Method and machine for scanning wafer defects, wafer defect scanning machine

A defect scanning and wafer technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of abnormal line width of fixed points, difficult to capture, etc., to achieve the effect of strengthening the ability to capture defects and improving the ability to capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with embodiment.

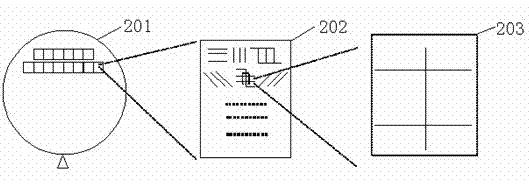

[0021] figure 2 The relationship between the unit pixel 203 , the wafer 201 and the unit chip 202 mentioned in the embodiment of the present invention is shown.

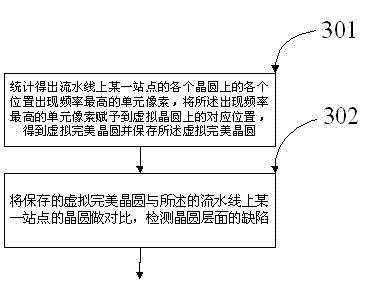

[0022] Such as image 3 As shown in the flow chart of the present invention, the steps of the wafer defect scanning method in the embodiment of the present invention include:

[0023] In step 301, the unit pixel with the highest frequency of occurrence at each position on each wafer of a certain station on the assembly line is counted, and the unit pixel with the highest frequency of occurrence is assigned to the corresponding position on the virtual wafer to obtain a virtual perfect wafer And save the virtual perfect wafer; the wafers passing through a certain station on the wafer processing line should have consistent morphological characteristics, so it is meaningful to carry out statistics at the same station, and the morphologies a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap