Wood board drying equipment

A technology of drying equipment and wood boards, which is applied in the field of wood processing, can solve the problems of low drying efficiency of wood boards and large labor input, and achieve the effects of simple structure, reduced labor input, and liberated labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

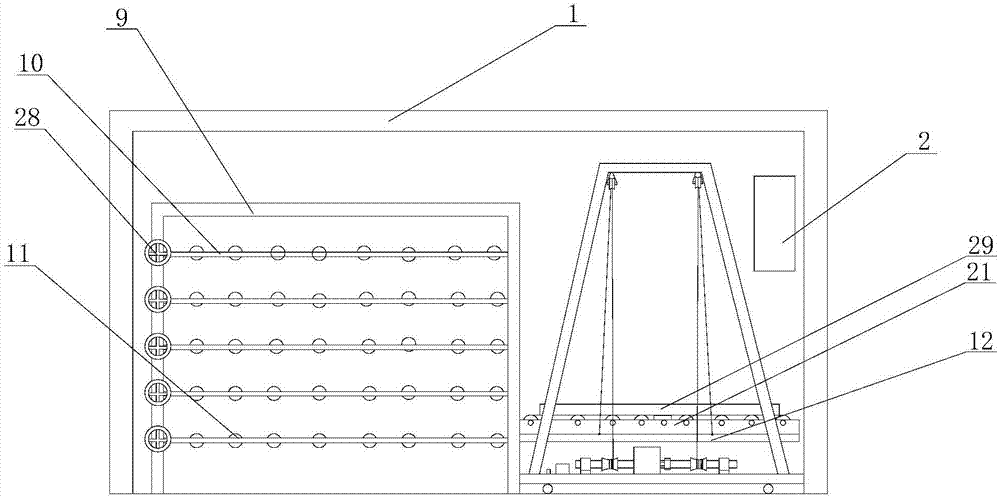

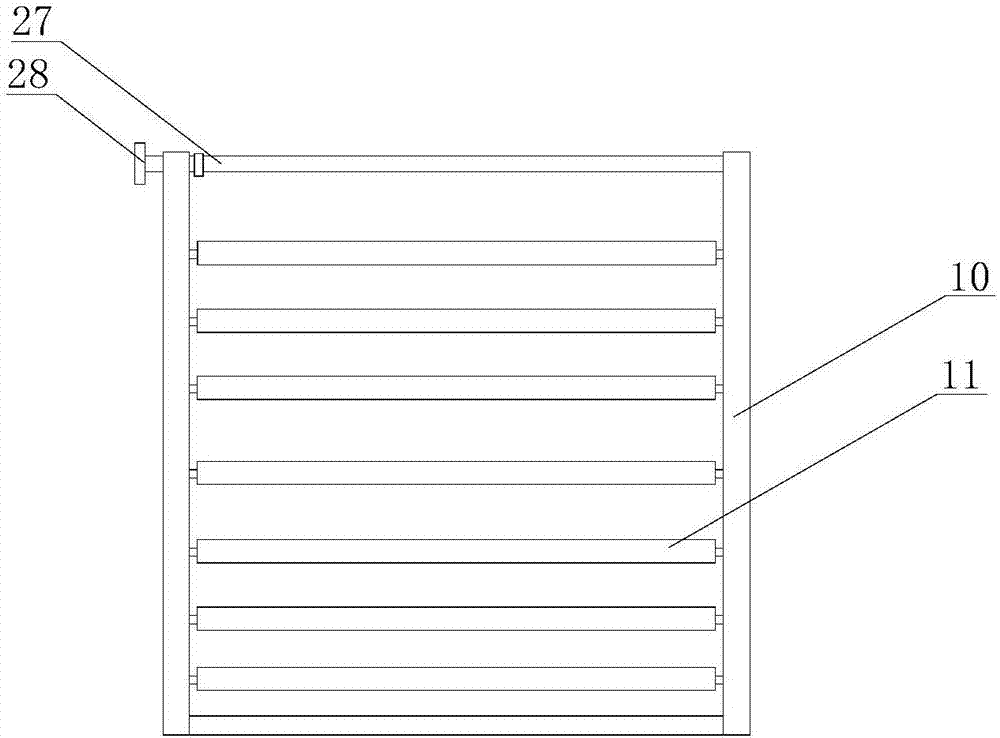

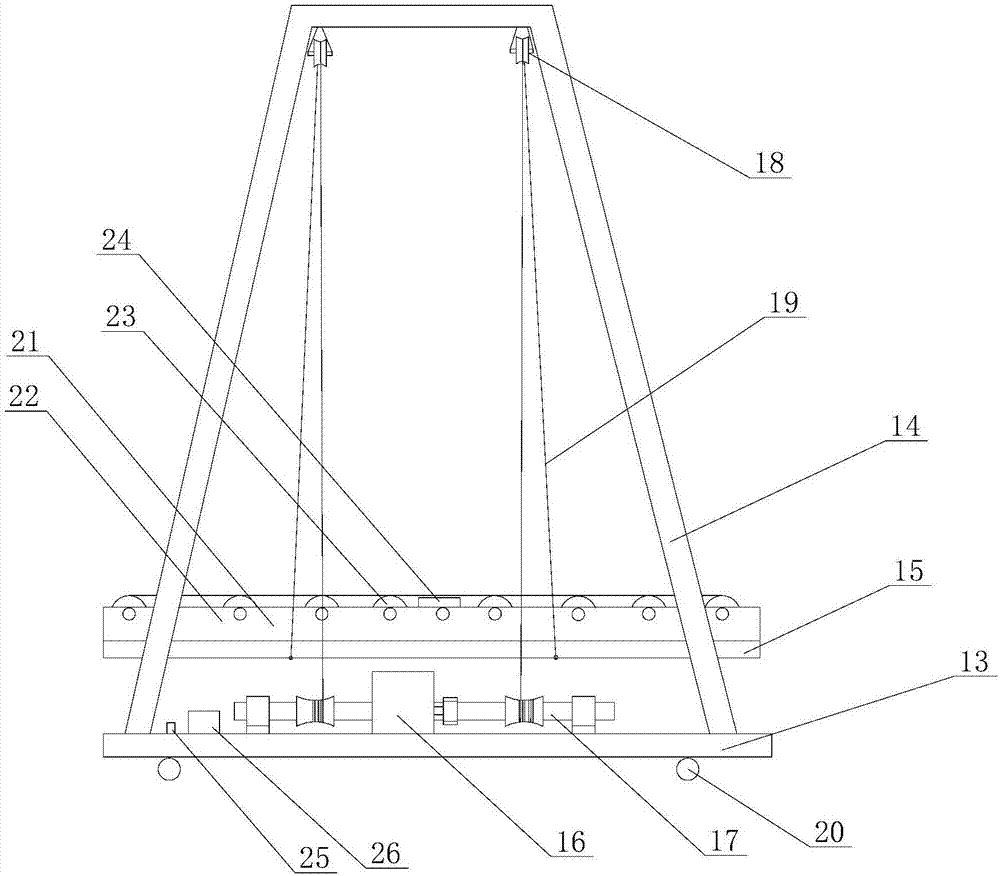

[0029] Such as Figure 1-4 As shown, a wood drying equipment includes a drying room 1, a drying rack 9, a lifting mechanism 12, a conveyor belt 21 and a control system. Wherein, the drying room 1 is a closed quadrilateral structure. Drying room 1 is equipped with drying system 2, drying system 2 includes temperature sensor 3, humidity sensor 4, heating device 5, fan 6, dehumidifier 7 and control box 8; temperature sensor 3, humidity sensor 4, heating device 5, fan 6 And the dehumidifier 7 is connected with the control box 8 . Such setting is convenient for monitoring the temperature and humidity in the drying room 1 , and regulating the environment in the drying room 1 as required, thereby improving the drying efficiency of the wooden boards 29 . Preferably, the fan 6 is arranged towards the drying rack 9 . Such setting facilitates blowing the d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap