High-concentration organic malodorous waste gas treatment machine for municipal sewage treatment plant

A technology for urban sewage and waste gas treatment, which is applied in the field of urban sewage treatment and resource utilization, and can solve problems affecting the normal operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Please refer to Figure 1-Figure 7 , the specific embodiments of the present invention are as follows:

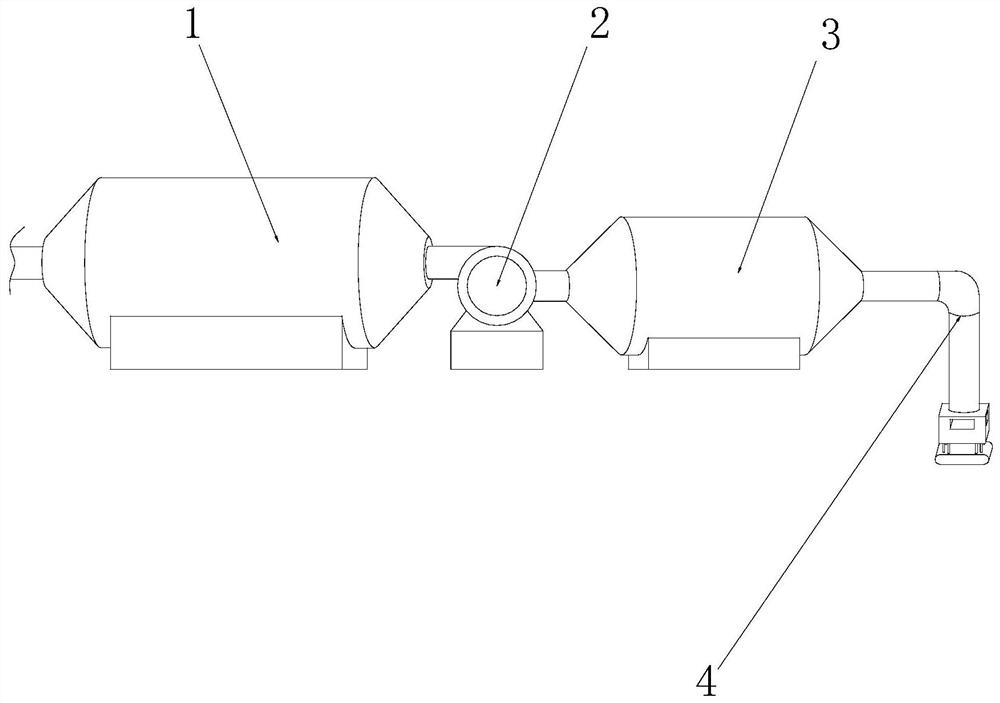

[0030] The invention provides a treatment machine for high-concentration organic malodorous waste gas in urban sewage treatment plants, the structure of which includes a filter 1, a fan 2, a deodorizer 3, and an extraction device 4. Between the machines 3, the extraction device 4 is installed at the right end of the extraction device 4.

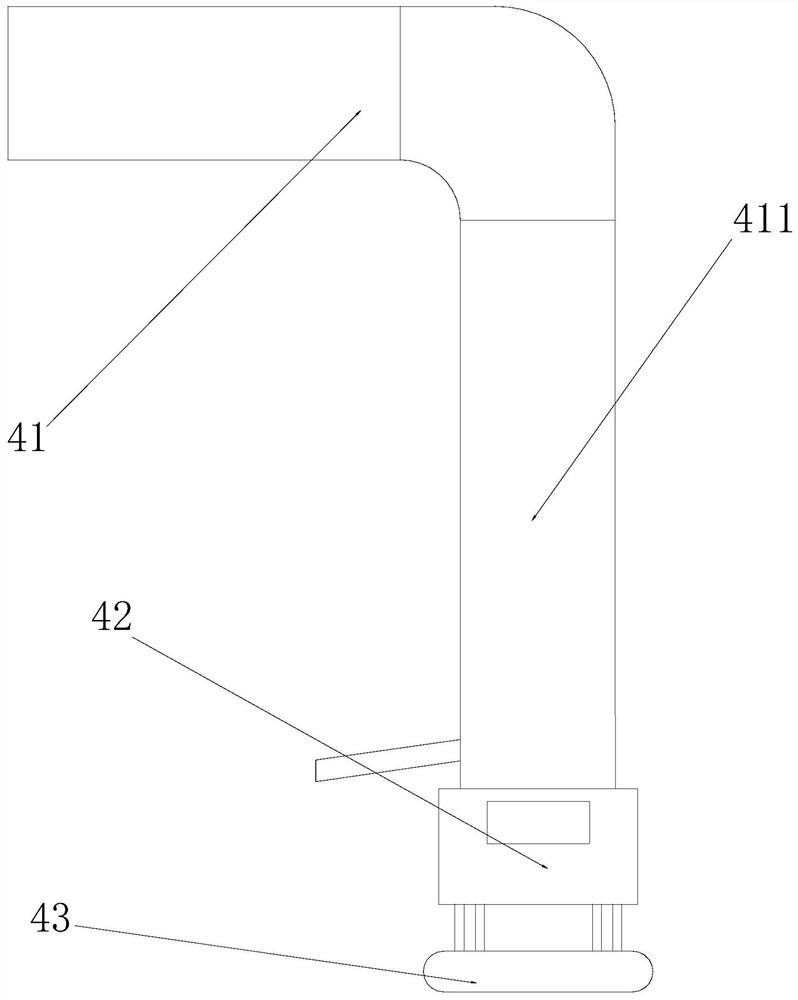

[0031] The extraction device 4 is composed of a first air passage 41, a second air passage 411, an air inlet 42, and a floating block 43. The left lower end of the first air passage 41 is welded and connected above the second air passage 411. , the upper end of the air inlet 42 is embedded and connected to the lower end of the second air passage 411, the floating block 43 is made of neoprene, the upper end of the floating block 43 is riveted and connected to the lower end of the air inlet 42, and the neoprene rubber The fl

Embodiment 2

[0037] Example 2: Please refer to Figure 8-Figure 11 , the specific embodiments of the present invention are as follows:

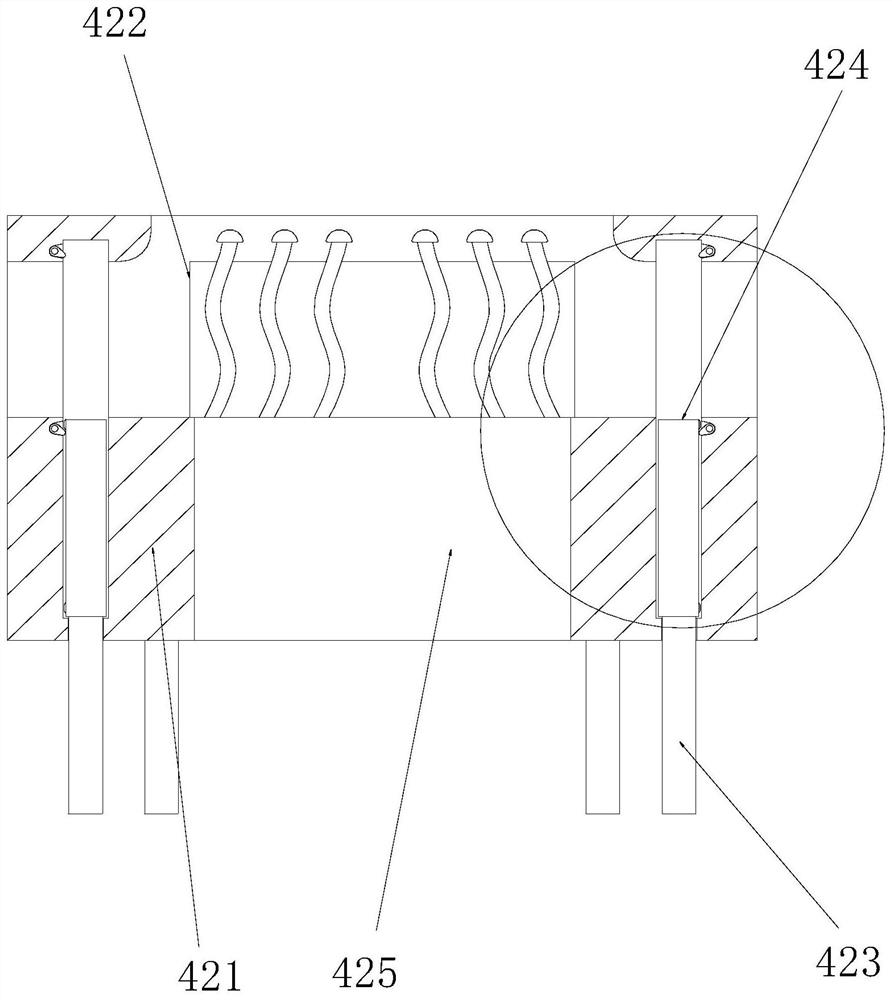

[0038] The present invention provides a high-concentration organic malodorous waste gas treatment machine for urban sewage treatment plants. The second air passage 411 is composed of a pipe body 131, a guide piece 132, a central column 133, a baffle 134, a drain pipe 135, and a waterproof cover 136. , the guide piece 132 is a spiral ribbon structure, the guide piece 132 is welded and connected between the pipe body 131 and the center column 133, the baffle plate 134 is embedded and connected to the bottom of the guide piece 132, and the drain pipe 135 is welded Connected to the lower surface of the pipe body 131, the waterproof cover 136 is movably engaged on the left end of the drain pipe 135, and the guide piece 132 of the spiral ribbon structure can guide the movement of the airflow, and improve the flow rate of the airflow inside the second air passage 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap