Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Polyurethane adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

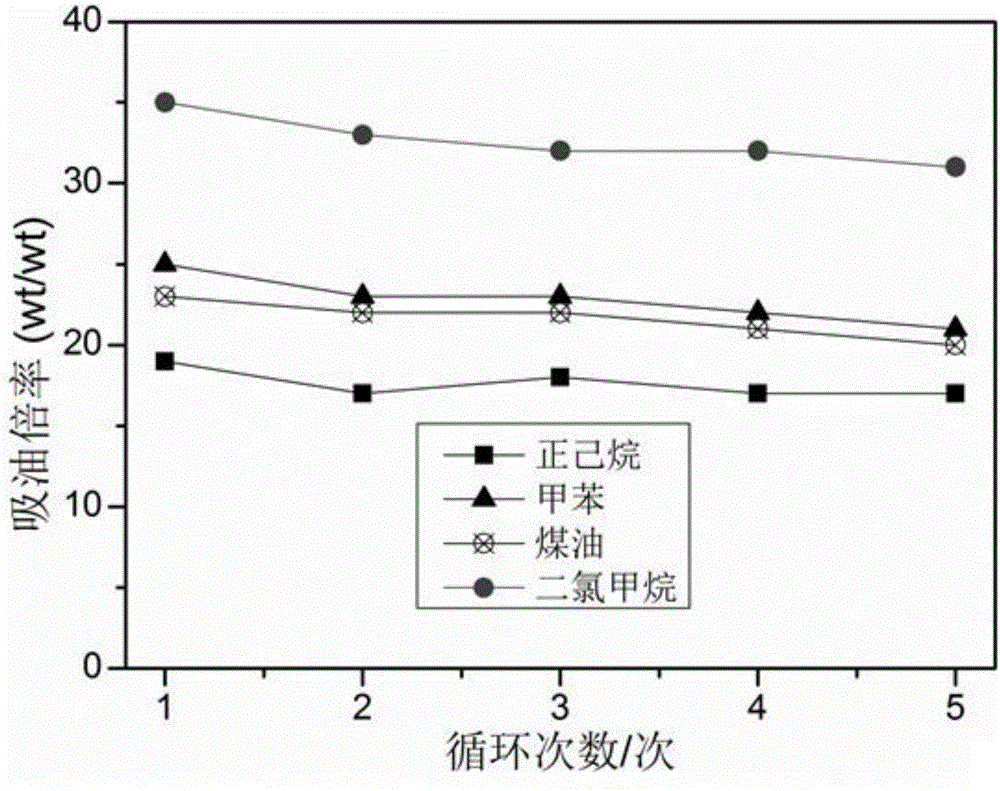

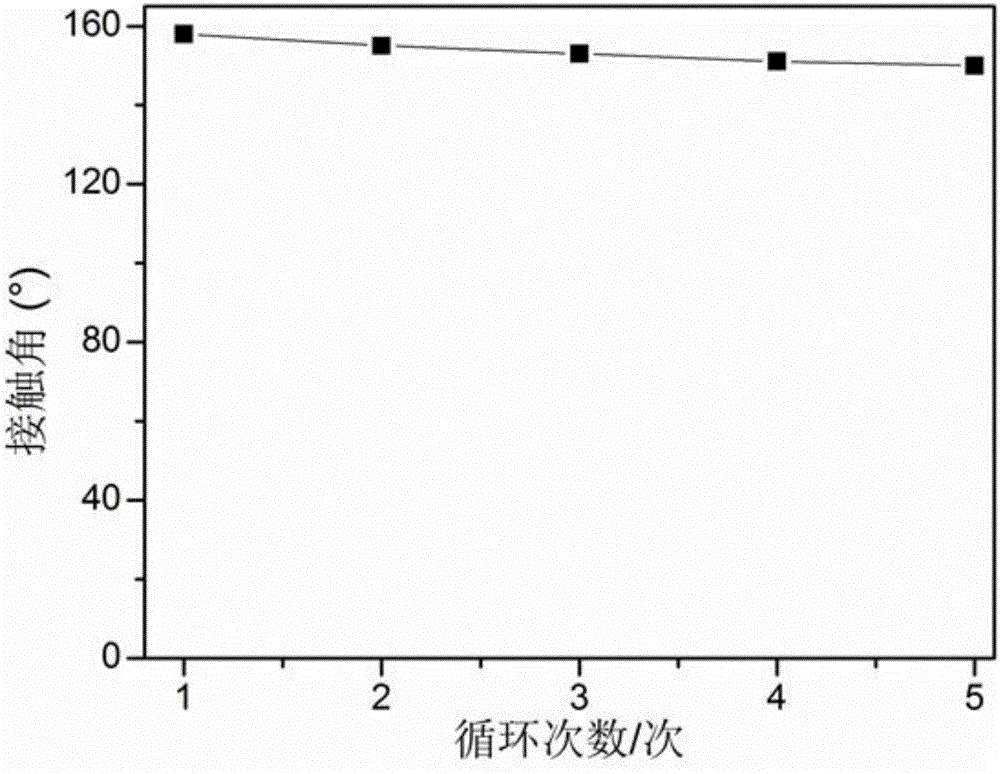

Preparation method for super-hydrophobic/super-oleophylic loofah sponge fiber and application thereof

InactiveCN106732463AEasy to degradeEasy to prepareOther chemical processesLiquid separationFiberPolymer science

Owner:FOSHAN UNIVERSITY

Novel acrylate modified waterborne polyurethane adhesive

InactiveCN109266267AShort curing timeImprove adhesionPolyureas/polyurethane adhesivesGraft polymer adhesivesPolyurethane adhesiveEmulsion

The invention provides a novel acrylate modified waterborne polyurethane adhesive. The adhesive is characterized by being prepared by the following steps: taking polyether glycol and polyisocyanate toreact, so as to obtain a waterborne polyurethane pre-polymer; enabling the waterborne polyurethane pre-polymer to react with an acrylic monomer or a methacrylic acid monomer under the action of an emulsifier and an initiator to obtain waterborne polyurethane acrylate, so as to obtain emulsion, wherein the emulsion is the acrylate modified waterborne polyurethane adhesive. The invention further discloses a preparation method and application of the adhesive. Compared with the prior art, the novel acrylate modified waterborne polyurethane adhesive has the advantages of better environment-friendly performance and improved anti-oxidization capability and anti-ageing capability; the adhesive has good bonding performance with adhesive films and paper products.

Owner:CHANGCHUN UNIV OF TECH

Preparation method of pearlescent anti-crease waterproof moisture-permeable polyurethane synthetic leather

InactiveCN105568701AImprove wear resistanceImprove wrinkle resistanceTextiles and paperWater basedFiber

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

High-elastic plastic runway and construction method thereof

ActiveCN111749078AGood runway mechanical propertiesImprove mechanical propertiesIn situ pavingsGround pavingsEpoxyPolyurethane adhesive

The invention discloses a high-elastic plastic runway and a construction method thereof. The high-elastic plastic runway sequentially comprises a base layer, a waterproof bonding layer, an elastic layer, a bonding layer and a surface layer from bottom to top, wherein the base layer is a cement base layer or an asphalt base layer; the waterproof bonding layer is a water-borne epoxy resin layer; theelastic layer is a mixture of a foamed polyurethane material and EPDM particles, and the mass ratio of the foamed polyurethane material to the EPDM particles is 1:(0.5-2); the bonding layer is made of a polyurethane adhesive; the surface layer is a mixture of a polyurethane adhesive and EPDM particles, and the mass ratio of the polyurethane adhesive to the EPDM particles is 1:(5-6). The high-elastic plastic runway is good in mechanical property, excellent in buffering and damping effect, resistant to aging, non-toxic, environmentally friendly and capable of being widely applied to indoor places such as kindergartens.

Owner:WUHAN RUITIAN NEW MATERIAL TECH CO LTD

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

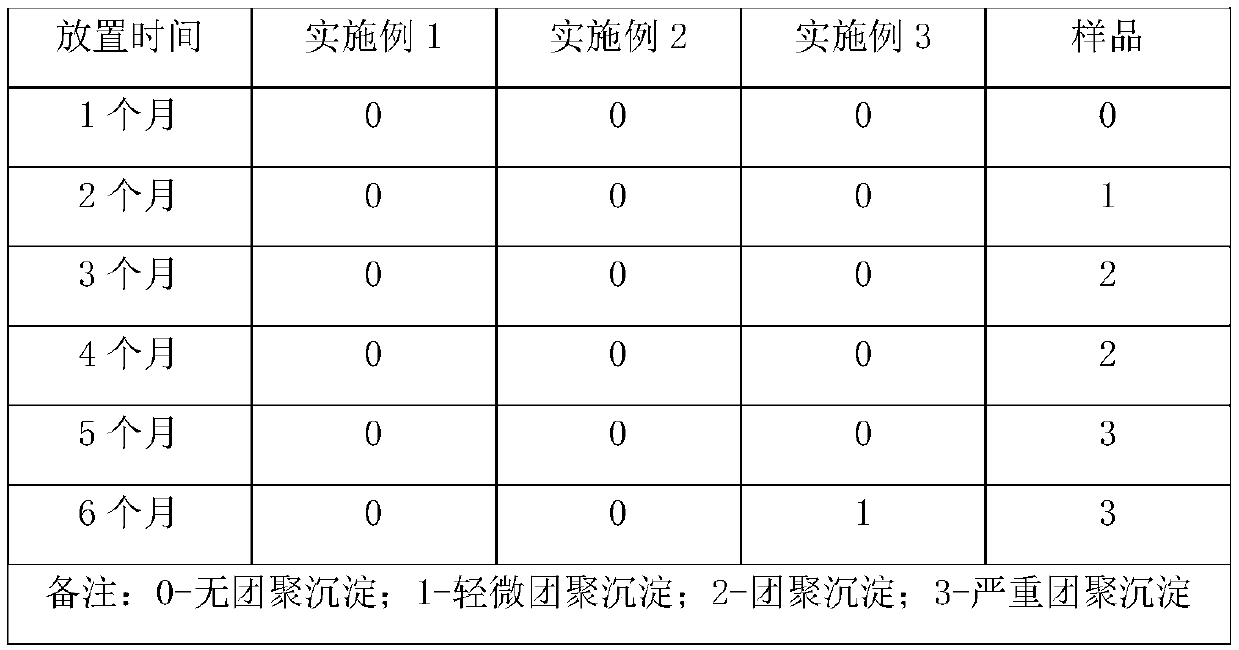

Preparation method of graphene modified polyurethane adhesive

InactiveCN110964474AGood dispersionNot easy to reunitePolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

Owner:SHANDONG WESTBORAN CHEM CO LTD

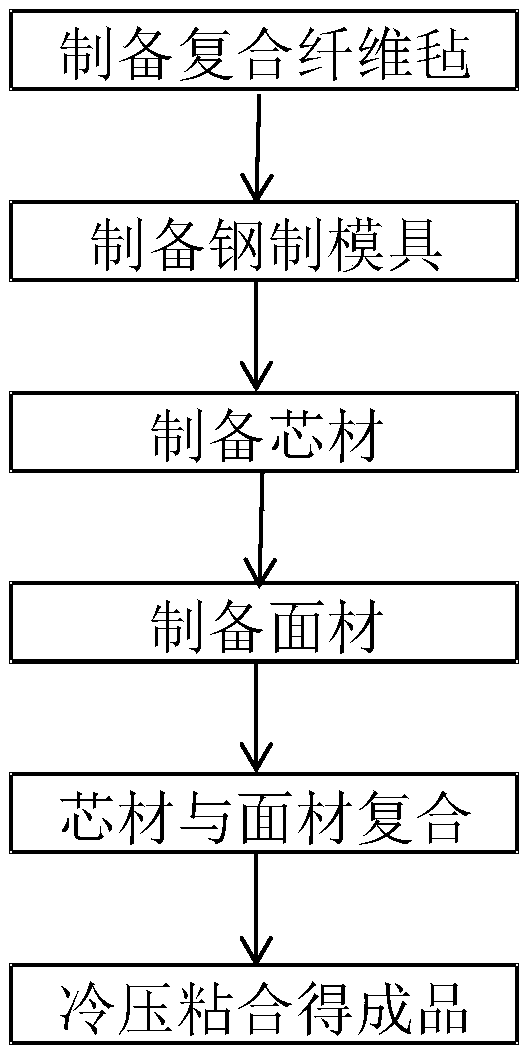

Method for producing environmentally-friendly lightweight composite board

InactiveCN107825812AEnvironmentally friendlyUnbreakableLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesivePolypropylene

The invention discloses a method for producing an environmentally-friendly lightweight composite board. The environmentally-friendly lightweight composite board is through the following steps: producing a composite fiber felt from natural fibers and polypropylene synthetic fibers, and performing a hot press molding technology through using a steel die. The environmentally-friendly lightweight composite board is produced from the natural fibers and the polypropylene synthetic fibers through using the thermoplastic technology, so the composite board is absolutely free from formaldehyde and otherharmful substances; a one-component water-soluble cold glue is a water-soluble polyurethane adhesive, and uses water as a medium, so the composite board is nontoxic, non-flammable, non-polluting andnon-hazardous, and can truly achieve zero formaldehyde environmental protection level; and the length, the width and the thickness of the lightweight composite board are correspondingly adjusted according to users' different needs, so the practicality is improved.

Owner:苏明义

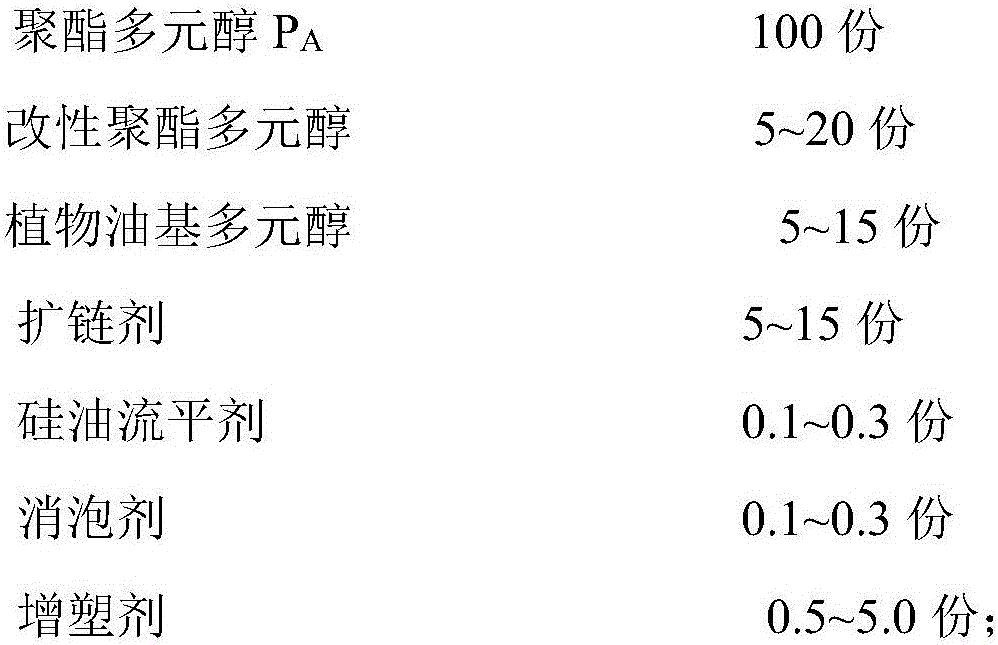

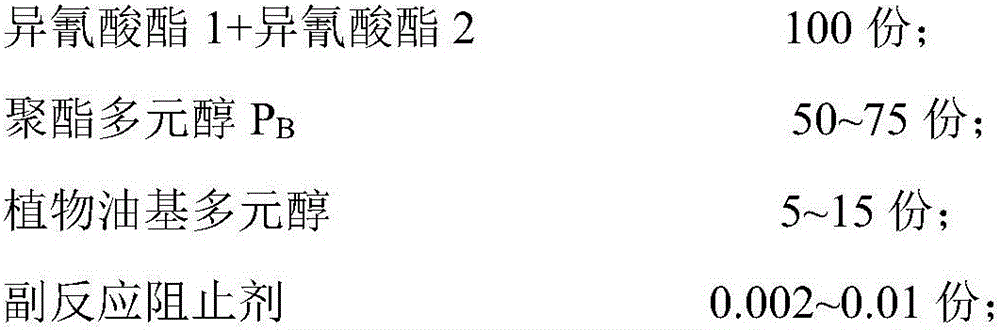

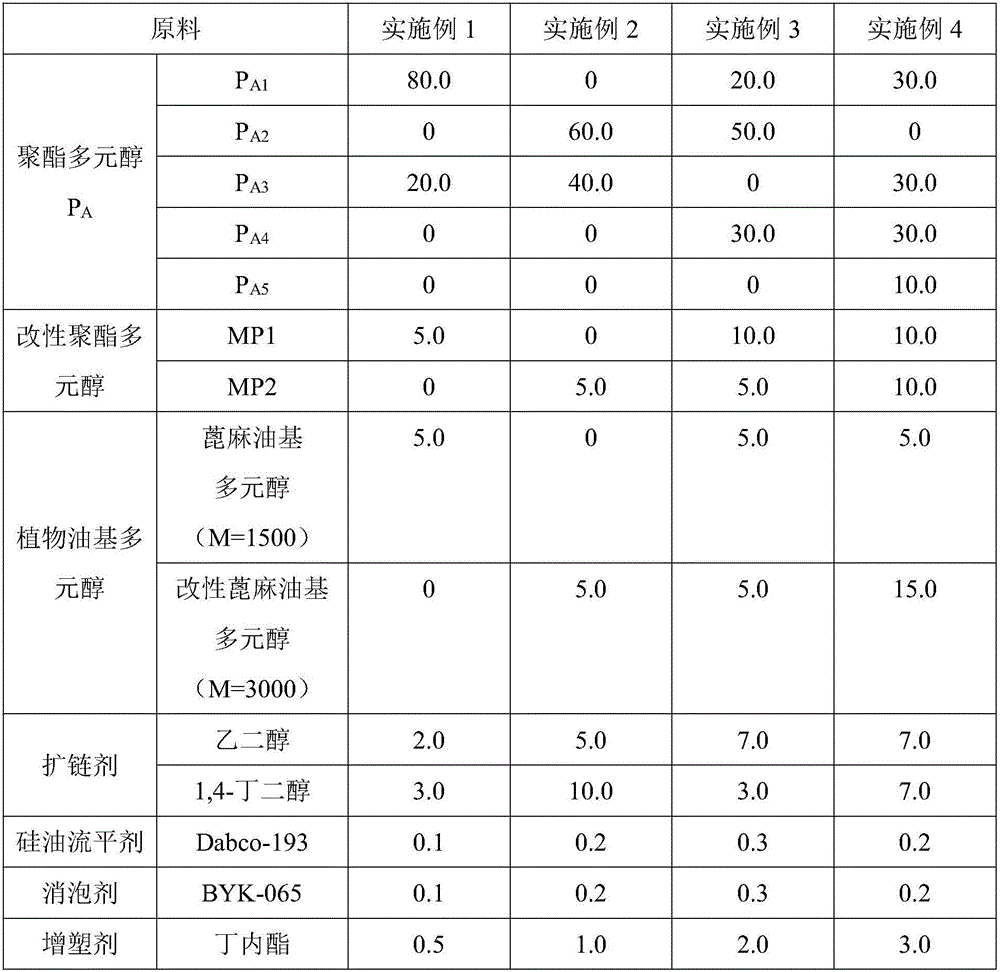

Solvent-free polyurethane adhesive for textiles, and preparation method thereof

InactiveCN108300337ANon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveSolventPolyurethane adhesive

Owner:昆山市冠宝化学有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap