Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Urethane acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the present paper we discuss UV-curable urethane acrylate coatings. The urethane acrylate oligomer is the main part of the coatings composition, which determines the properties of both the liquid and the cured coating.

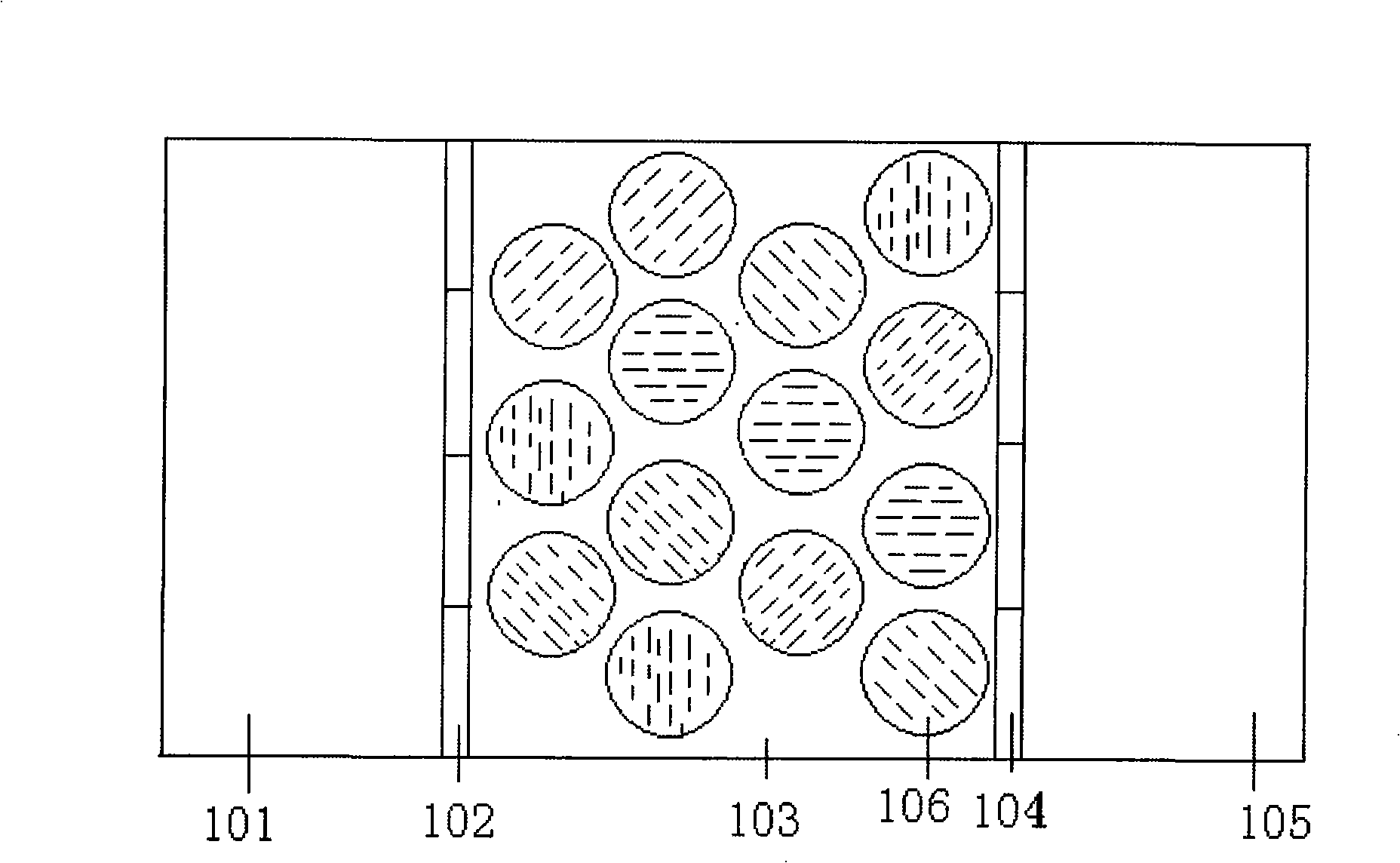

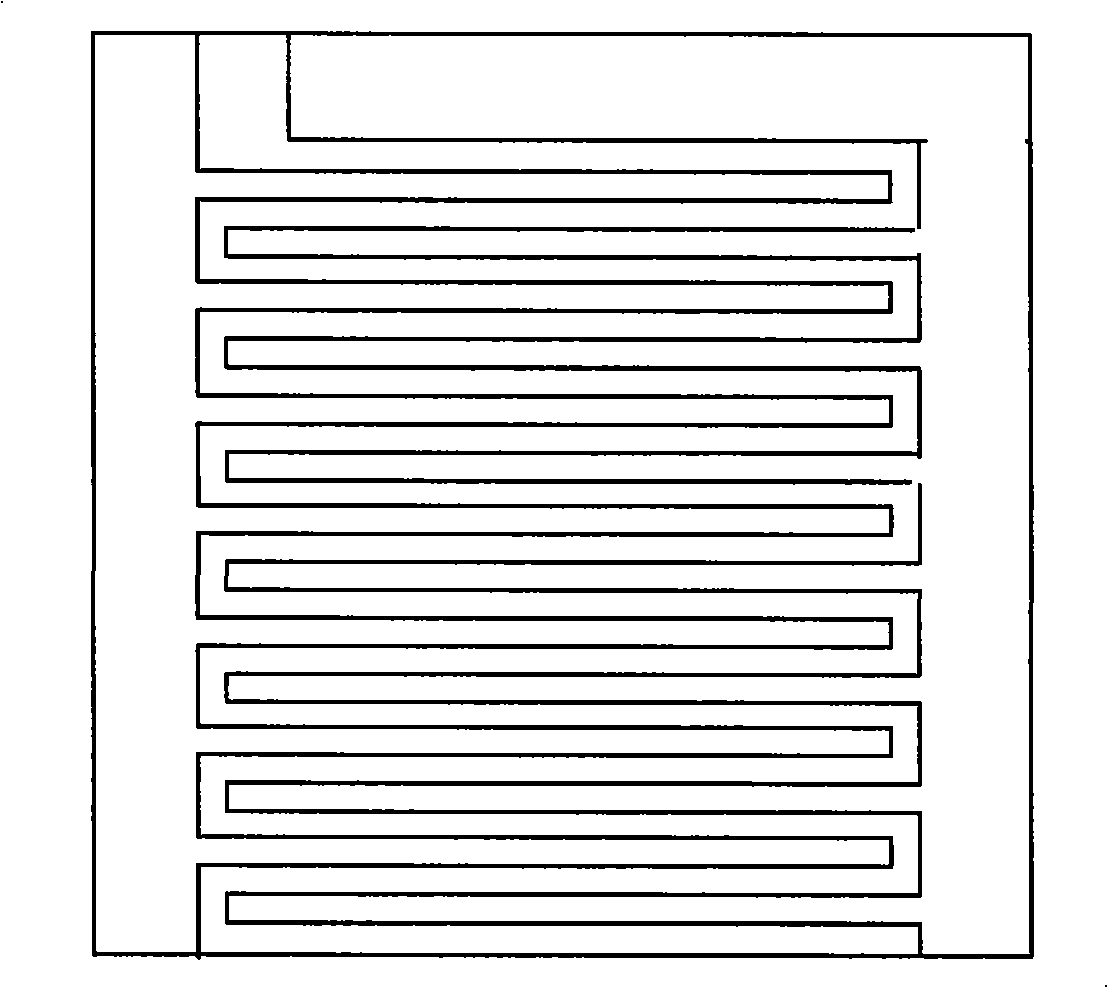

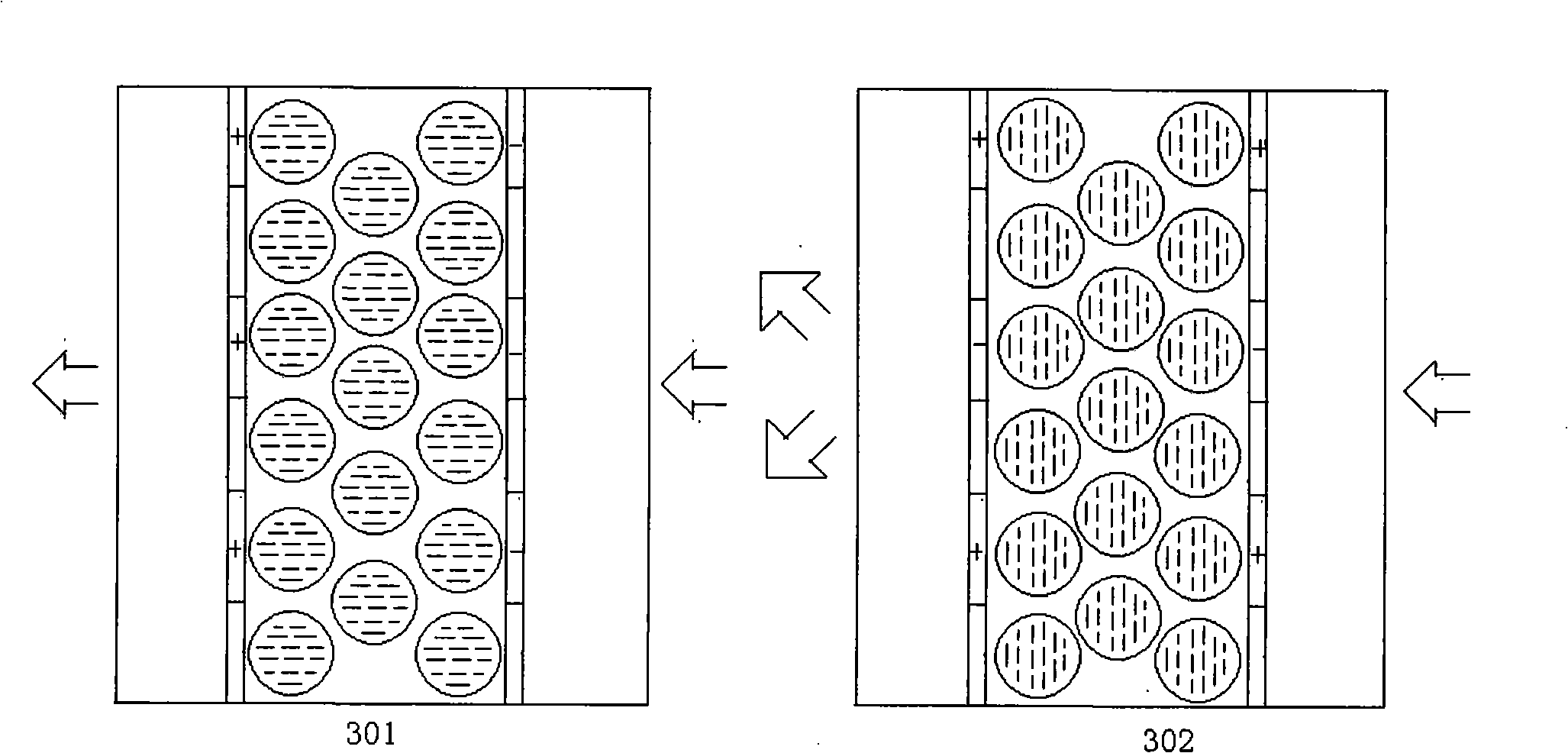

Polymer dispersed LCD bistable film and method of manufacture

Owner:HEBEI UNIV OF TECH

Novel acrylate modified waterborne polyurethane adhesive

InactiveCN109266267AShort curing timeImprove adhesionPolyureas/polyurethane adhesivesGraft polymer adhesivesPolyurethane adhesiveEmulsion

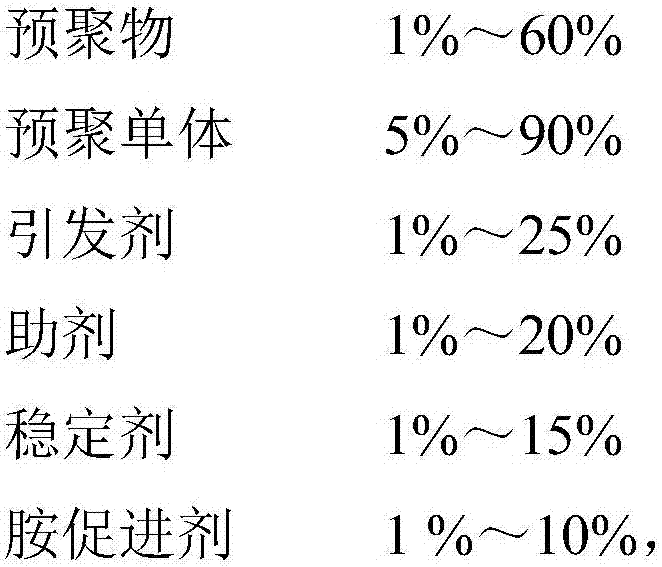

The invention provides a novel acrylate modified waterborne polyurethane adhesive. The adhesive is characterized by being prepared by the following steps: taking polyether glycol and polyisocyanate toreact, so as to obtain a waterborne polyurethane pre-polymer; enabling the waterborne polyurethane pre-polymer to react with an acrylic monomer or a methacrylic acid monomer under the action of an emulsifier and an initiator to obtain waterborne polyurethane acrylate, so as to obtain emulsion, wherein the emulsion is the acrylate modified waterborne polyurethane adhesive. The invention further discloses a preparation method and application of the adhesive. Compared with the prior art, the novel acrylate modified waterborne polyurethane adhesive has the advantages of better environment-friendly performance and improved anti-oxidization capability and anti-ageing capability; the adhesive has good bonding performance with adhesive films and paper products.

Owner:CHANGCHUN UNIV OF TECH

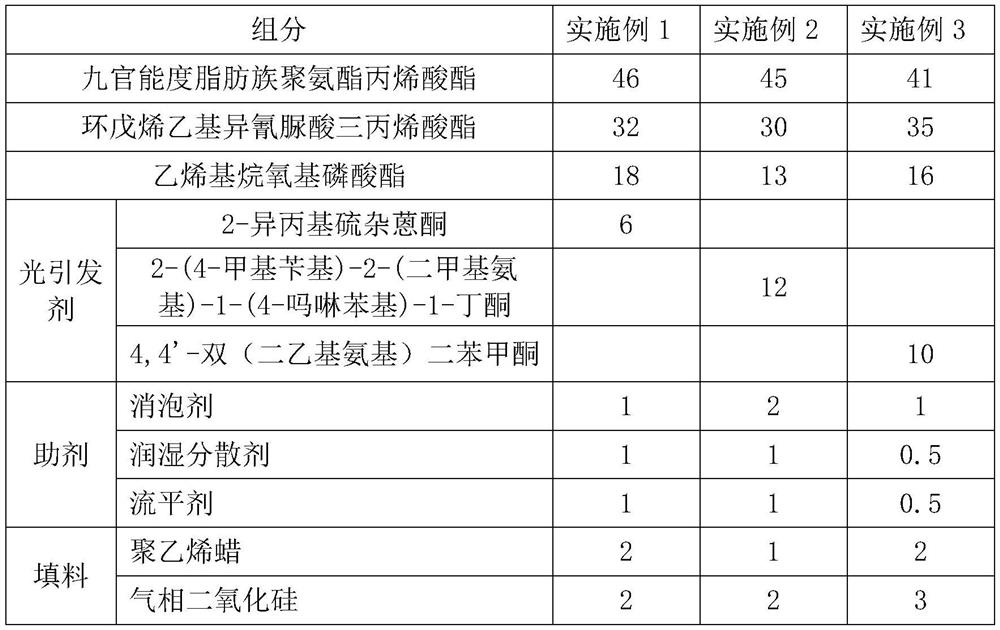

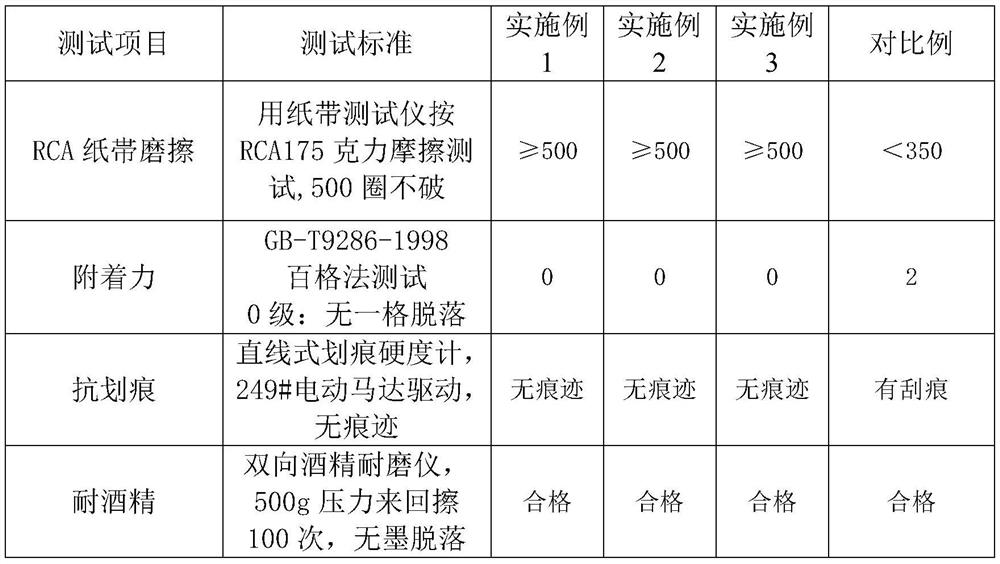

High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

InactiveCN107325691ALow VOC/NOVOCWith transparentWax coatingsPaper coatingMethacrylateVinyl ether

Owner:XIAN BANKNOTE PRINTING +1

Fiber coatings with low modulus and high critical stress

Fiber coatings with low Young's modulus, high tear strength, and / or high critical stress are achieved with coating compositions that include an oligomeric material formed from an isocyanate, a hydroxyacrylate compound and a polyol. The oligomeric material includes a polyether urethane acrylate and a di-adduct compound. The reaction mixture used to form the oligomeric material includes a molar ratio of isocyanate:hydroxy acrylate:polyol of n:m:p, where when p is 2, n is in the range from 3.0 to 5.0 and m is in the range from 1.50n-3 to 2.50n-5. Control of the n:m:p ratio leads to compositionsthat, when cured, provide coatings and cured products having high critical stress, high tear strength, and a high ratio of tear strength to Young's modulus.

Owner:CORNING INC

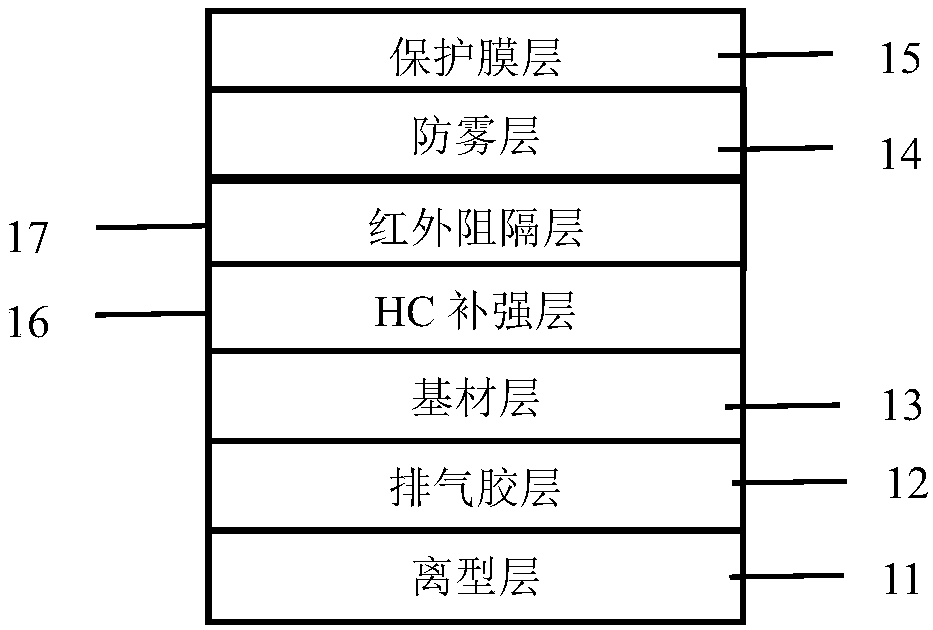

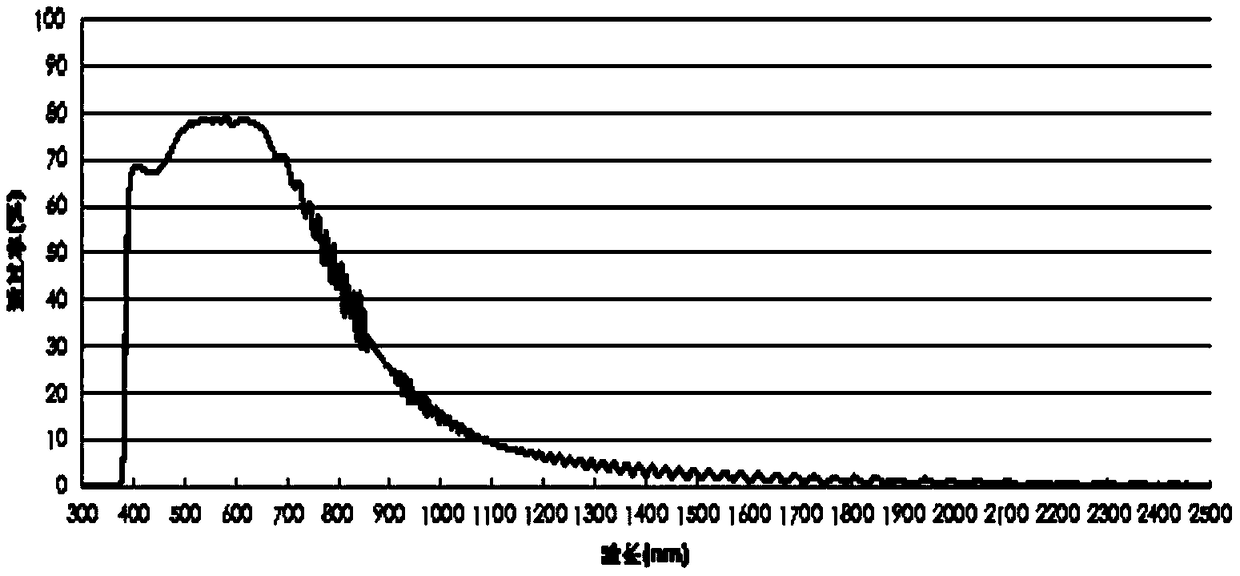

Anti-fogging film and application thereof

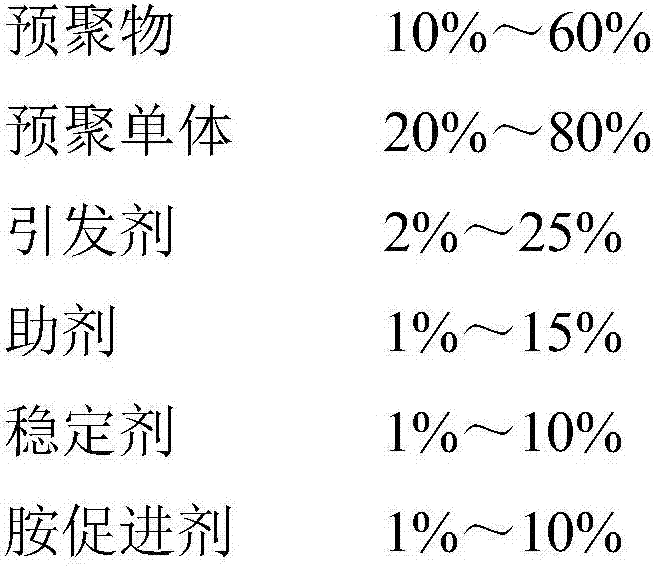

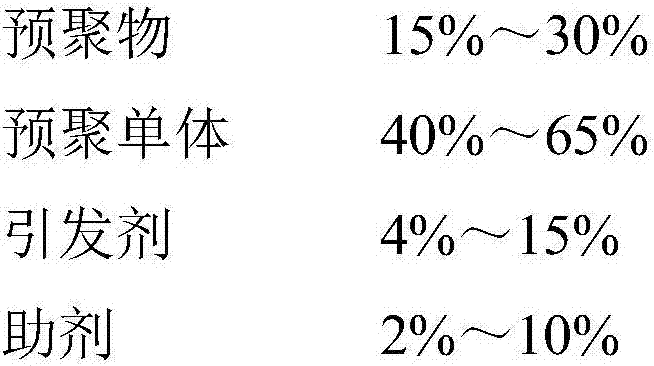

InactiveCN108949055AContinuous anti-fogContinuous anti-fog performanceFilm/foil adhesivesTransmittanceUrethane acrylate

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

High-adhesion wear-resistant UV-LED ink and preparation method thereof

Owner:中山市中益油墨涂料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap