Conductive plastic for processing power supply cover plate, and fabrication method of power supply cover plate

A technology of conductive plastic and power supply cover, which is applied in the field of conductive materials, can solve the problems of high cost, heavy aluminum die castings, and non-adjustable shielding performance, and achieve strong acid and alkali corrosion resistance, convenient molding and processing, and overall cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

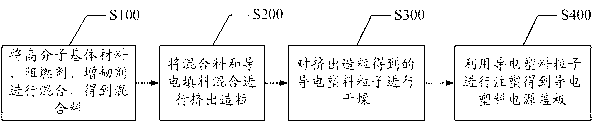

Method used

Image

Examples

Embodiment 1

[0052] Conductive plastics used to process power supply covers include:

[0053] PC / ABS 60%;

[0054] Stainless Steel Fiber 18%;

[0055] Flame retardant 17%;

[0056] Toughener 5%.

[0057]The method for preparing a power cover using the above-mentioned conductive plastic component comprises the following steps:

[0058] Add PC / ABS, flame retardant and toughening agent to the high mixer, and mix at 1300 rpm for 5 minutes;

[0059] The mixture and stainless steel fibers are extruded and granulated by a twin-screw extruder. Particle length 5mm;

[0060] Dry the conductive plastic particles in a blower constant temperature drying oven, set a constant temperature of 80°C for 16 hours;

[0061] Conductive plastic particles are used for injection molding to obtain a conductive plastic power supply cover plate. Use an injection molding machine for injection molding, and the tonnage of the beer machine is 160T. Injection molding process parameters: the water temperature of t

Embodiment 2

[0063] Conductive plastics used to process power supply covers include:

[0064] PC / ABS 50%;

[0065] Stainless steel fiber 25%;

[0066] Flame retardant 20%;

[0067] Toughener 5%.

[0068] The method for preparing a power cover using the above-mentioned conductive plastic component comprises the following steps:

[0069] Add PC / ABS, flame retardant and toughener to the high mixer, and mix at 1000 rpm for 5 minutes;

[0070] The mixture and stainless steel fibers are extruded and granulated by a twin-screw extruder. Particle length 5mm;

[0071] Dry the conductive plastic particles in a blower constant temperature drying oven, set a constant temperature of 80°C for 16 hours;

[0072] Conductive plastic particles are used for injection molding to obtain a conductive plastic power supply cover plate. Use an injection molding machine for injection molding, and the tonnage of the beer machine is 160T. Injection molding process parameters: the water temperature of the fro

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap