Power adjustable ultrasonic wave flue dust purification apparatus

A fume purification and ultrasonic technology, which is applied in the field of adjustable power ultrasonic fume purification devices, can solve the problems of high investment cost, huge equipment, cumbersome and other problems, and achieve the effects of convenient installation and disassembly, improved working life and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

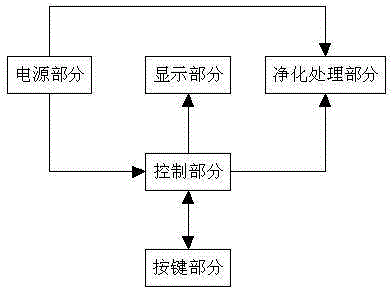

[0023] Combine below Attached picture Detailed description: As shown in the picture show, see figure 1 , The present invention is composed of a power part circuit, a control part circuit, a display part circuit, a button part circuit, and an ultrasonic cleaning treatment part circuit.

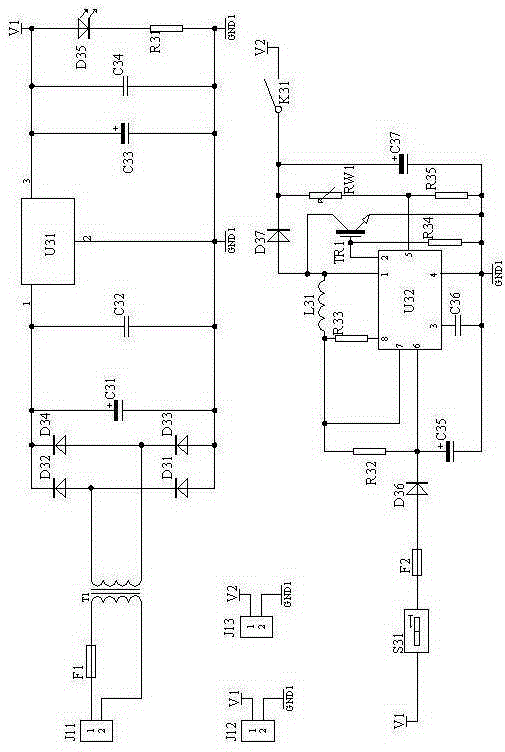

[0024] See figure 2 , in the power part circuit, the pin 1 of the socket J11 is connected to one end of the fuse F1, the other end of the fuse F1 is connected to one end of the primary coil of the transformer T1, and the pin 2 of the socket J11 is connected to the other end of the primary coil of the transformer T1, One end of the secondary coil of the transformer T1 is respectively connected to the P pole of the diode D32 and the N pole of the diode D31, and the other end of the secondary coil of the transformer T1 is respectively connected to the P pole of the diode D34 and the N pole of the diode D33. The N pole, the N pole of the diode D34, the positive pole of the electrolytic capac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap