Implementation method of wear-resistant and skid-resistant tunnel cement concrete pavement

A cement concrete and implementation method technology, applied in the field of construction, can solve problems such as easily damaged groove wall structures, tire stress concentration, and excessive structural wear, and achieve the effects of reducing engineering costs, improving frictional resistance, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] The invention provides a wear-resistant and anti-skid tunnel cement concrete pavement implementation method, comprising the following steps:

[0032] Ordinary cement concrete is laid on the tunnel pavement, and after the curing period is completed, the lower layer of cement concrete is formed;

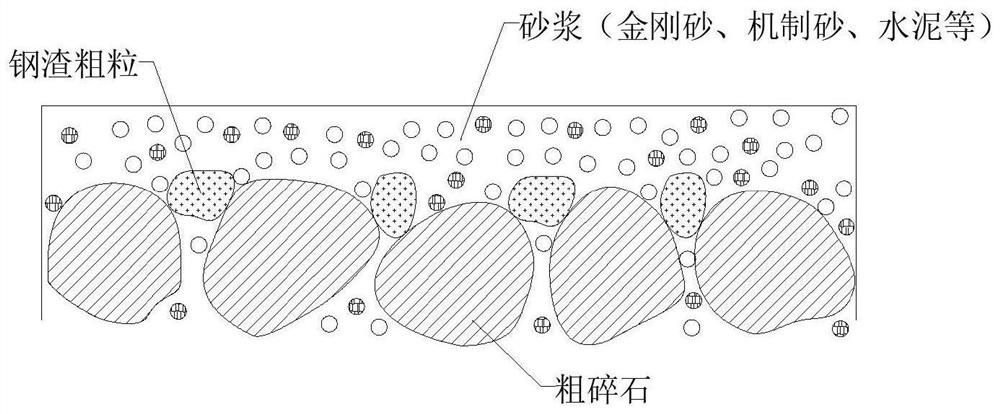

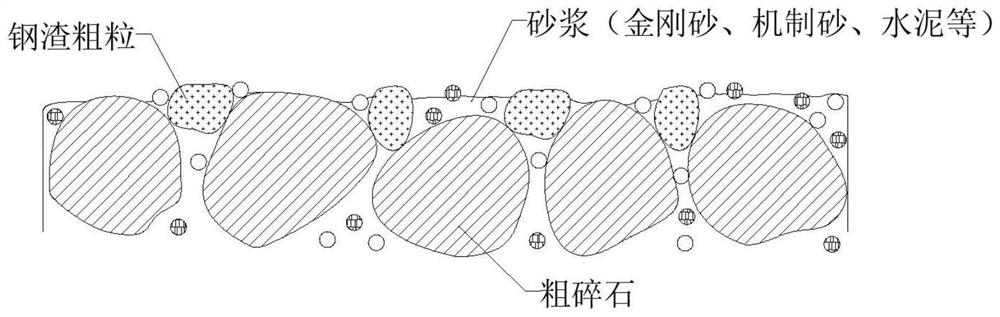

[0033] High-performance cement concrete is laid on the lower layer of the cement concrete to form an upper layer of cement concrete; the high-performance cement concrete includes the following preparation materials in parts by mass: 95-105 parts of cement, 22-26 parts of slag micropowder, silica fume 6 to 10 parts, 70 to 75 parts of steel slag particles, 45 to 55 parts of emery, 52 to 56 parts of machine-made sand, 64 to 68 parts of coarse steel slag, 260 to 270 parts of gravel, 0.5 to 1 part of polyoxymethylene fiber, water reduction 0.4-0.8 part of antifoaming agent, 0.4-0.8 part of defoamer and 22-26 parts of water;

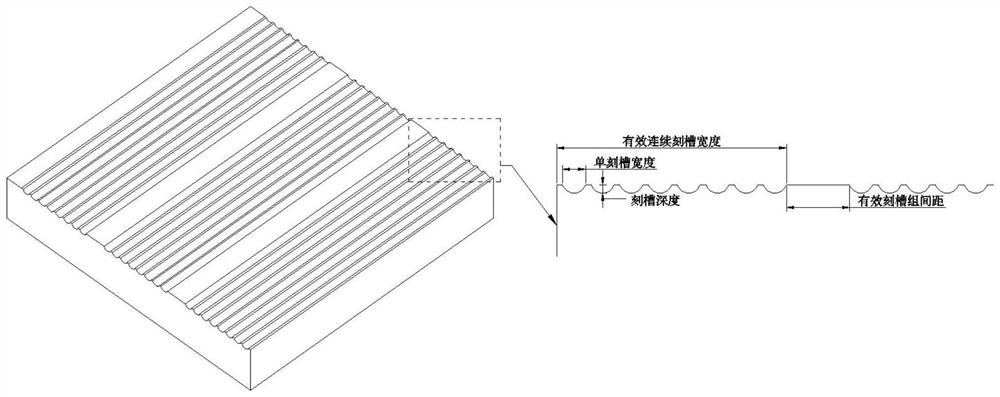

[0034] The upper layer of the cement concrete is grooved to

Example Embodiment

[0094] Example 1

[0095] The C40 grade concrete ordinary cement concrete is paved on the tunnel road surface, and the slits are cut after 8 hours. The horizontal spacing of the slits is controlled at 6m and corresponds to the joints of the second lining of the tunnel. The depth of the slits is 1 / 3 of the plate thickness; the slits are completed. Rinse with clean water afterwards, after the first curing, form the lower layer of cement concrete (thickness is 23cm);

[0096] Raw materials for the preparation of high-performance cement concrete: 100 parts of ordinary Portland cement 42.5R, 24 parts of slag micropowder, 8 parts of silica fume, 72 parts of steel slag particles, 50 parts of emery, 54 parts of machine-made sand, 66 parts of coarse steel slag, crushed stone 265 parts, 0.8 part of polyoxymethylene fiber, 0.6 part of water reducing agent, 0.6 part of defoamer, and 25 parts of water;

[0097] The preparation steps of high performance cement concrete are:

[0098] All ma

Example Embodiment

[0113] Example 2

[0114] The only difference from Example 1 is: the raw materials for the preparation of high-performance cement concrete: 42.5R95 parts of ordinary Portland cement, 26 parts of slag micropowder, 10 parts of silica fume, 75 parts of steel slag particles, 55 parts of emery, 52 parts of machine-made sand, 68 parts of coarse steel slag, 263 parts of crushed stone, 0.8 part of polyoxymethylene fiber, 0.6 part of water reducing agent, 0.6 part of defoamer, and 25 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap