Device and method for detecting surface imperfection of curved-surface optical element

An optical element and detection device technology, applied in the field of optical detection, can solve the problems of reduced accuracy, open air bubbles, visual fatigue, etc., and achieve the effects of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

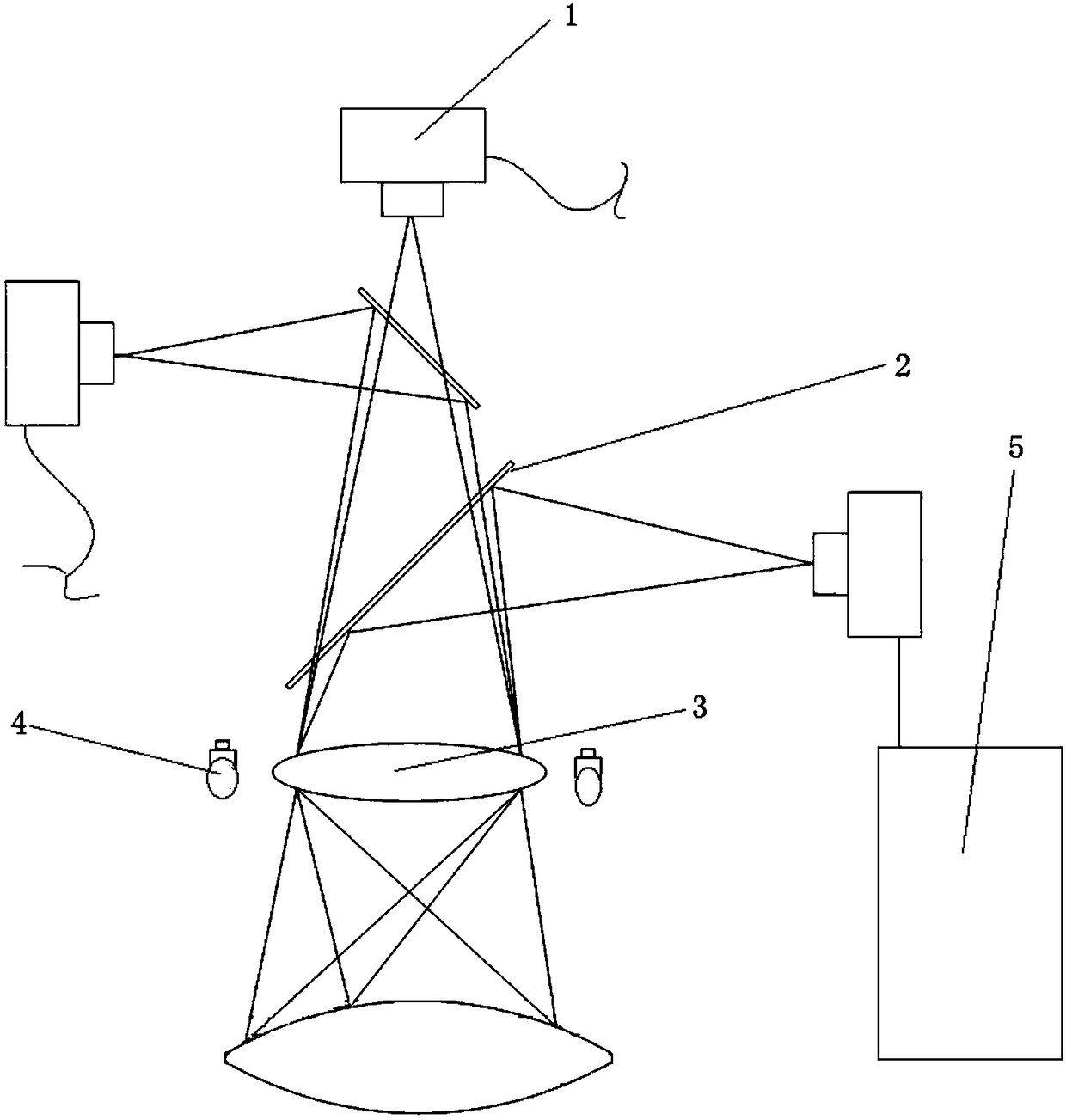

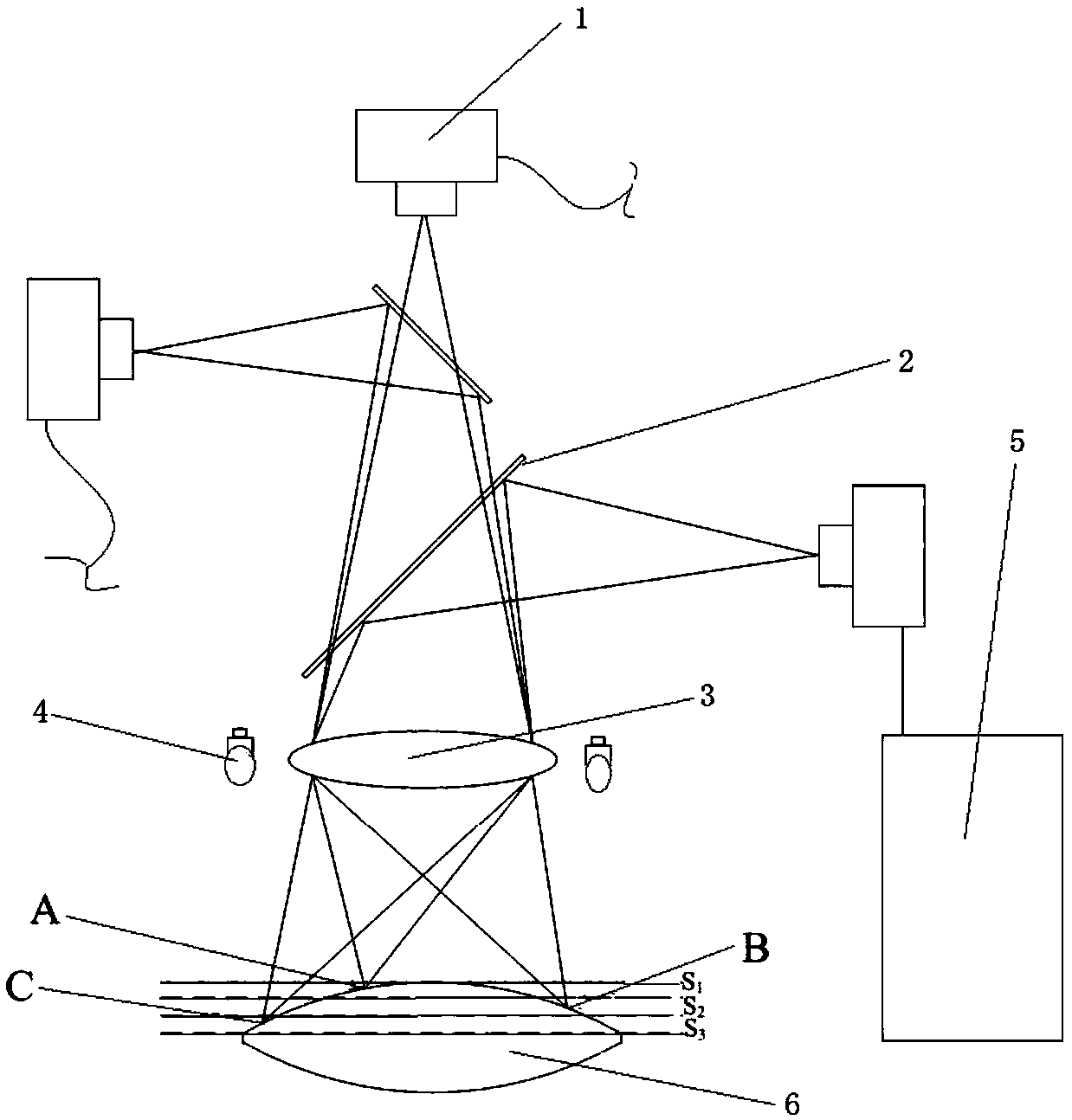

[0024] see Figure 1-2 , in an embodiment of the present invention, a device for detecting surface defects of a curved optical element includes an illumination system and an imaging system. The imaging system is provided with an imaging lens 3, an imaging device, and a processor 3 connected to the imaging device for signals. The device has three groups, including one group of coaxial imaging mechanism and two groups of side imaging mechanism, the axial imaging mechanism includes a third camera sensor located above the imaging lens 3 and coaxial with the imaging lens 3, the side imaging mechanism includes a The first camera sensor on the right side of the imaging lens 3 and the second camera sensor arranged on the left side of the imaging lens 3, the axis of the first camera sensor and the axis of the imaging lens 3 are vertically intersected and at the point of intersection, an angle of 45° with the horizontal is provided. The first visible light part reflector, and the reflectiv

Embodiment 2

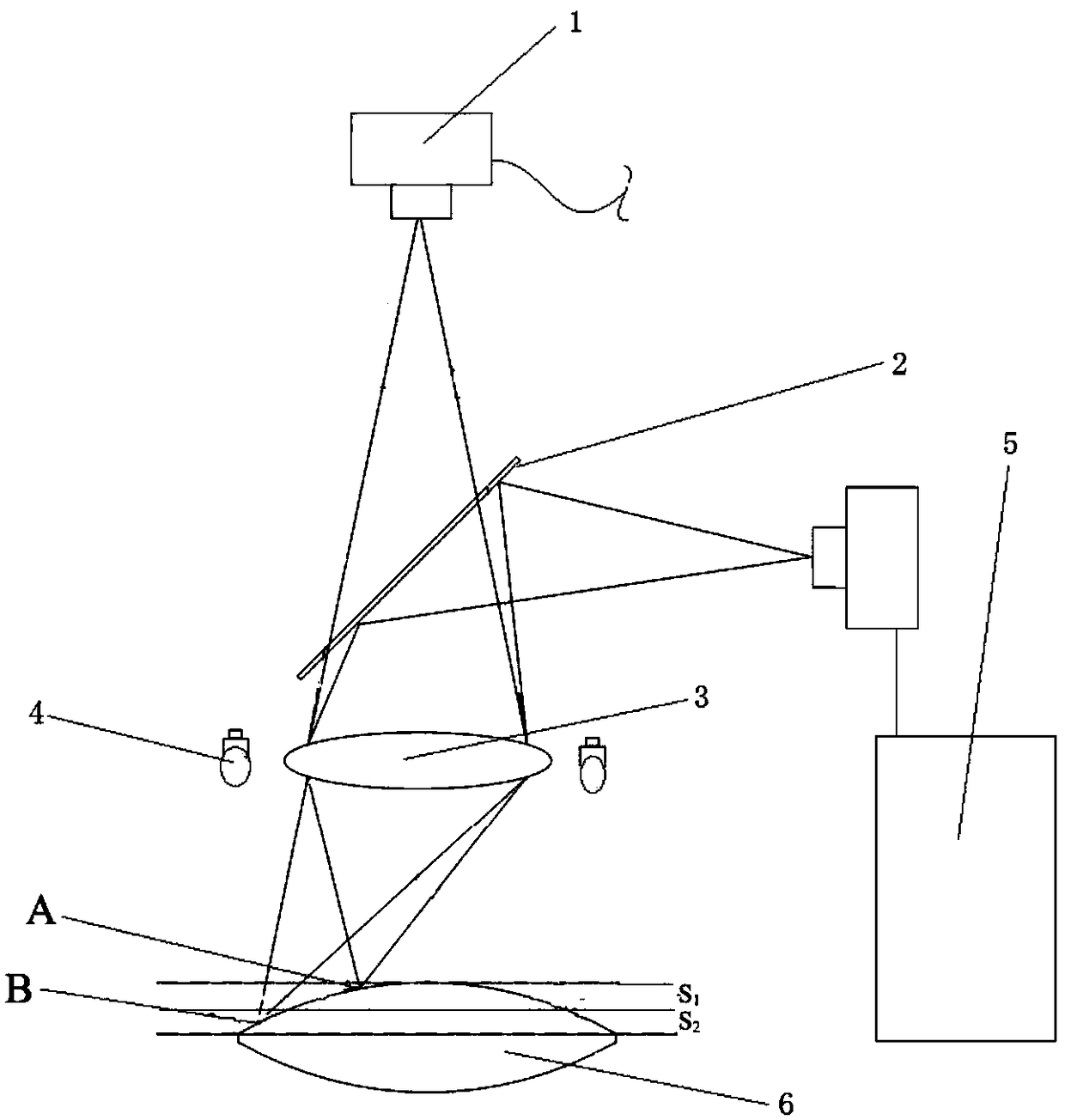

[0027] see image 3 , compared with Embodiment 1, the present embodiment measures the difference of the curved surface optical element at all, and a group of axial imaging mechanism and a group of side imaging mechanism are set, and the reflectivity of the visible light partial reflector 2 in the side imaging mechanism is 50%. , the rest of the structure and detection process are the same as in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap