System and method for monitoring dynamic disaster of coal mine with fiber bragg gratings

A fiber grating and dynamic disaster technology, applied in mine/tunnel ventilation, measuring devices, mining equipment, etc., can solve problems such as weak anti-interference ability, many underground interference factors, and difficulty in determining a reasonable drilling depth, and achieve easy prediction and prevention, strong ability to prevent external interference, and the effect of high-precision non-disturbance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

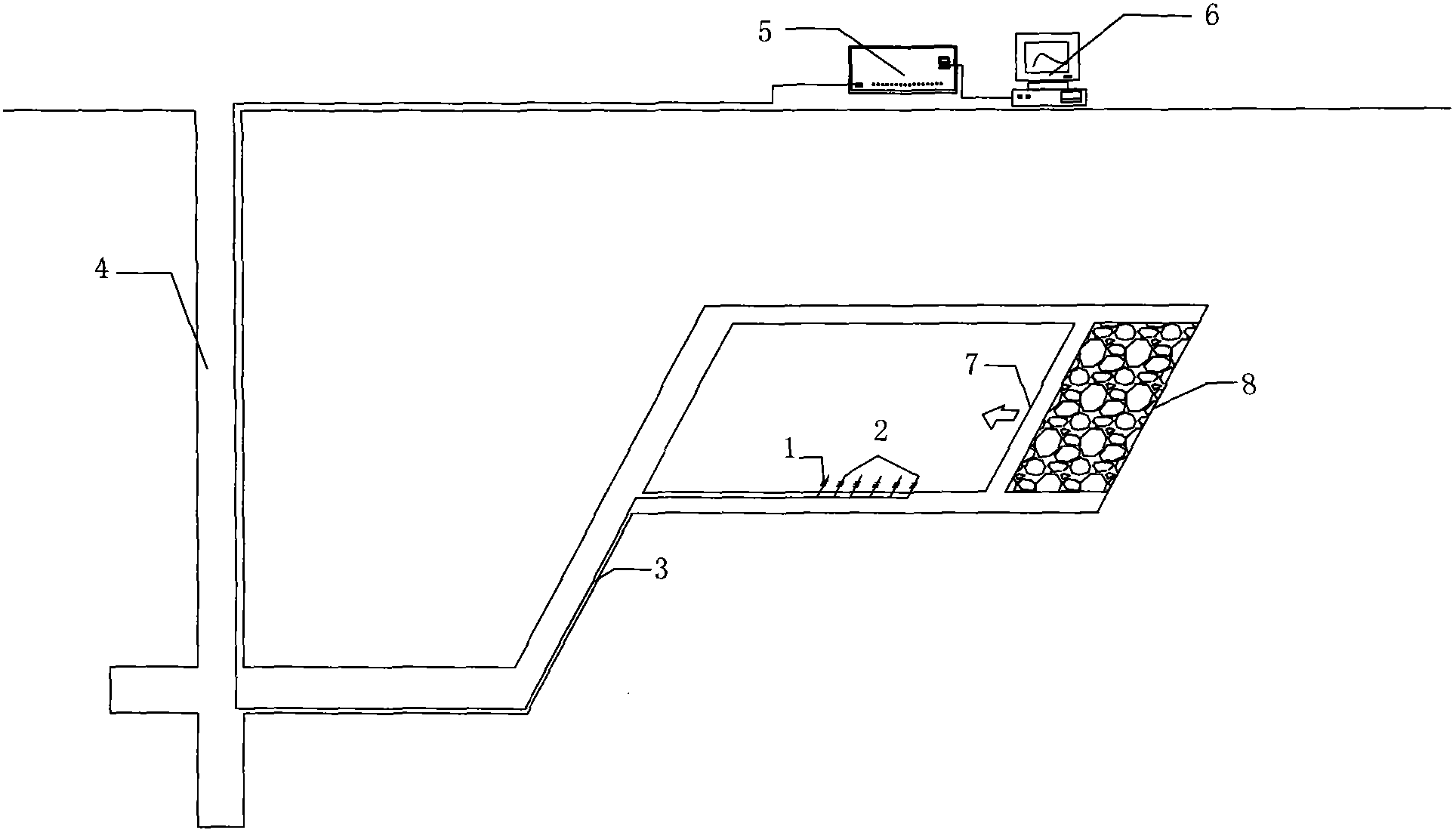

[0021] Such as figure 1 As shown in the schematic diagram of the fiber grating testing system of the present invention, the fiber grating 1 is arranged inside or on the surface of the anchor rod 2, and the anchor rod 2 is implanted into the two sides of the coal mine roadway or other effective positions by the method of drilling, and is drawn out at the tail of the anchor rod 2. An optical fiber connector 11 that can be connected to the outside, the optical fiber connector 11 is connected to the fiber grating network demodulator 5, and the grating network demodulator 5 is connected to the test computer 6 to form a test system that can be used for dynamic strain monitoring.

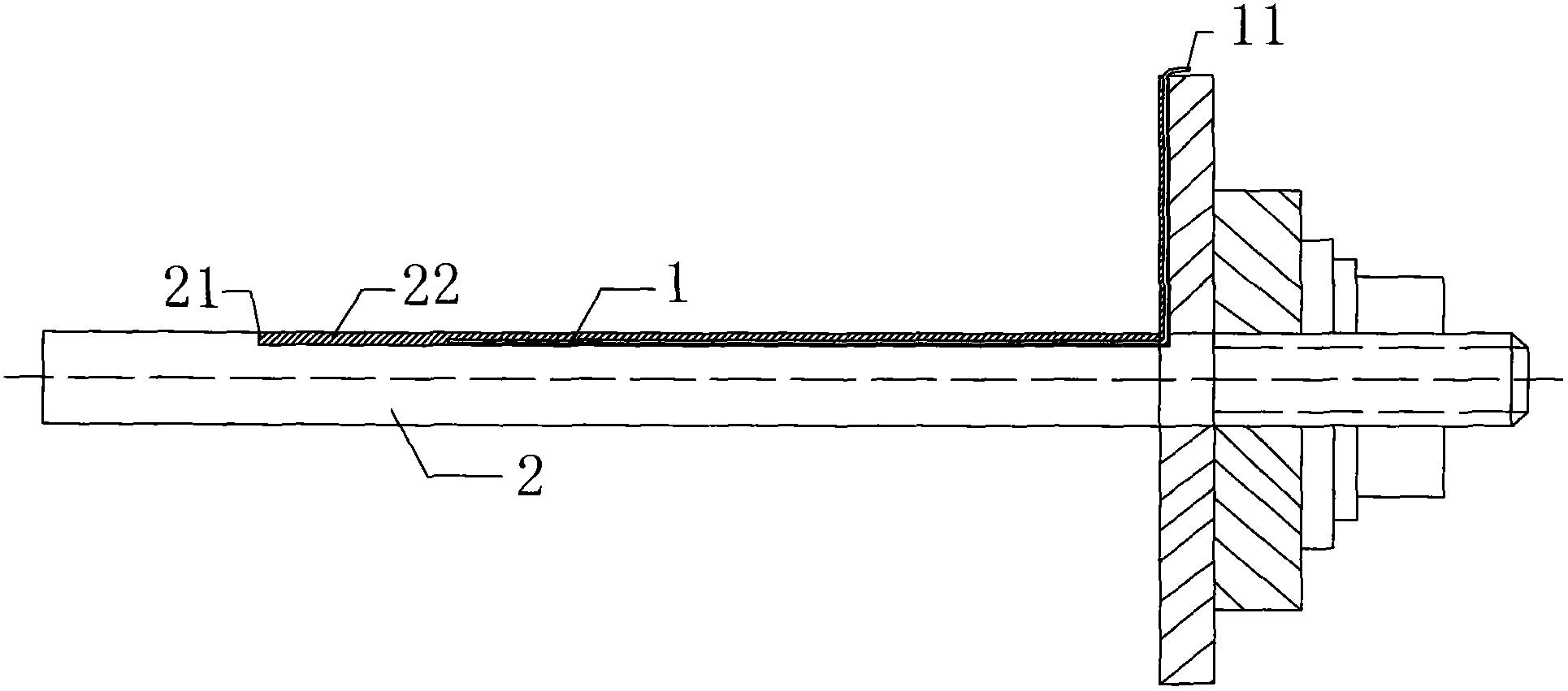

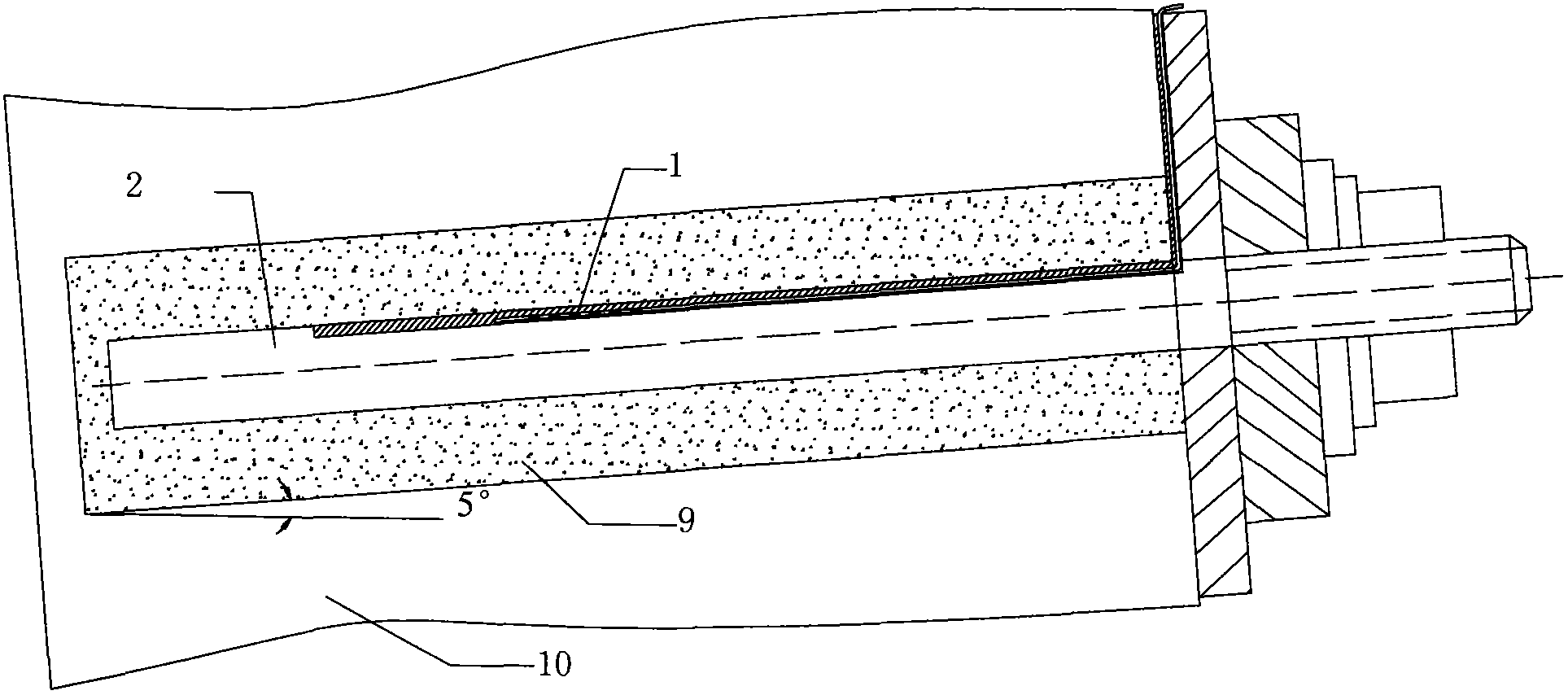

[0022] Such as figure 2 As shown, a small groove 21 with a width of 1 mm and a depth of about 1.5 mm is opened on the surface of the metal or resin anchor rod 2 with a length of 50-100 mm, and the fibe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap