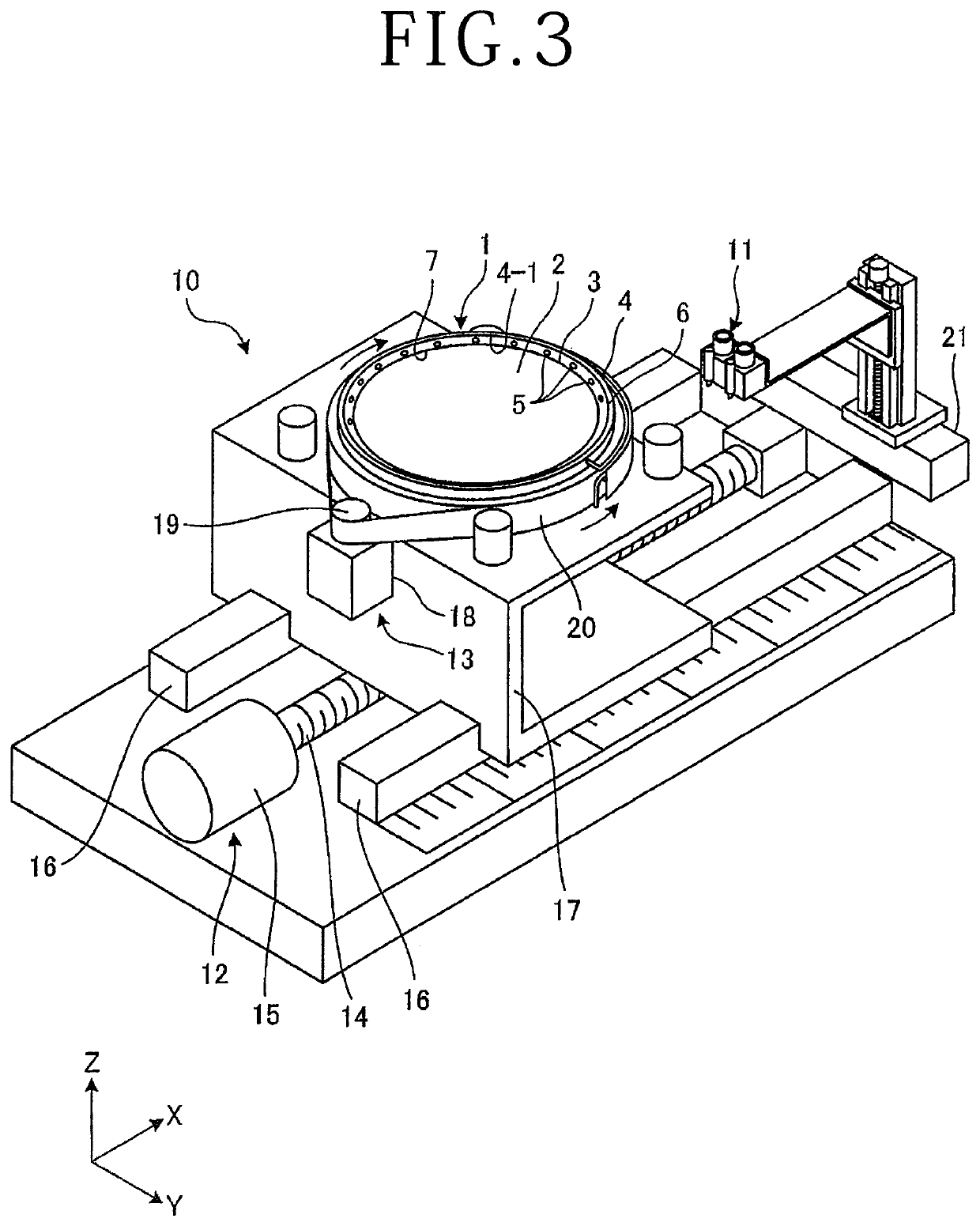

Chuck table and inspection apparatus

ActiveUS20200266091A1Eliminate needSemiconductor/solid-state device testing/measurementWelding/cutting auxillary devicesSuction forceAdhesive belt

Owner:DISCO CORP

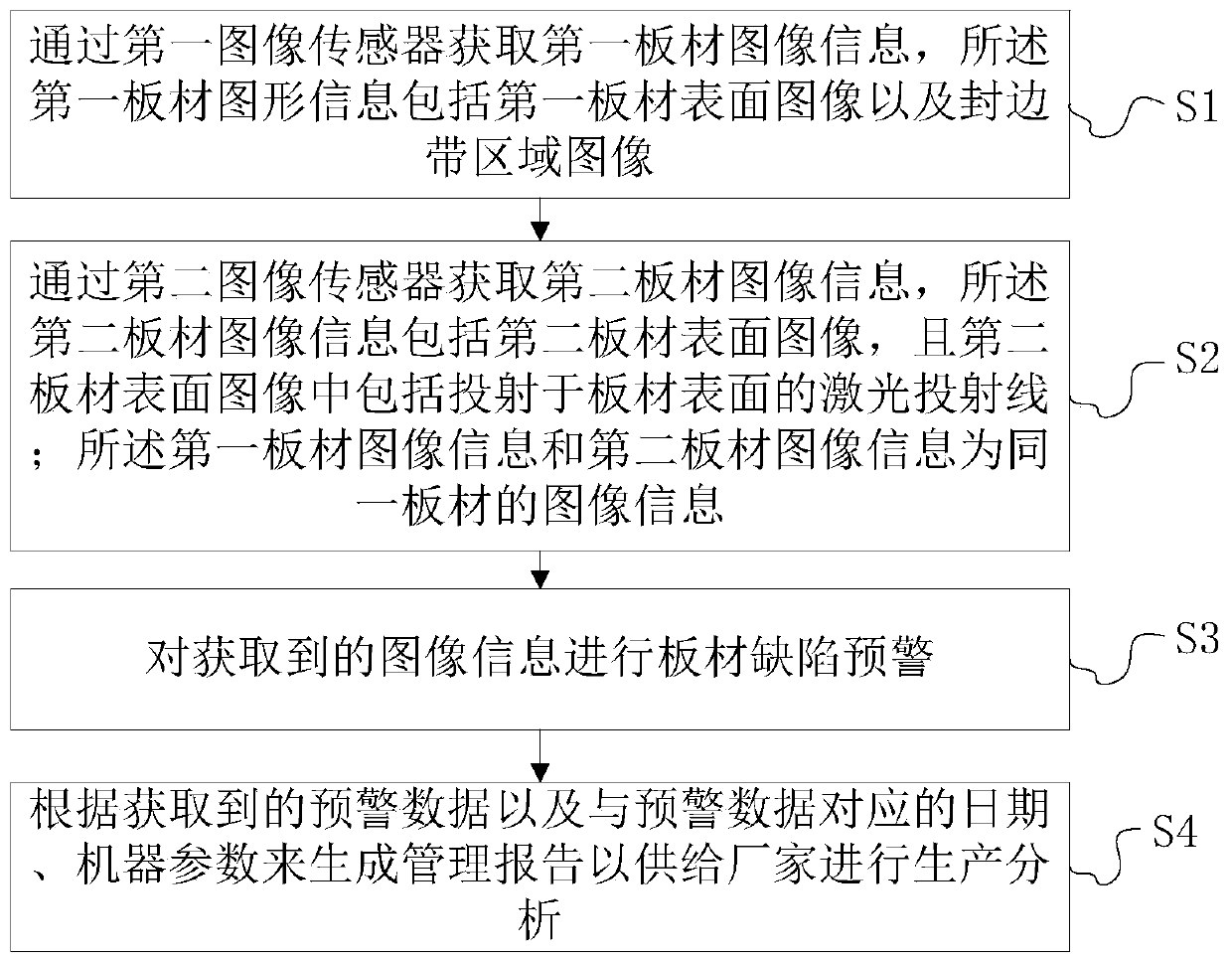

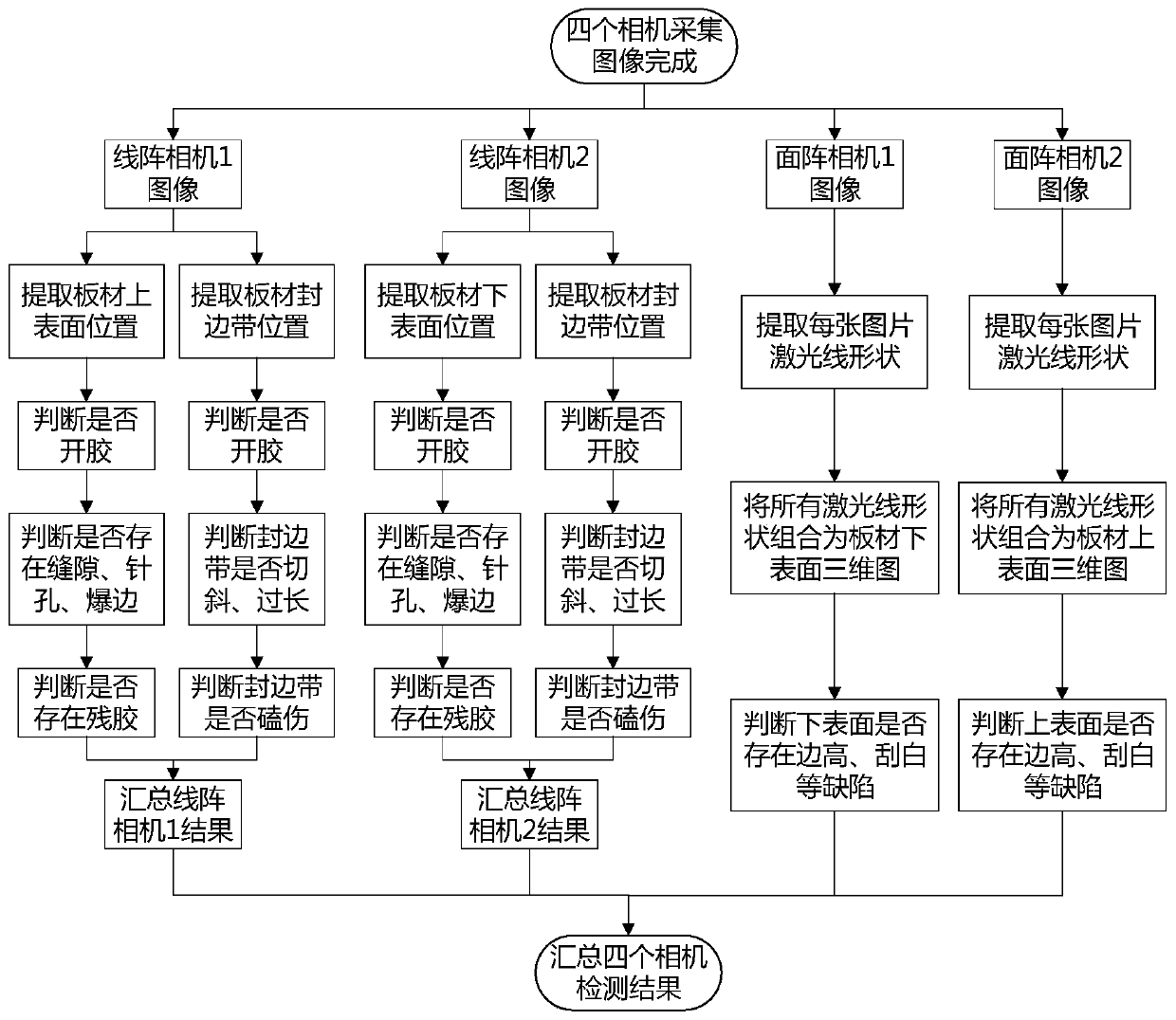

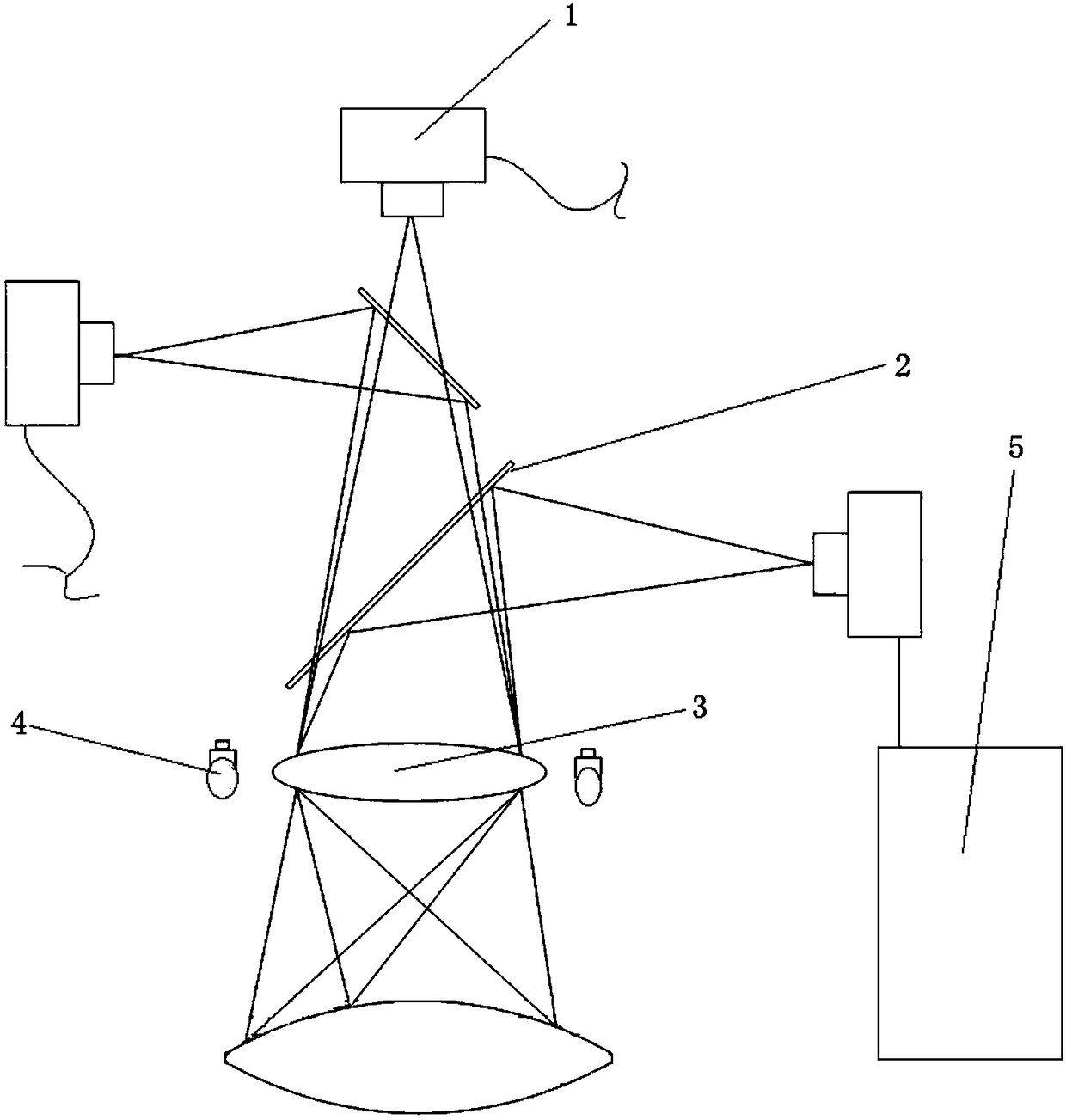

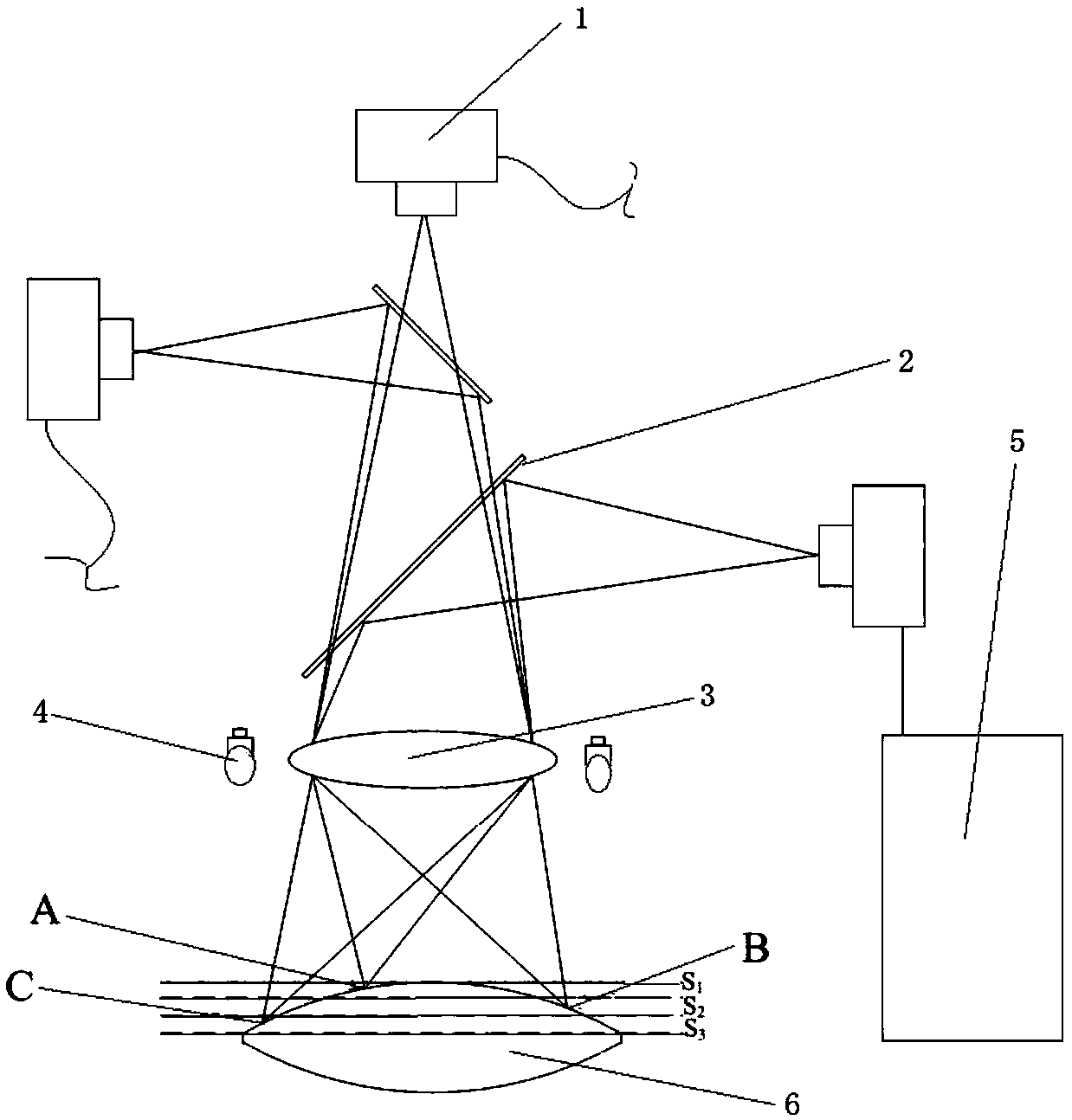

Method and apparatus for detecting edge sealing effect of board

ActiveCN110658200AImprove detection efficiencyEasy to detectOptically investigating flaws/contaminationComputer graphics (images)Engineering

Owner:广州深路自动化科技有限公司

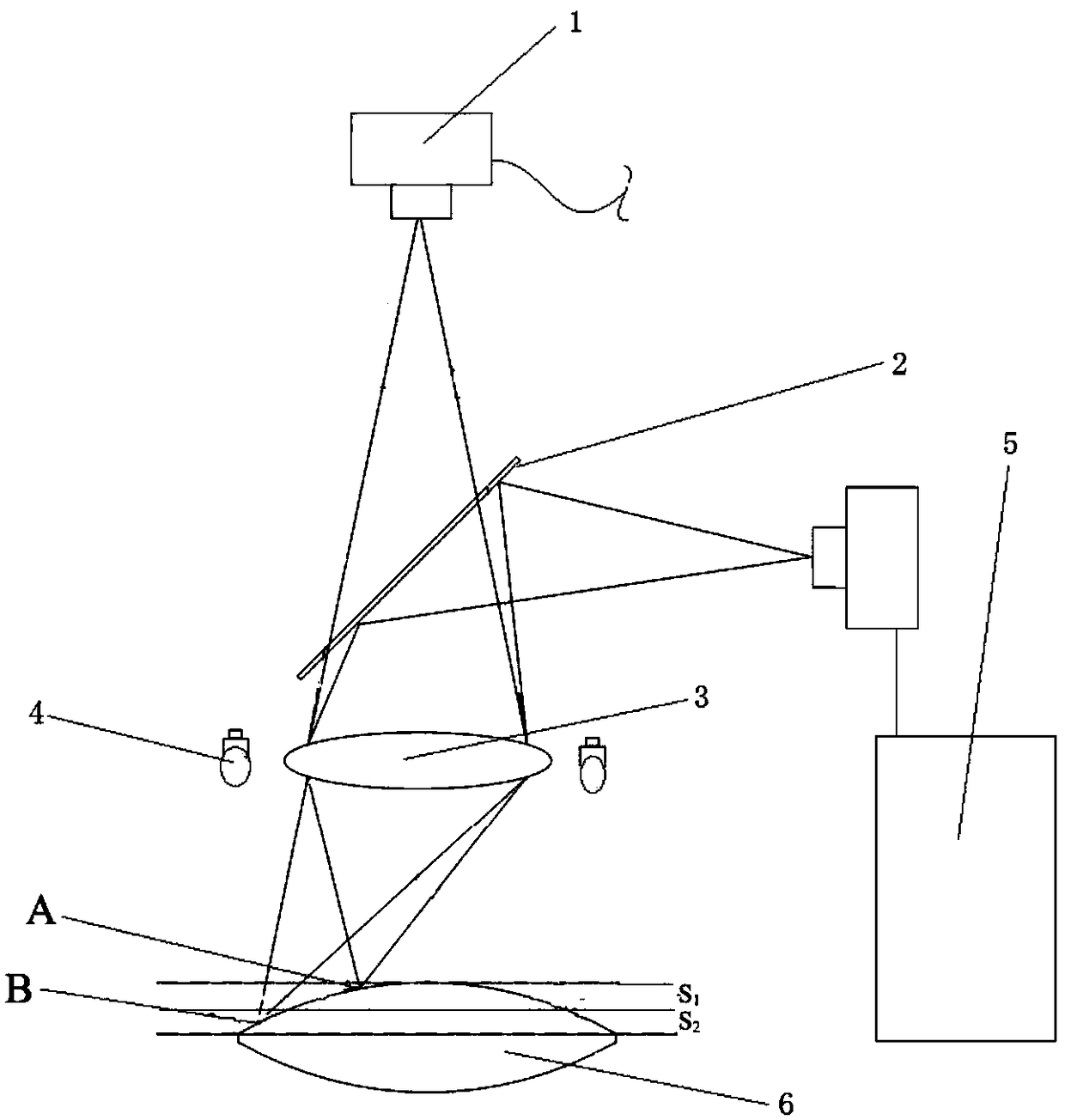

Device and method for detecting surface imperfection of curved-surface optical element

PendingCN108152302ASolving problems that cannot be detected automaticallyLow costOptically investigating flaws/contaminationCamera lensImaging lens

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

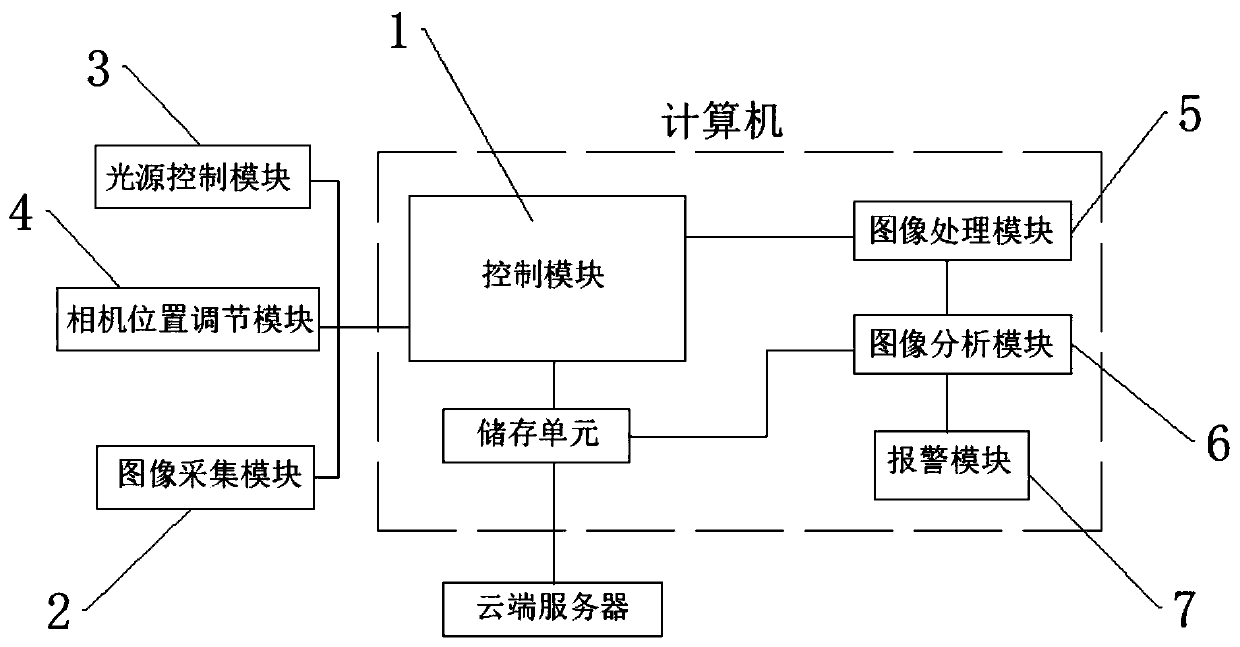

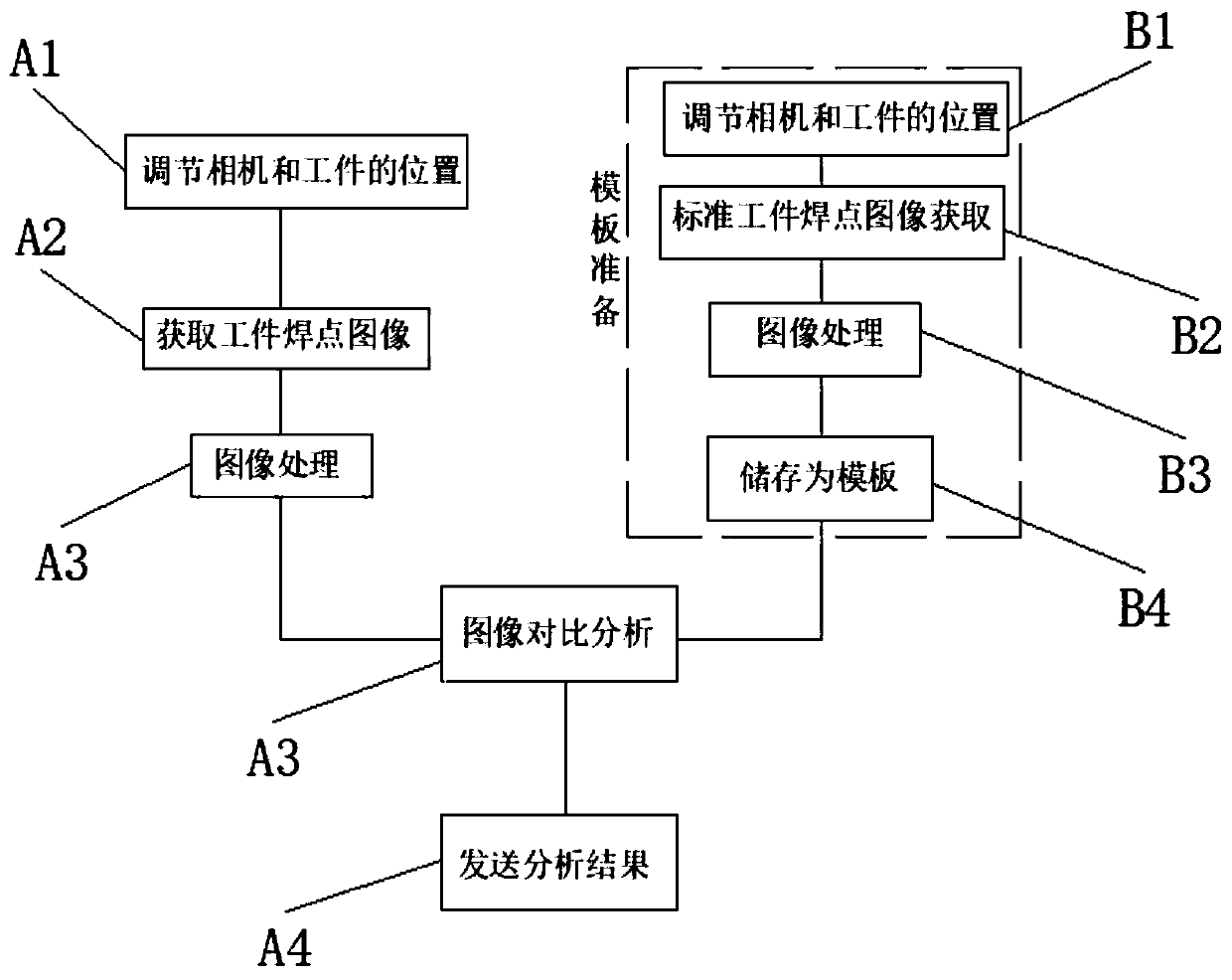

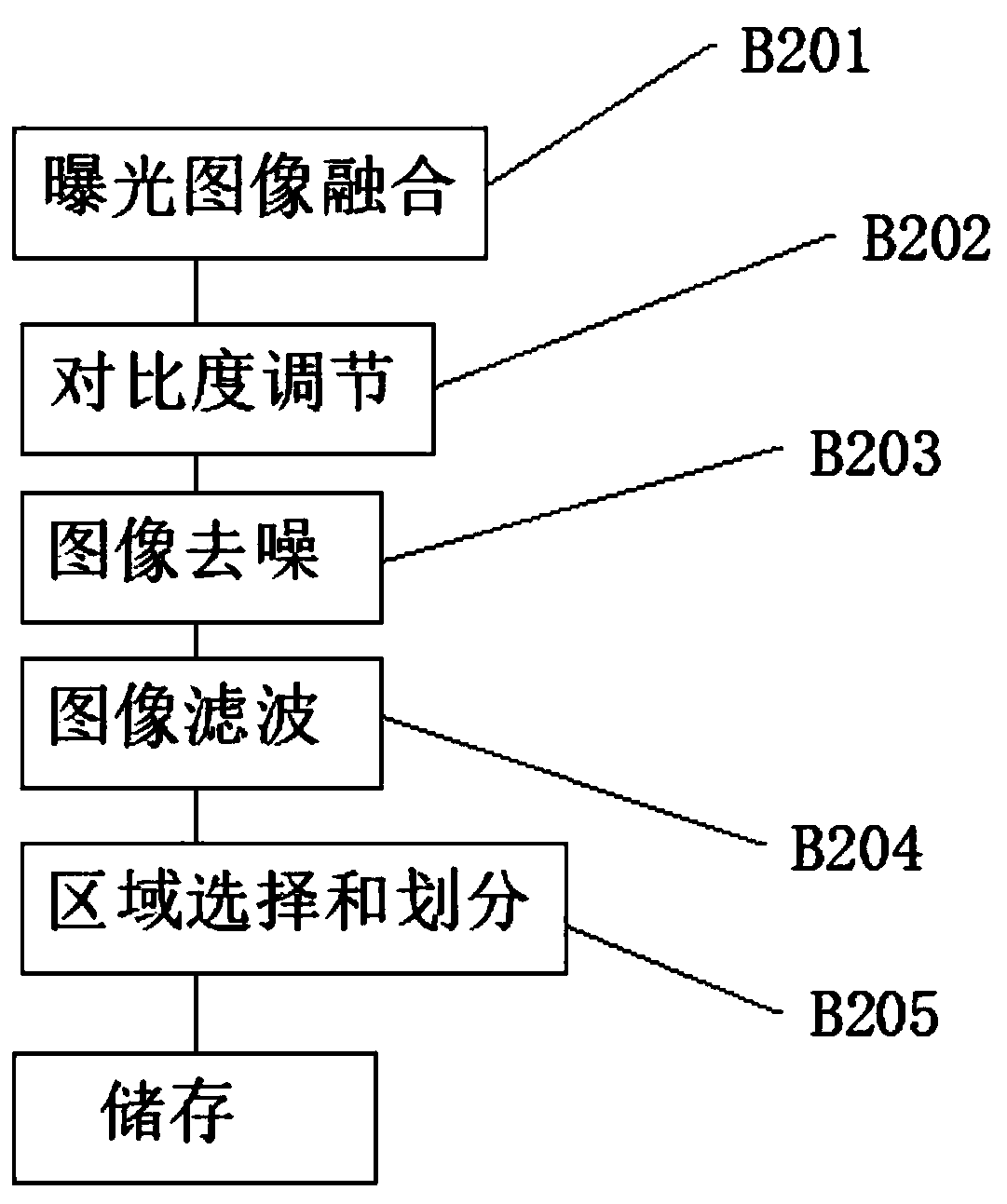

Welding spot appearance detection method based on machine vision

PendingCN111307812AEasy to collectThe analysis result is accurateOptically investigating flaws/contaminationImaging processingMachine vision

Owner:NANCHANG INST OF TECH

Photomask dirt detection system and detection method for laser radar and laser radar

PendingCN112099044AOptically investigating flaws/contaminationElectromagnetic wave reradiationPhysicsEngineering

Owner:HESAI TECH CO LTD

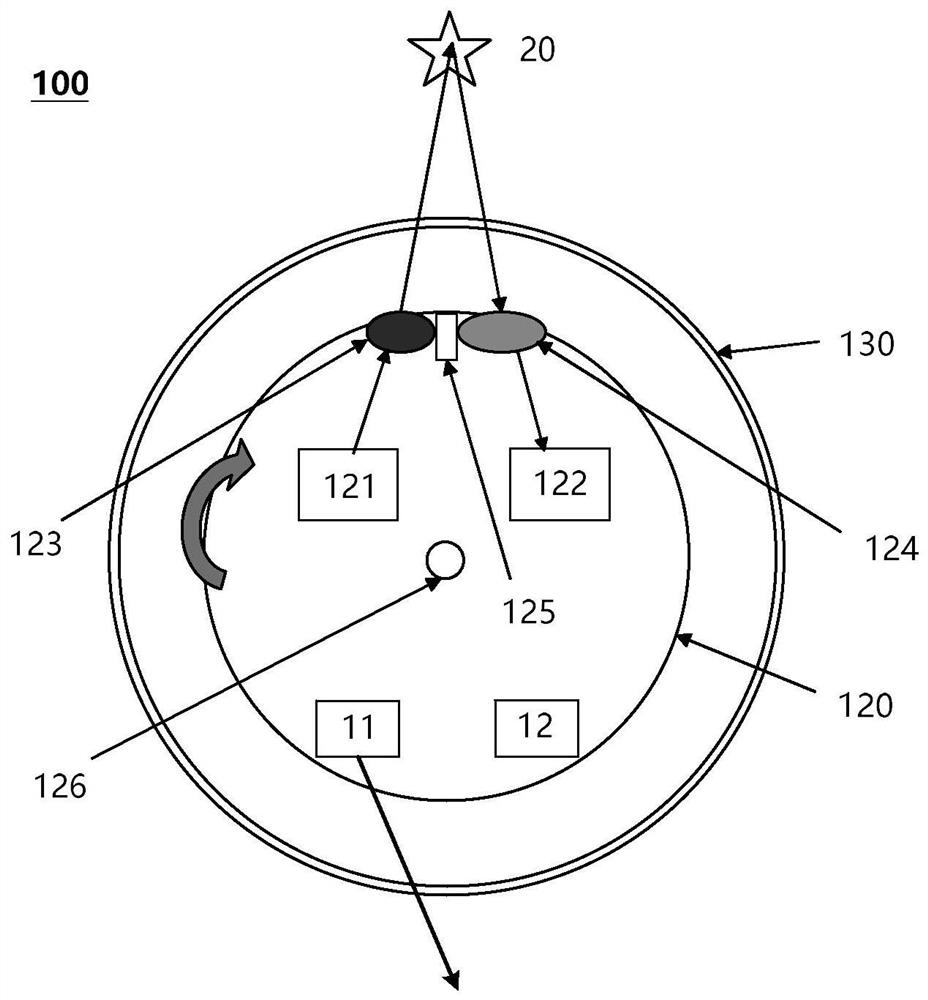

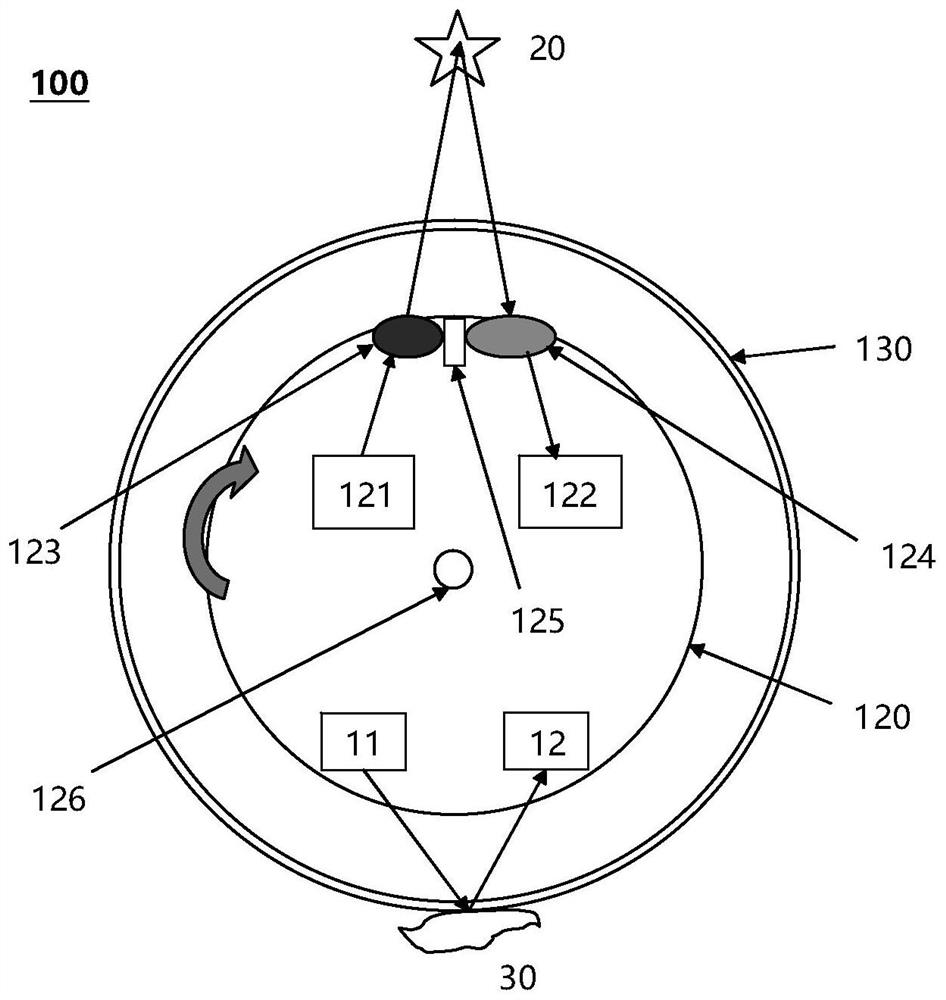

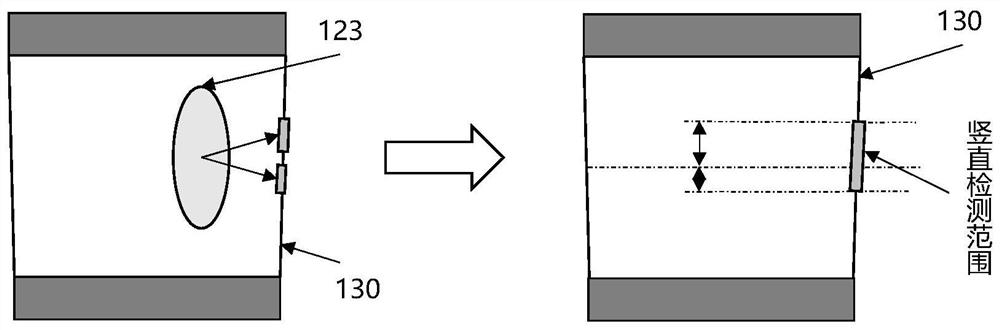

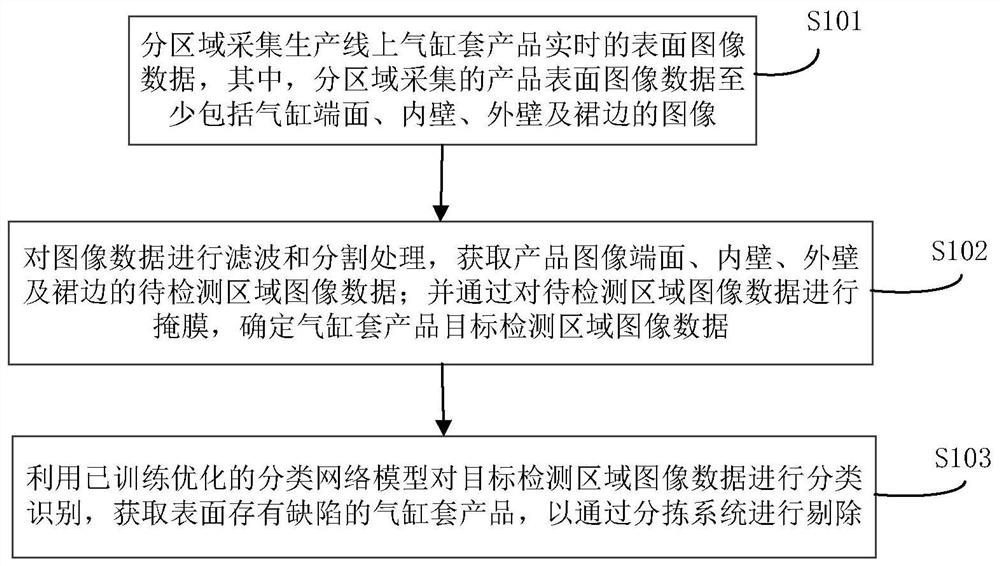

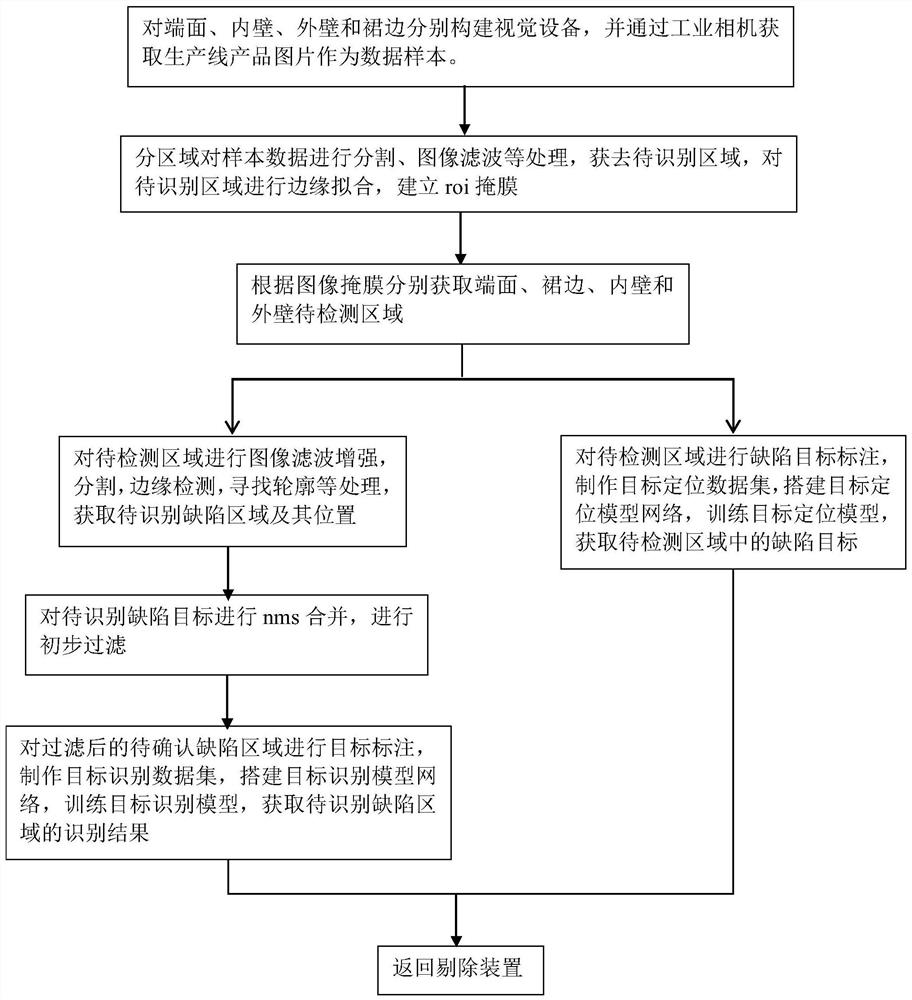

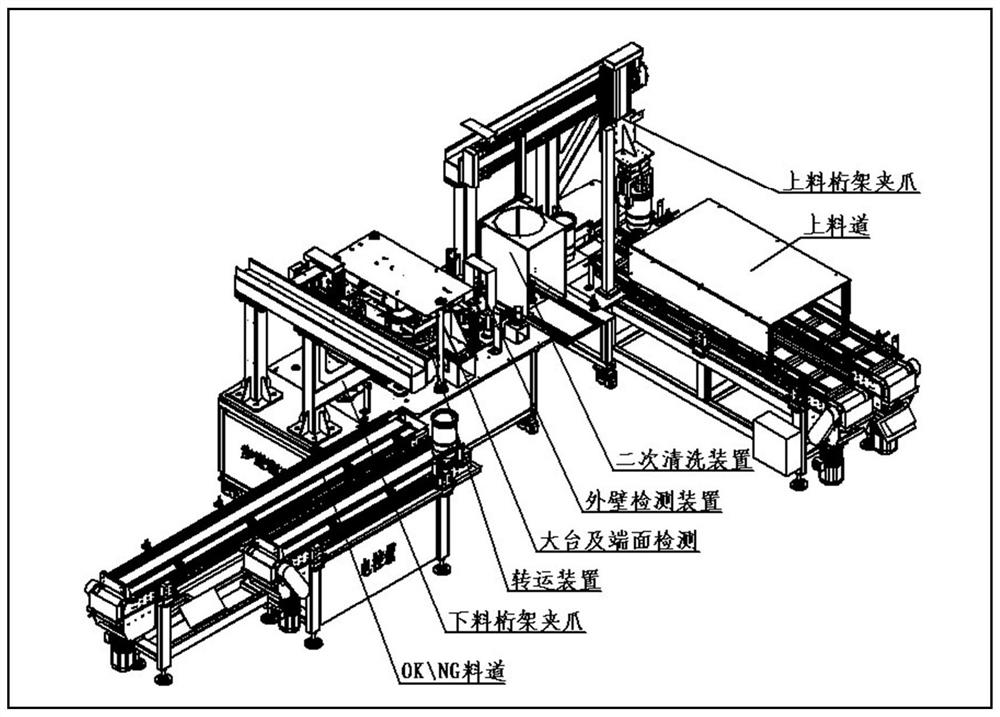

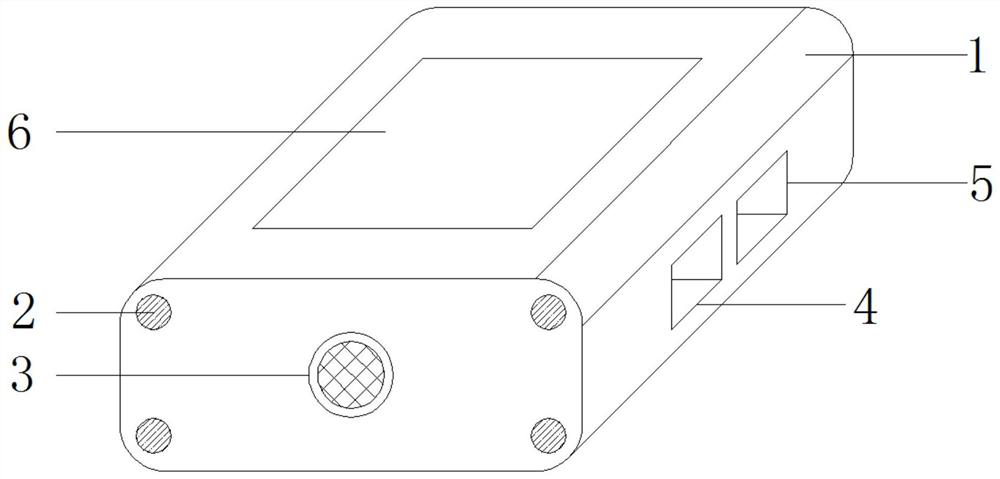

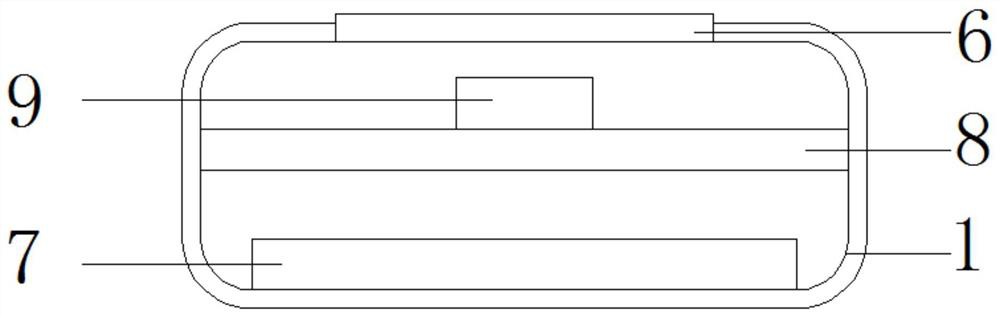

Cylinder sleeve surface defect detection method, system and device based on deep learning

PendingCN112733882AHigh speedStrong generalizationImage analysisCharacter and pattern recognitionPattern recognitionProduction line

Owner:ZHENGZHOU JINHUI COMP SYST ENG

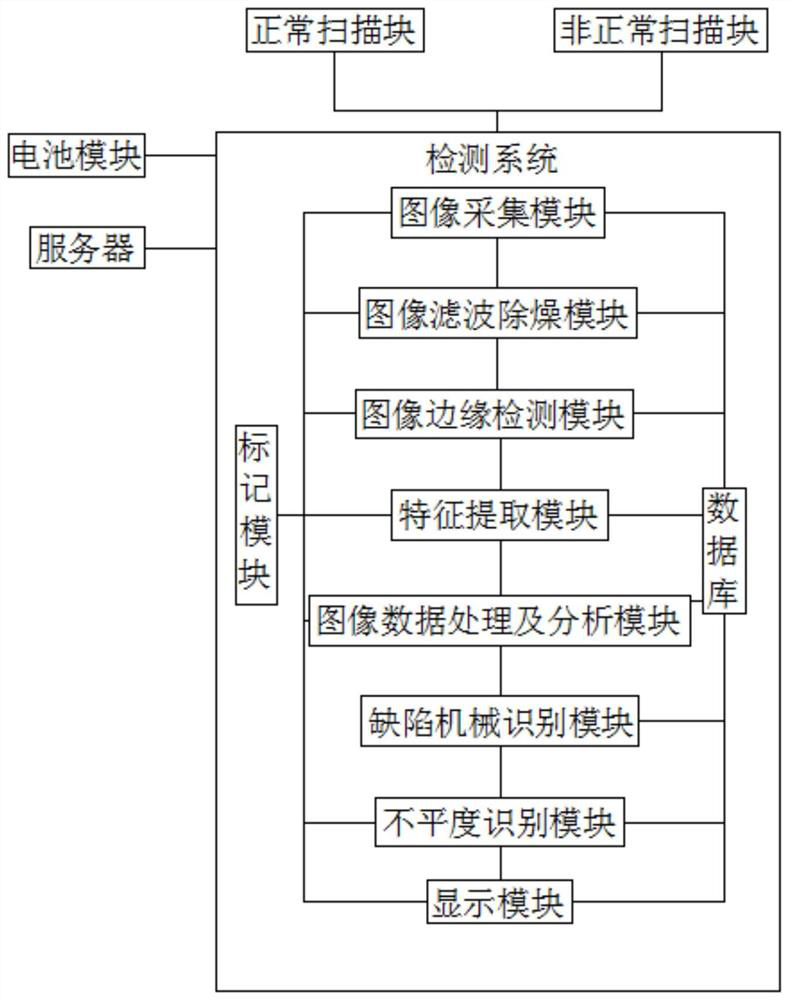

Defect recognition device and system based on image recognition technology

PendingCN112697806AReduce distractionsCancel noiseImage enhancementImage analysisComputer hardwareNetwork socket

Owner:南京英诺森软件科技有限公司

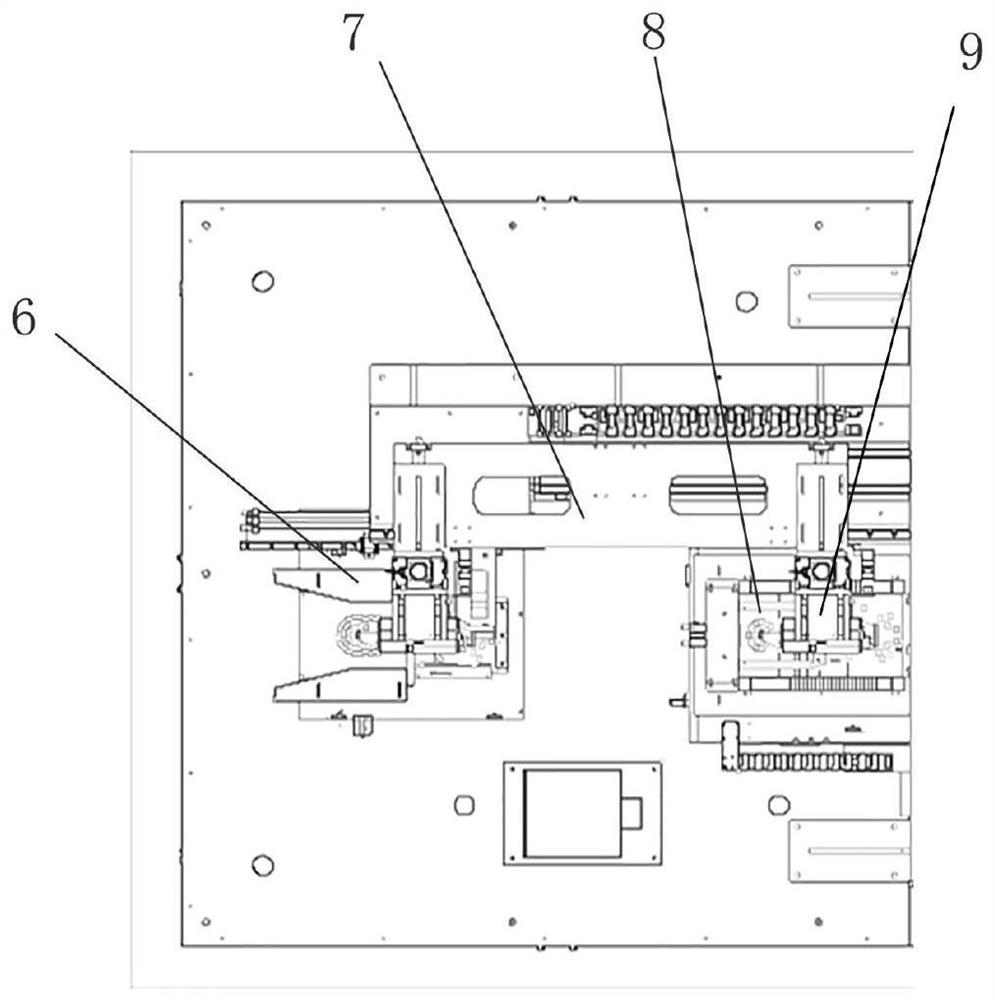

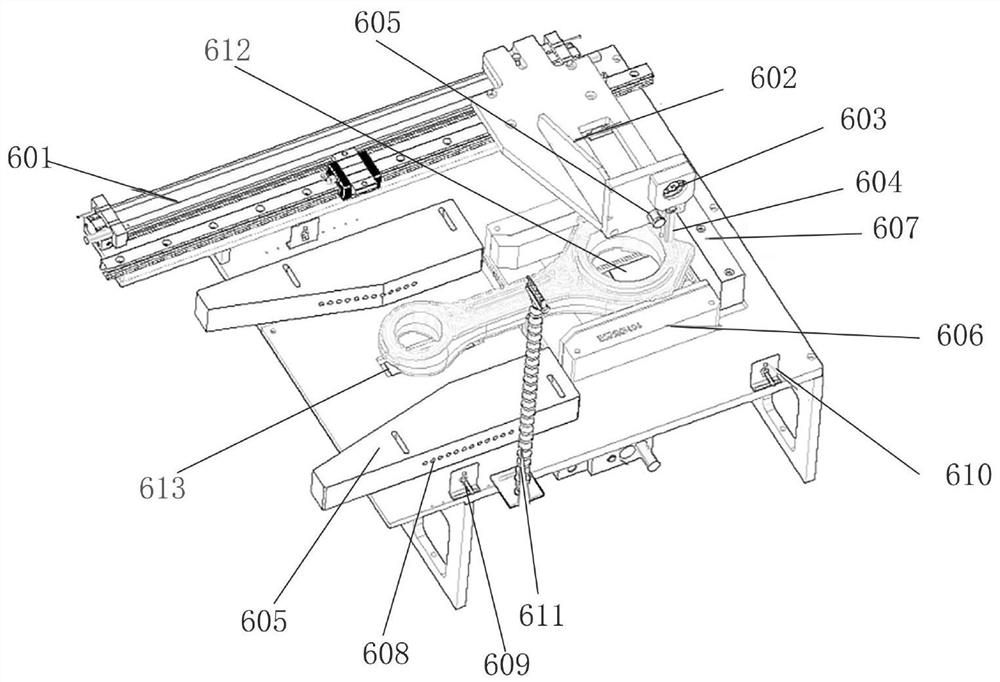

Connecting rod appearance size detection system and detection method

ActiveCN111649674AOptically investigating flaws/contaminationUsing optical meansMechanical engineeringLaser detection

Owner:ZHEJIANG YUEJIN MACHINERY

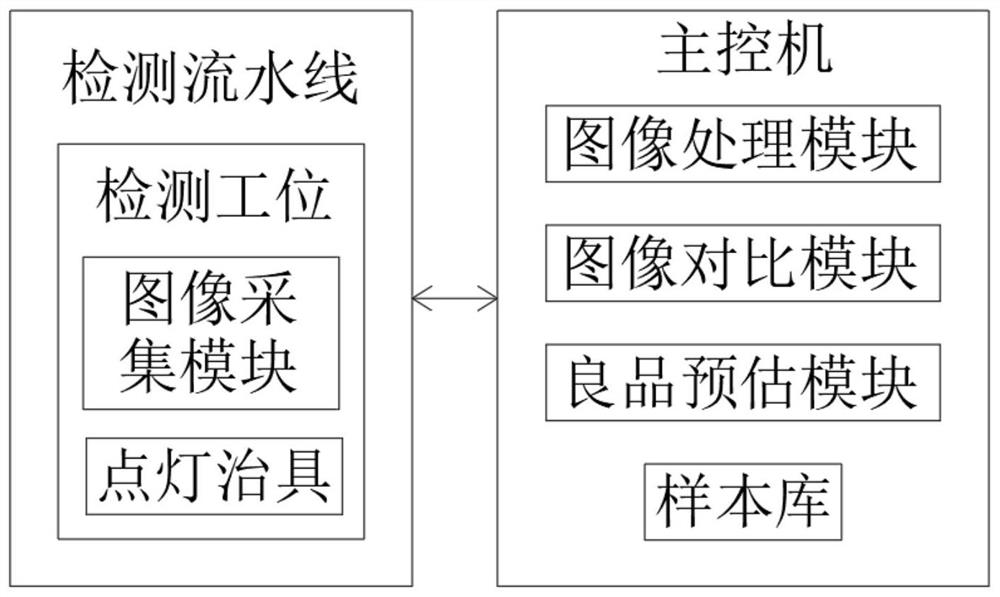

Display screen defect monitoring system based on image recognition and detection method thereof

PendingCN112881430AEfficient detectionImprove detection efficiencyImage enhancementImage analysisImaging processingComputer graphics (images)

Owner:深圳汇义科技有限公司

Working table for display panel testing

Owner:BOE TECH GRP CO LTD +1

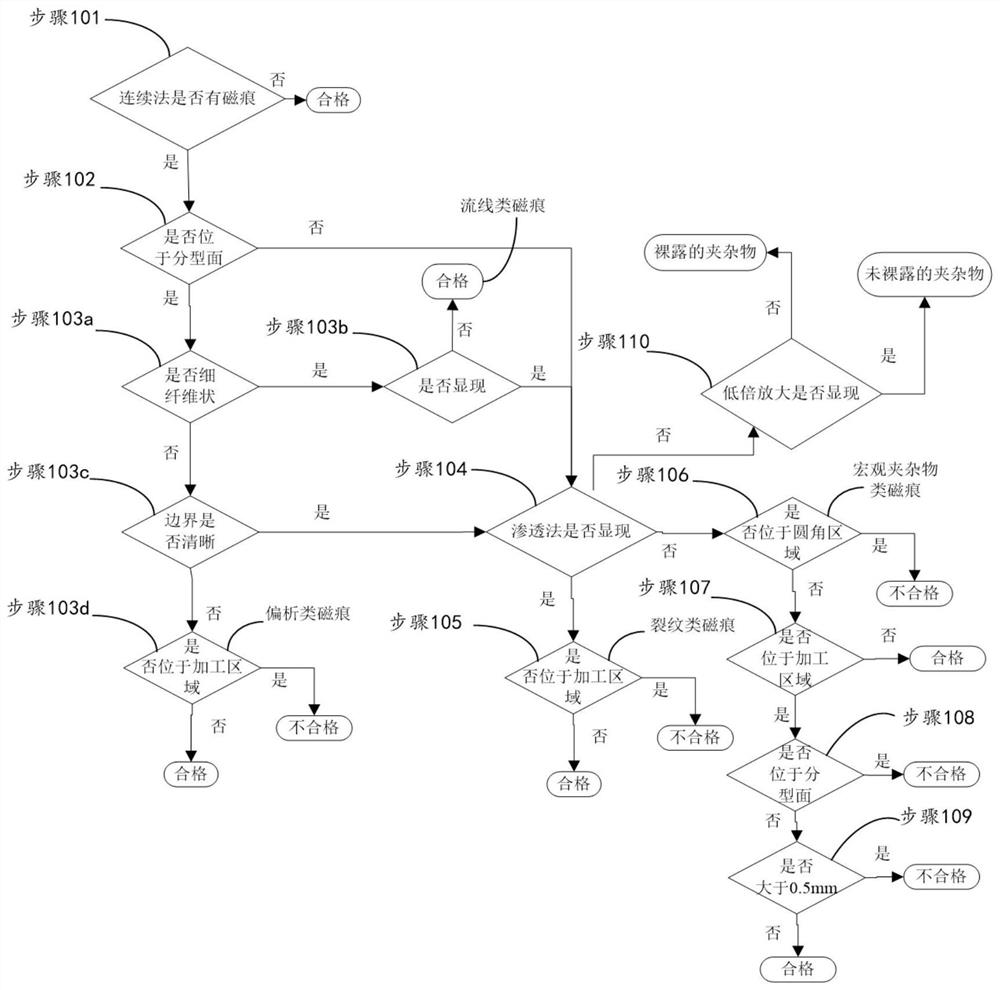

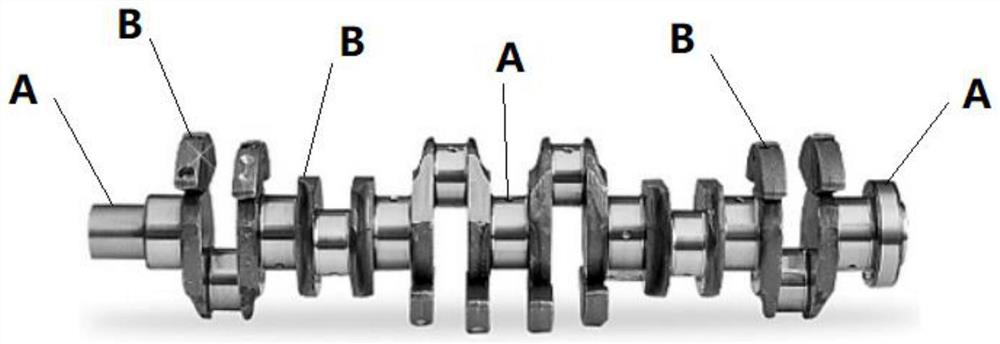

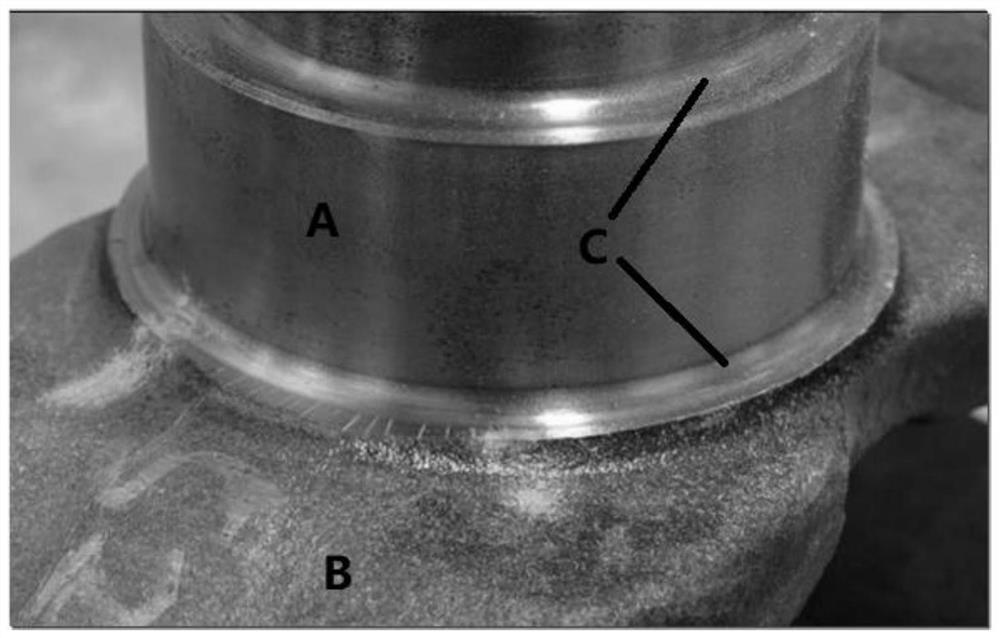

Engine crankshaft inspection method

ActiveCN113740416AAvoid misjudgmentImprove reliabilityInternal combustion piston enginesOptically investigating flaws/contaminationMechanical engineeringCrankshaft

Owner:DONGFENG COMML VEHICLE CO LTD

Automatic focusing device for linear scanning automatic optical detection system

Owner:盛吉盛(宁波)半导体科技有限公司 +1

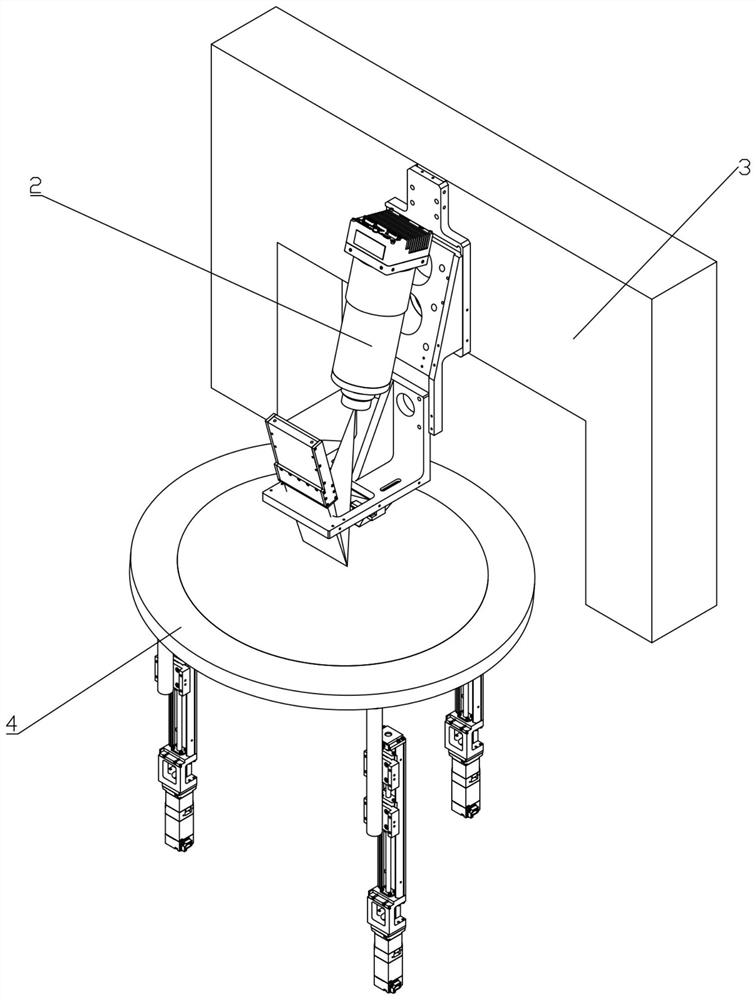

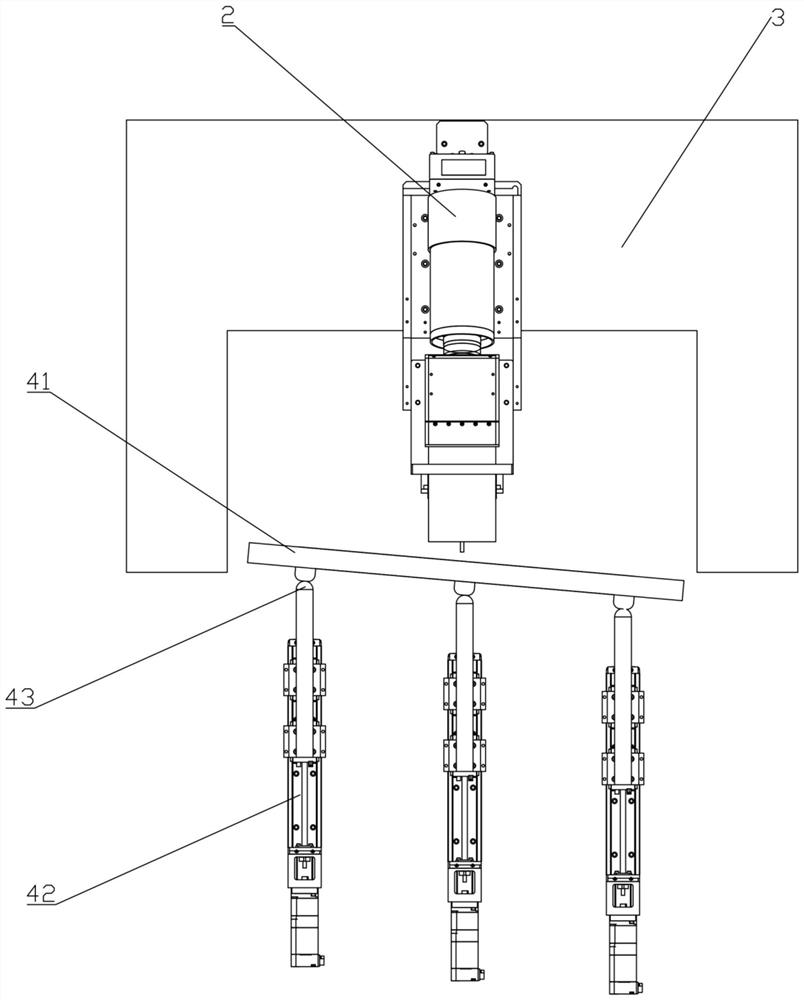

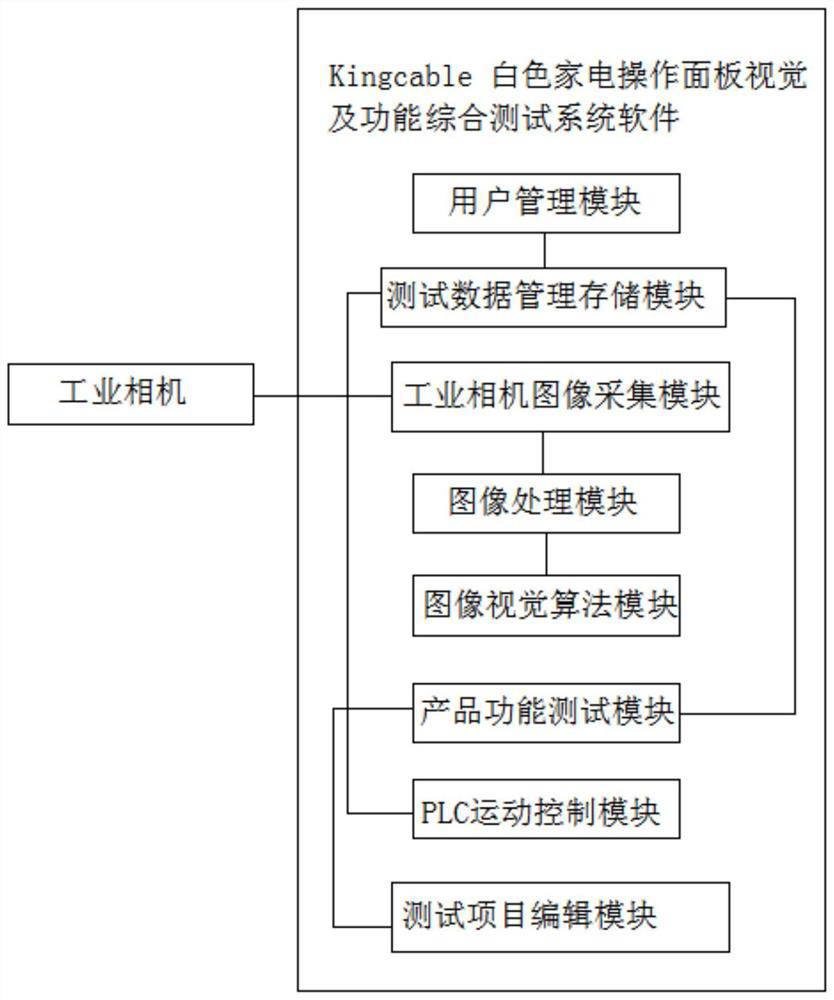

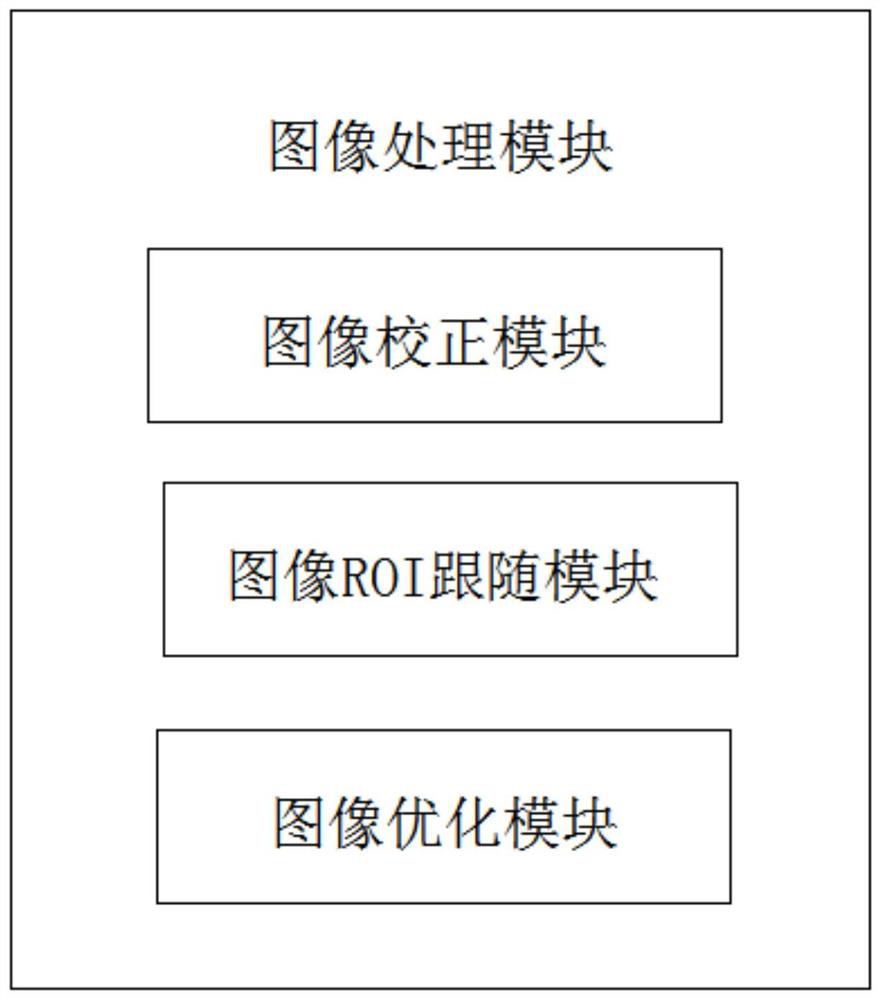

Kingcable white household appliance operation panel vision and function comprehensive test system

Owner:深圳市金凯博自动化测试有限公司

Method for counting microparticles on glass

Owner:无锡领先针测电子有限公司

Popular searches

Closed circuit television systems Neural architectures Position/course control in two dimensions Semiconductor/solid-state device manufacturing Auxillary welding devices Welding/soldering/cutting articles Metal working apparatus Laser beam welding apparatus Soldering auxillary devices Semiconductor devices

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap