Textile arrangement and method for manufacturing

a technology of textiles and fabrics, applied in the direction of printed circuit aspects, sports equipment, trousers, etc., can solve the problems of difficult implementation of reliable and miniature joint and connection techniques for detachable electronic components, slow sewing of electrically-conducting cables or wires into textiles or garments, and inability to meet the requirements of high-speed, reliable and cost-effective manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

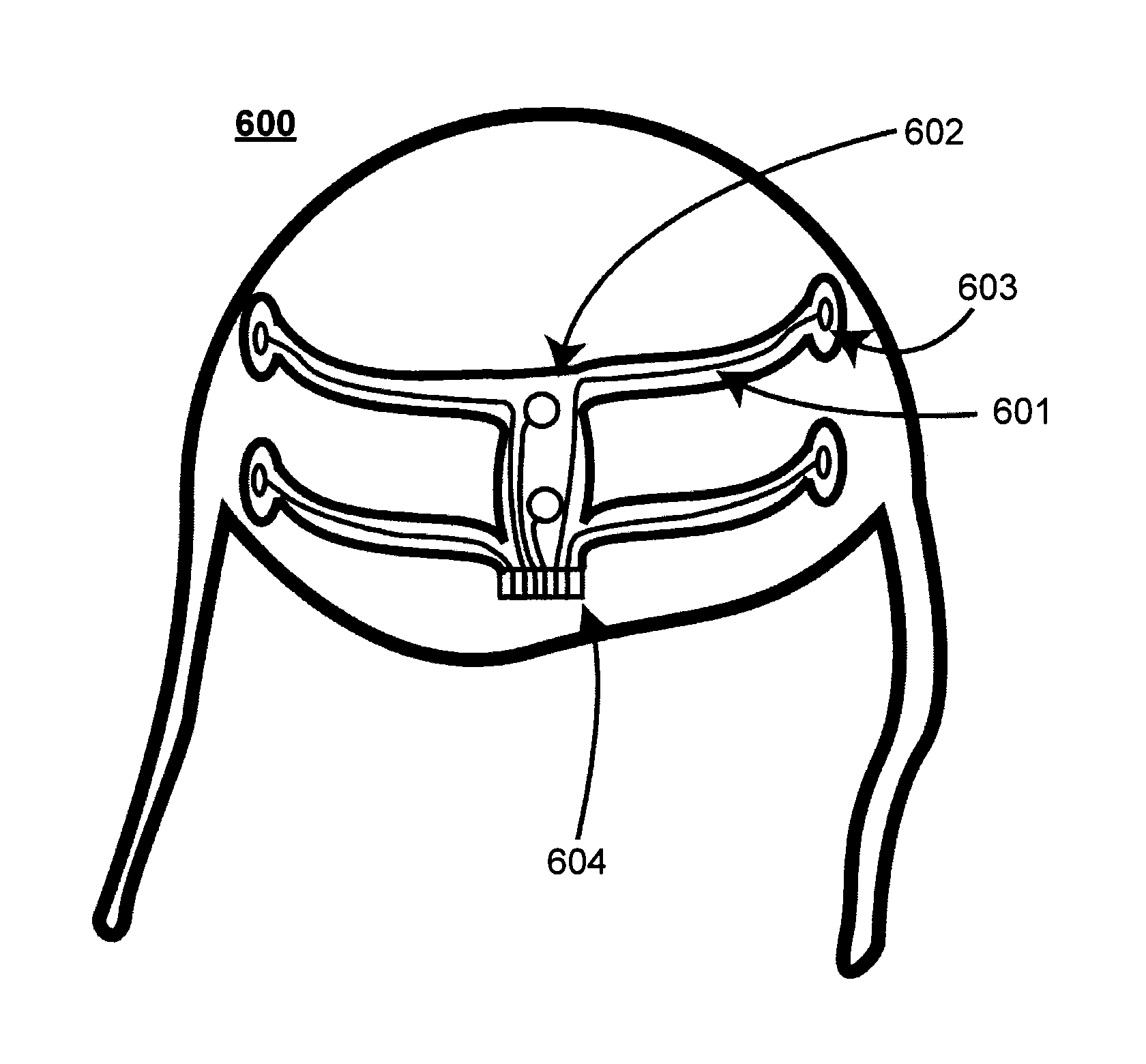

[0026]FIG. 1 illustrates an exemplary circuit board 100 with an electrically-conducting trace 101 according to an advantageous embodiment of the invention, where said circuit board is made of flexible and / or tensile substrate material and can thereby bend and / or stretch at least in one direction. The other end of the electrically-conducting trace is formed as a joint or pad 102, where a fixedly-integrated electronic component 103 is connected into the circuit board.

[0027]The electrically-conducting trace 101 is corrugated so that when the circuit board is bent and / or stretched, e.g., in the direction of the arrow, the corrugated trace 101 will be straightened out especially in the direction of the arrow, thereby allowing the trace to bend or stretch together with the circuit board without breaking, perishing or getting cut off.

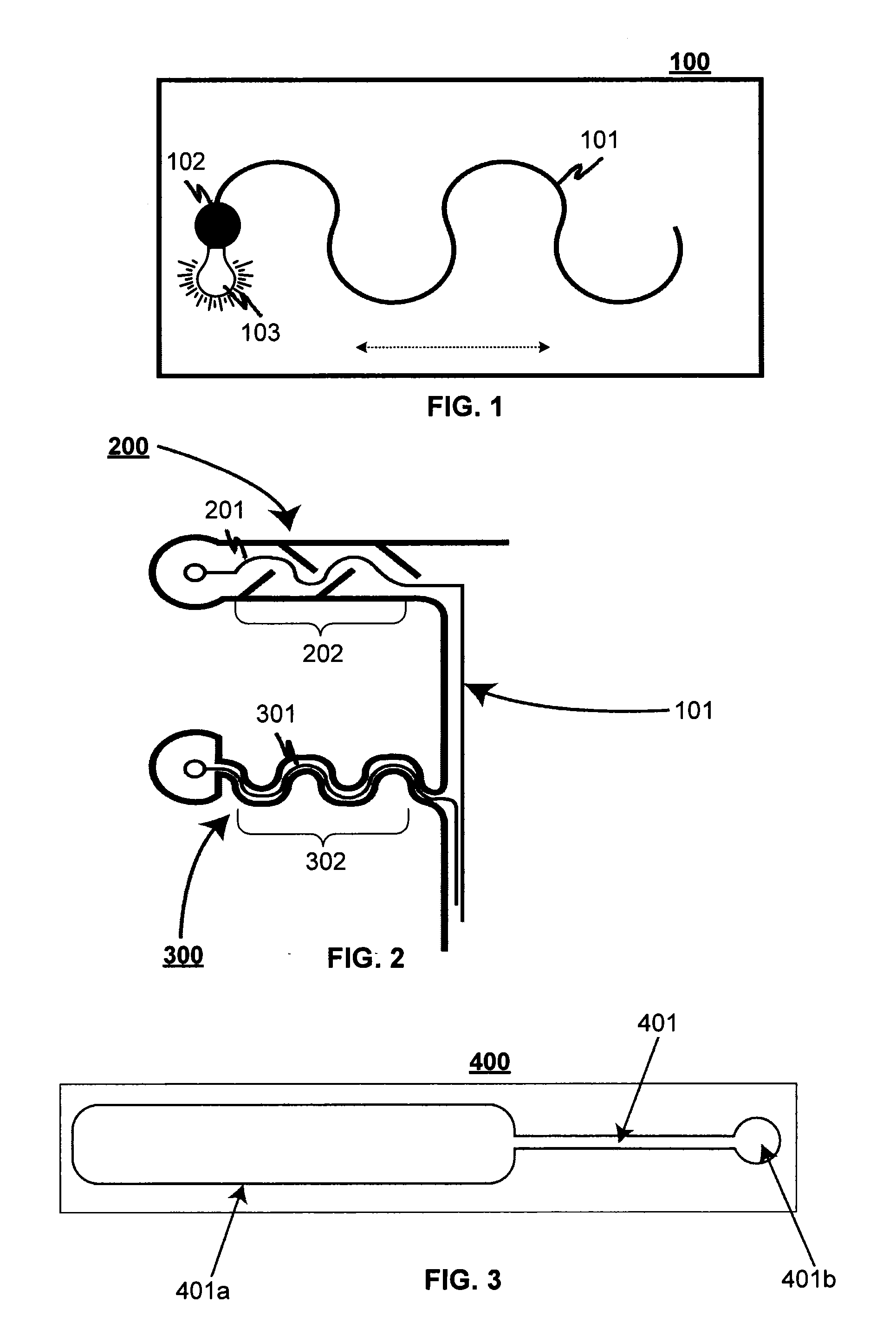

[0028]FIG. 2 illustrates examples of flexible circuit boards 200, 300 with electrically-conducting traces according to an advantageous embodiment of the in

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap