Dispersing Element, Method for Manufacturing Structure with Conductive Pattern Using the Same, and Structure with Conductive Pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

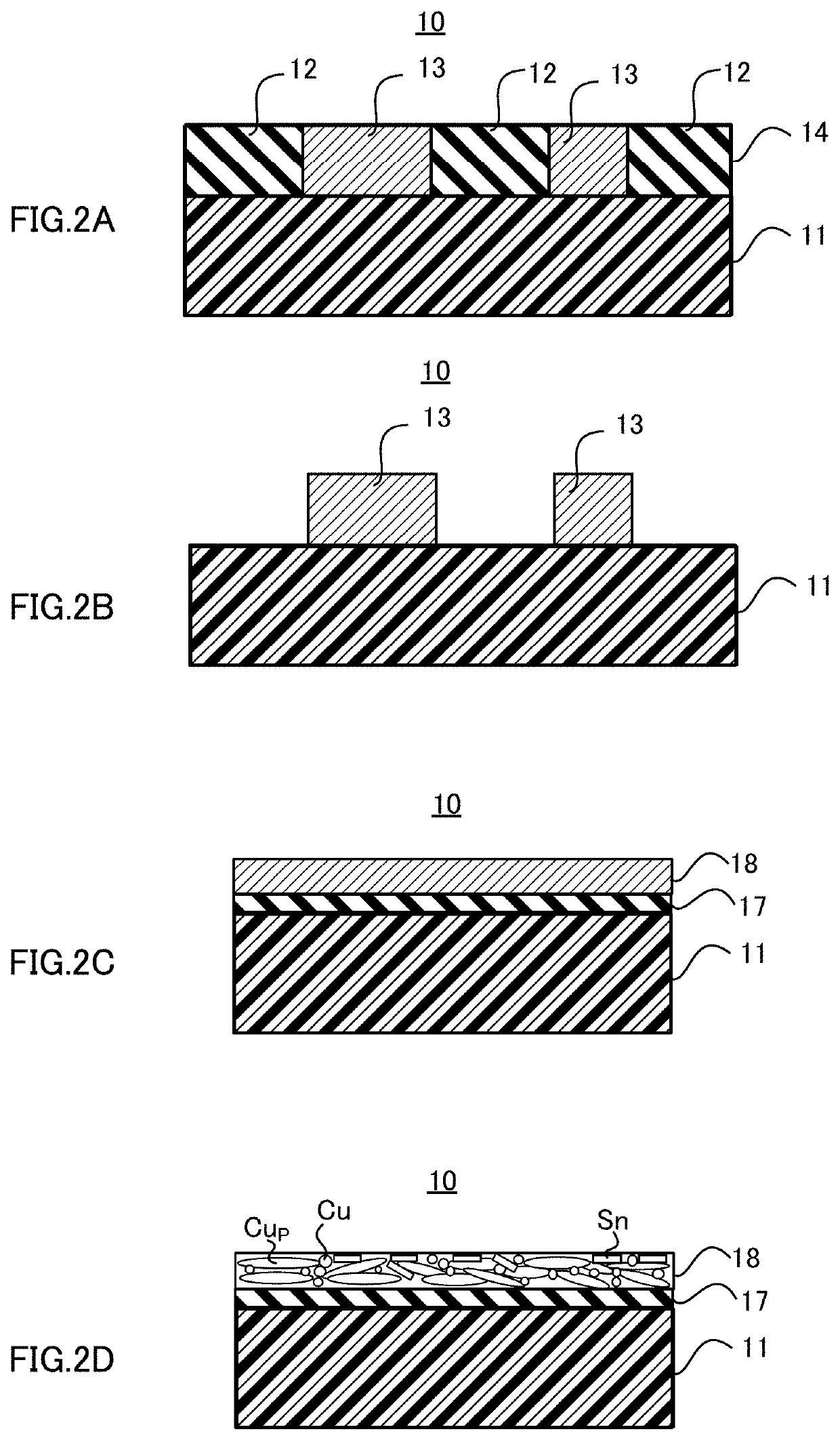

first embodiment

[0072]A dispersing element of the first embodiment contains (1) copper oxide, (2) dispersing agent, and (3) reductant. The dispersing element containing the reductant promotes reduction of copper oxide to copper in firing and promotes sintering of the copper.

[0073]The content of the reductant meets a range of the following formula (1). A mass ratio of the reductant of 0.0001 or more improves dispersion stability and decreases a resistance of a copper film. Additionally, the mass ratio of 0.1 or less improves long-term stability of the dispersing element.

0.0001≤(reductant mass / copper oxide mass)≤0.10 (1)

[0074]The content of the dispersing agent meets a range of the following formula (2). This reduces aggregation of the copper oxide and improves the dispersion stability.

0.0050≤(dispersing agent mass / copper oxide mass)≤0.30 (2)

[0075]The dispersing element of the first embodiment is limited in the ranges of the masses of the reductant and the dispersing agent to that of the copper ox

second embodiment

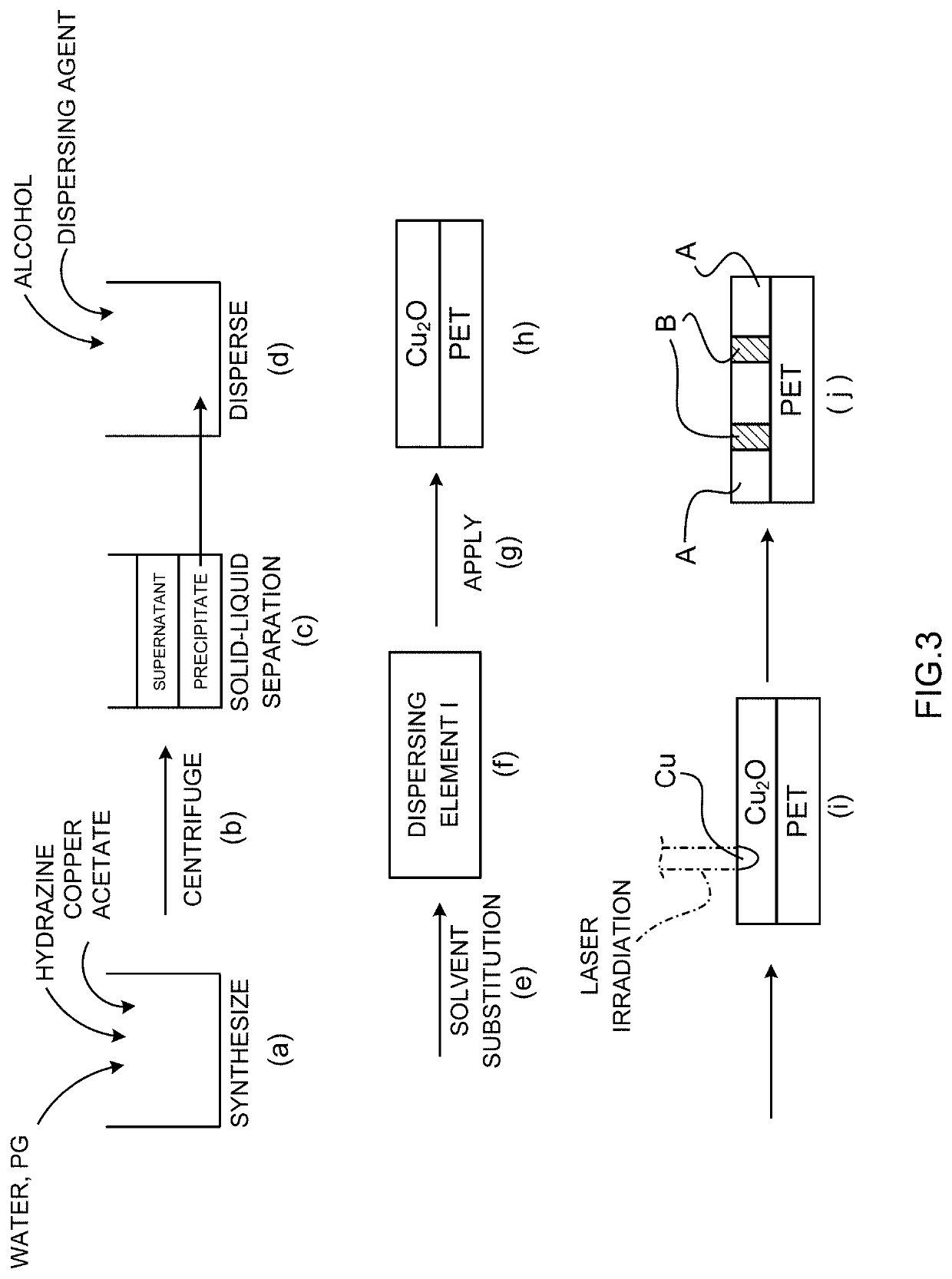

[0080]As a result of diligent examination, the inventors have found the following. The use of the copper oxide particles having specific particle diameters and the copper particles having specific particle diameters in combination for the dispersing element and the use of the dispersing agent reduce both cracks generated in sintering and cracks generated over time, thereby ensuring obtaining a conductive film having low resistivity and excellent stability of resistivity over time.

[0081]It has been found that although the above-described dispersing element contains the ultrafine particles in high concentration, the dispersing element is less likely to aggregate. Accordingly, it has been found that the dispersing element is also applicable to the screen-printing method and is excellent in printability. Moreover, it has been found that the above-described dispersing element exhibits excellent dispersion stability against a change over time in high concentration and allows screen-printing

third embodiment

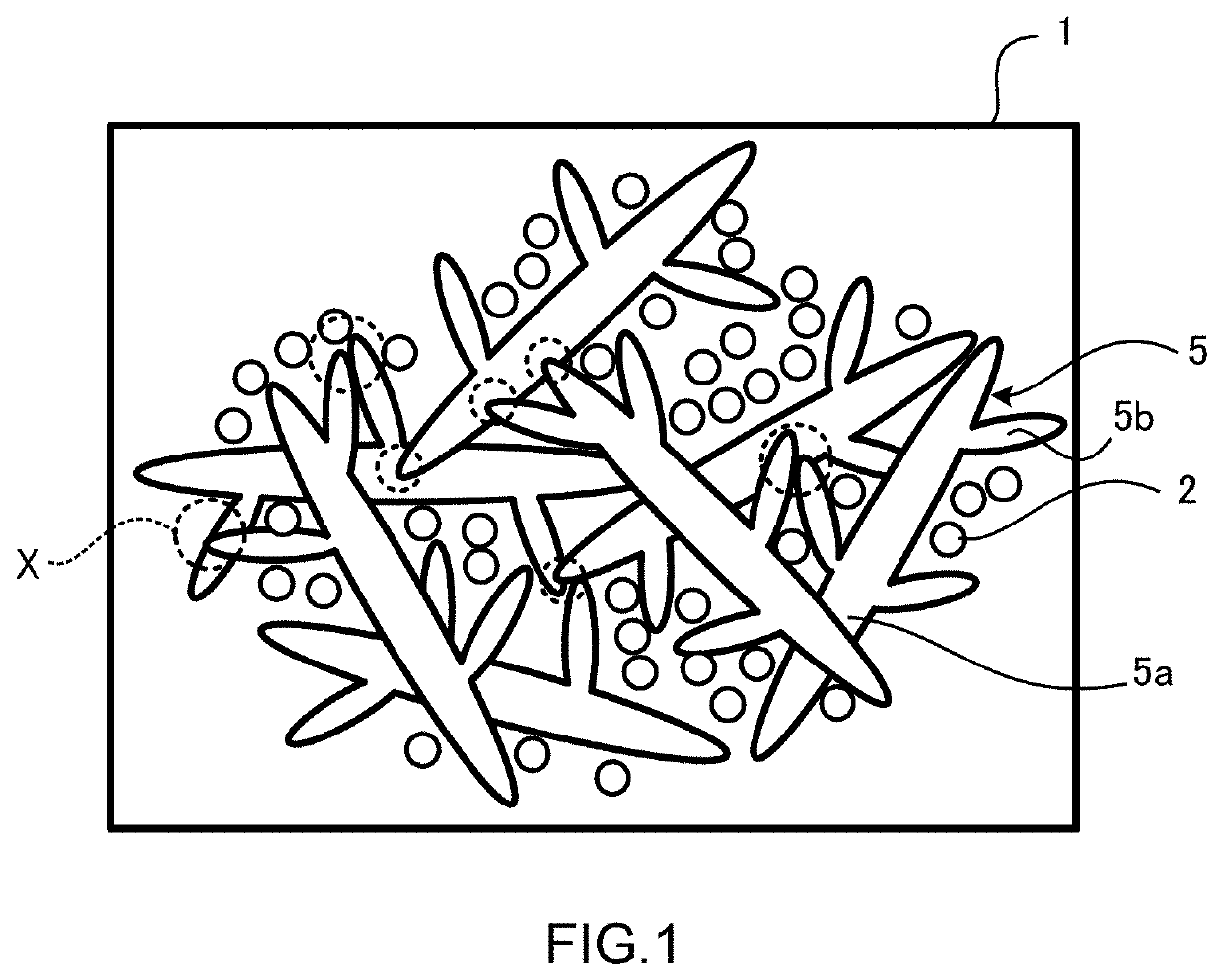

[0102]As a result of diligent examination, the inventors have found the following. The use of the dispersing element containing the copper oxide particles and the copper particles having a specific grain shape can obtain a conductive film that reduces both cracks generated during sintering and cracks generated over time, and has low resistivity and excellent stability of resistivity over time.

[0103]It has been found that although the above-described dispersing element contains the ultrafine particles in high concentration, the dispersing element is less likely to aggregate. Accordingly, it has been found that the dispersing element is also applicable to the screen-printing method and is excellent in printability. Moreover, it has been found that the above-described dispersing element exhibits excellent dispersion stability against a change over time in high concentration and allows screen-printing even after storage over a long period of time.

[0104]Furthermore, it has been found that t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap