Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Thermoplastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermoplastic, or thermosoftening plastic, is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling.

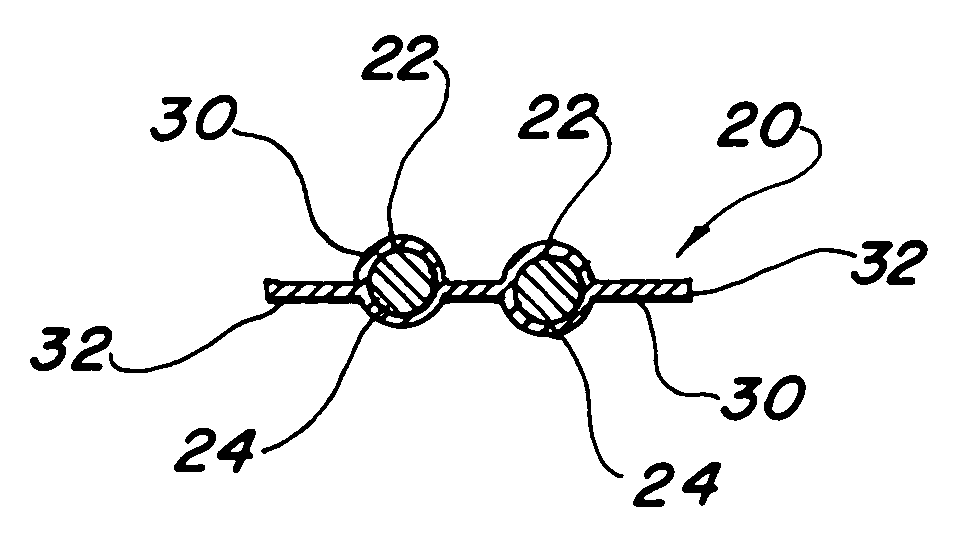

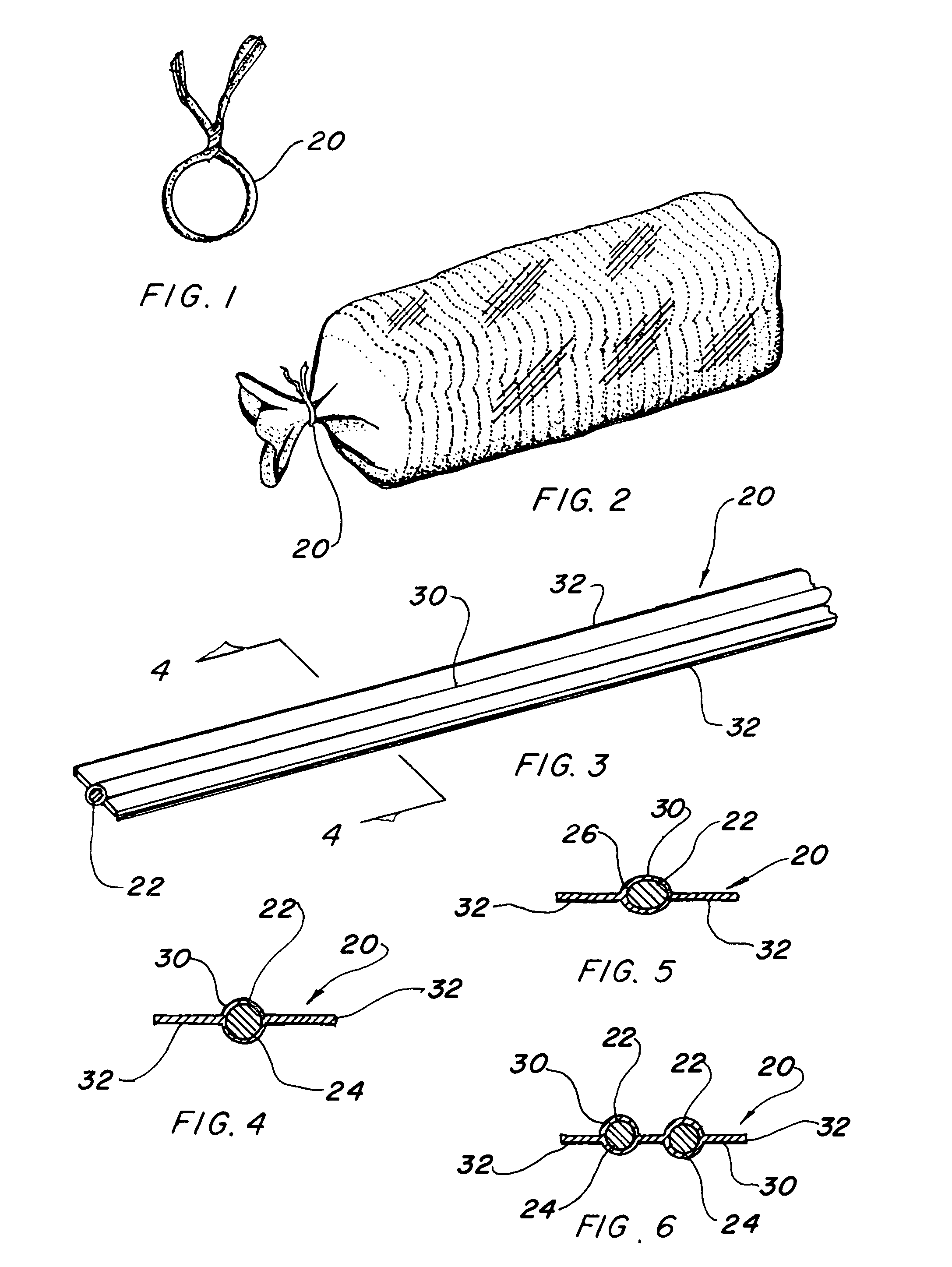

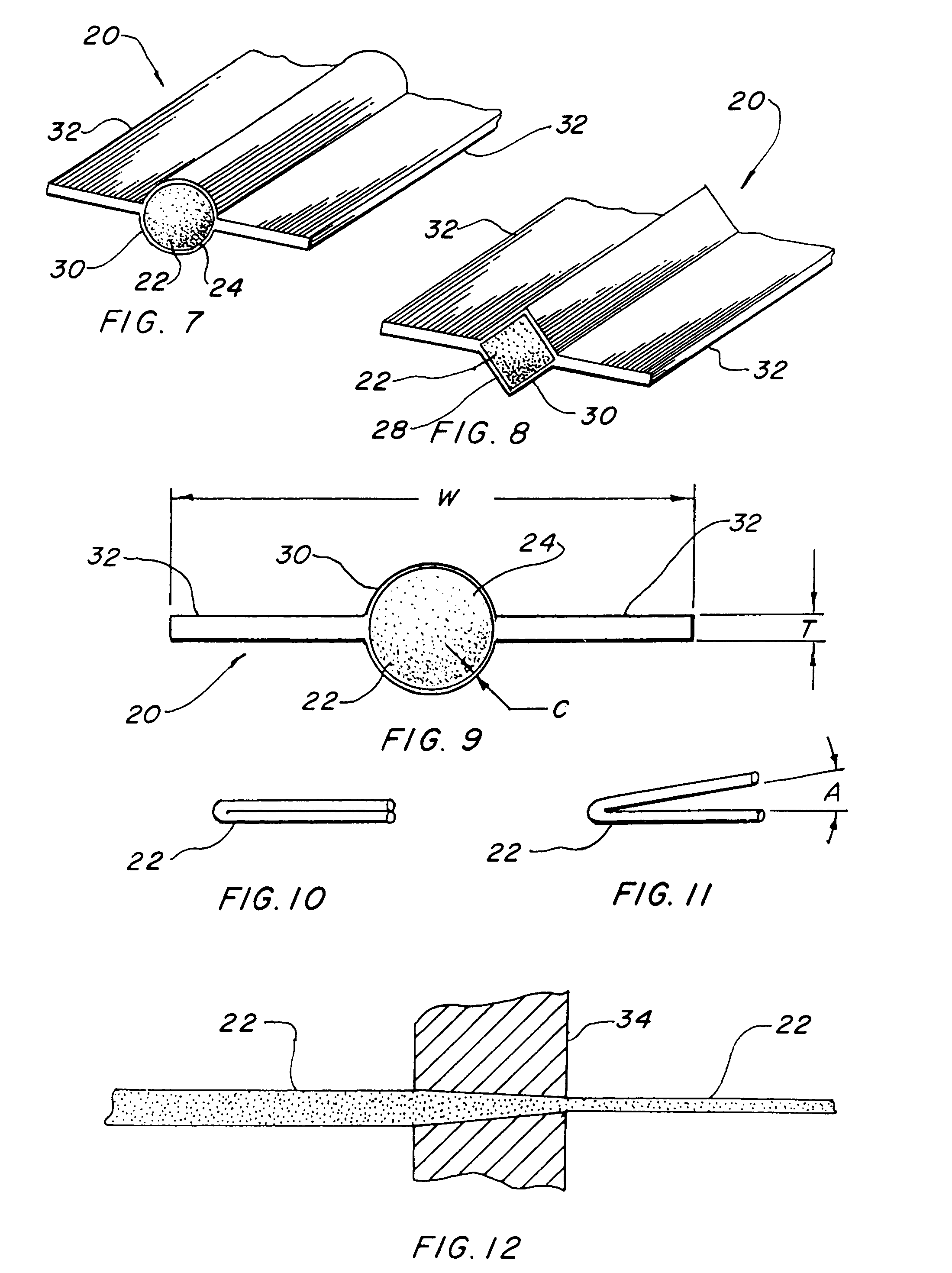

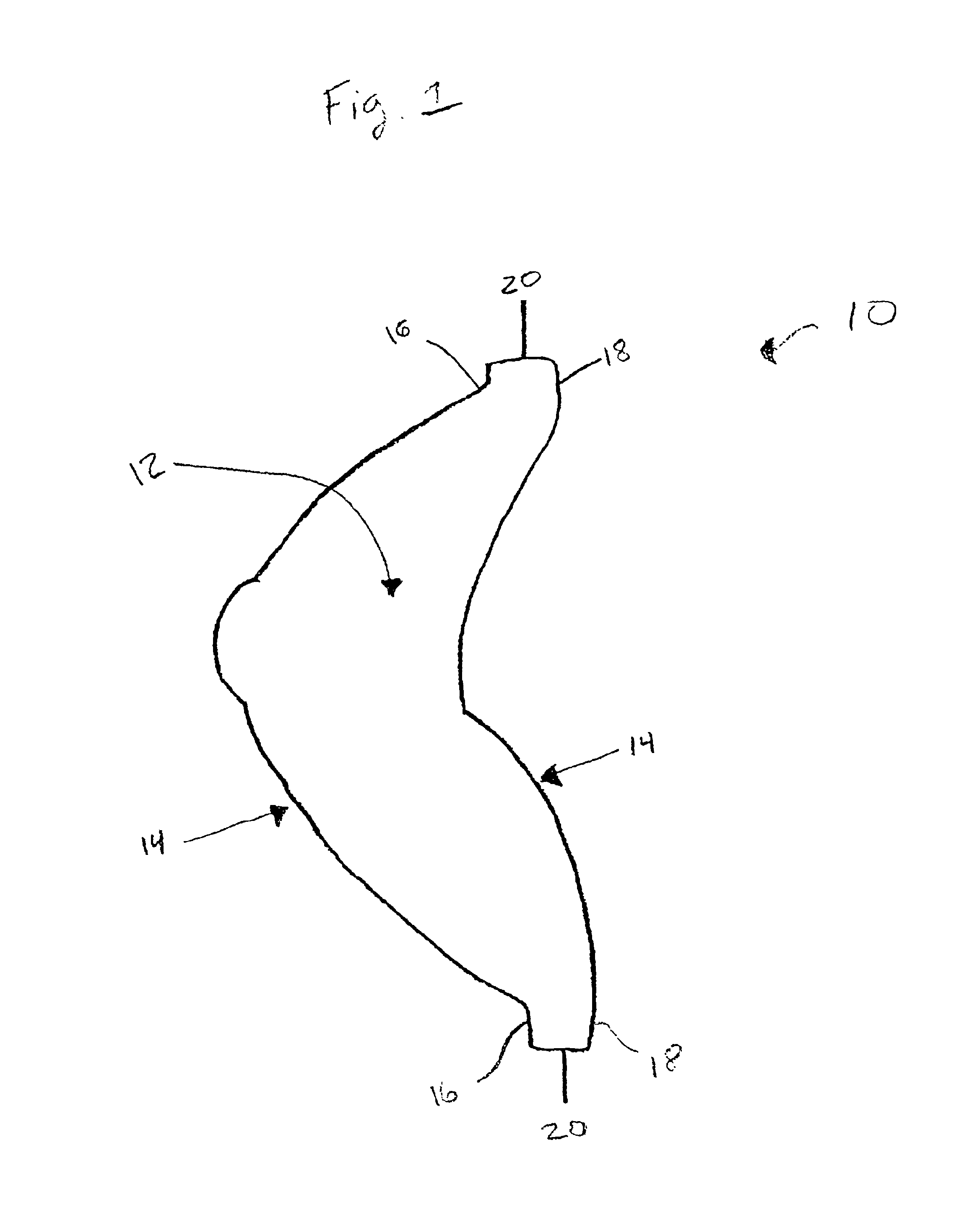

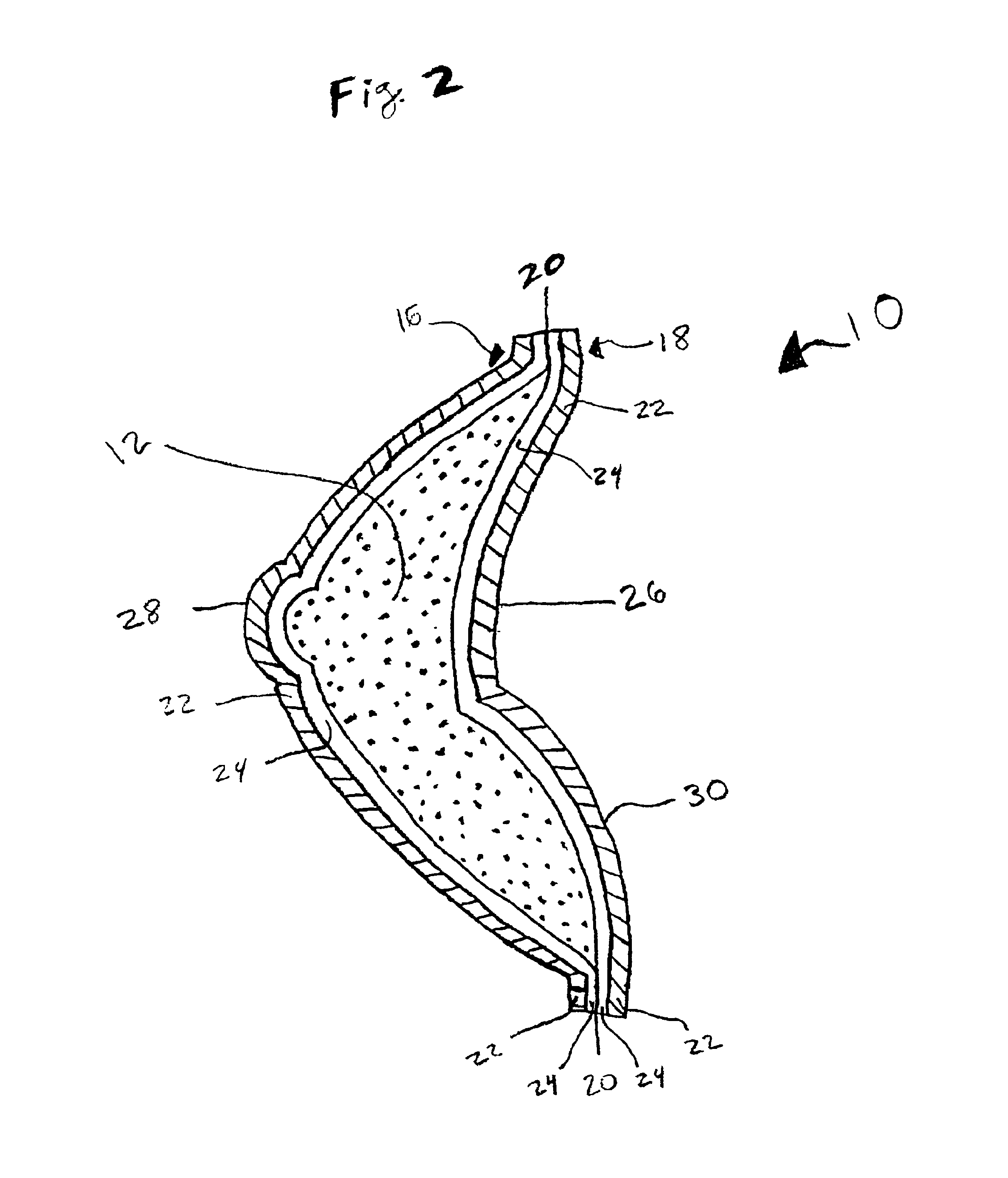

Composite polymeric twist tie

InactiveUS7011879B1Readily availableCompetitively pricedPaper-makingBagsThermoplasticHigh-density polyethylene

Owner:BEDFORD IND INC

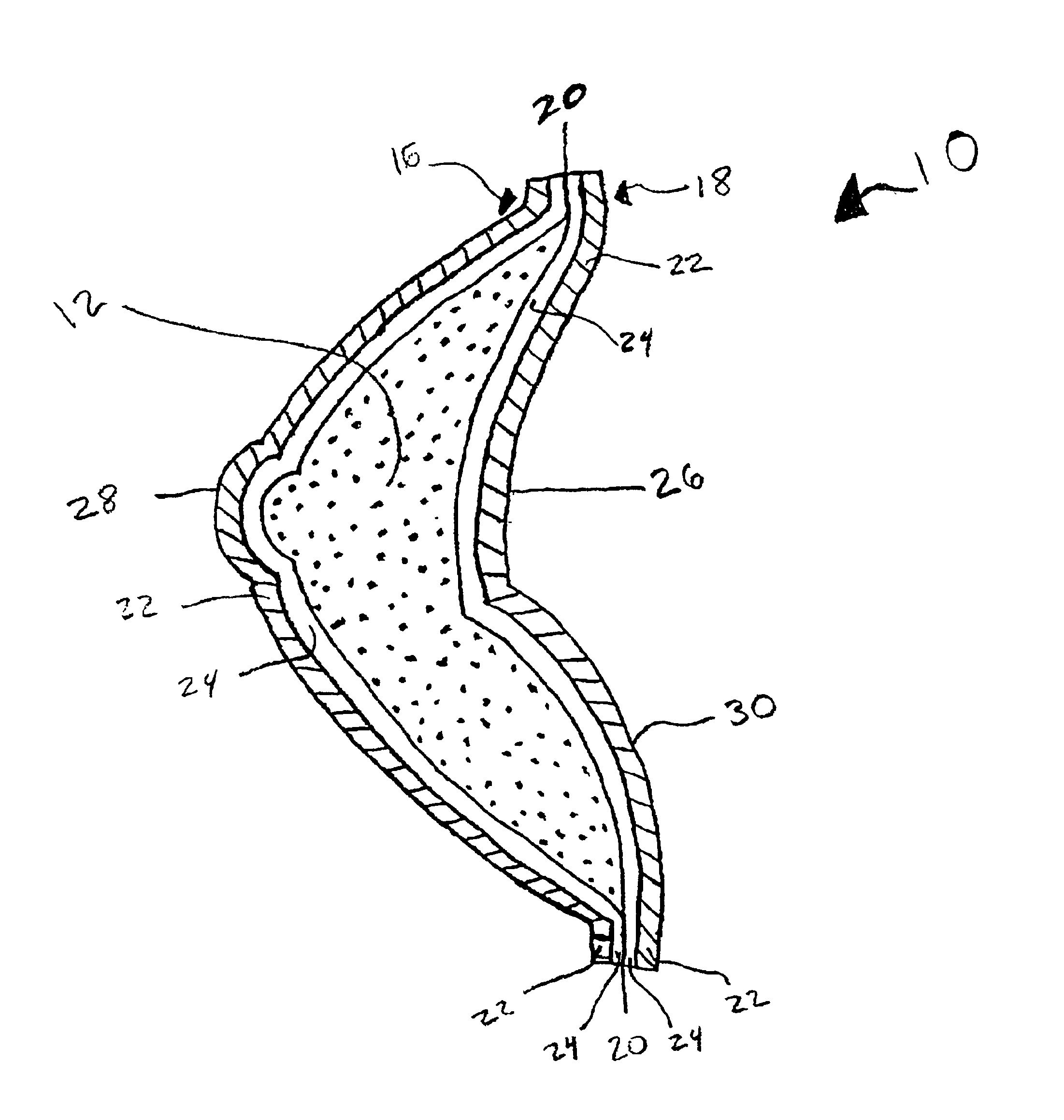

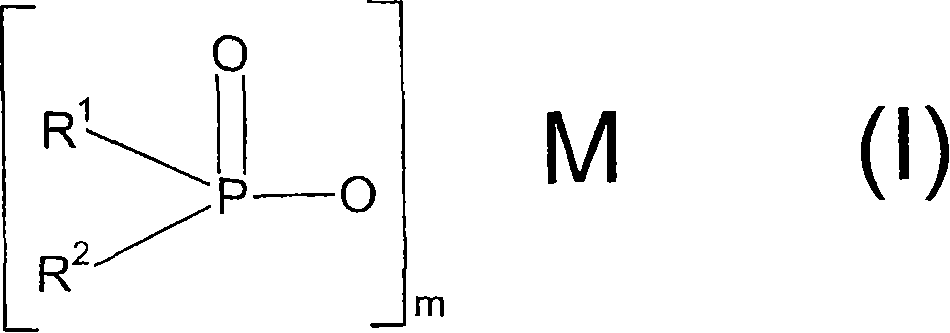

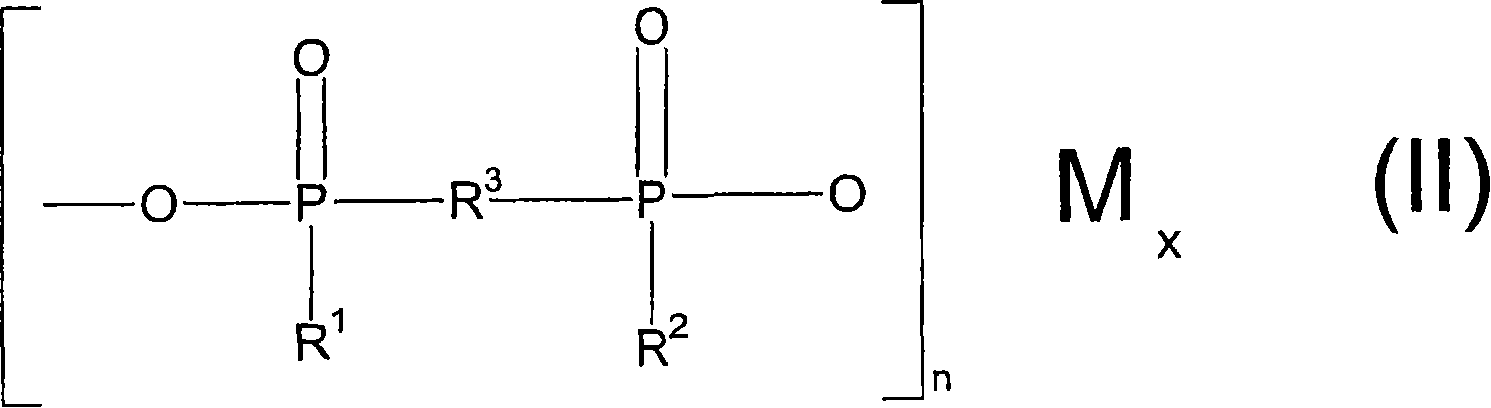

Breast form encased with fabric laminated thermoplastic film

InactiveUS6857932B2Prevent movementGarmentsBrassieresThermoplasticSilicone Gels

Owner:BRAGEL INT INC

Laser-markable flameproof molding compounds and laser-markable and laser-marked products obtained from said molding compounds

The subject invention discloses a variety of different maintenance devices for use with a filling valve apparatus. The maintenance devices each include a movable component and a locking mechanism. An actuator of the locking mechanism is coupled to a caming section of the movable component for moving the movable component between a release position with a rim of the movable component spaced from fingers of the locking mechanism and an engaged position with the rim abutting the fingers. The fingers are wedged between the movable component and the filling valve apparatus when the movable component is in the engaged position for securing the device to the filling valve apparatus.

Owner:TICONA GMBH

Reinforced polyethylene glycol terephthalate-modified material and preparation method thereof

InactiveCN101875759AImprove low temperature resistanceImprove creep resistanceGlass fiberThermoplastic

The invention discloses a reinforced polyethylene glycol terephthalate-modified material and a preparation method thereof. The reinforced polyethylene glycol terephthalate-modified material comprises the following components in part by weight: 100 parts of polyethylene glycol terephthalate, 30 to 50 parts of glass fibers, 6 to 10 parts of flexibilizer, 0.5 to 1 part of antioxygen, 3 to 6 parts of compound nucleating agent and 10 to 15 parts of elastomer SEBS. The reinforced polyethylene glycol terephthalate-modified material has high low temperature resistance and creep resistance and can be used in place of the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer to make frame seals and other parts and reduce use cost of the materials. A new application field of the modifying polyethylene glycol terephthalate is opened, the conventional thermoplastic ethylene-propylene diene methylene dynamically vulcanized elastomer can be replaced by the material, and the use cost of the material is reduced greatly.

Owner:SHENZHEN KEJU NEW MATERIAL

Thermoplastic starch-polyvinyl alcohol composite plastic film

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

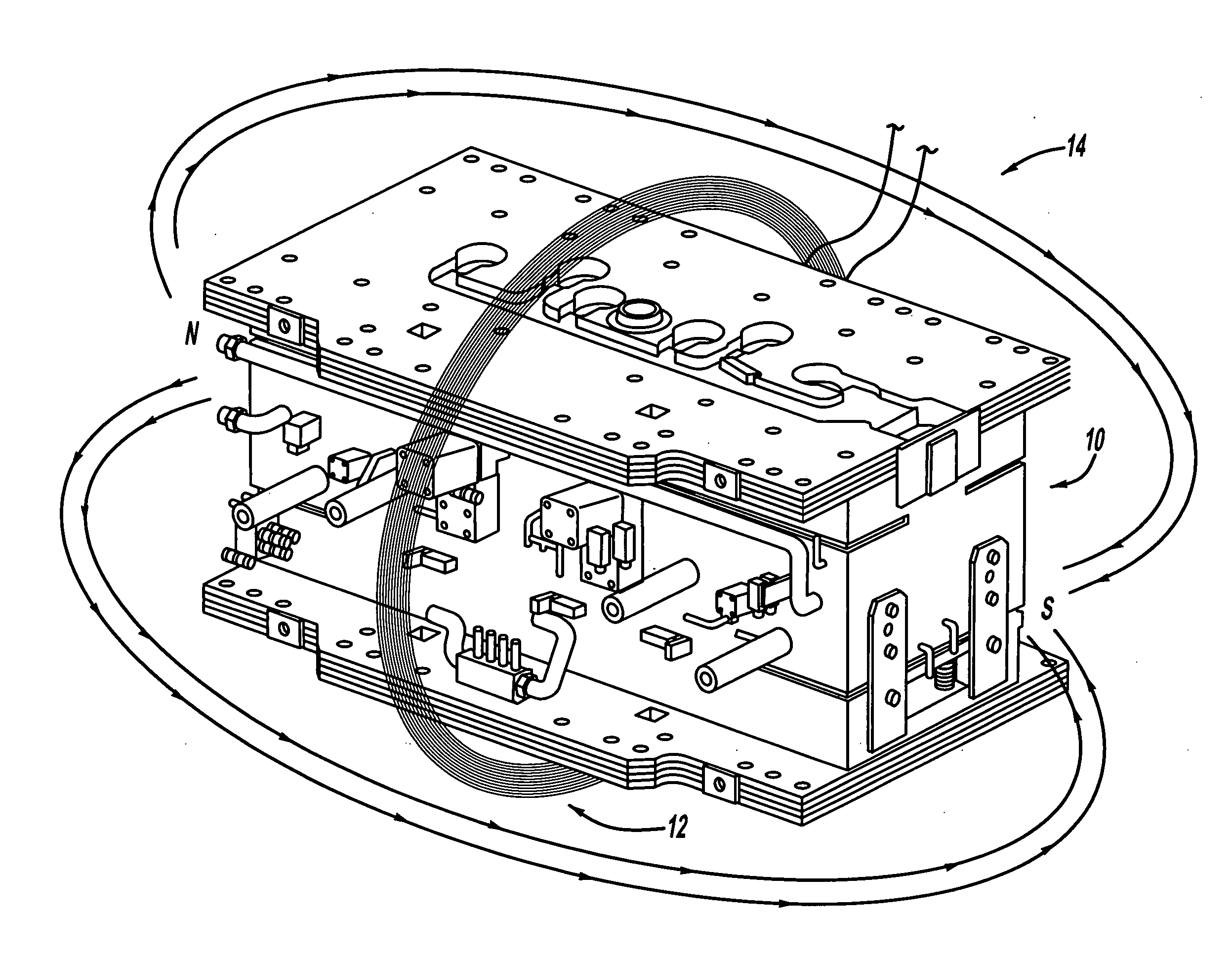

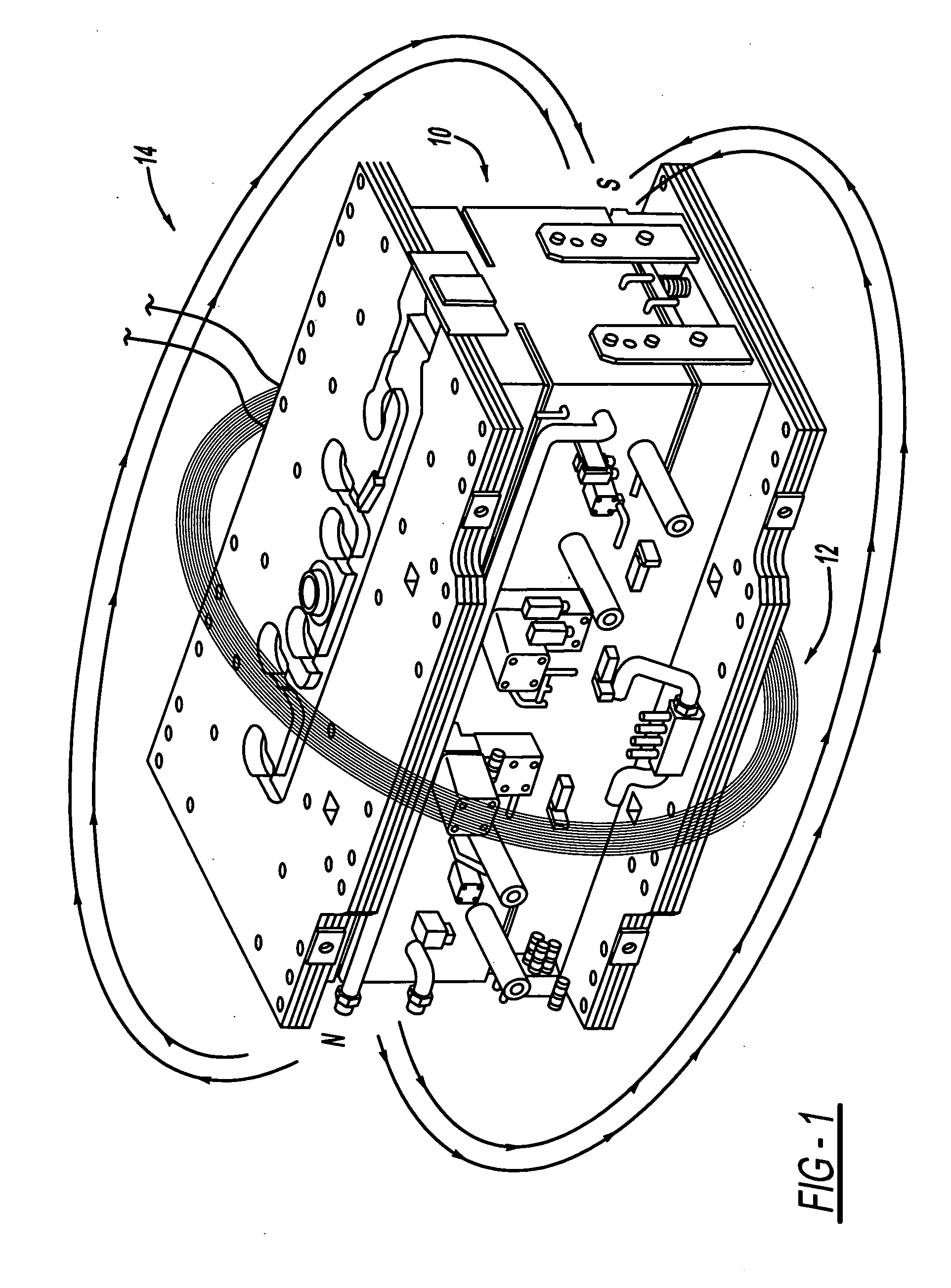

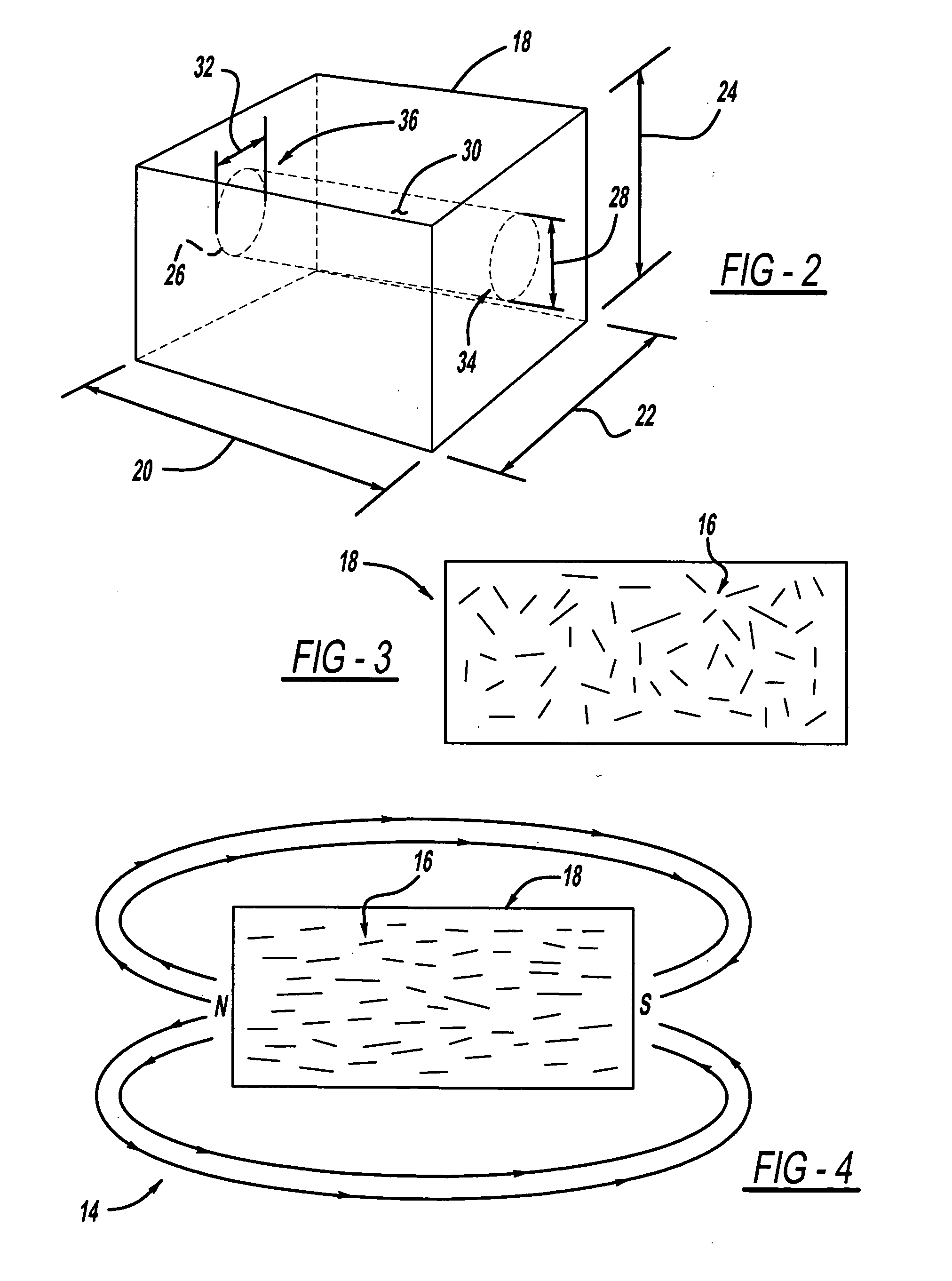

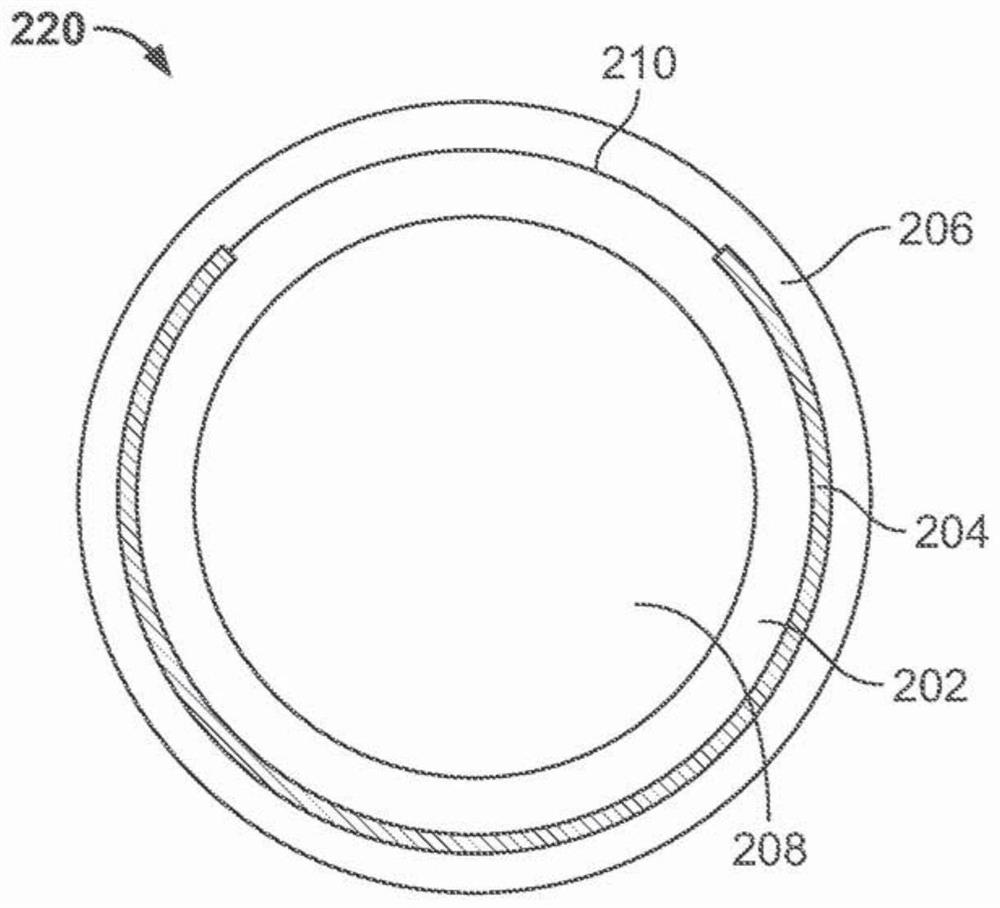

Magnetic alignment of nanoparticles within a polymer

InactiveUS20120183762A1Uniform sizeMaterial nanotechnologyLayered productsThermoplasticPlastic materials

Owner:MAGNA INTERNATIONAL INC

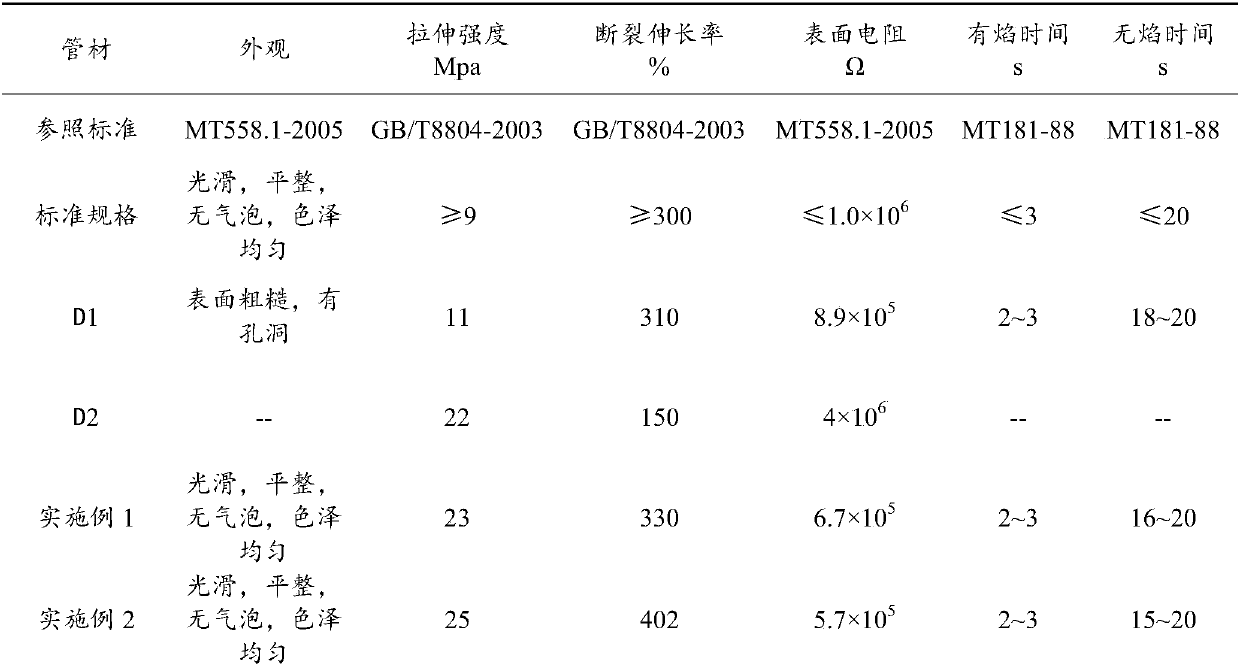

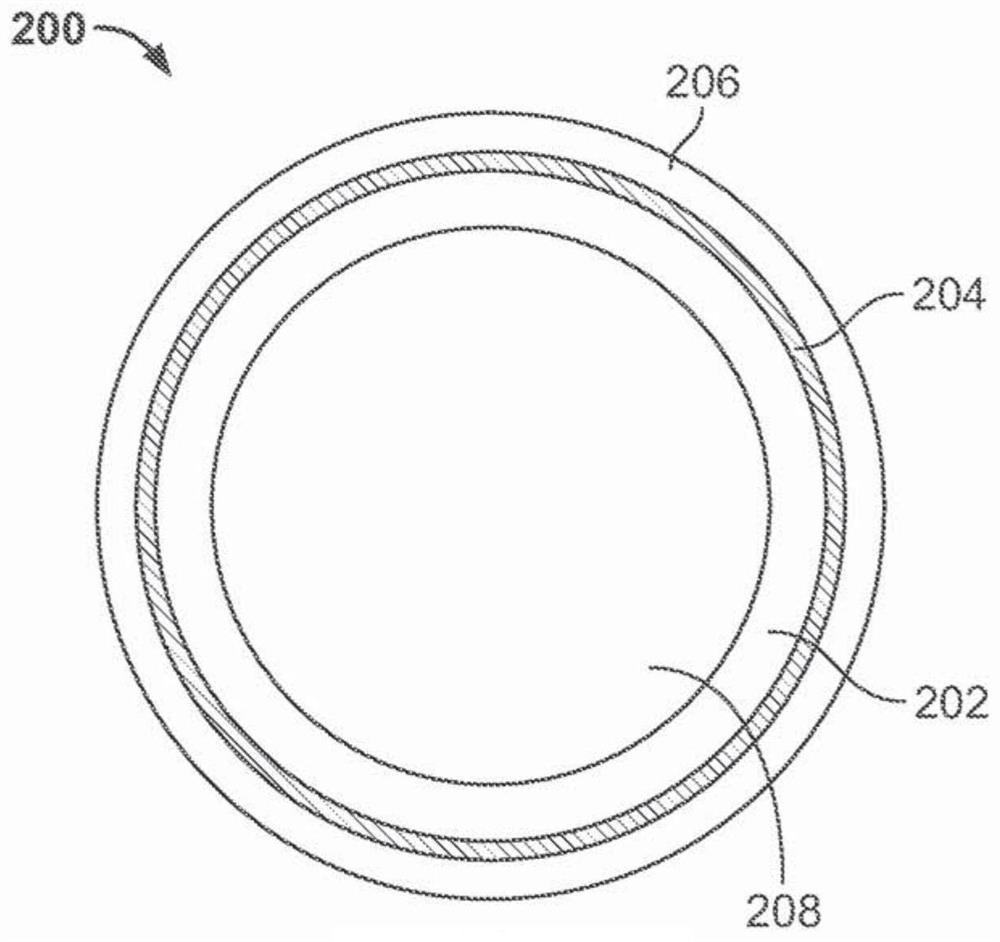

Mining graphene, carbon black and polystyrene composite pipe and production method thereof

Owner:山东方大新材料科技有限公司 +1

TPO (thermoplastic polyolefin) waterproof roll material and preparation method thereof

ActiveCN104212066AImprove flame retardant performanceGood low temperature bending resistanceThermoplasticPolyolefin

Owner:河南蓝翎环科防水材料有限公司

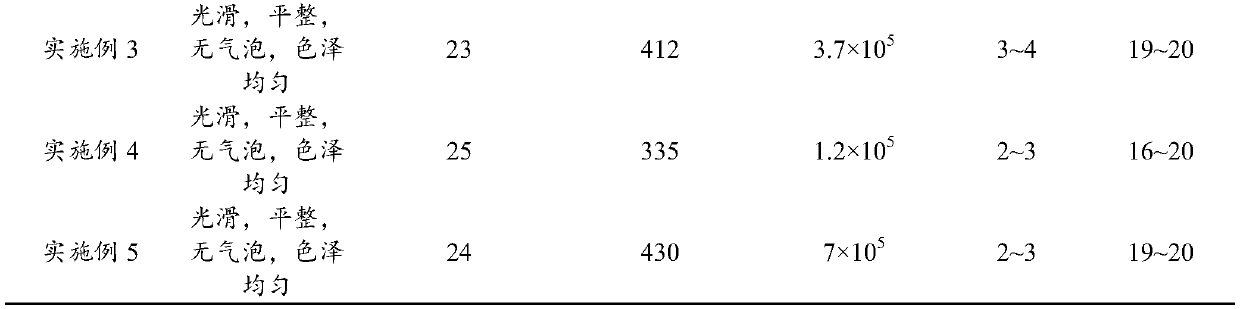

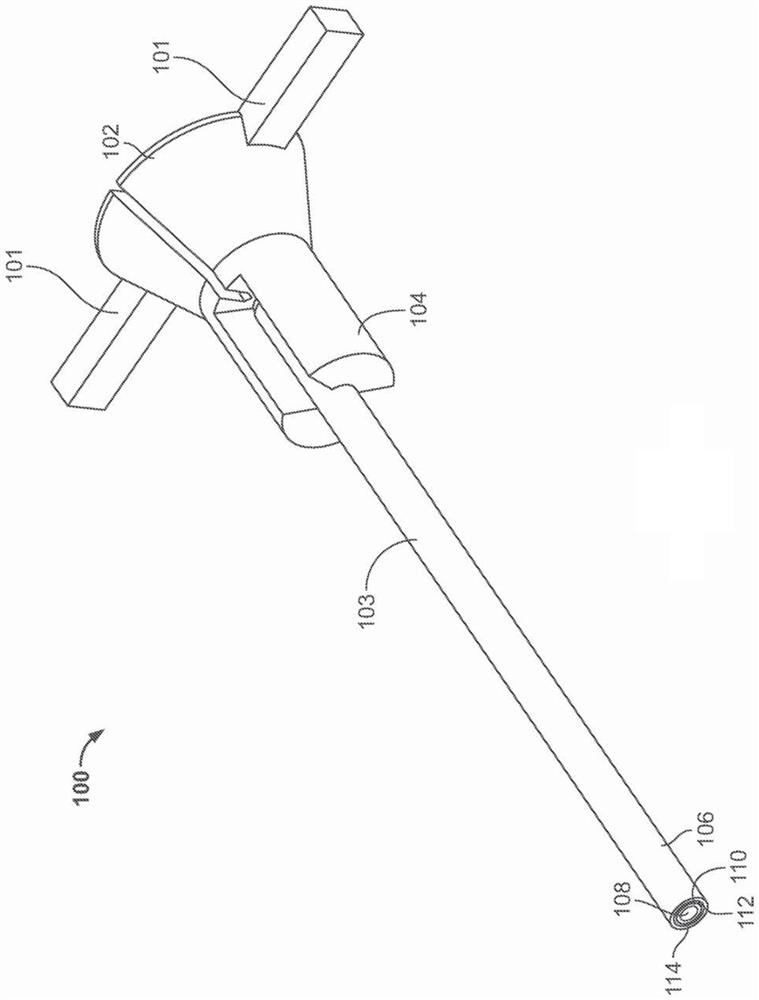

Peel-away sheath assembly

Owner:ABIOMED

Monocomponent thermoplastic acrylic surfacer

Owner:广东花王涂料有限公司

Use of aramid fiber conjunction with thermoplastic to improve wash-off resistance and physical properties such as impact and expansion

InactiveUS20060189722A1Excellent characteristicsIncrease resistanceEster polymer adhesivesEpoxy resin adhesivesThermoplasticPolymer science

One-part epoxy adhesive formulations, and methods of using the same, are described. The formulations include, among other things, powdered methacrylate butadiene styrene and aramid pulp to, among other things, improve the wash off resistance, T peel strength, and impact strength characteristics thereof. Additionally, the formulations exhibit desirable expansion characteristics. The formulations are especially suitable for use in joining automotive components.

Owner:DOW GLOBAL TECH LLC

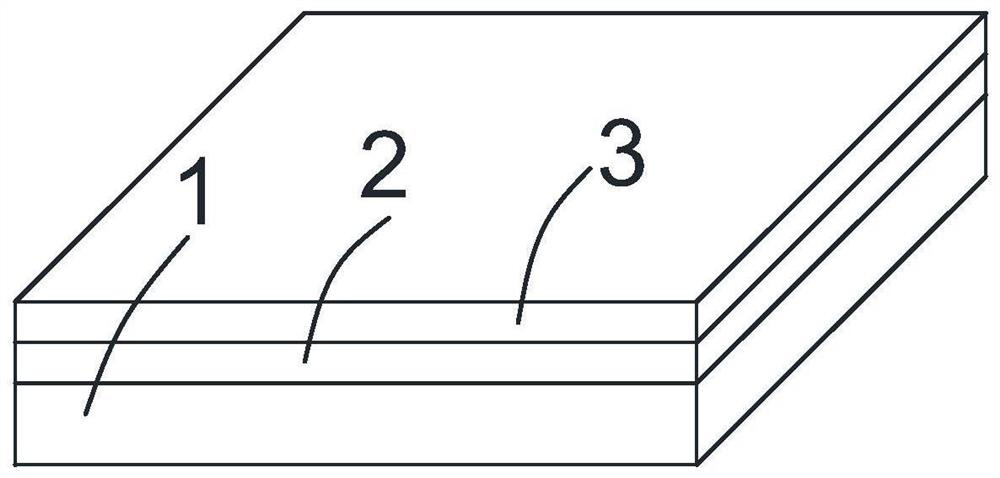

Multilayer natural fiber sheet and thermoplastic plastic composite material, and preparation method thereof

ActiveCN107057189AHigh mechanical strengthEasy to stretchOther domestic articlesThermoplasticThermoplastic elastomer

The invention discloses a multilayer natural fiber sheet and thermoplastic plastic composite material, and a preparation method thereof. The multilayer natural fiber sheet and thermoplastic plastic composite material is mainly formed by stacking and laminating natural fiber sheets and thermoplastic plastics, wherein the natural fiber sheets are made by mixing about 10 to 40 percent of natural fibers and about 2 to 5 percent of dispersing agents in percentage by volume, and the remaining are the thermoplastic plastics. The natural fibers are cut short, and after being blended, the dispersing agents and the natural fibers are added into distilled pure water and are ultrasonically dispersed to obtain suspension liquid; the water and the dispersing agents are filtered, and then the suspension liquid is dried to obtain the natural fiber sheets; thermoplastic plastic particles are pressed into plastic sheets, and the natural fiber sheets and the plastic sheets are stacked into a multilayer material which is placed into a mold frame and then pressed. The material is completely based on a green material and environment protection process, the mechanical performance of the material is associated with the number of layers of natural sheets and is maximized in case of four to five layers, the tensile strength, the bending strength and the impact strength can be more than two times those of raw materials, and the industrial application prospect is great.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

ACM thermoplastic vulcanized rubber and preparation method and application thereof

Owner:浙江科普特新材料有限公司

Thermoplastic PVDF fluorocarbon powder coated aluminum veneer

InactiveCN111926957AImprove wear resistanceImprove corrosion resistanceWallsPretreated surfacesThermoplasticWeather resistance

Owner:方大新材料(江西)有限公司

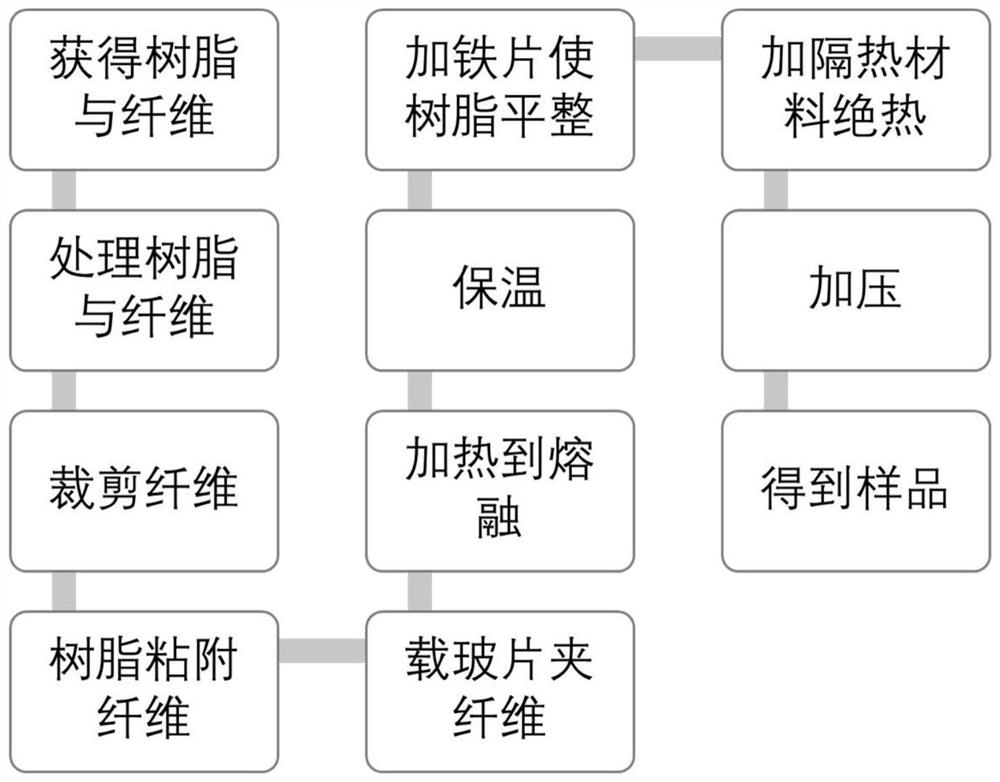

Sample preparation and observation method for fiber-induced thermoplastic resin crystallization

ActiveCN114701106AObserve the black cross extinction phenomenonObserving the crystallization effectPreparing sample for investigationCoatingsThermoplasticFiber

Owner:DONGHUA UNIV

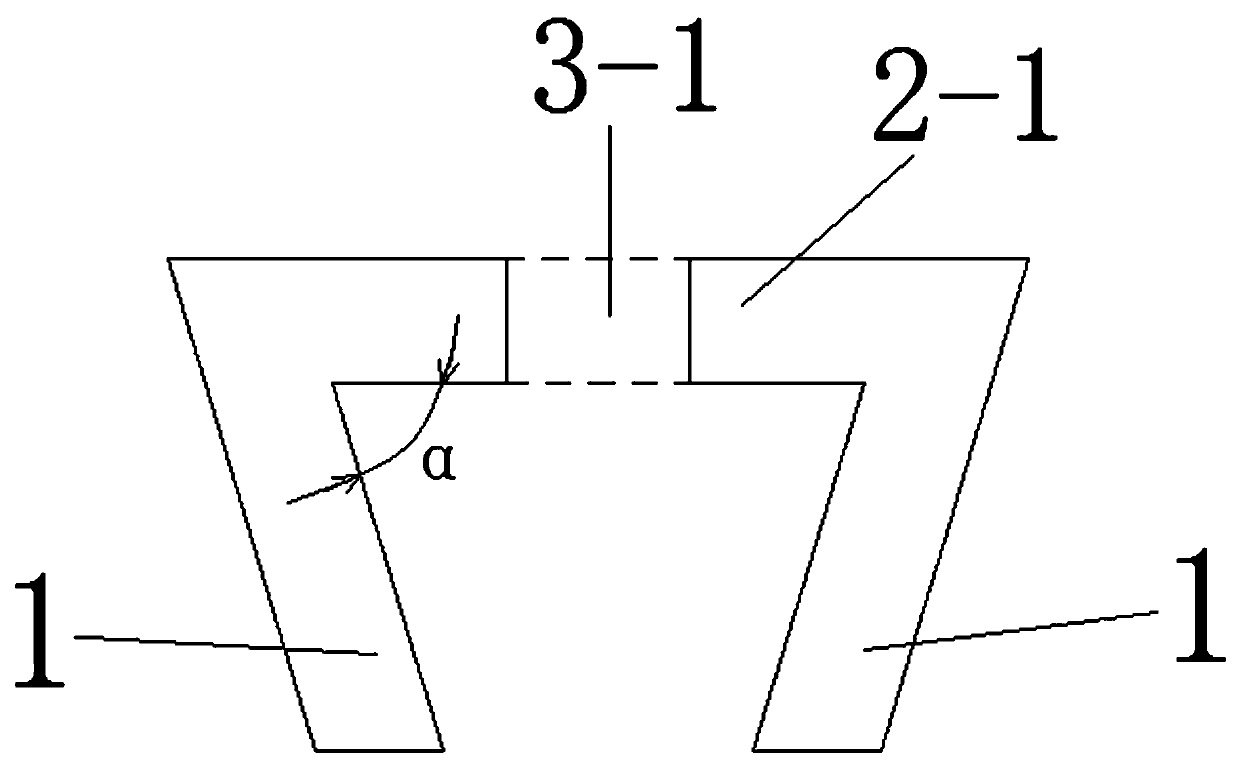

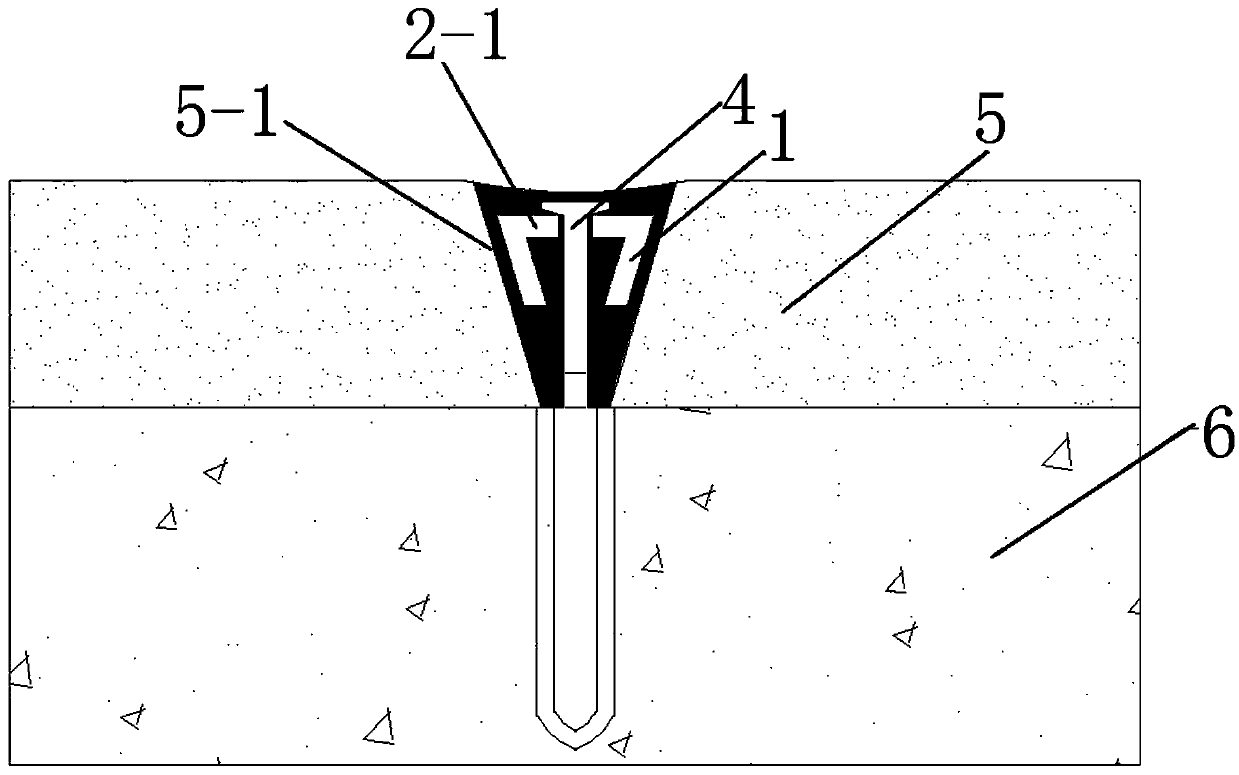

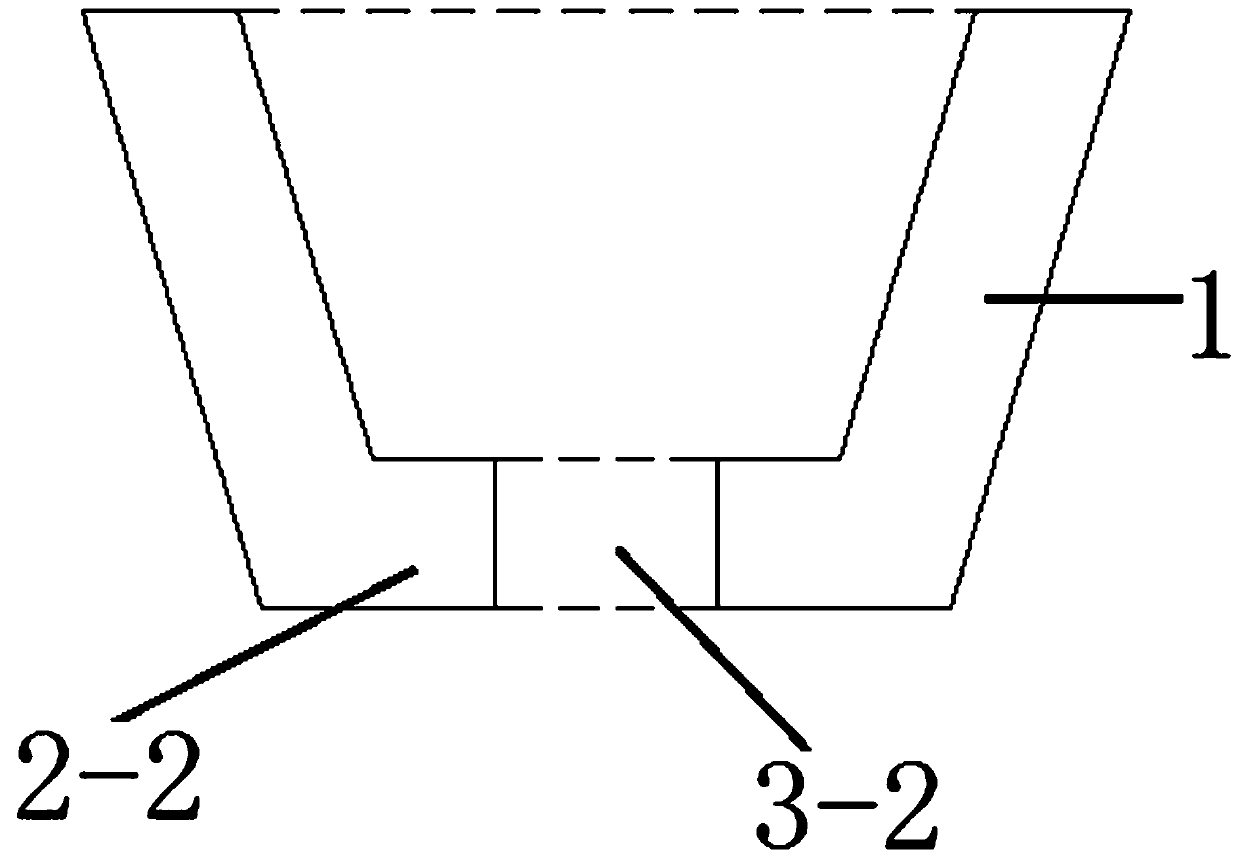

Swallow tail tenon and mortise fixing method of heat-preserving decoration integrated plate and fixing device thereof

PendingCN109098384ANot easy to fall offSimple structureCovering/liningsBuilding material handlingIsosceles trapezoidThermoplastic

Owner:吕明芳 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap