Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Ceramic glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic glaze is an impervious layer or coating of a vitreous substance which has been fused to a ceramic body through firing. Glaze can serve to color, decorate or waterproof an item. Glazing renders earthenware vessels suitable for holding liquids, sealing the inherent porosity of unglazed biscuit earthenware. It also gives a tougher surface. Glaze is also used on stoneware and porcelain. In addition to their functionality, glazes can form a variety of surface finishes, including degrees of glossy or matte finish and color. Glazes may also enhance the underlying design or texture either unmodified or inscribed, carved or painted.

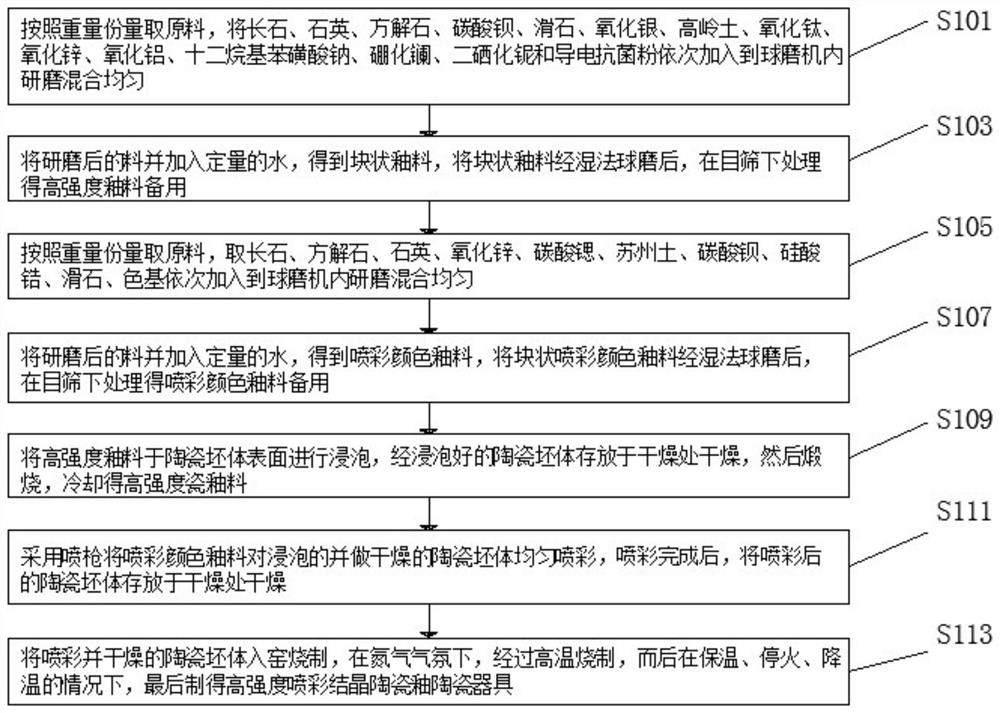

Ceramic glaze and preparation method thereof

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

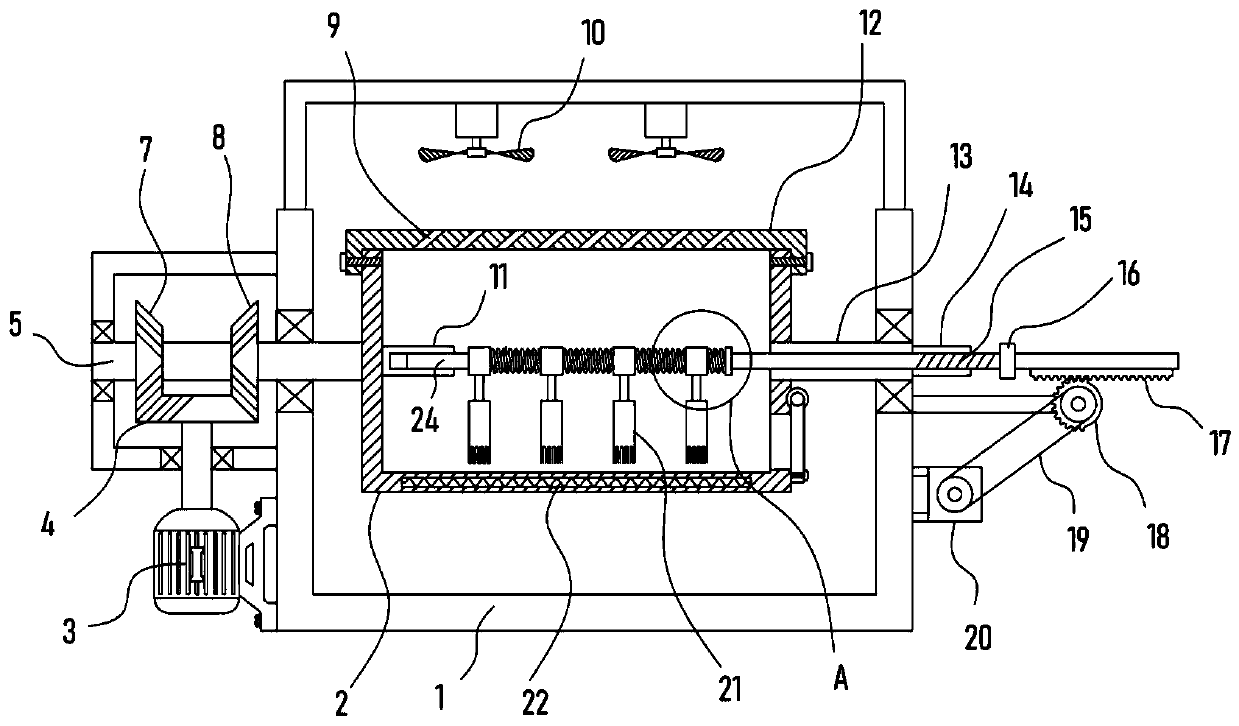

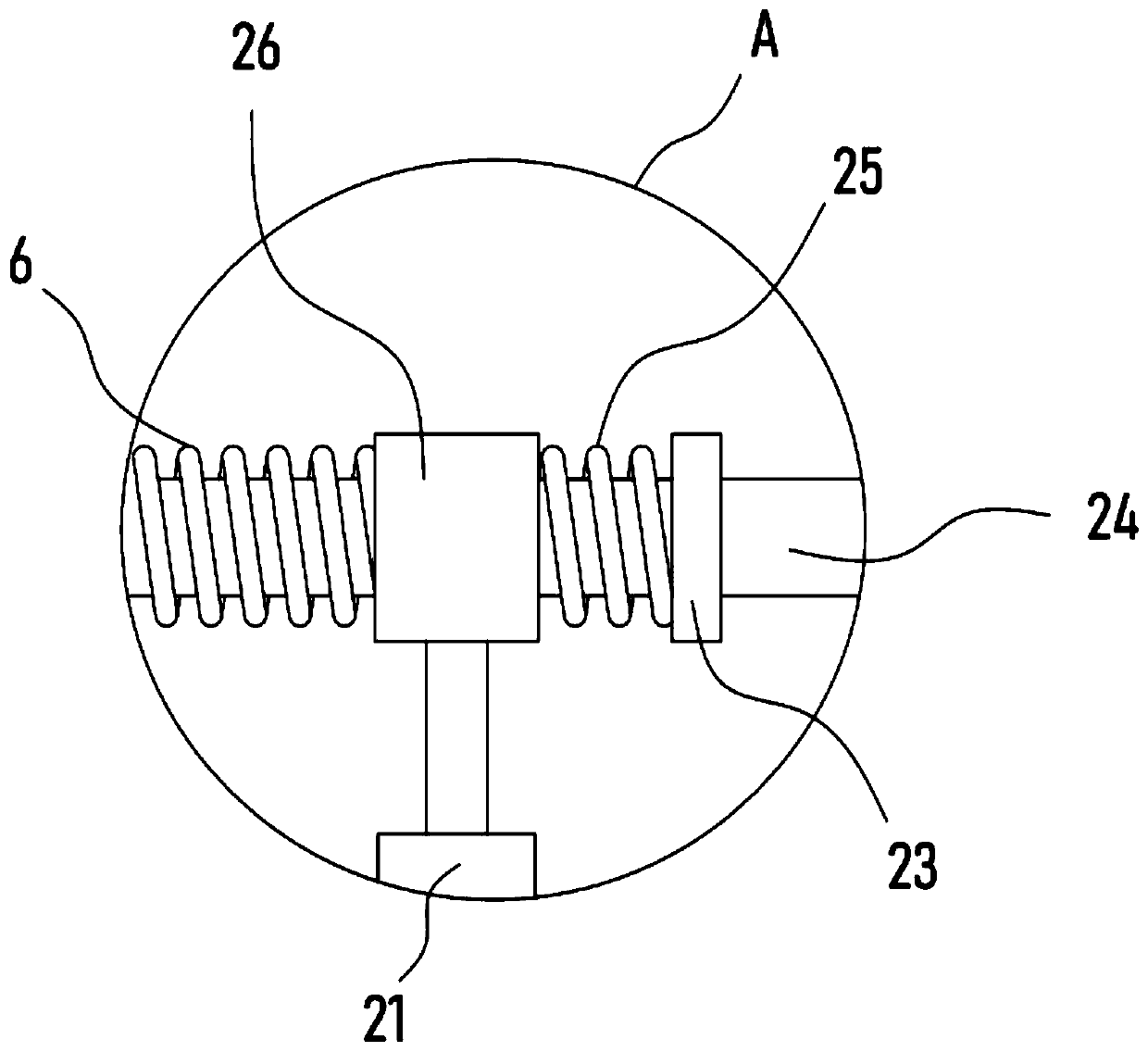

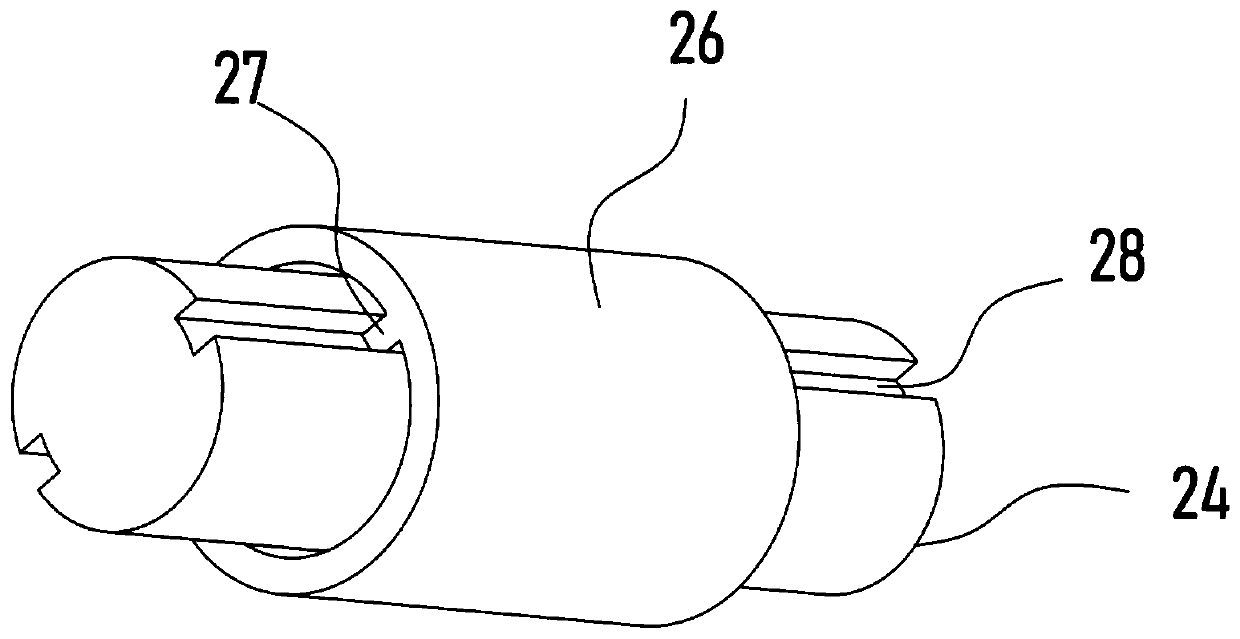

Ceramic glaze drying device

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

Environment-friendly antique imitation porcelain with firewood-calcined porcelain imitation texture and production method thereof

Owner:FUJIAN QUANZHOU LONGPENG GROUP

Large-size ceramic decorative sheet and formula process

Owner:MANLEY CHINA

Underglaze hand painting production technique of calcium porcelain

The invention relates to a production method of porcelain and in particular relates to an underglaze hand painting production technique of calcium porcelain. The technique comprises the following steps: 1) body porcelain shaping: firing a clay body for 15-20 minutes, thus preparing a porcelain body; 2) Xuan porcelain firing: spraying a layer of flux on the surface of the porcelain body, and firing the porcelain body for 15-20 minutes, thus preparing Xuan porcelain; 3) hand painting: using special pigments to carry out hand painting creation on the surface of the Xuan porcelain, thus preparing a colored body; 4) finished product firing: carrying out biscuit firing on the colored body for 15-20 minutes, and then carrying out glaze firing for 10-15 minutes, thus preparing a finished product. The calcium porcelain product prepared by using the technique has high whiteness, glossiness and percent of pass, is low in production cost, and has the advantages of environment friendliness, energy conservation and high efficiency due to short firing time and low energy consumption.

Owner:WUDIHAI BEICI CULTURE CO LTD

Antibacterial ceramic glaze and preparation method thereof

PendingCN109399933AImprove antibacterial propertiesGuaranteed glaze effectMontmorilloniteSodium silicate

The invention discloses an antibacterial ceramic glaze and a preparation method thereof. The glaze includes 30-50 parts of montmorillonite, 30-50 parts of talc, 10-30 parts of quartz, 5-10 parts of barium carbonate, 5-15 parts of manganese dioxide, 10-25 parts of sodium silicate, 20-50 parts of feldspar, 5-10 parts of titanium dioxide, and 2-10 parts of silver nitrate. The antibacterial performance of the glaze can be enhanced while the glaze effect is ensured, and the antibacterial ceramic glaze can keep a stable and sustained antibacterial effect at high temperatures.

Owner:FOSHAN UNIVERSITY

Ceramic glaze and preparation method thereof

The invention discloses a ceramic glaze. The ceramic glaze is characterized by being prepared from the following raw materials in parts by weight: 35-50 parts of nano-silica, 55-75 parts of kaolin, 15-30 parts of albite, 5-15 parts of magnesium oxide, 5-15 parts of sodium oxide, 25-50 parts of dolomite, 25-40 parts of limestone, 3-8 parts of pigment and filler, 15-20 parts of property-modifying additive, and 55-70 parts of deionized water. The invention further discloses a preparation method of the ceramic glaze. The ceramic glaze disclosed in the invention has good brightness and glossiness,and the prepared pigment and filler are present in a nanometer-grade form, have a good coloring effect and are not easy to agglomerate; the ceramic glaze prepared from the activated kaolin, the pigment and filler and the property-modifying additive has not only good mechanical properties, but also good chemical stability and wear resistance, and can effectively protect a ceramic body and allow theceramic to have a better appearance.

Owner:CHANGSHA JIZHI INNOVATION IND DESIGN CO LTD

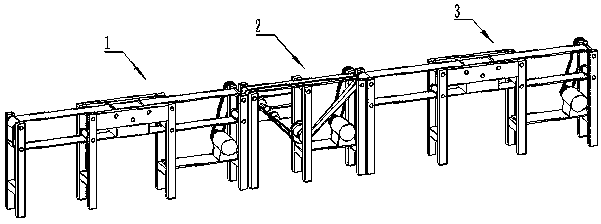

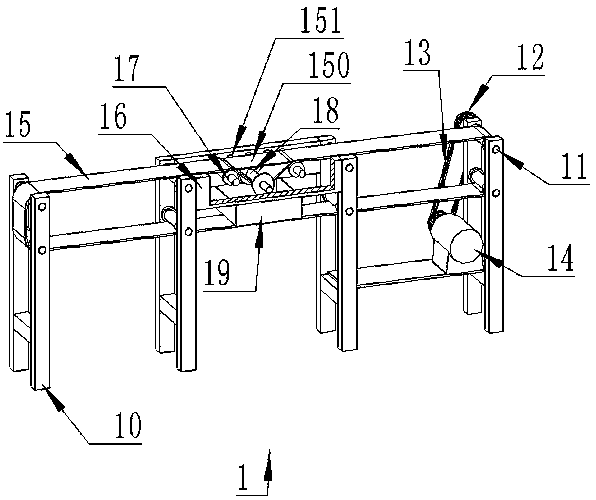

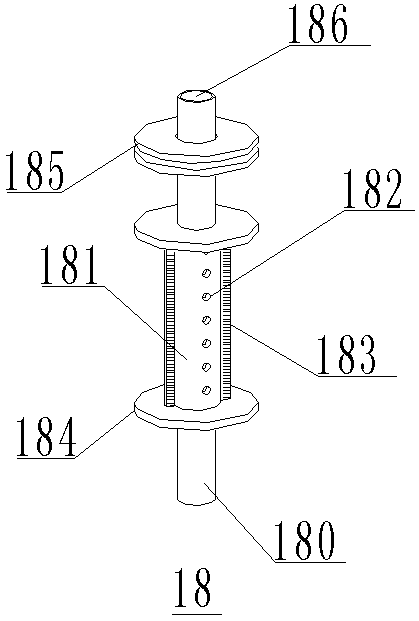

Ceramic bottom glaze removal transmitting device

PendingCN107720170AIncrease productivityAvoid hard-to-clean problemsDischarging arrangementCleaningEvaporationConveyor belt

Owner:GUANGXI NANSHAN PORCELAIN

Novel anti-electrostatic ceramic glaze as well as preparation method and application thereof

Owner:ZHONGSHAN ADVANCED ENG & TECH RES INST WUHAN UNIV OF TECH +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap