Multilayer wiring board and power supply structure to be embedded in multilayer wiring board

a multi-layer wiring board and power supply technology, applied in pulse generators, printed circuit non-printed electric components association, pulse technique, etc., can solve problems such as reducing electrical resistance, and achieve the effects of low resistance, high current, and large power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

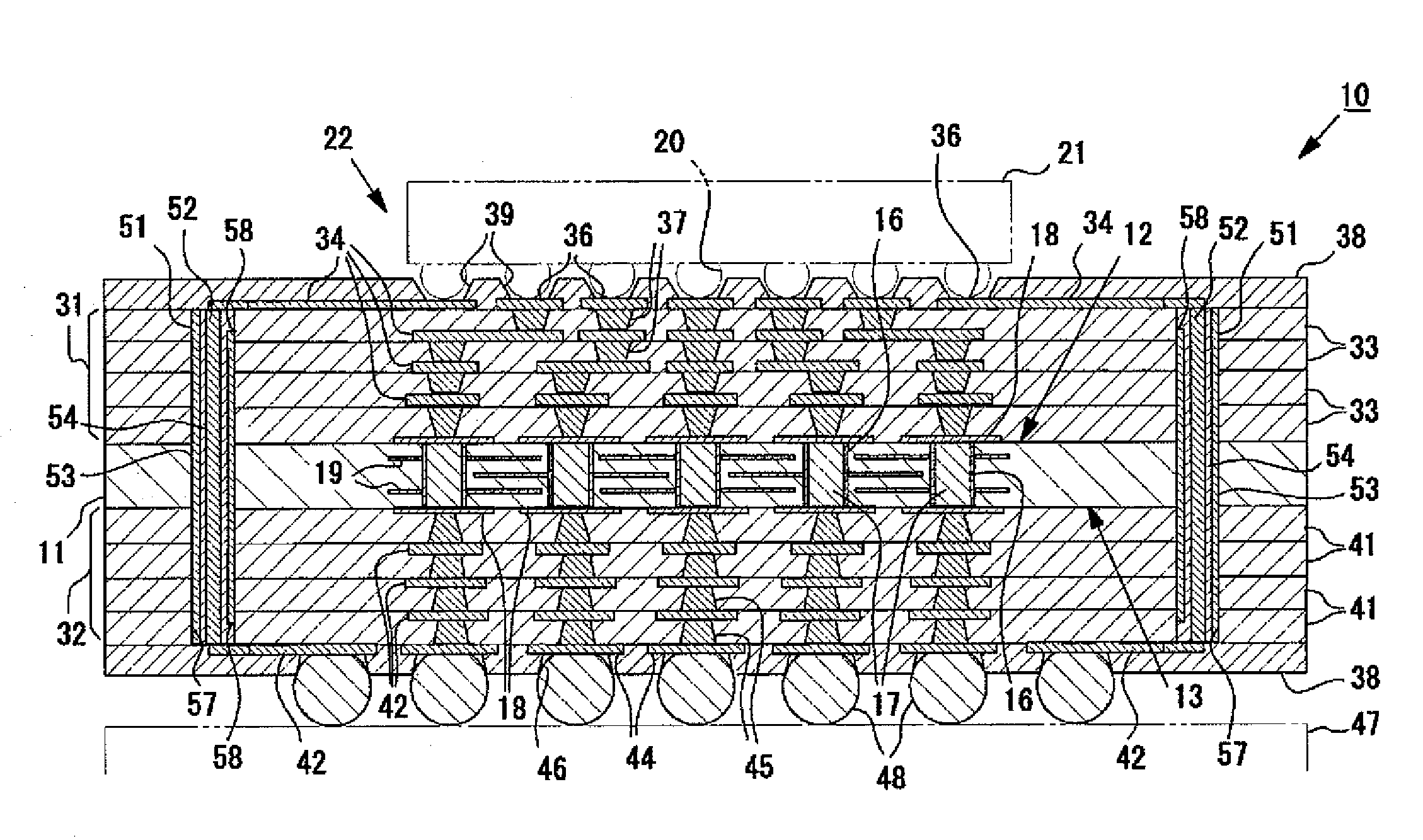

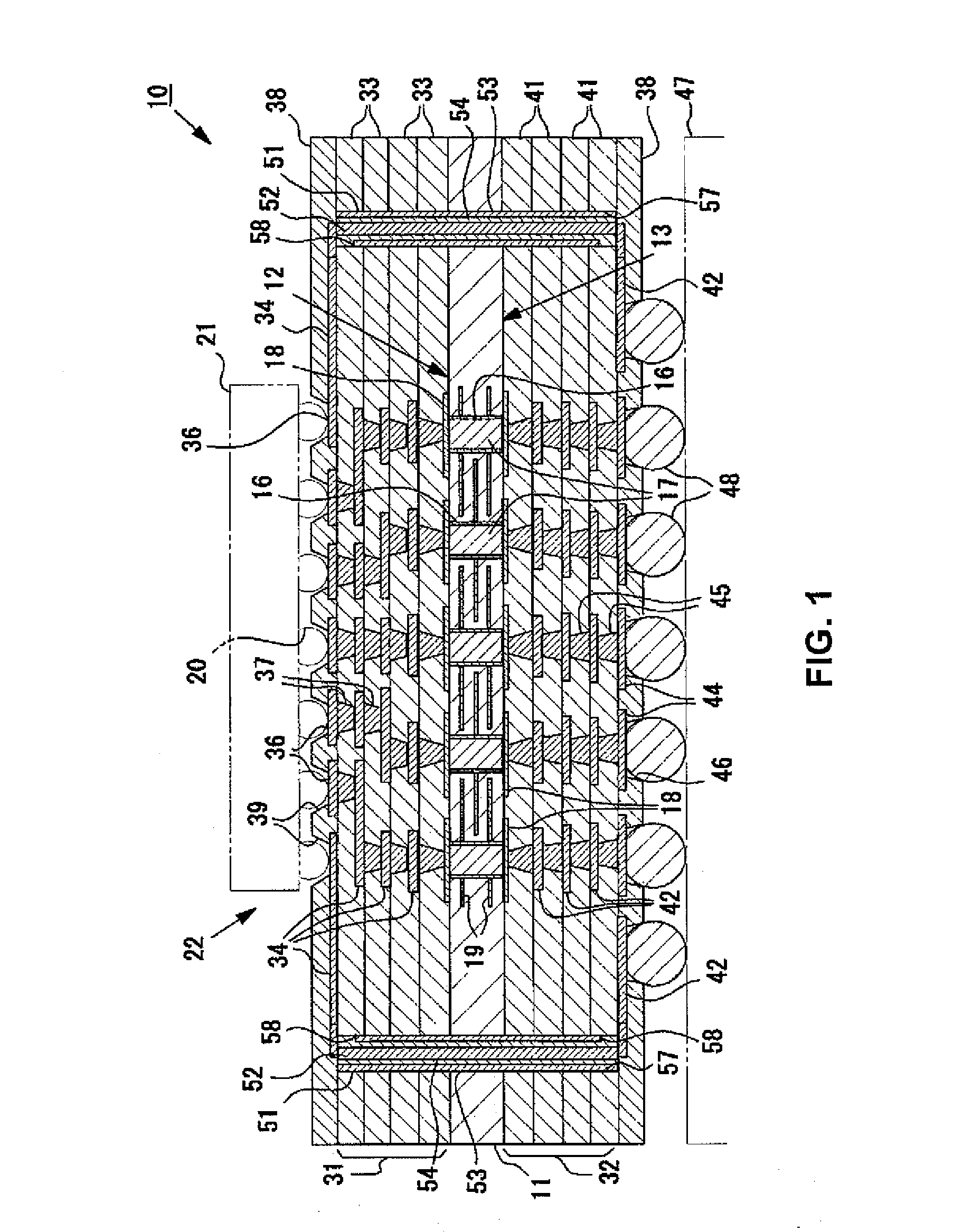

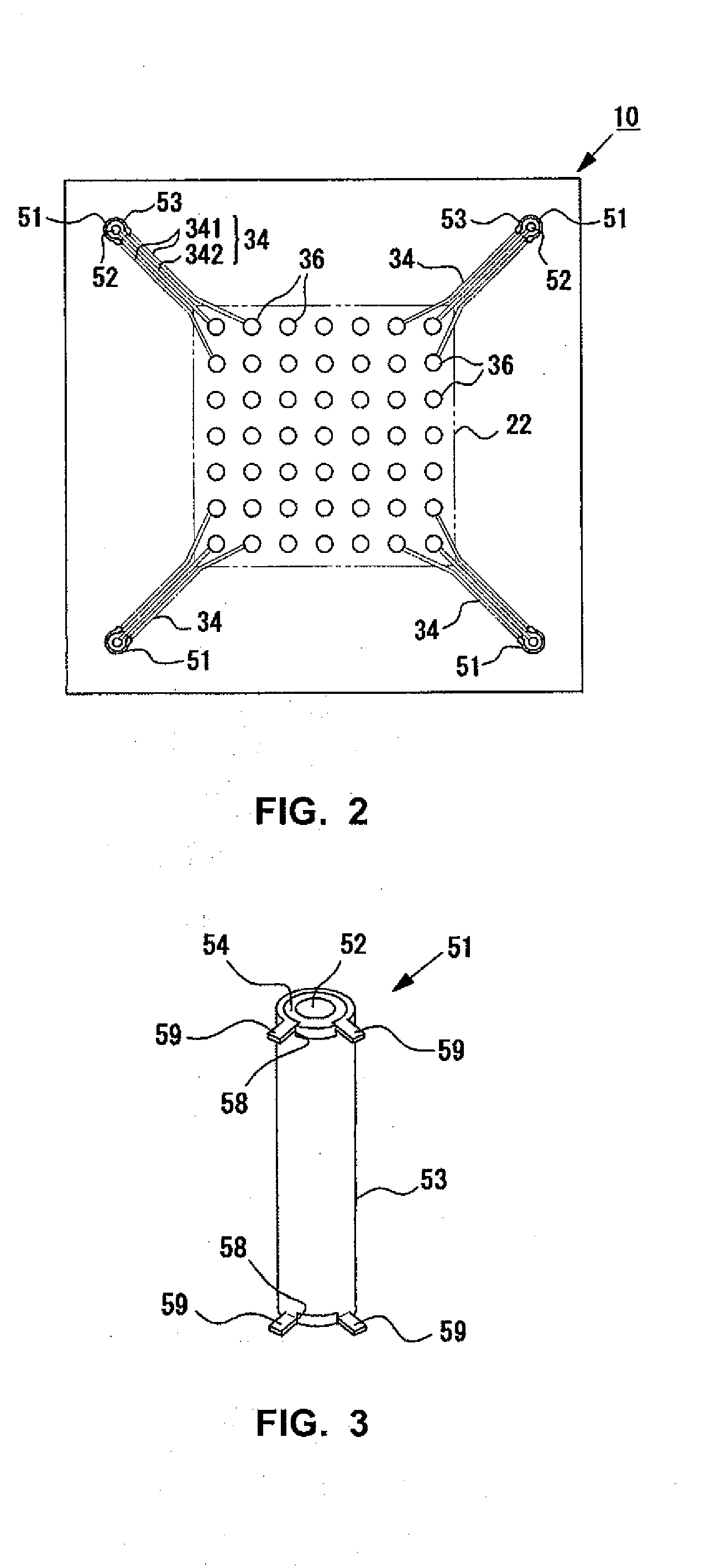

[0063]An embodiment for carrying out a multilayer wiring board of the present invention will be described in detail with reference to the drawings. FIG. 1 is a schematic sectional view showing a multilayer wiring board 10 according to an embodiment of the invention.

[0064]As shown in FIG. 1, the multilayer wiring board 10 is a wiring board for mounting an IC chip thereon and is comprised of: a generally rectangular core board 11 made of glass epoxy; a build up layer 31 (first laminated wiring portion) formed on an upper surface 12 (main surface) of the core board 11; and a build up layer 32 (second laminated wiring portion) formed on a lower surface 13 (rear surface) of the core board 11. Through hole conductors 16 are formed at a plurality of locations in the core board 11. These through hole conductors 16 are formed by applying a copper plating to an inner circumference of a through hole to thereby electrically connect the upper surface 12 and the lower surface 13 of the core board 11

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap