Method for synthesizing heat-resistant polyurethane based on soybean oil

A polyurethane and heat-resistant technology, applied in the field of synthesizing heat-resistant polyurethane materials, can solve the problem of no literature report on heat-resistant polyurethane, and achieve the effects of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

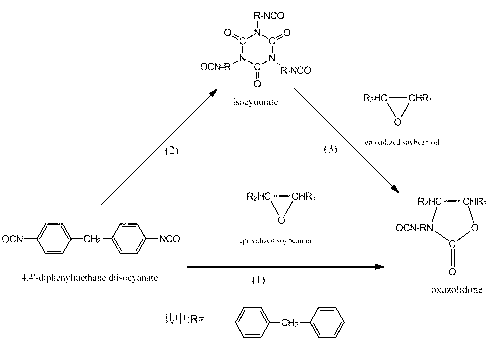

Method used

Image

Examples

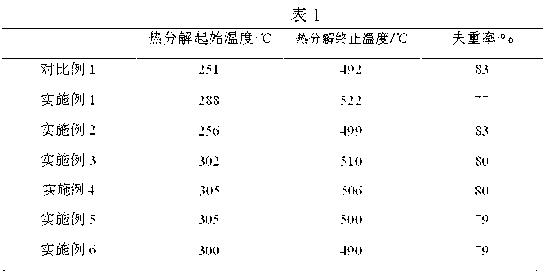

Embodiment 1

[0032] Accurately weigh 54.03g of epoxidized soybean oil (the molar number of epoxy groups is about 0.20mol) and 2.04g of AlCl 3 / HMPA (5% of the total mass of epoxidized soybean oil and TDl) in a 250ml three-necked bottle, under normal pressure, heat and stir and raise the temperature to 80°C, and weigh 34.82g TDl (the molar number of isocyanate group is 0.40 mol), at an interval of 10 minutes, added to the three-necked bottle in equal amounts twice, and reacted for 5 hours to obtain a polyurethane prepolymer; the NCO% of the prepolymer was determined to be 7.45% according to the HG / T2409-92 standard, and 67.25g of the prepolymer was weighed body, add 2.56gBDO and 28.44gPPG-1000 according to the formula, stir well for 2min, and press into tablets on a vulcanizer to prepare polyurethane.

Embodiment 2

[0034] Accurately weigh 54.29g of epoxidized soybean oil (the molar number of epoxy groups is about 0.20mol) and 2.42g of AlCl 3 / HMPA (about 2% of the total mass of epoxidized soybean oil and IPDI) in a 250ml three-necked bottle, under normal pressure, heat and stir and raise the temperature to 100°C, and weigh 66.69gIPDI (the molar number of isocyanate groups is about 0.60mol), at intervals of 8min, add 3 equal amounts into the three-necked bottle, react for 4h, and obtain the polyurethane prepolymer; measure the NCO% of the prepolymer according to the HG / T2409-92 standard to be 9.96%, weigh 85.25 g prepolymer, add 4.33g BDO and 96.22g PPG-2000 according to the formula, stir well for 1min, and press on a vulcanizing machine to prepare polyurethane.

Embodiment 3

[0036] Accurately weigh 27.10g of epoxidized soybean oil (the molar number of epoxy groups is about 0.10mol) and 2.30g of AlCl 3 / HMPA (about 3% of the total mass of epoxidized soybean oil and MDl) in a 250ml three-necked bottle, under normal pressure, heat and stir and raise the temperature to 120°C, and weigh 49.67gMDl (the molar number of isocyanate group is about 0.40mol), at intervals of 5min, add it into the three-necked bottle in 4 equal amounts, react for 2h, and obtain the polyurethane prepolymer; measure the NCO% of the prepolymer according to the HG / T2409-92 standard to be 13.34%, and weigh 56.30g of prepolymer, add 3.83g of BDO and 85.11g of ODX-218 according to the formula, fully stir for 3 minutes, and press on a vulcanizing machine to prepare elastomers.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap