Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about "Drying solid materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

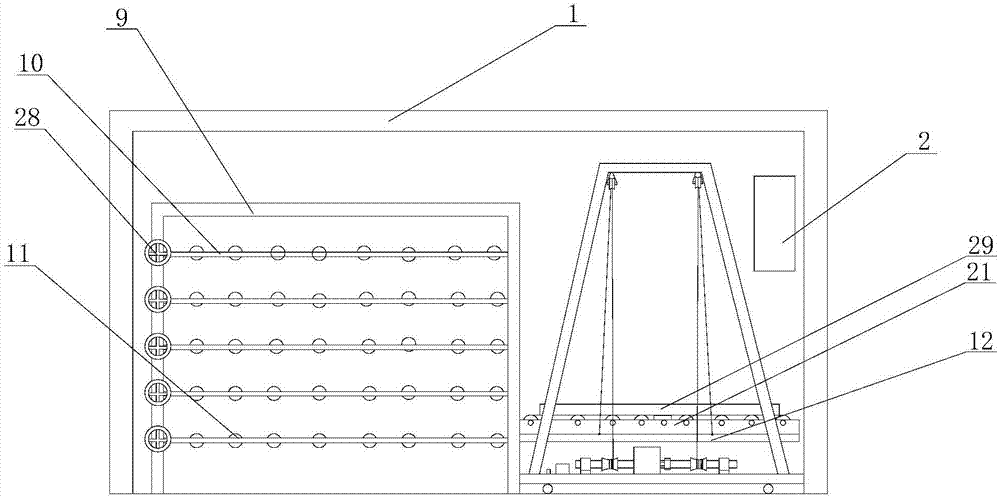

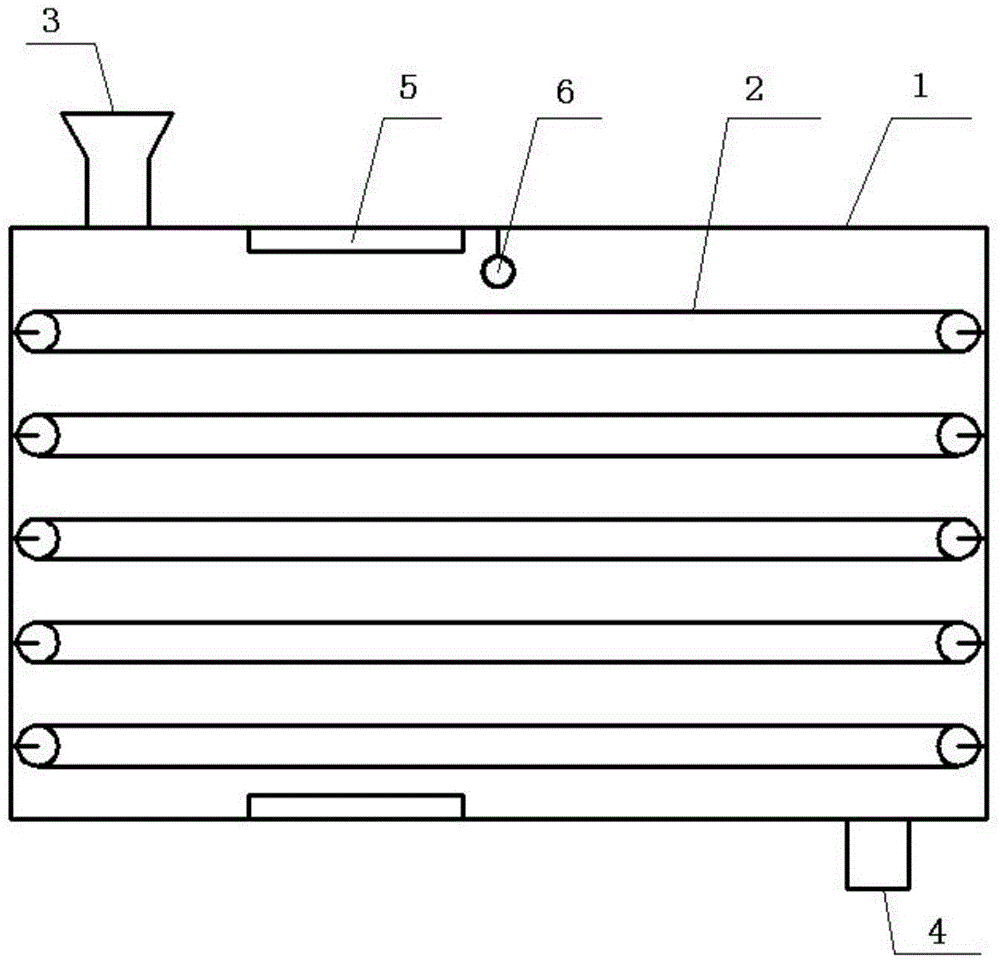

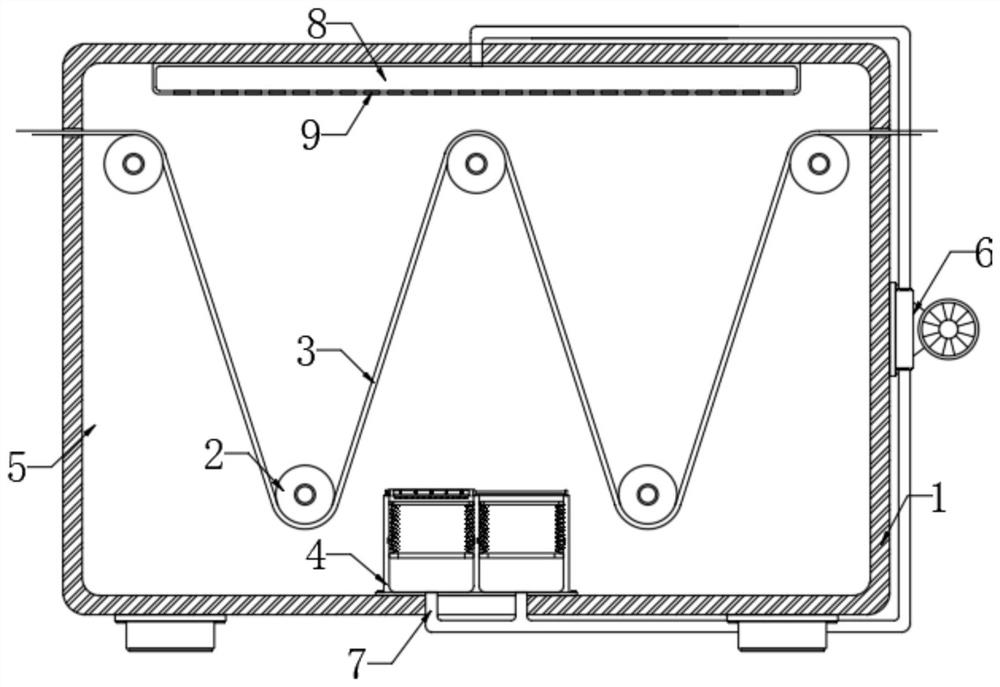

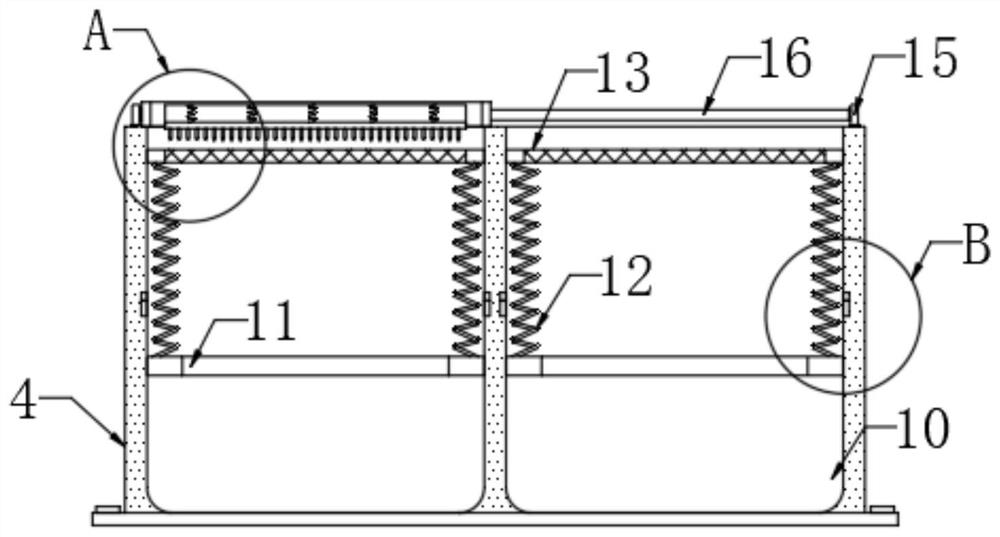

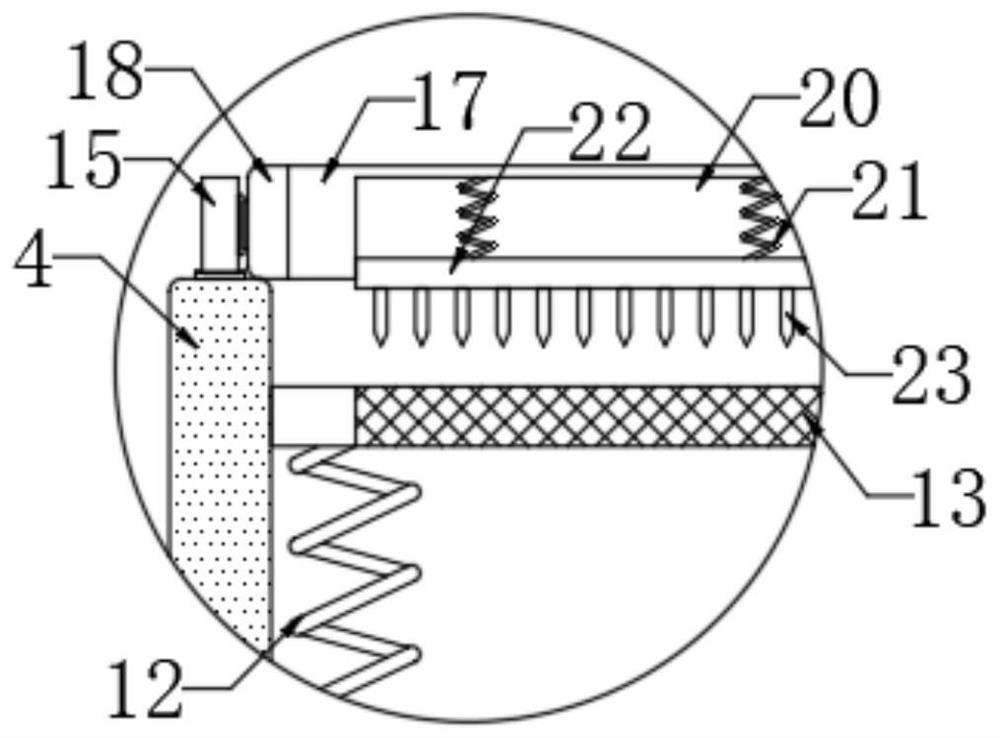

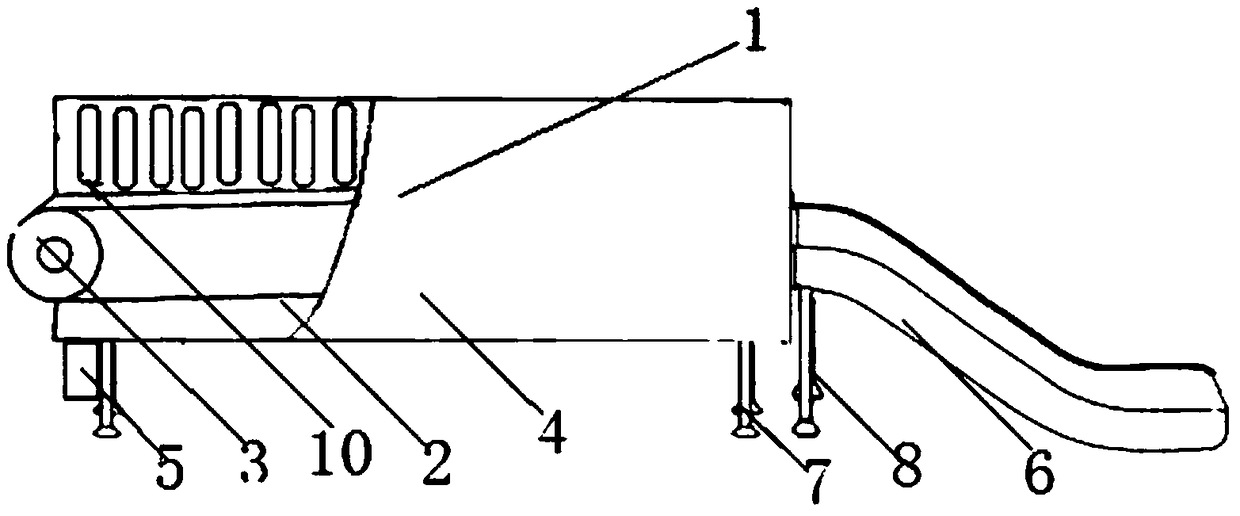

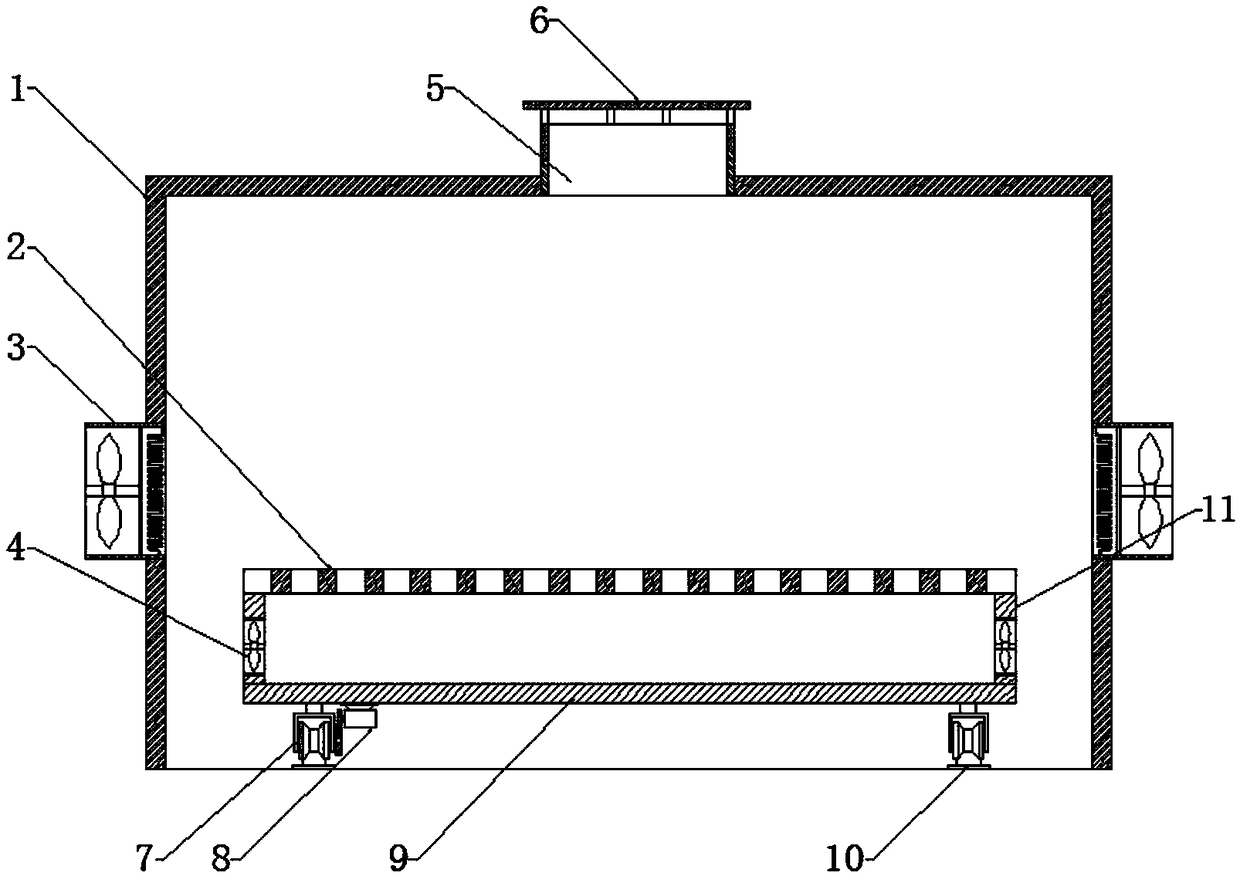

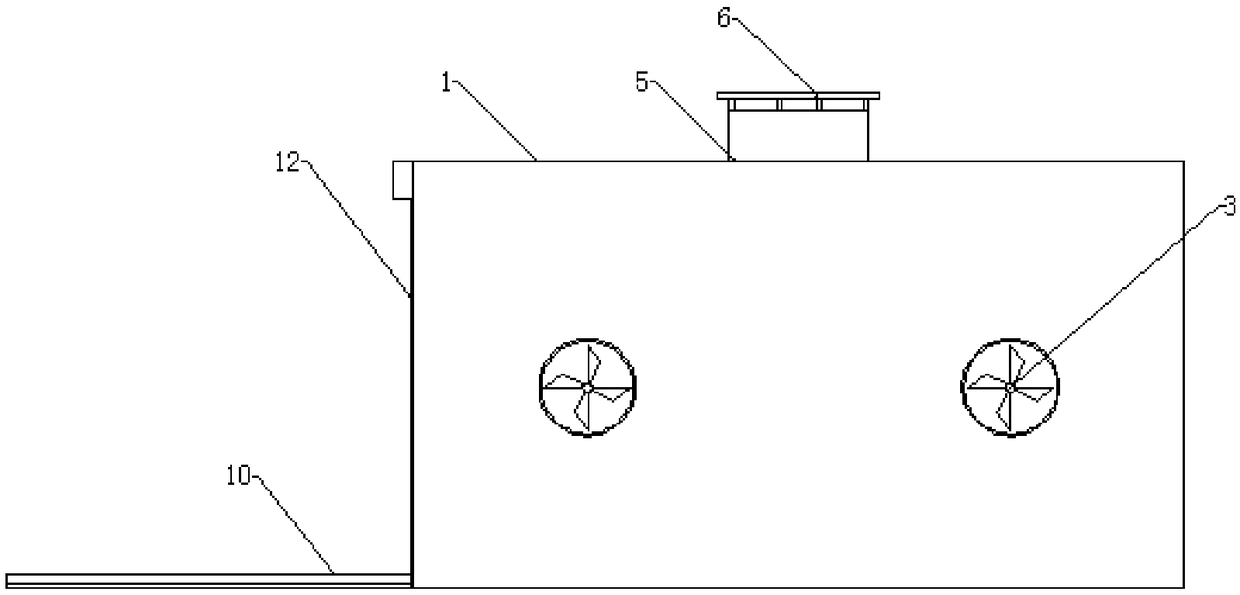

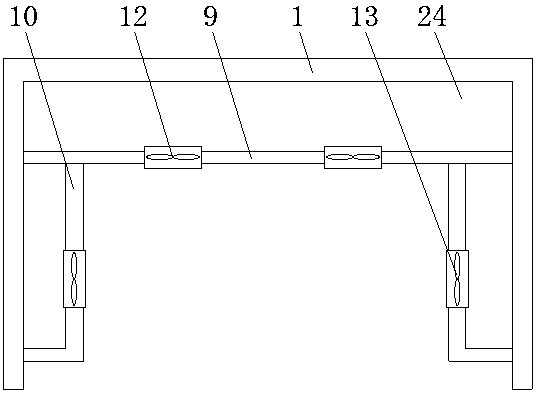

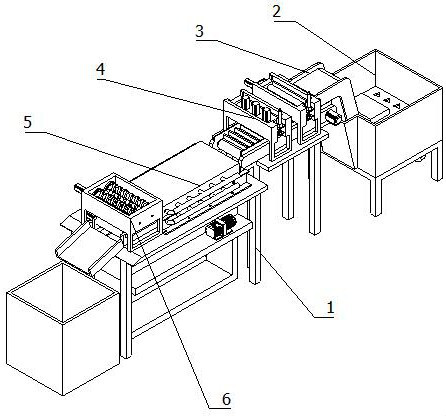

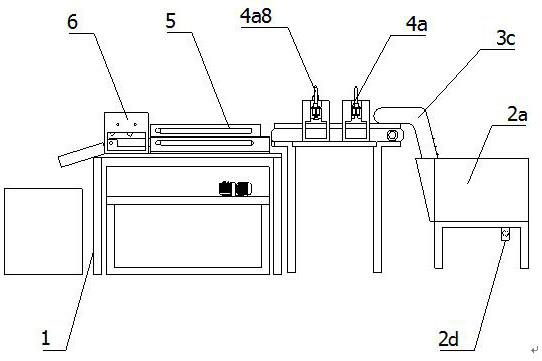

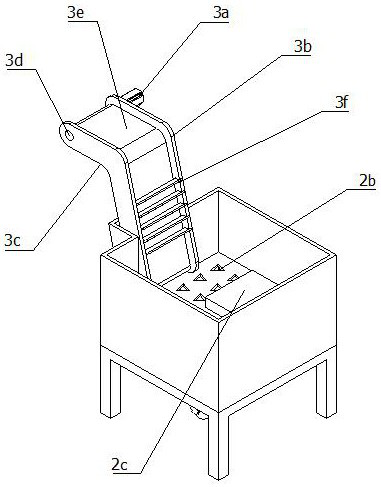

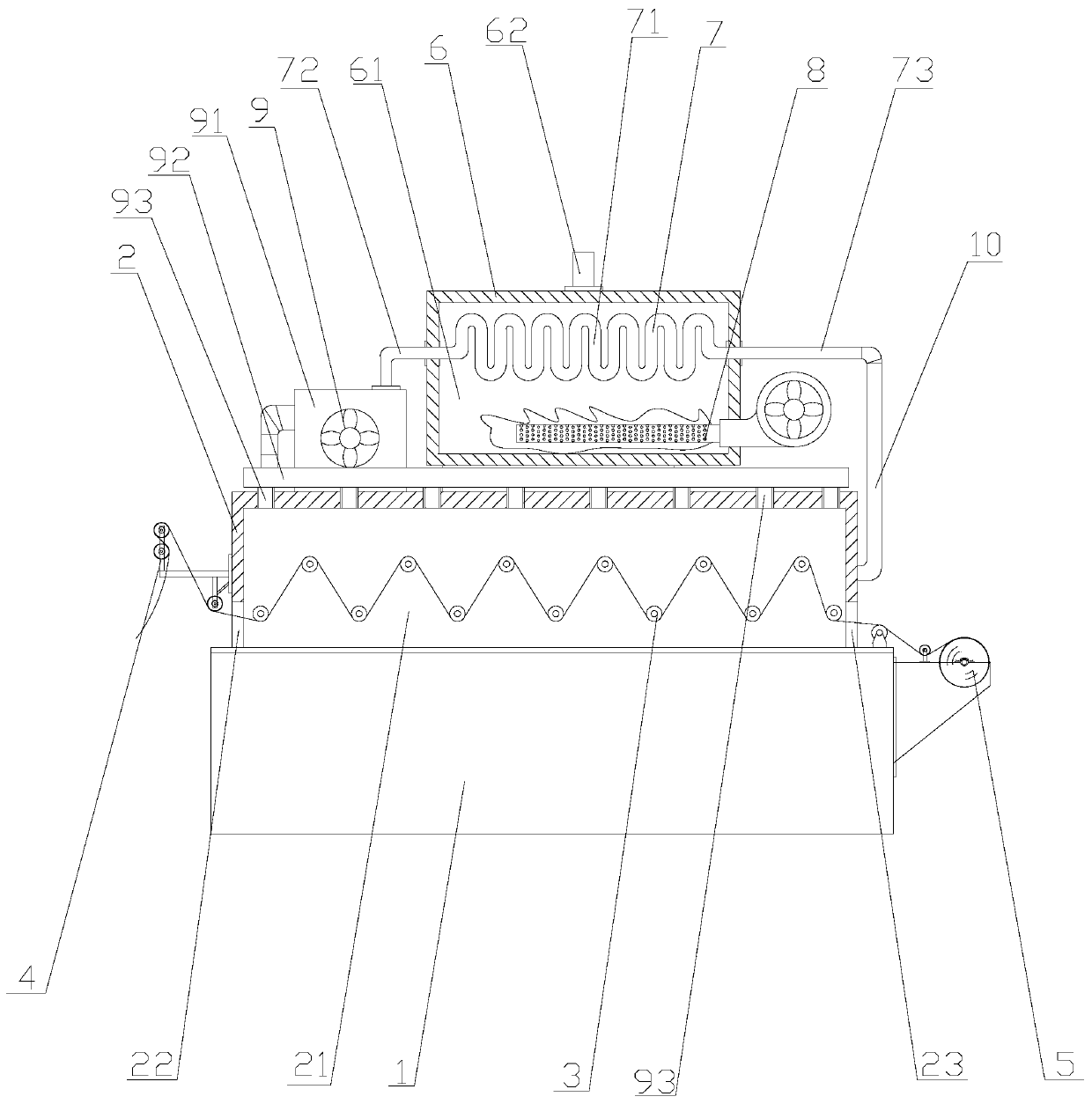

Matching drying equipment for dyeing clothing cloth

InactiveCN109654856AConvenient and fast windingFully heatedDrying gas arrangementsDrying machines with progressive movementsEngineeringCopper

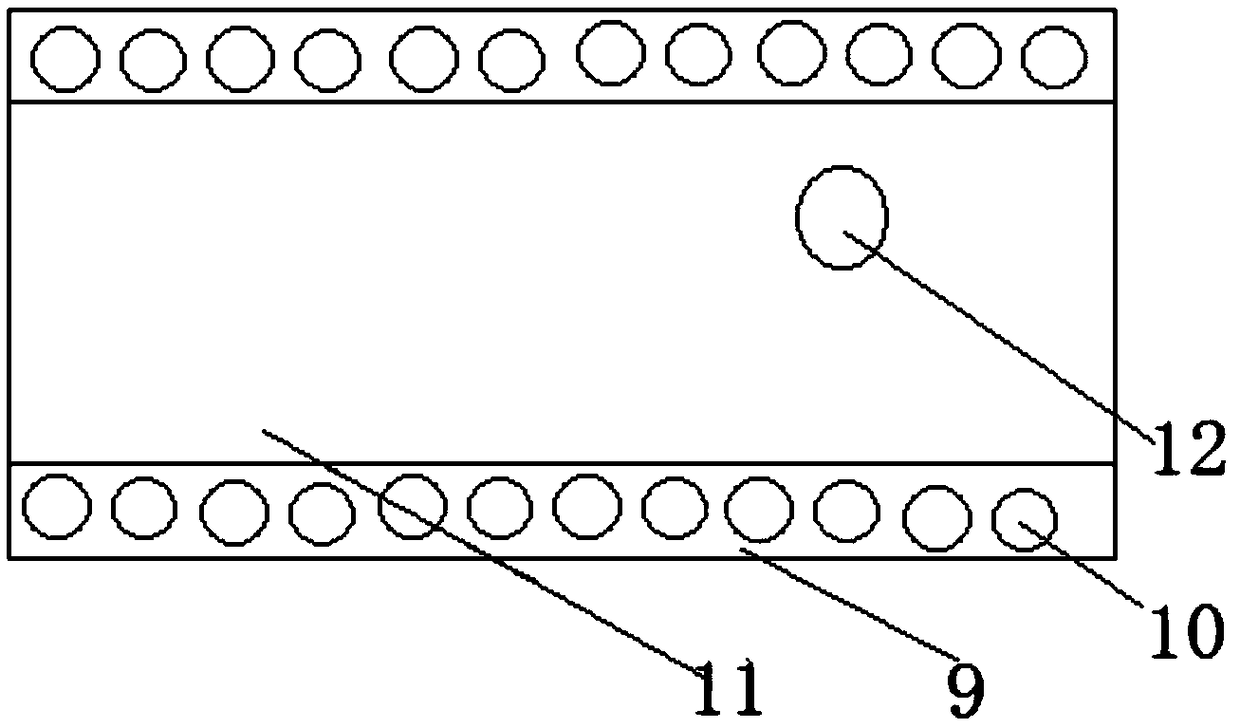

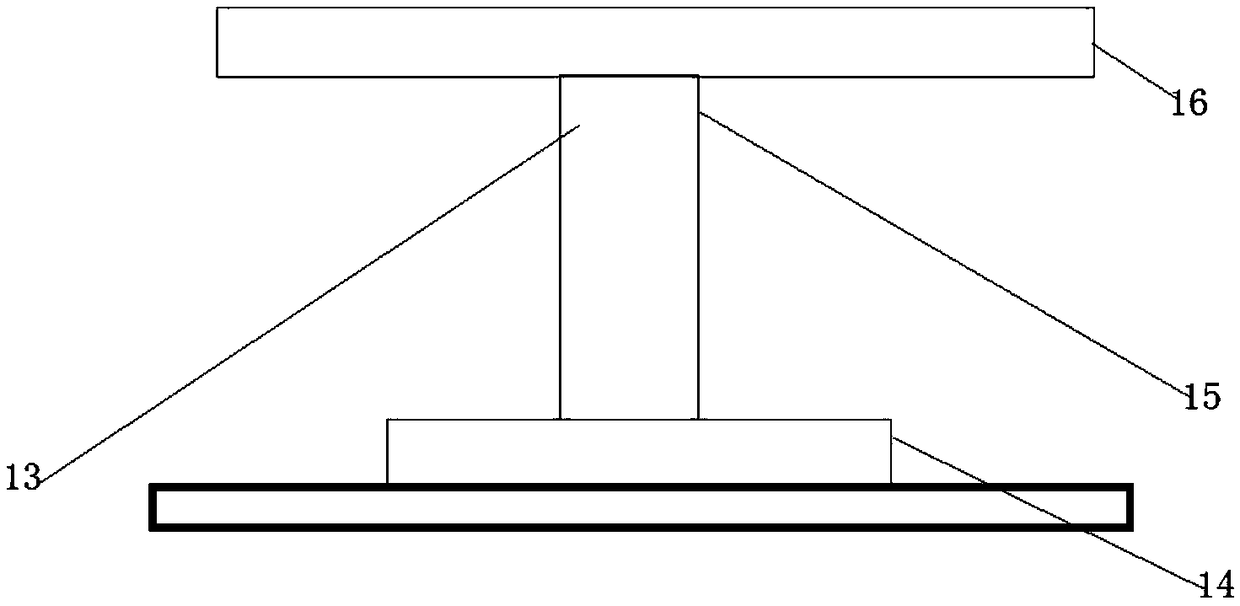

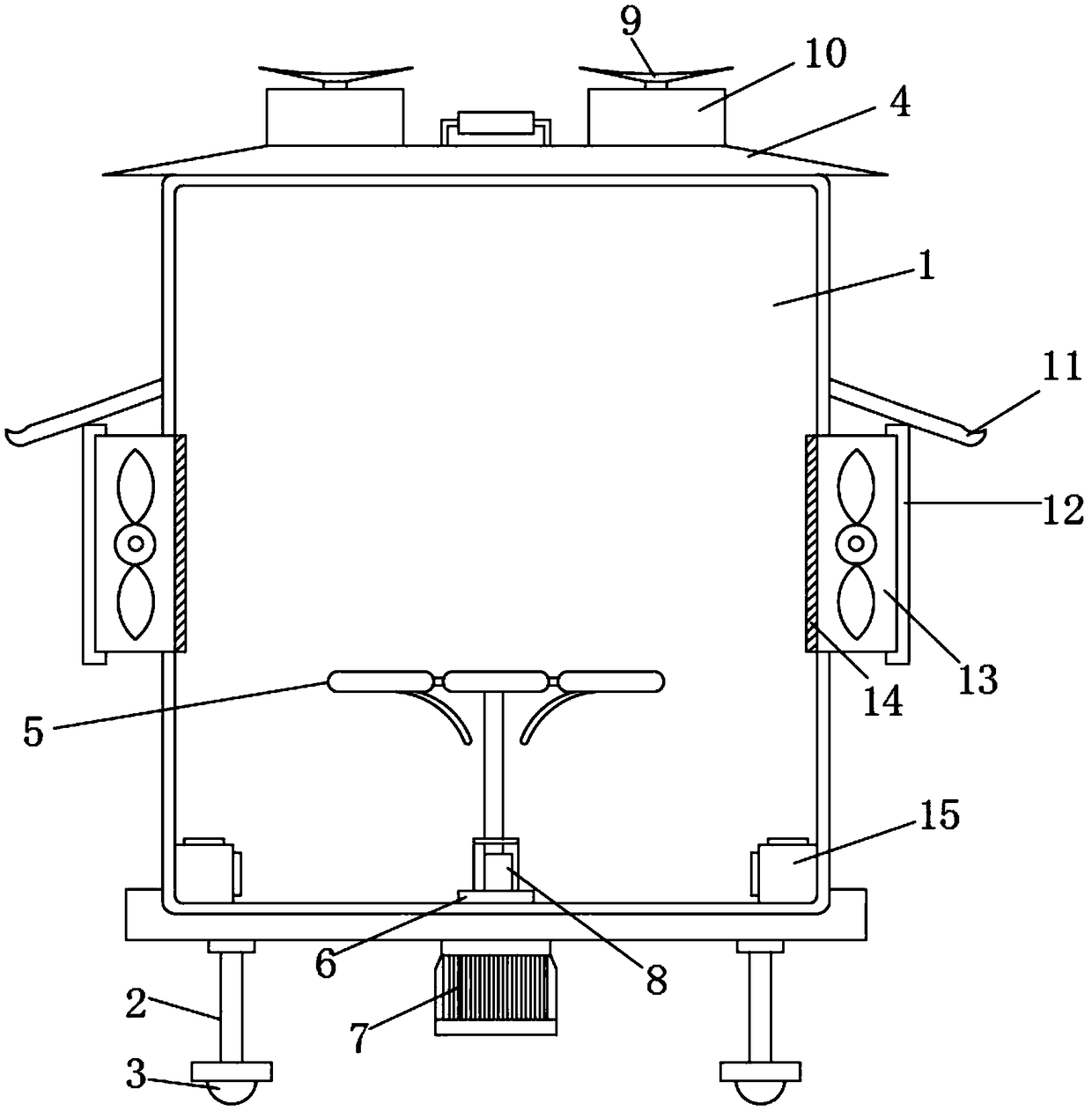

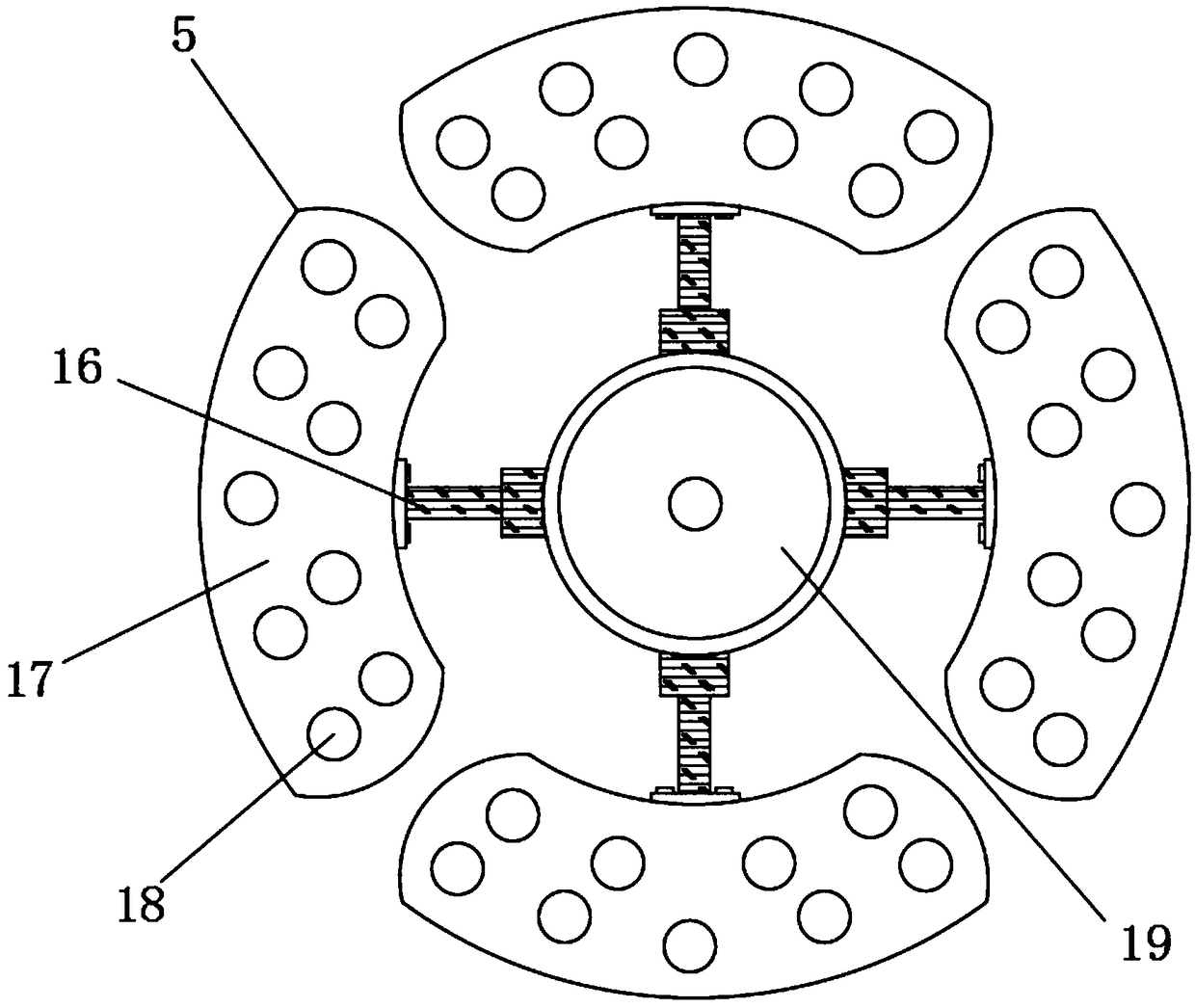

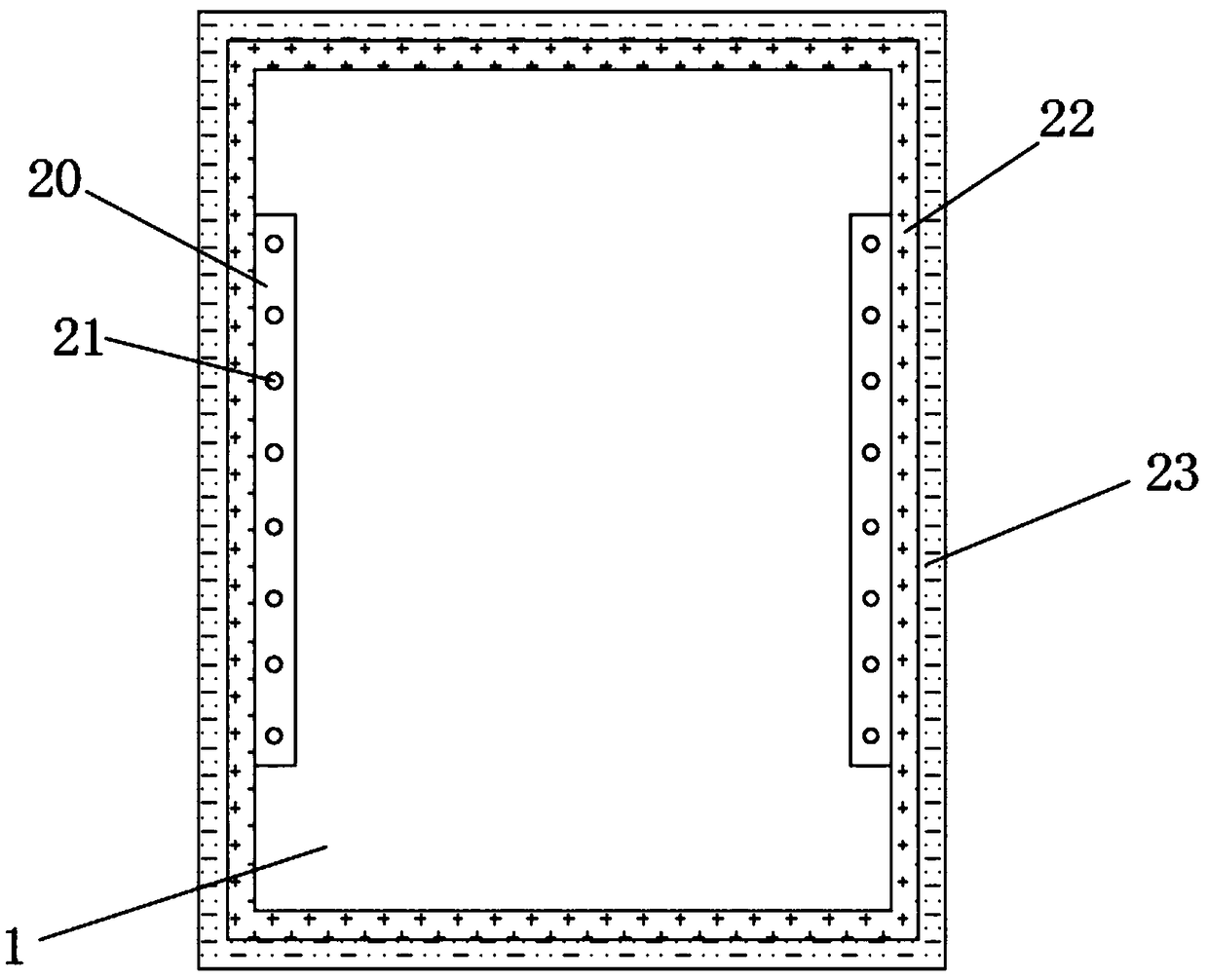

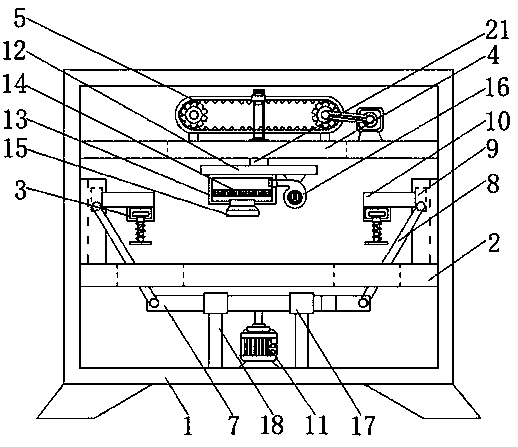

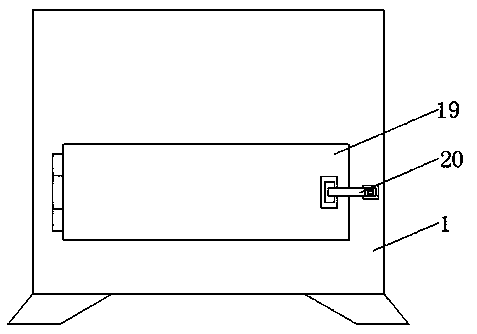

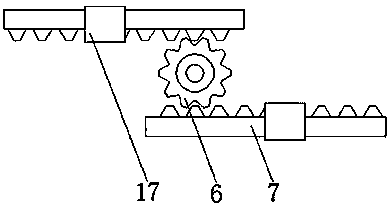

The invention provides matching drying equipment for dyeing clothing cloth. The matching drying equipment comprises lower guide rollers, upper guide rollers, guide roller mounting plates, a cloth passing frame, a positioning plate and a top plate. A drying box is integrally arranged in a rectangular shape. The bottom of the drying box is provided with a water receiving tank. A group of pressing rollers driven by a motor are supported and welded to openings in the front end of the drying box. The middle of the bottom of the outer wall at the front end of the water receiving tank is provided with a drain copper ball valve in a threaded locking mode. Two electric heating fans are symmetrically locked and installed on the top plate of a hot air box. The three groups of lower guide rollers arearranged and supported at bottom positions of the left and right side walls of the drying box at equal intervals. Four electric push rods are symmetrically and vertically supported on the left side and right side of the water receiving tank. Piston rods of the four electric push rods are connected with screws of the two guide roller mounting plates in a screw locking mode. Due to the arrangement of the four positioning rods, the left-and-right swinging of the three upper guide rollers can be limited by the four positioning rods, and the piston rods of the four electric push rods are preventedfrom being broken by conveying and drawing force of cloth.

Owner:FO SHAN SHI TAO LIAN RAN ZHENG DING XING YOU XIAN GONG SI

Heat recycling type efficient medicinal material drying device

ActiveCN106382808ADrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

Owner:深圳市惠普生科技发展有限公司

Tea leaf drying equipment

PendingCN107514879AReduce the impactRealize rolling back and forthPre-extraction tea treatmentTea dryingElectric machineryStructural engineering

Owner:池州市华茂茶业有限公司

Open type absorption heat pump-MVR technology coupled closed cycle drying system

ActiveCN111947443AReduce trafficReduce the risk of entrainmentEnergy efficient heating/coolingClimate change adaptationThermodynamicsEngineering

The invention discloses an open type absorption heat pump-MVR technology coupled closed cycle drying system which comprises an open type absorption heat pump system and a mechanical compression heat pump cycle system. An outlet of a mechanical heat pump compressor is divided into two paths, one path is in pipeline connection with a hot channel inlet of a heat removal device through a hot channel of a condenser, and the other path is in pipeline connection with the hot channel inlet of the heat removal device through a 2# heat and mass exchanger; and a hot channel outlet of the heat removal device is connected with an expansion valve through a pipeline, an outlet of the expansion valve is divided into two paths, one path is in pipeline connection with an inlet of the mechanical heat pump compressor through a 1# heat and mass exchanger, the other path is in pipeline connection with the inlet of the mechanical heat pump compressor through a cold channel of an evaporator, and a mechanicalcompression type heat pump cycle system is formed. According to the open type absorption heat pump-MVR technology coupled closed cycle drying system, absorbed heat is used for regenerating a dilute solution through the mechanical compression type heat pump cycle system, regenerated steam is used for heating dry gas after the grade of the regenerated steam is improved through an MVR technology; andby means of the open type absorption heat pump-MVR technology coupled closed cycle drying system, a large amount of latent heat in damp and hot gas exhausted by a dryer can be reasonably utilized.

Owner:ZHEJIANG UNIV OF TECH +1

Wood board drying equipment

InactiveCN107976046AImprove drying efficiencyFully contactedDrying gas arrangementsDrying machines with progressive movementsControl systemEngineering

Owner:广西桂林林博士家具有限公司

Medicine heating and drying device

InactiveCN105021006ADrying machines with progressive movementsDrying solid materialsElectric heatingEngineering

Owner:蒋魏

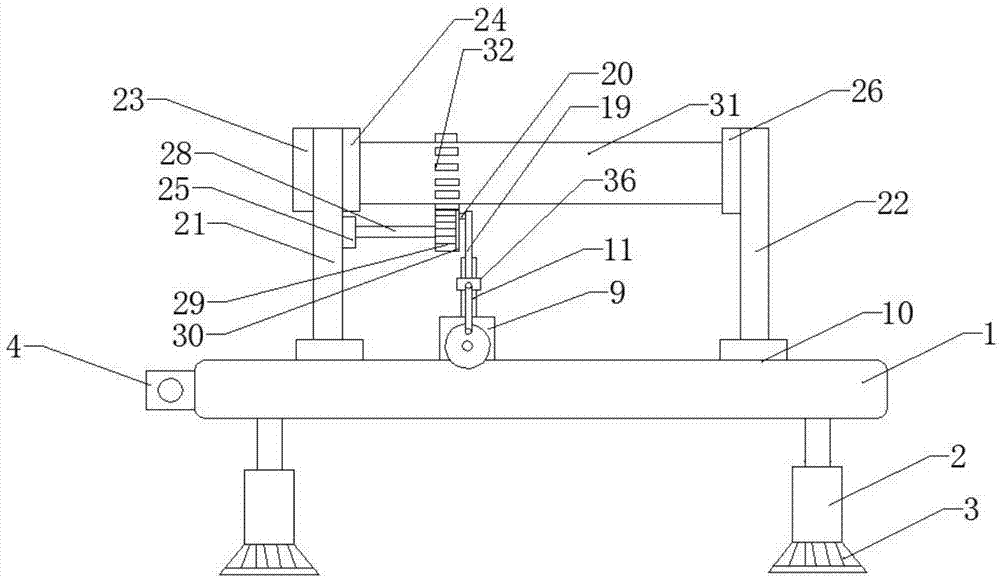

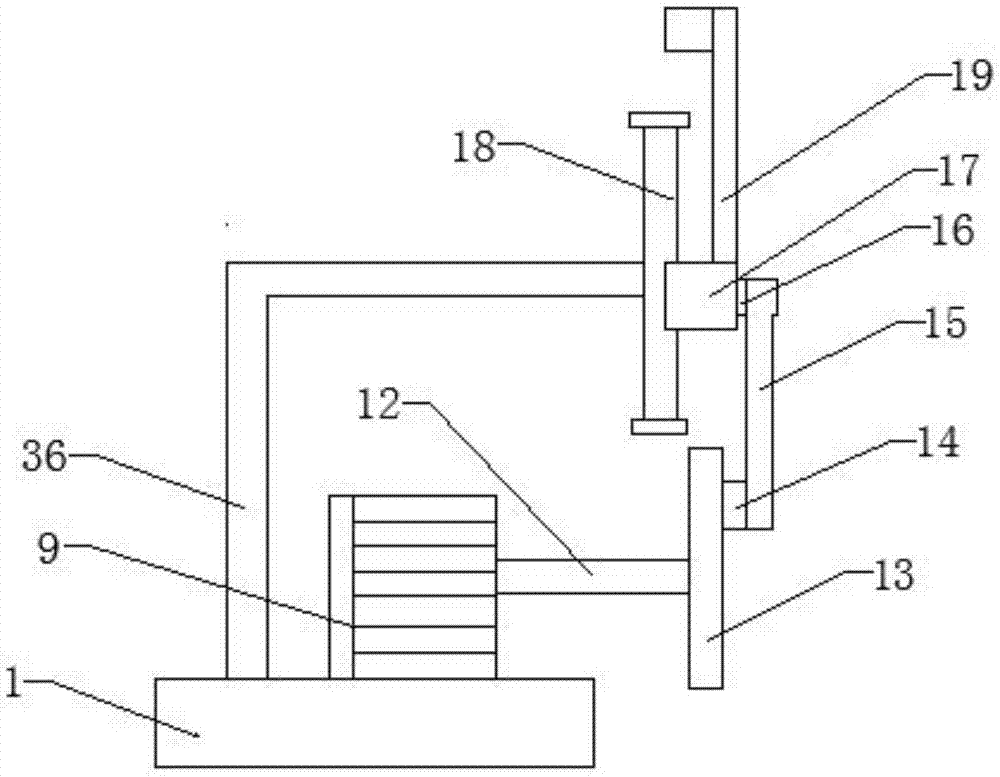

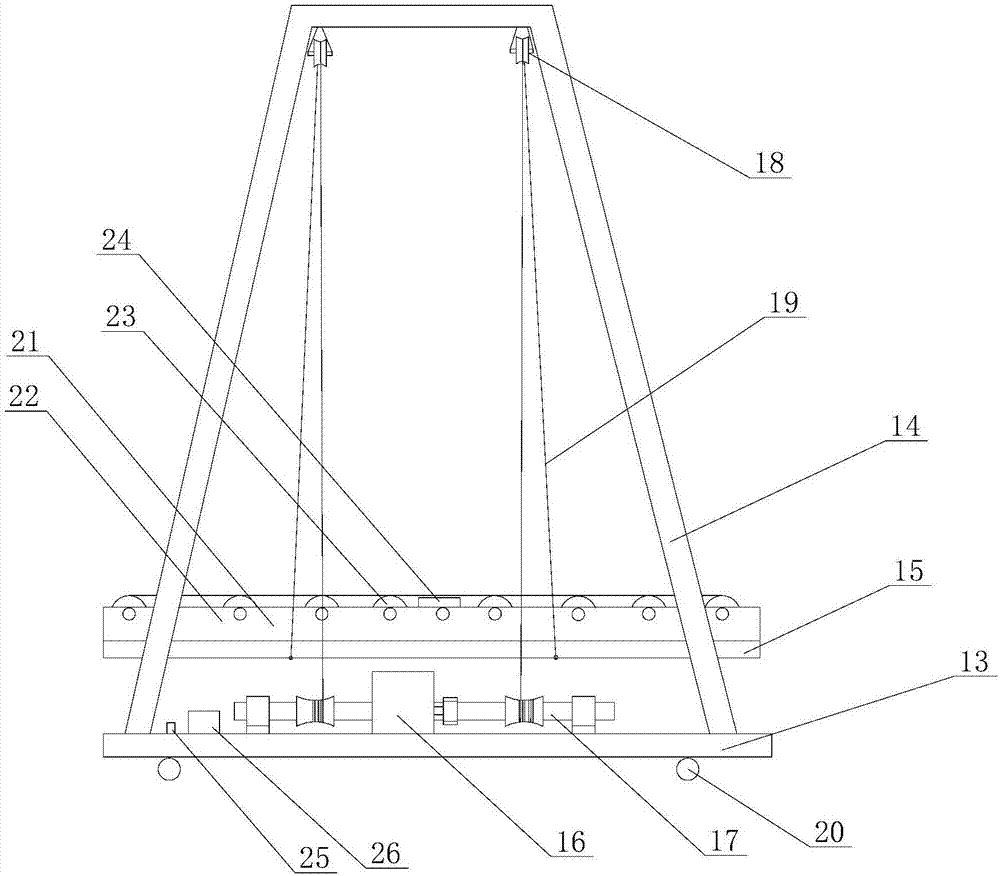

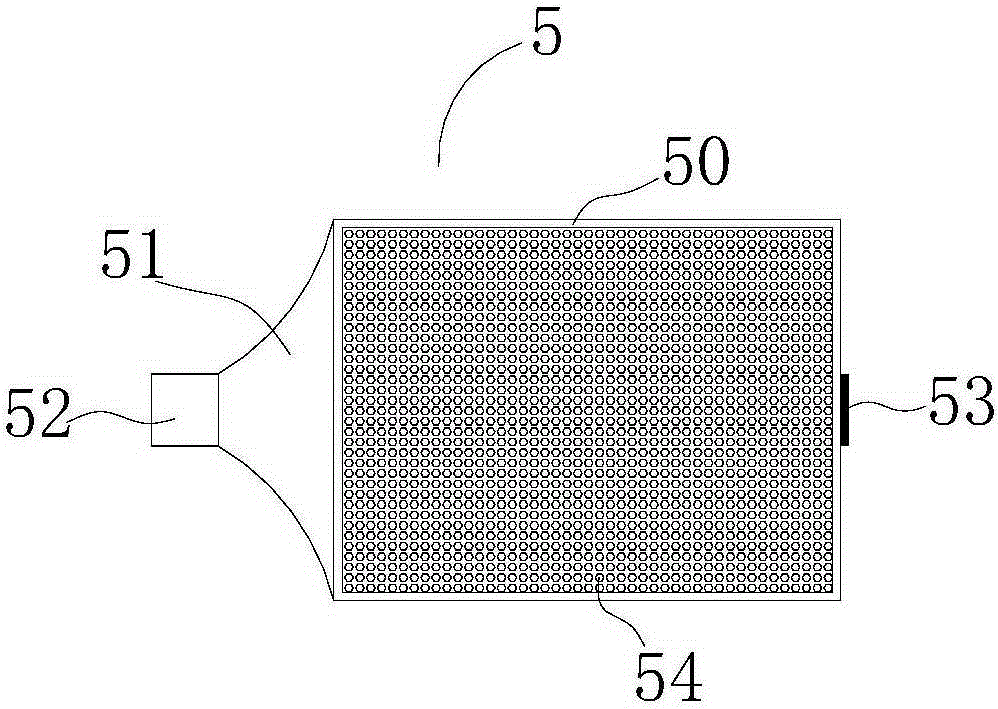

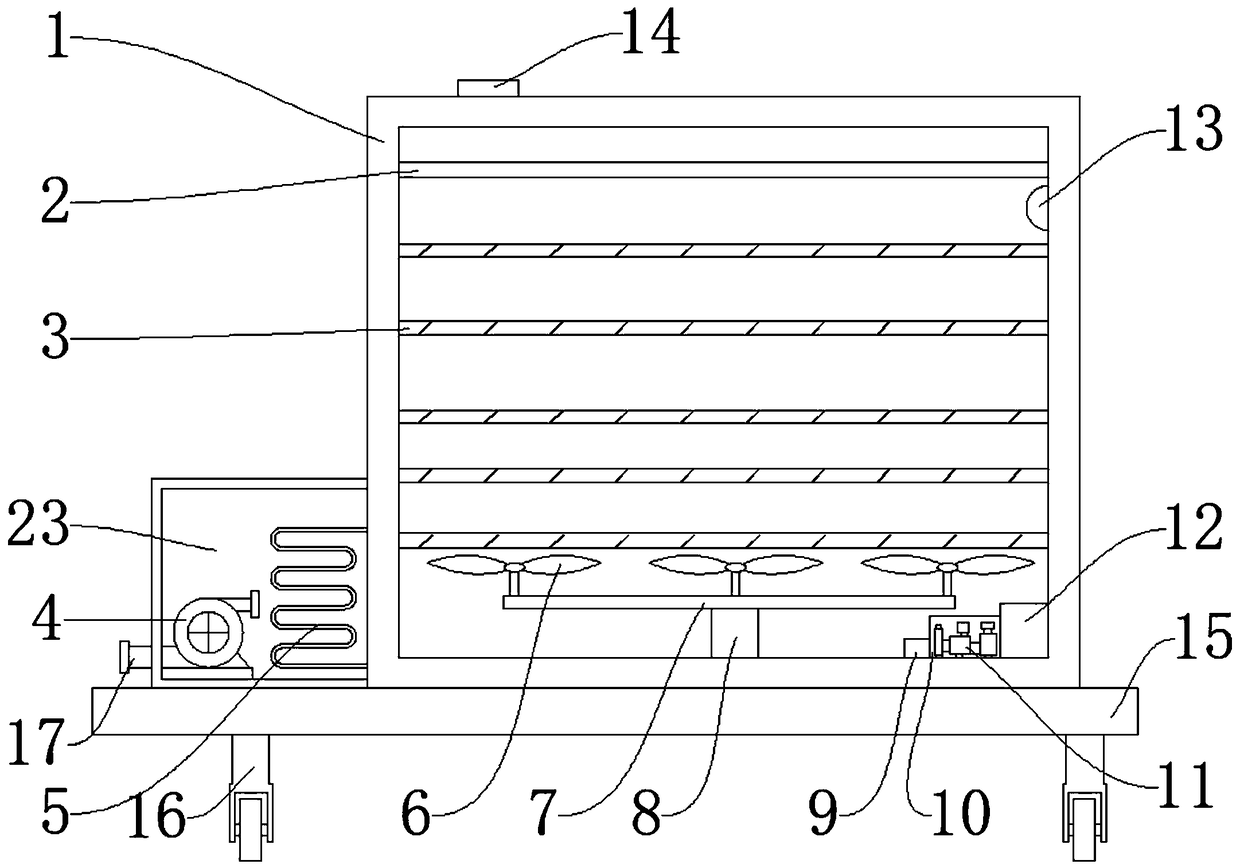

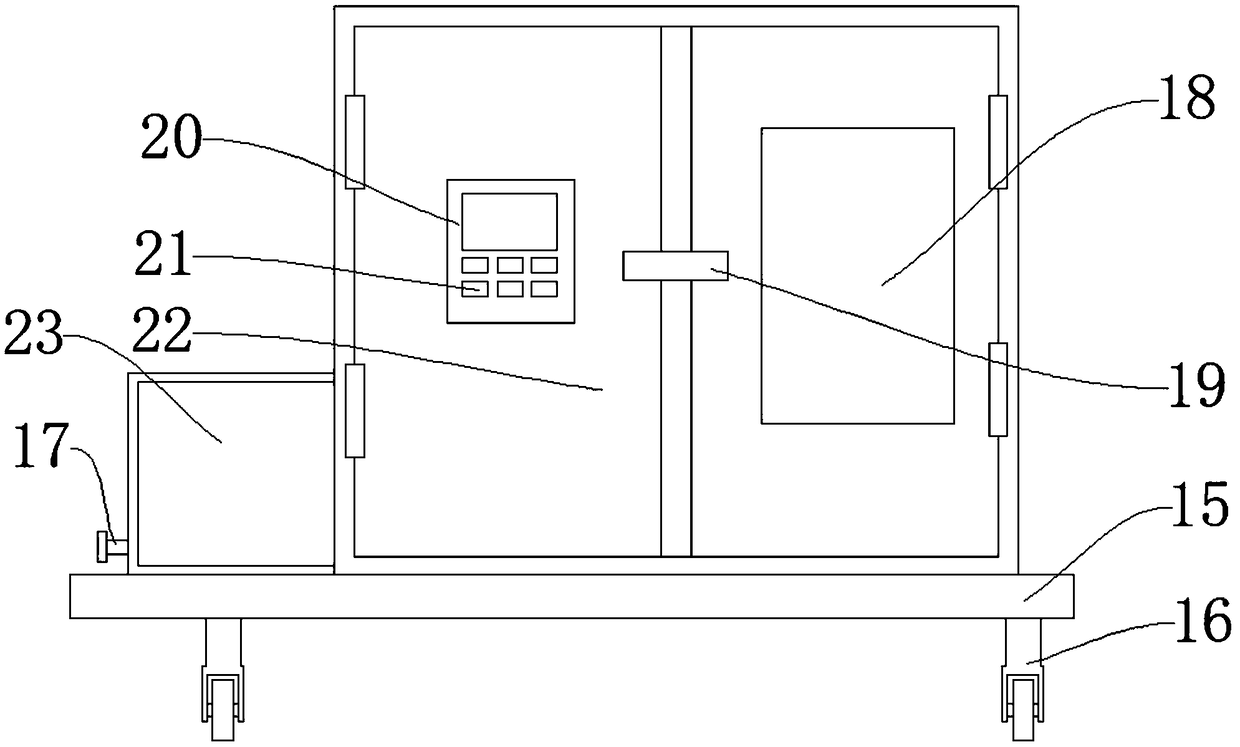

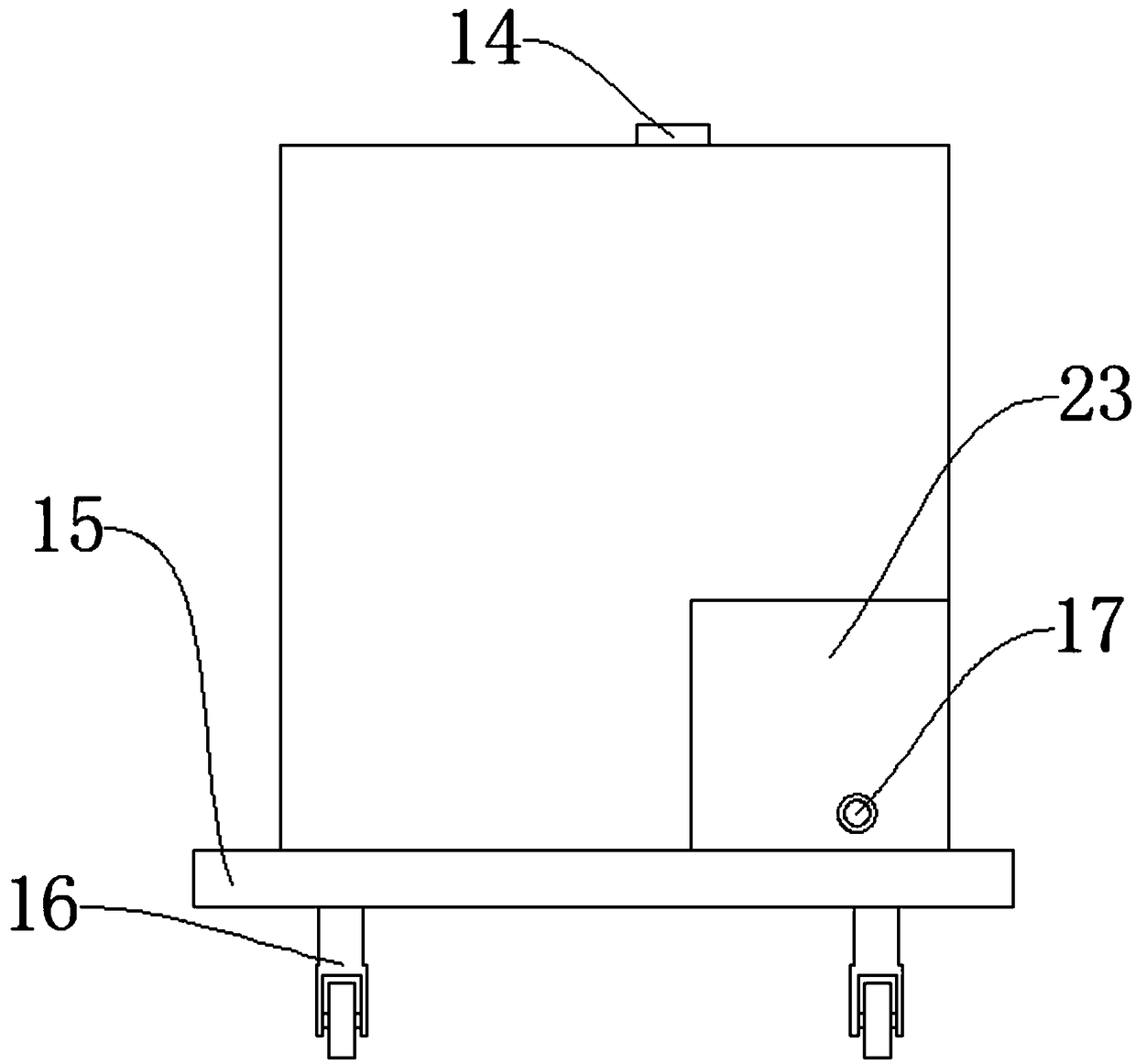

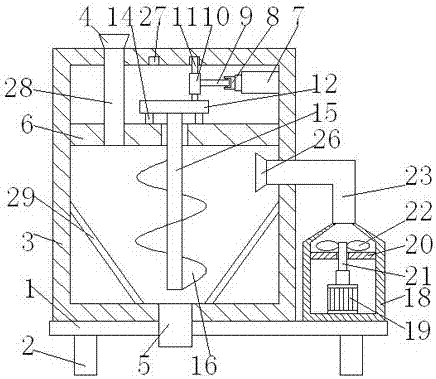

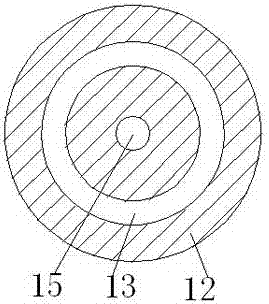

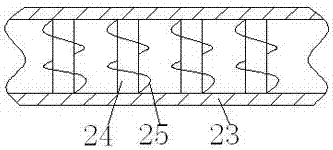

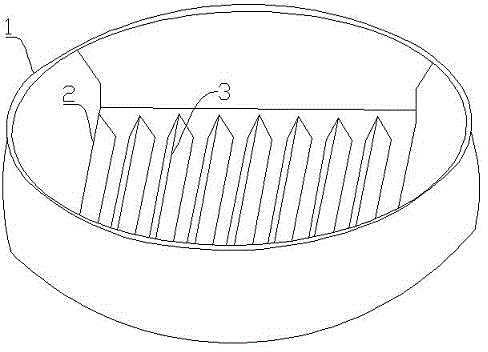

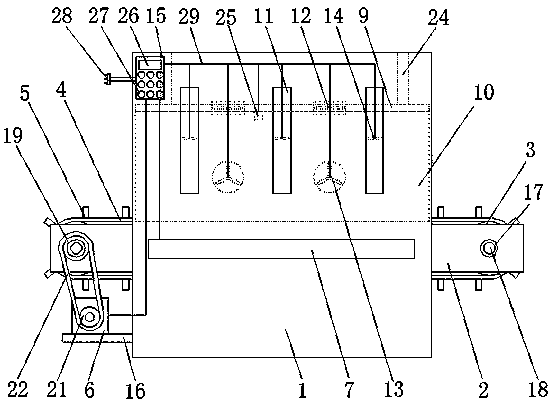

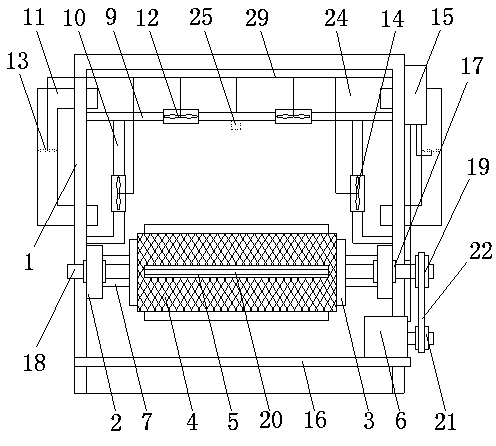

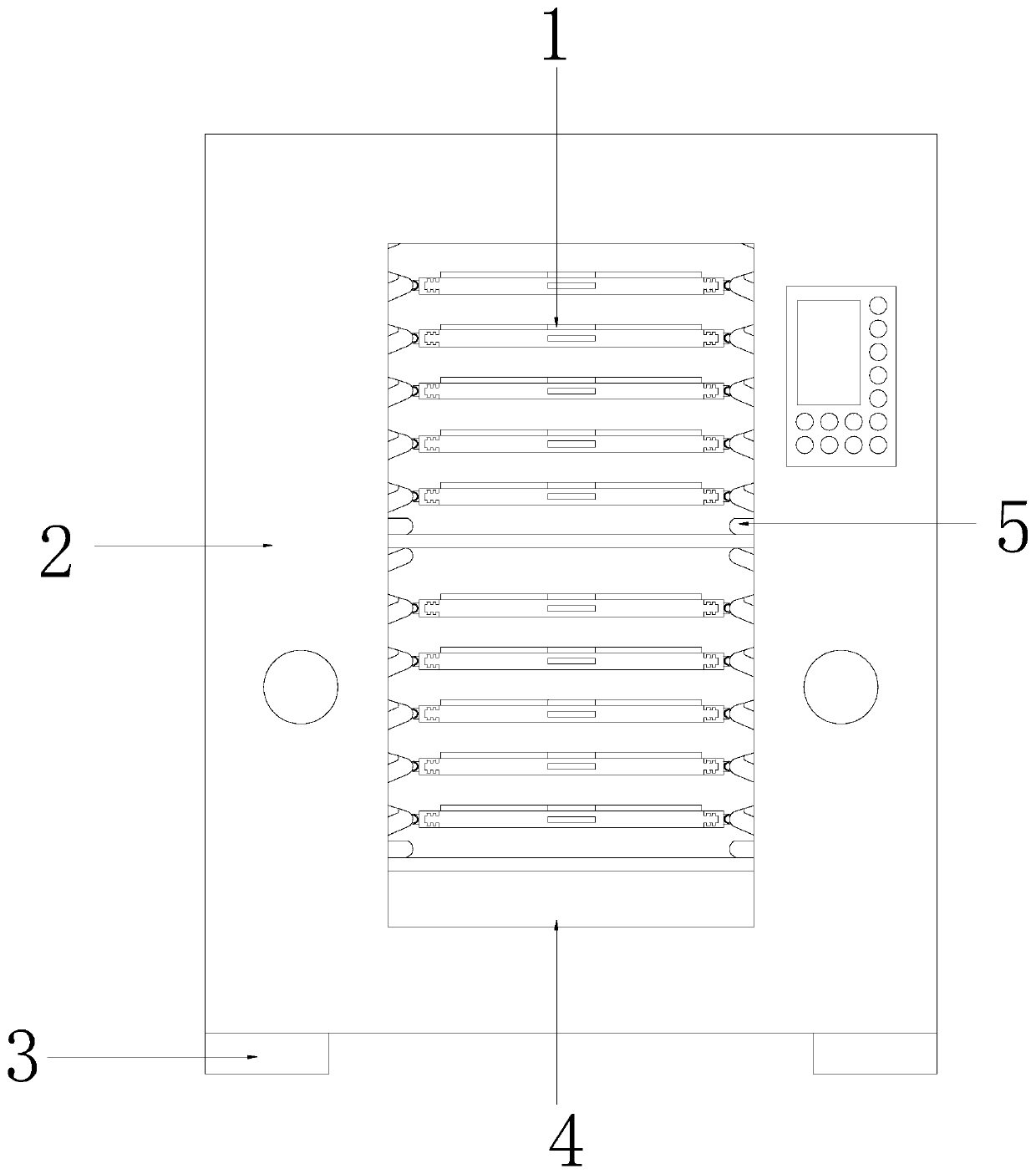

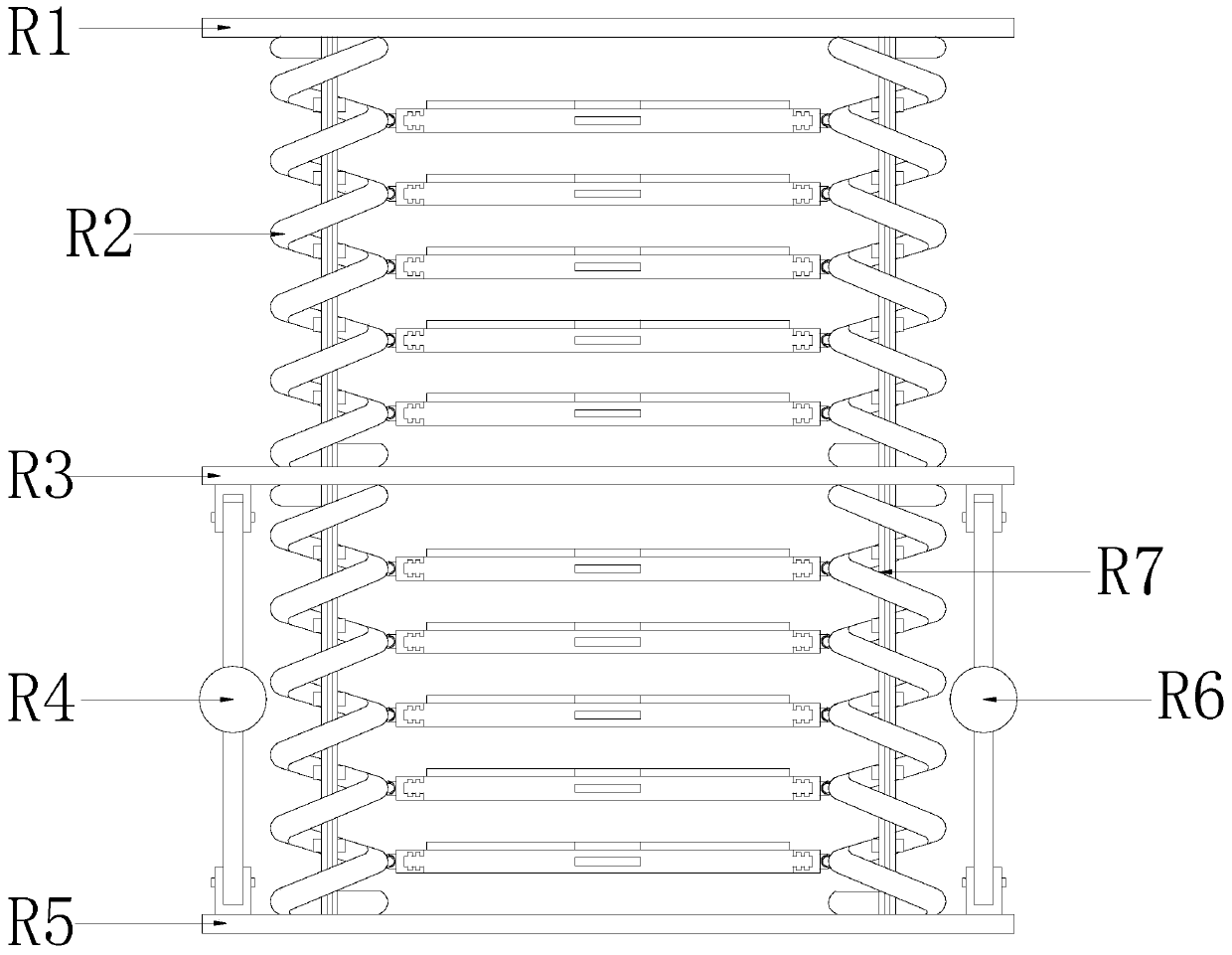

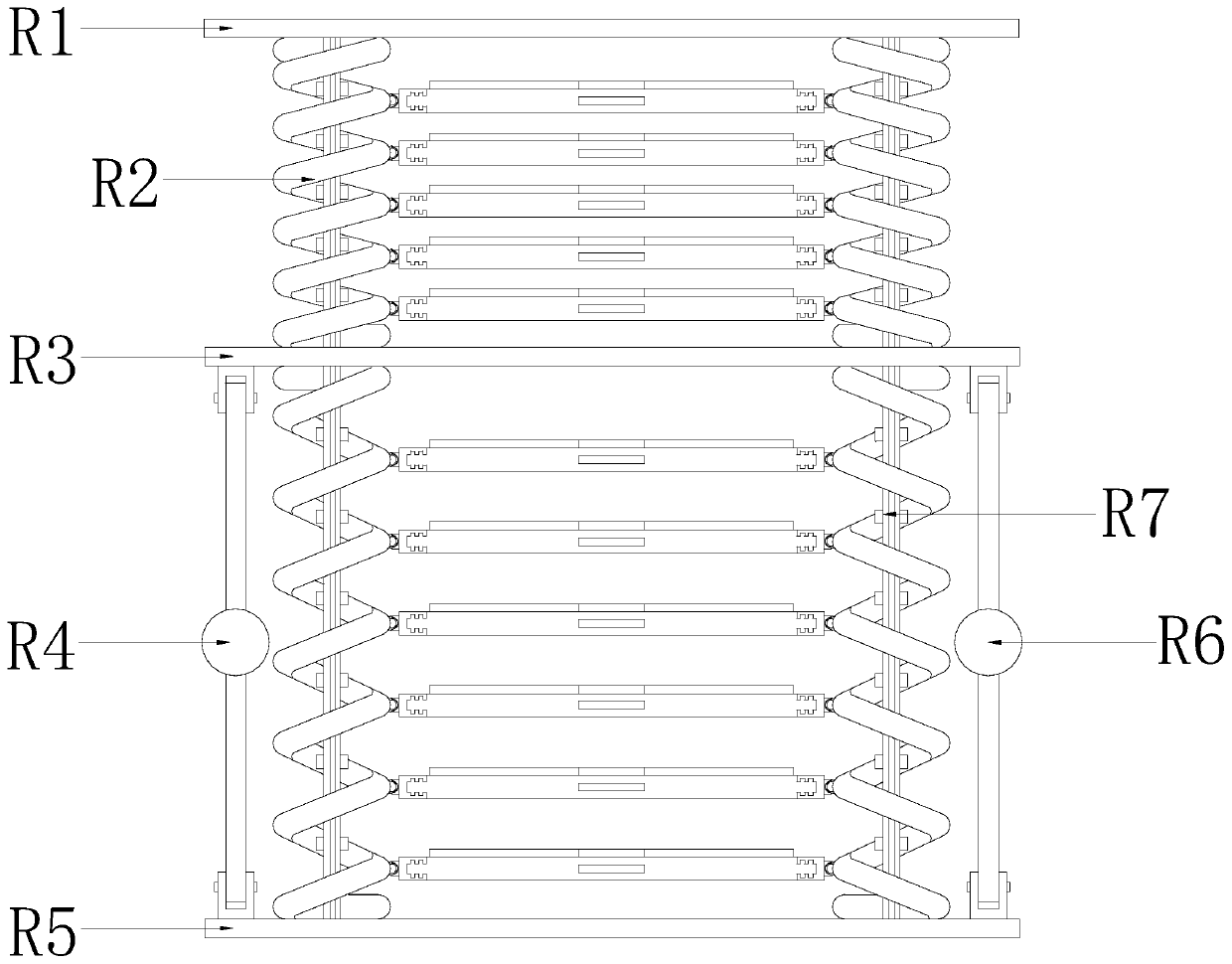

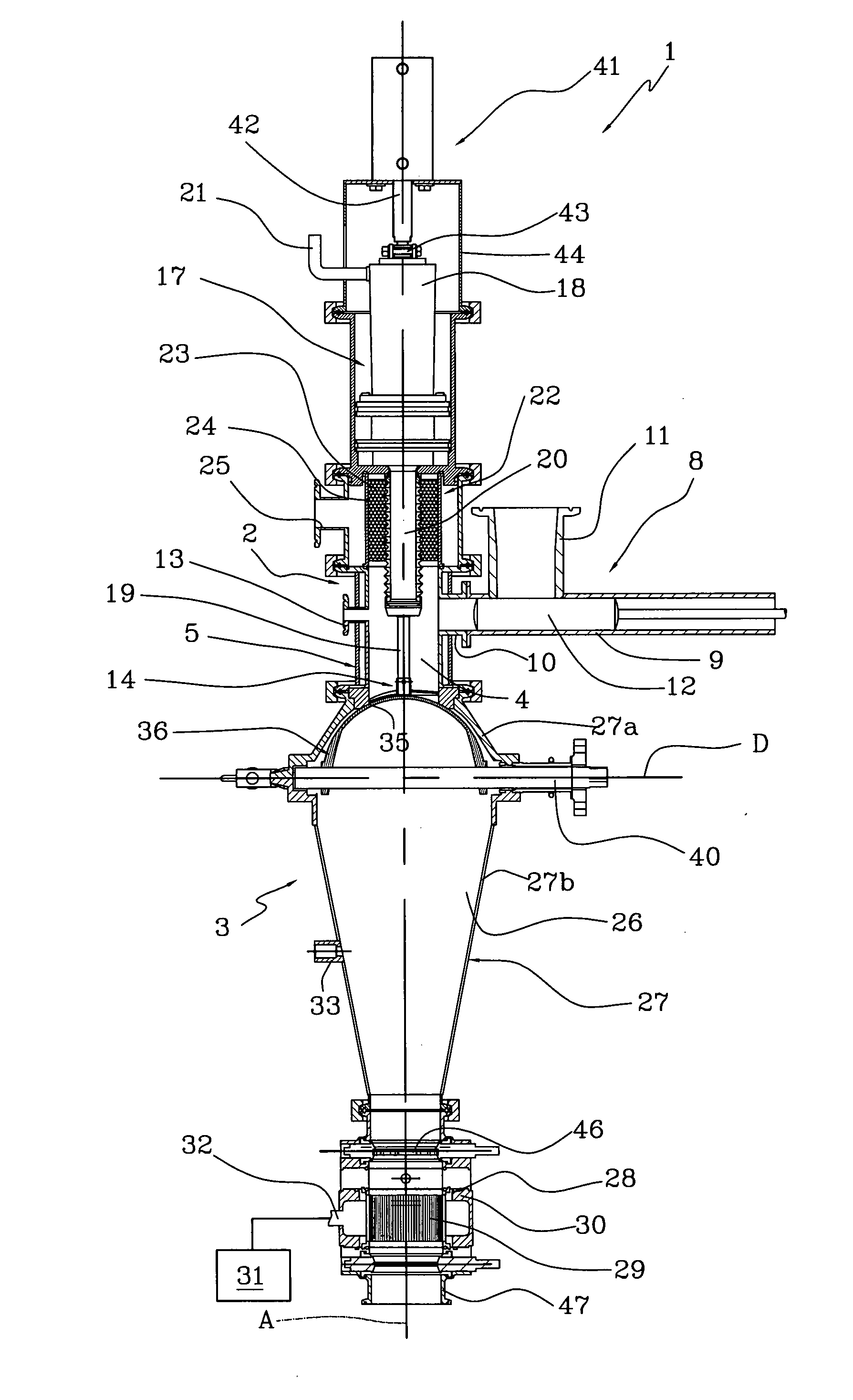

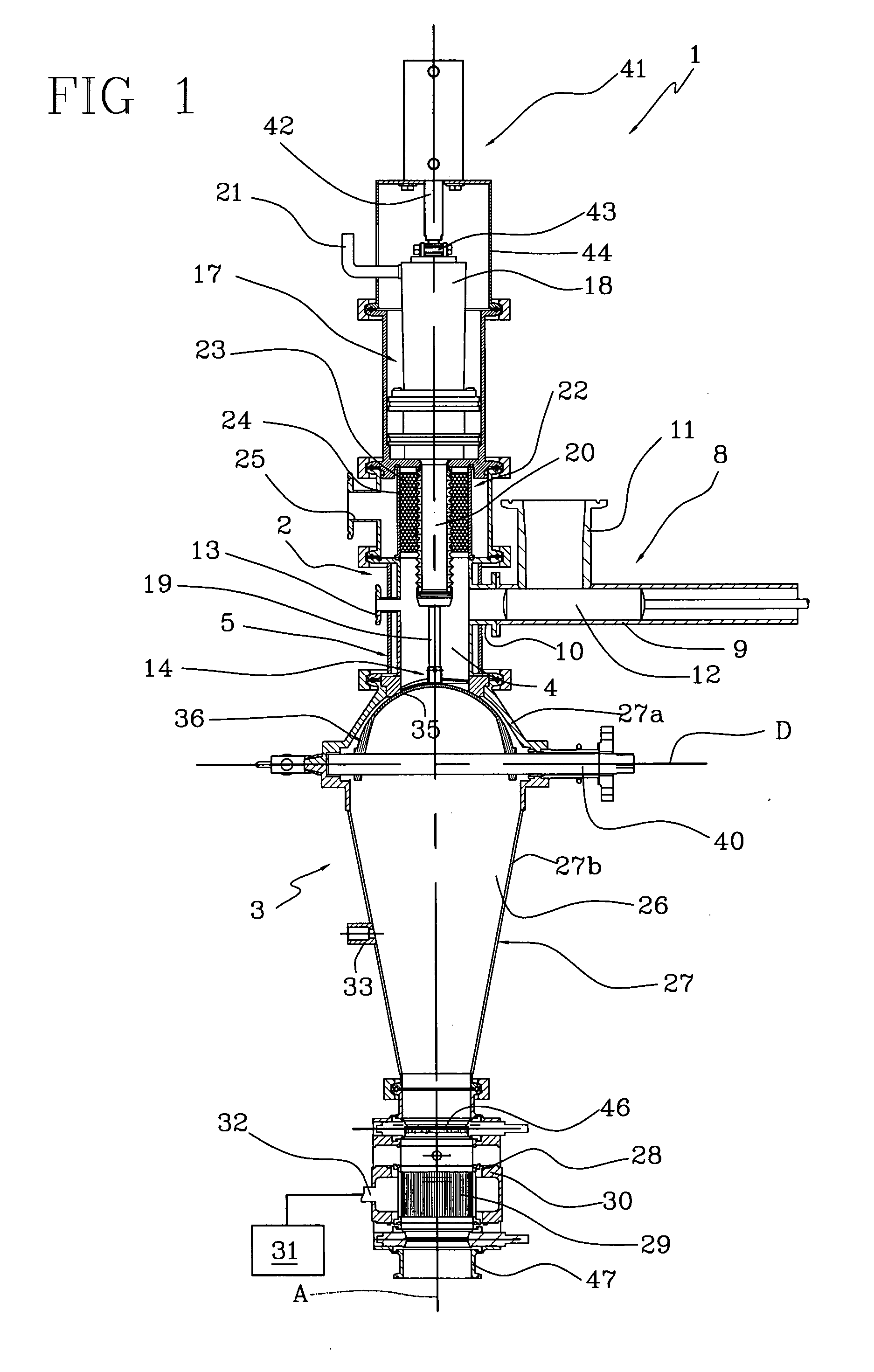

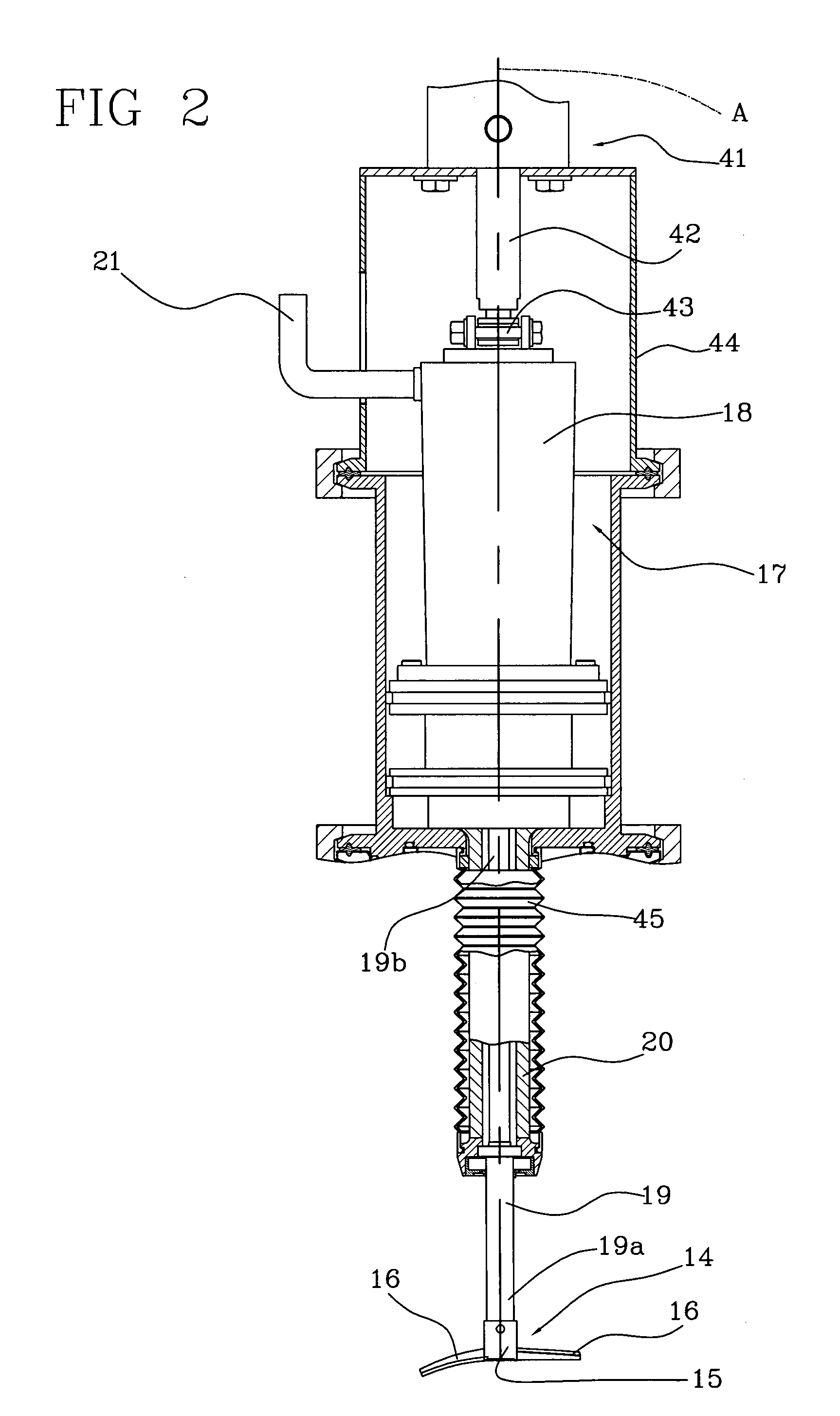

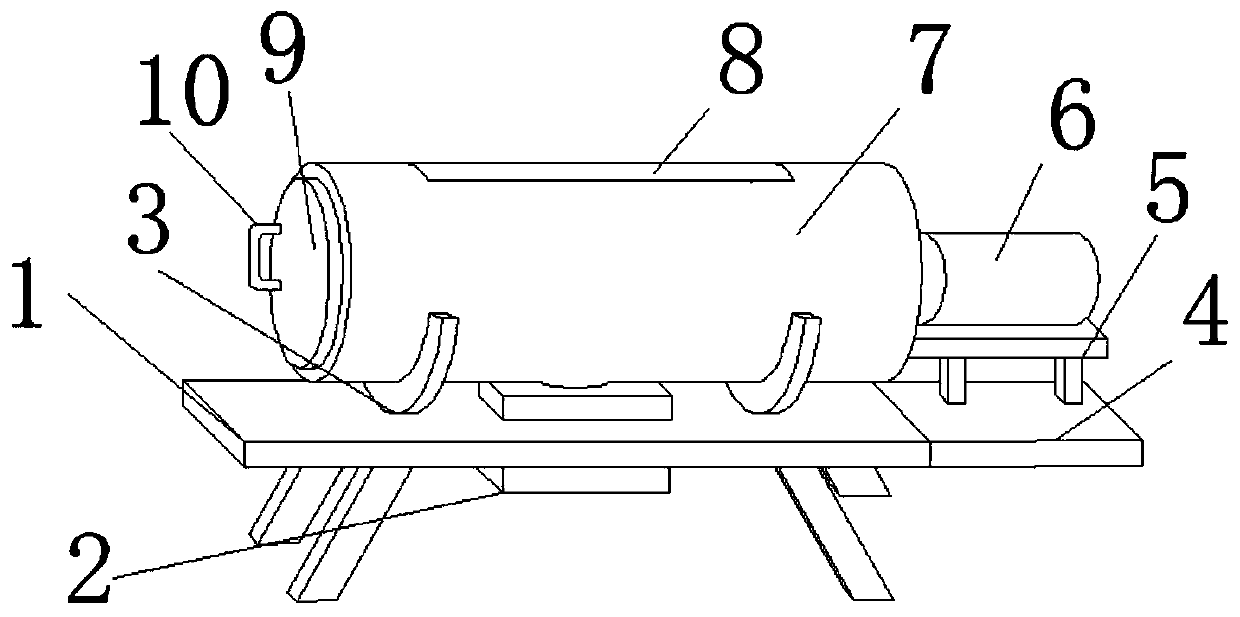

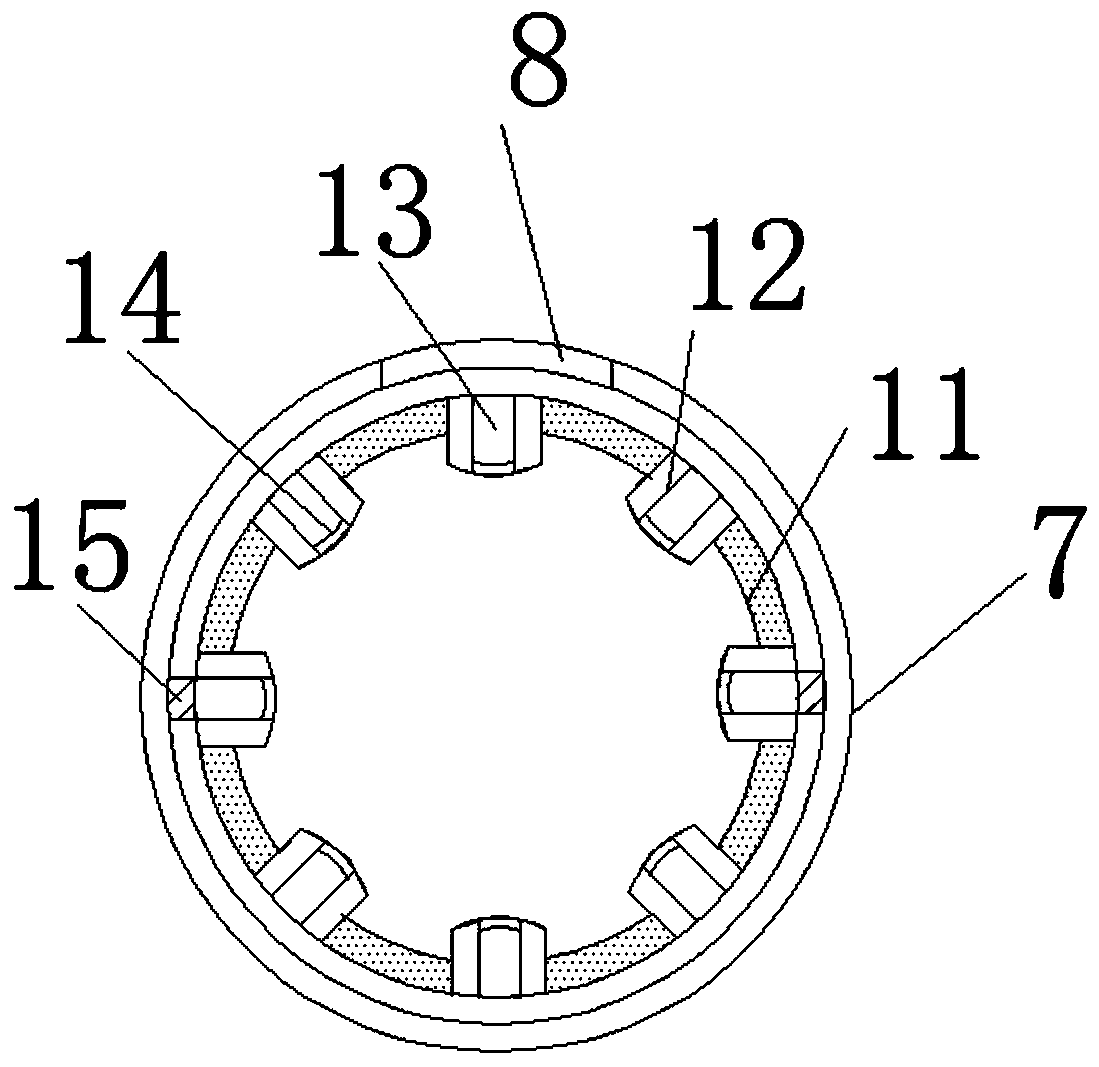

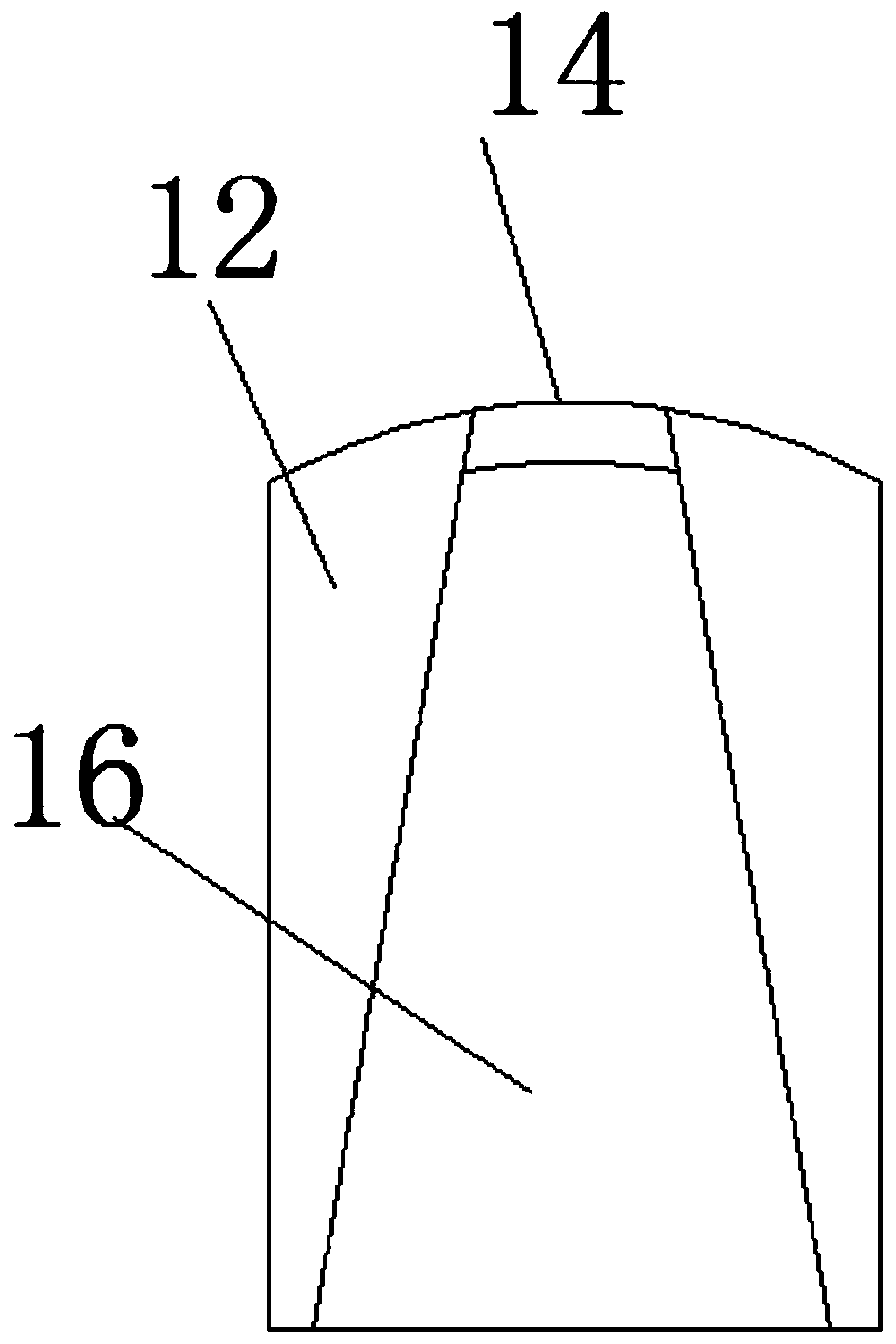

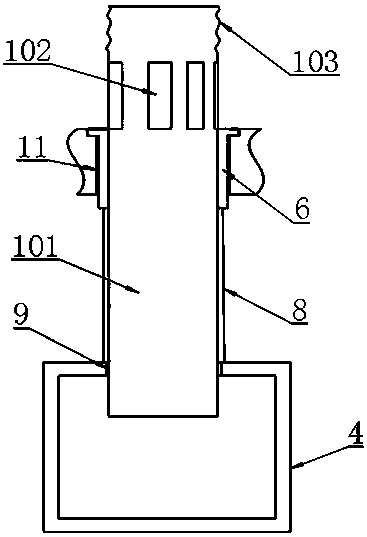

Screw walking type soft capsule drying device

ActiveCN105276959AReasonable structureLiquidityDrying solid materialsHeating arrangementEngineeringMotor drive

The invention discloses a screw walking type soft capsule drying device which comprises a drying room, a base, a dehumidifying device, a hollow cylindrical frame, trays, a screw conveying device, a heating device, a motor and a control device. The lower portion of the drying room is installed on the base. The base is internally provided with the motor, a motor driving device and the control device. The dehumidifying device is installed on the upper portion of the drying room. The hollow cylindrical frame is installed in the drying room. Screw channels are formed in the hollow cylindrical frame, and the screw conveying device is installed in the hollow cylindrical frame. The screw conveying device is connected with the motor and is provided with a plurality of conveying connecting blocks. The conveying connecting blocks are connected with the trays and walk along the screw channels. The screw walking type soft capsule drying device is reasonable in structure, the phenomenon that drying of a soft capsule is not uniform is improved, fluidity in the drying process is high, the phenomenon that external force is adopted, and consequently the soft capsule deforms is avoided, and the drying efficiency and the drying quality of the capsule are greatly improved.

Owner:浙江绿健胶囊有限公司

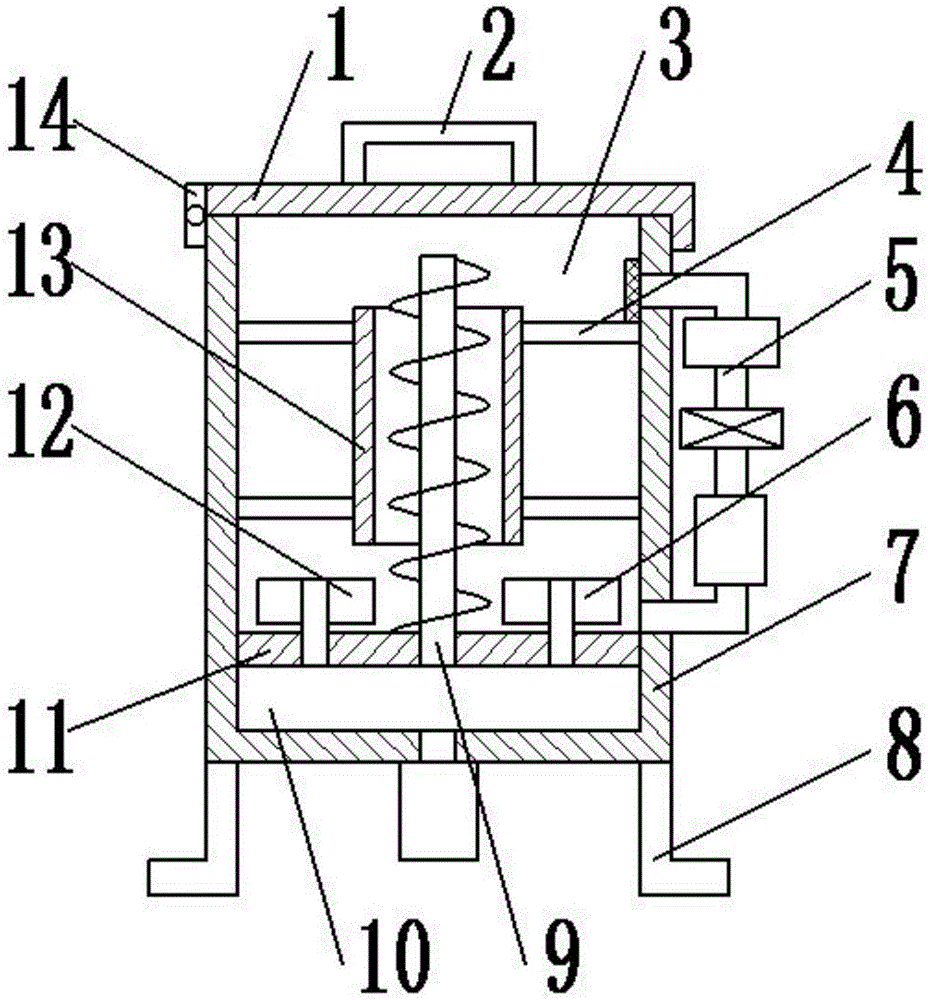

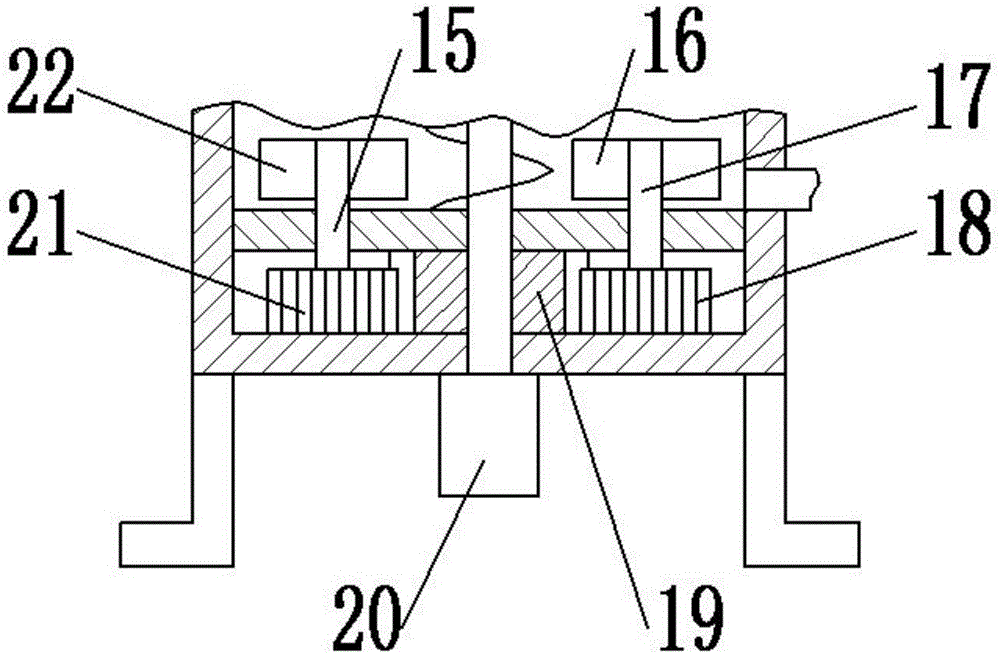

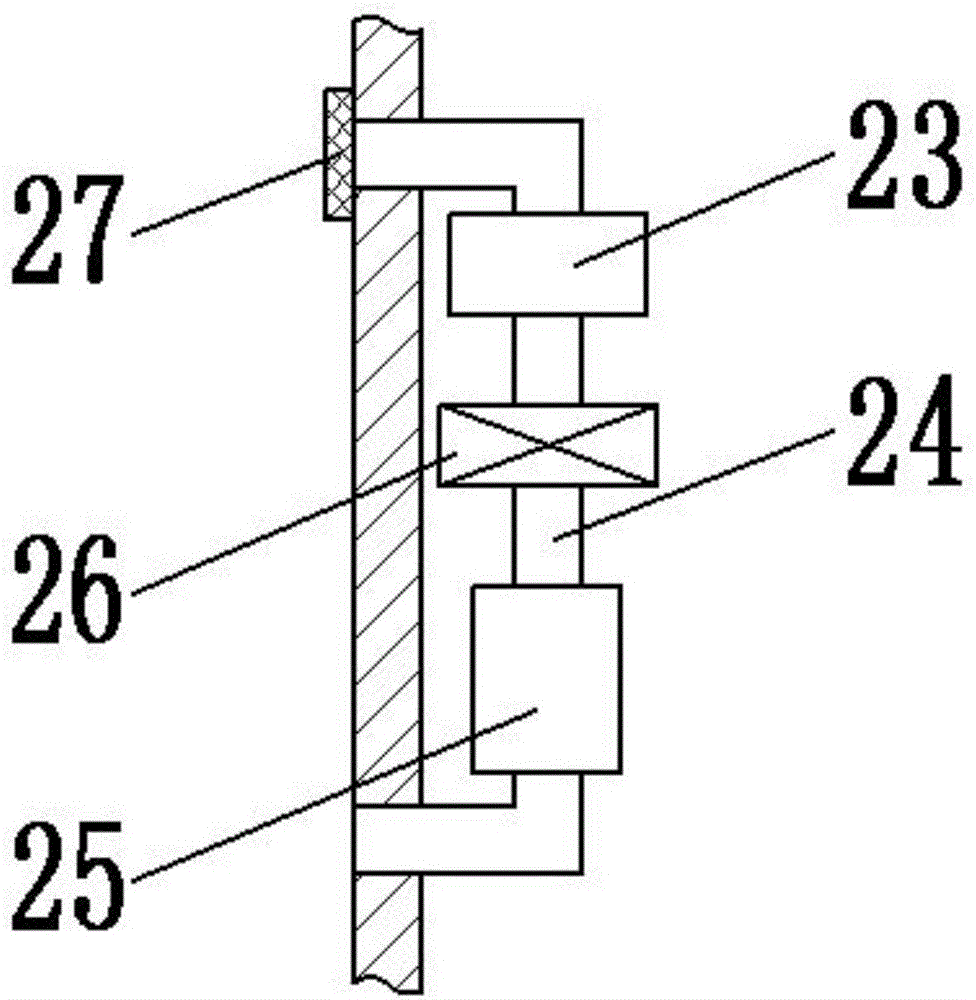

Drying box with vibration material cylinders for evenly shaking materials

InactiveCN107421294AEvenly heatedConvenience to workDrying machines with non-progressive movementsDrying solid materialsEngineeringFan blade

The invention discloses a drying box equipped with a vibrating material cylinder for shaking materials evenly, which comprises a box body. The inside of the box body is provided with a lifting mechanism. The lifting mechanism is arranged at the bottom end of the box body. The upper end of the mechanism is provided with a rotating motor, and the rotating motor leads vertically upward to the rotating shaft rod. The upper end of the rotating shaft rod is provided with fan blades. There is an interval between them, a spring is provided at the center of the upper end of the pole, one end of the spring is fixedly connected to the upper surface of the pole, the other end of the spring is provided with a barrel, and the barrel The upper end of the barrel is hingedly connected with a cover, one end of the barrel is provided with a folding handle, the inside of the barrel is a cavity, the outer end surface of the barrel is uniformly provided with ventilation holes, the inner wall There are several heating tubes. Through the above method, the present invention can shake the material evenly through the vibration of the material cylinder, so that the material is heated evenly.

Owner:WUXI TAISHUN FLOCKING MACHINERY FACTORY

Drying device for food processing

InactiveCN111879073AHigh speedFully heatedDrying gas arrangementsDrying solid materialsElectric machineProcess engineering

The invention discloses a drying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problem that existing raw materials are easy to accumulate.The drying device comprises a box body and a drying unit, a plurality of electric heating elements are installed on the two side walls of the box body, the drying unit comprises a dispersing assemblyused for dispersing materials and an air spraying assembly used for spraying hot air for drying, and the dispersing assembly comprises a supporting net, a first motor, a disc and a driving rod; the air spraying assembly comprises an air heater, a hollow rotating shaft, a driving mechanism used for driving the hollow rotating shaft to rotate, a hard air pipe, a sliding sleeve and a sliding block,the dispersing assembly is mounted, the supporting net is rapidly pulled outwards through the rapid return characteristic, raw materials on the supporting net are made to fly off upwards at a high speed and are fully and evenly heated, and the drying efficiency is improved; and the air spraying assembly is arranged, upward cyclone is formed, the drying effect is good, the air spraying angle is continuously changed, the drying range is enlarged, and the efficiency is improved.

Owner:马迎锋

Medicinal material dendrobe drying device

InactiveCN109282586AFully contactedReduce volumeDrying gas arrangementsDrying solid materialsEngineeringAir heating

Owner:NANJING ZHENGKUAN MEDICAL TECH

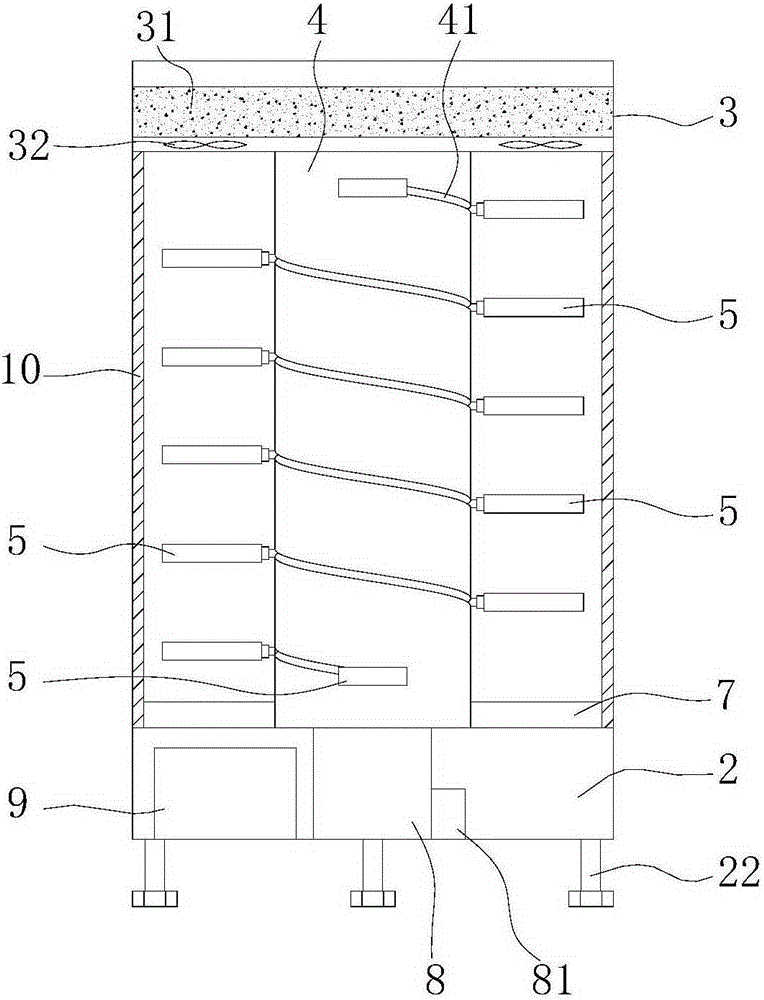

Efficient alloy baking device and baking method thereof

The invention discloses an efficient alloy baking device and a baking method thereof in the field of alloy baking. The efficient alloy baking device comprises a hot-blast stove, the hot-blast stove isconnected with an air inducing mechanism through a hot-blast pipeline, a temperature adjusting mechanism is further arranged between the air inducing mechanism and the hot-blast stove, the air inducing mechanism is connected with a baking bin, and the baking bin is arranged on a rack. The hot-blast stove is arranged on one side of the rack, a weighing and discharging mechanism is arranged below the baking bin, the baking bin is further provided with a feeding mechanism in a matched mode, and the hot-blast stove is controlled by an intelligent detection control system. The hot-blast stove andthe baking bin are of a separated structure, coal gas can be fully combusted, carbon monoxide poisoning accidents are avoided, safety measures are complete, the hot-blast stove is controlled by the intelligent detection control system, the hot-blast stove and the baking bin can be monitored in real time, and the heat energy utilization efficiency is greatly improved through the air inducing mechanism and the temperature adjusting mechanism. The efficient alloy baking device and the baking method thereof can be used for iron alloy baking.

Owner:JIANGSU EURASIA ENVIRONMENTAL PROTECTION TECH CO LTD

Crop uniform drying device

InactiveCN108007128ASolve the problem of not having uniform dryingDry evenlyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDrying time

Owner:王腾蛟

Collecting material-distributing device

InactiveCN104896912AAddress the Possibility of Inhomogeneous FeedEnhanced Uniformity PropertiesSeed preservation by dryingDrying solid materialsFlangeFunnel shape

Owner:ANHUI SUNMIRO AGRI TECH

Continuous operation type energy-saving drying device for textile production

PendingCN113251775AWon't wasteTake advantage ofDrying gas arrangementsLiquid/gas/vapor removal by gas jetsProcess engineeringAir blower

Owner:杨干英

Bus umbrella drying system

InactiveCN109059507AEasy to take umbrellaBatteries circuit arrangementsElectric powerHeat conductingConveyor belt

Owner:SHAANXI UNIV OF SCI & TECH

Straw particle storage device

PendingCN109484776AEffective flippingEffectively dryDrying gas arrangementsLarge containersEngineeringWater spray

Owner:安徽翔丰再生能源有限公司

Anti-wrinkle processing device for bamboo charcoal fiber antibacterial lace fabric production

InactiveCN109579443AEasy to placeThe distance is easy to adjustDrying gas arrangementsDrying chambers/containersWrinkle skinEngineering

Owner:苏州优捷纺织品有限公司

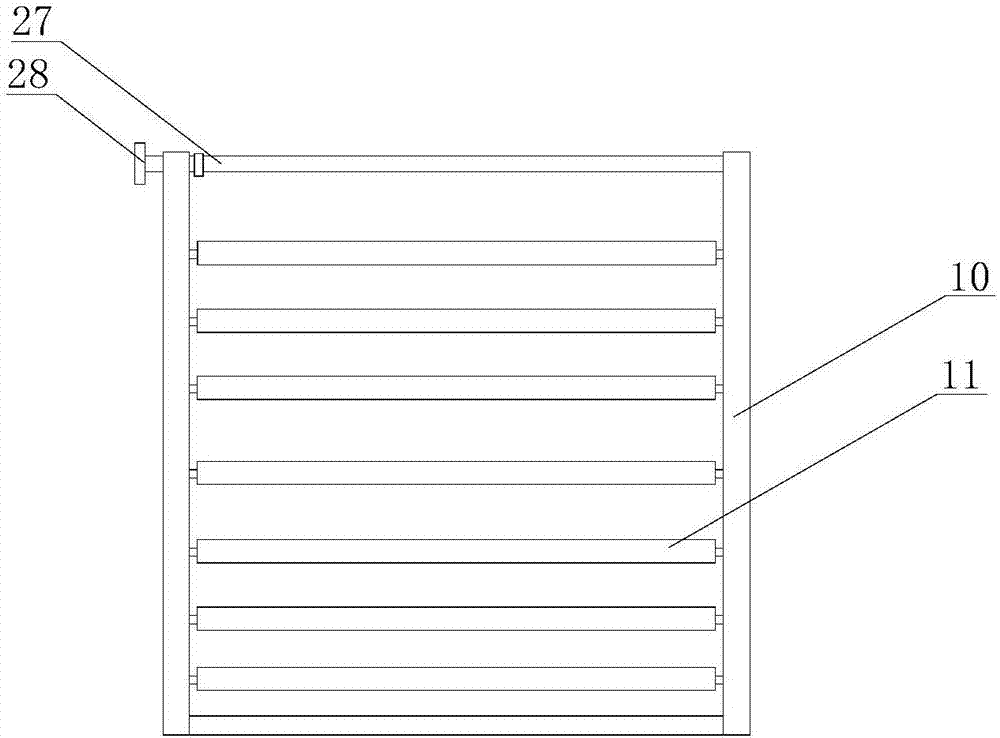

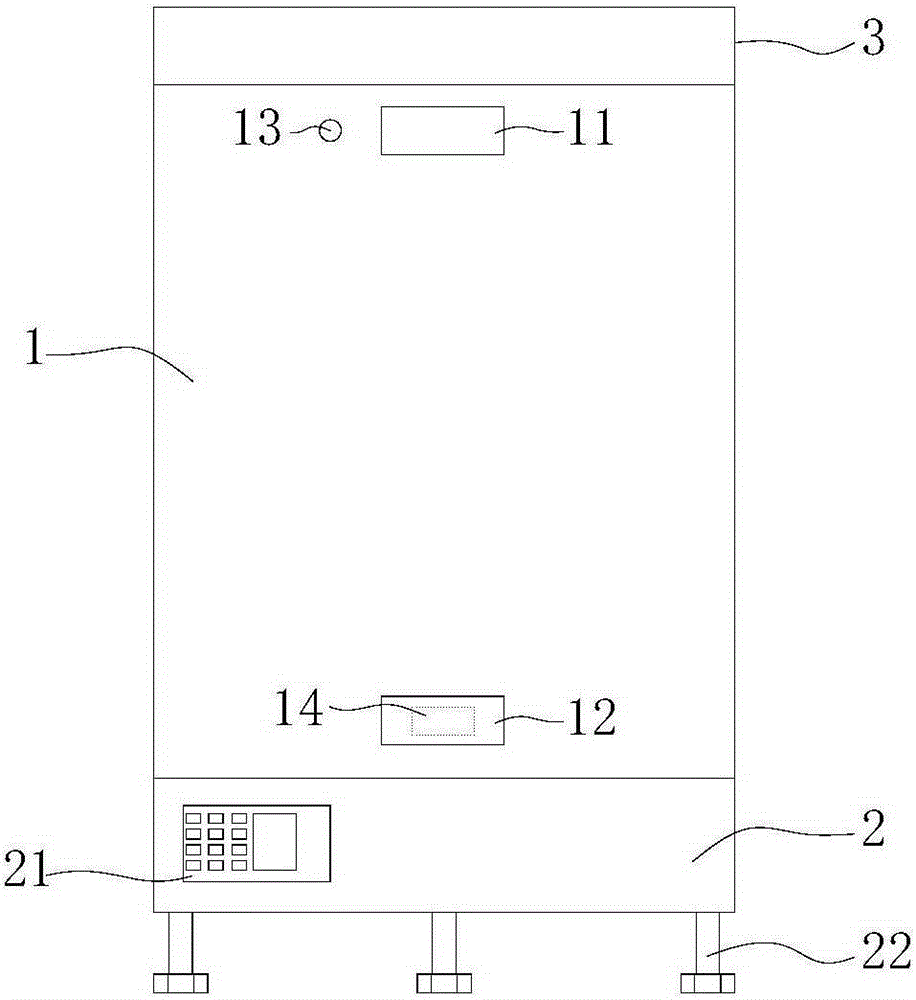

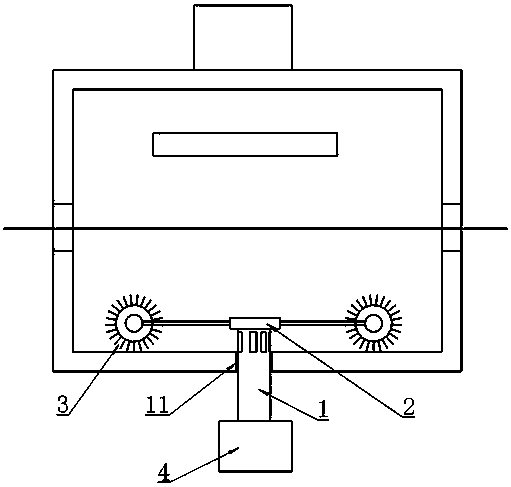

Rapid drying and disinfecting device for glass culture dish

InactiveCN109458797AEasy to dryImprove the bactericidal effectDrying gas arrangementsDrying chambers/containersEngineeringBreathing

The invention discloses a rapid drying and disinfecting device for a glass culture dish. The rapid drying and disinfecting device comprises a box body, a box cover, a partition plate, a bottom plate,a placing unit, a hot air circulating device and a disinfecting device, wherein a box cover is movably connected to the top end of the box body, a partition board is arranged in the box body, a plurality of uniformly-disposed placing units are formed between the partition plate and the bottom plate, the hot air circulating device is arranged in the box body below the bottom plate, the hot air circulating device is connected with ventilation pipelines, ventilation holes are formed in the partition plate on the side wall of the box body, ventilation holes are communicated with the ventilating pipelines, the disinfecting device is arranged at the bottom end of the box cover. According to the drying and disinfecting device, rapid drying and disinfecting can be carried out on the culture dish,and the culture dishes with different sizes can be suitable for placement, meanwhile, effective protection can be provided for the culture dishes, the phenomena of crushing and the like of the culturedishes can be prevented, and unnecessary loss can be avoided.

Owner:王小改

Drying device for automobile accessory production

PendingCN108662852AAvoid getting lostImprove drying effectDrying gas arrangementsDrying chambers/containersEngineeringHeat losses

Owner:安吉前程竹木机械有限公司

Heat cycle type wood plank drying device suitable for furniture processing

InactiveCN108518958AReduce wasteImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsWater vaporFixed frame

Owner:萧县智鑫知识产权运营有限公司

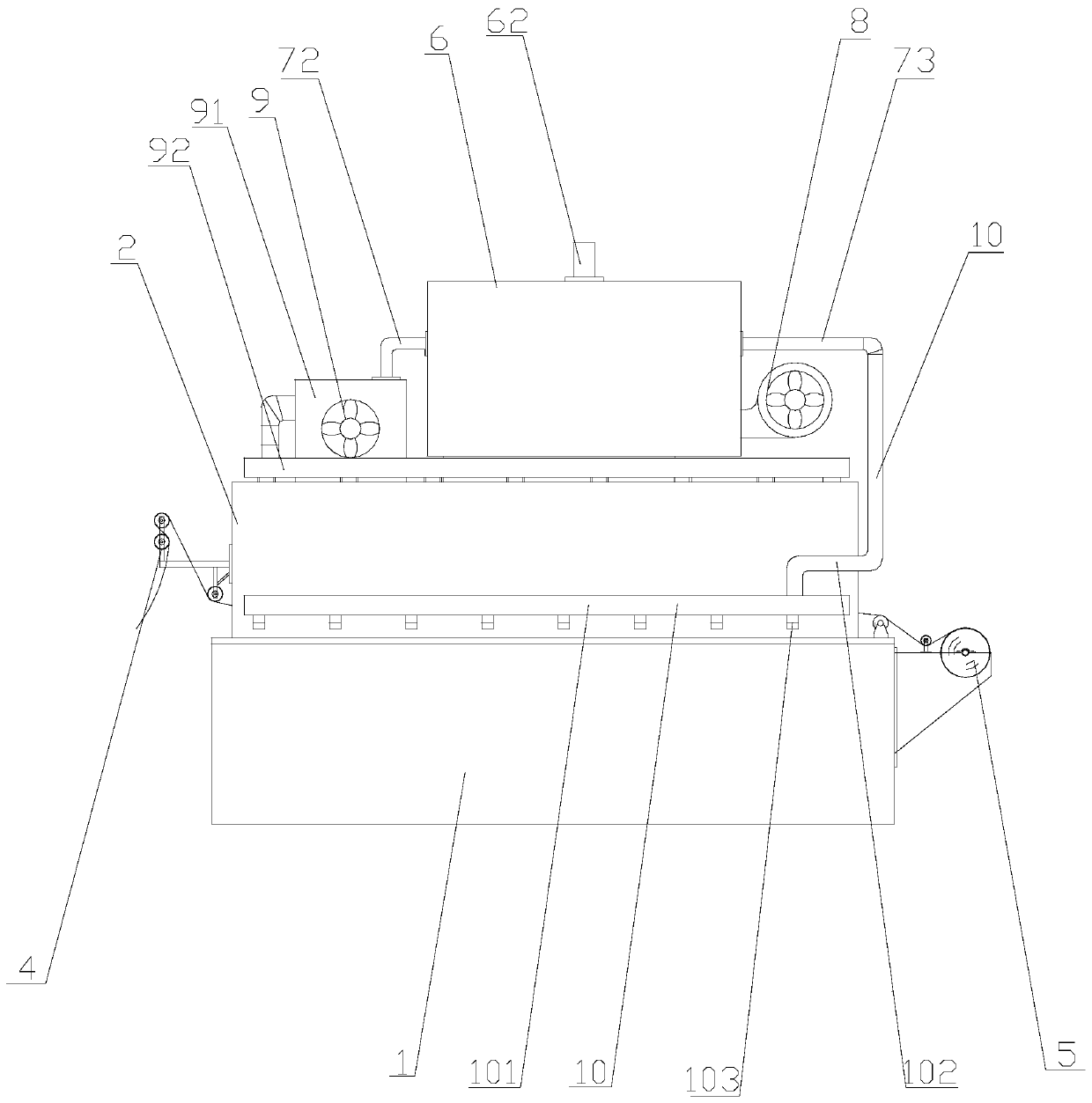

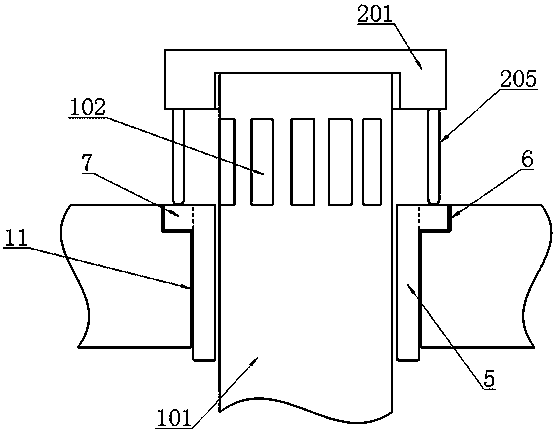

Heat dissipation device for new energy drying machine

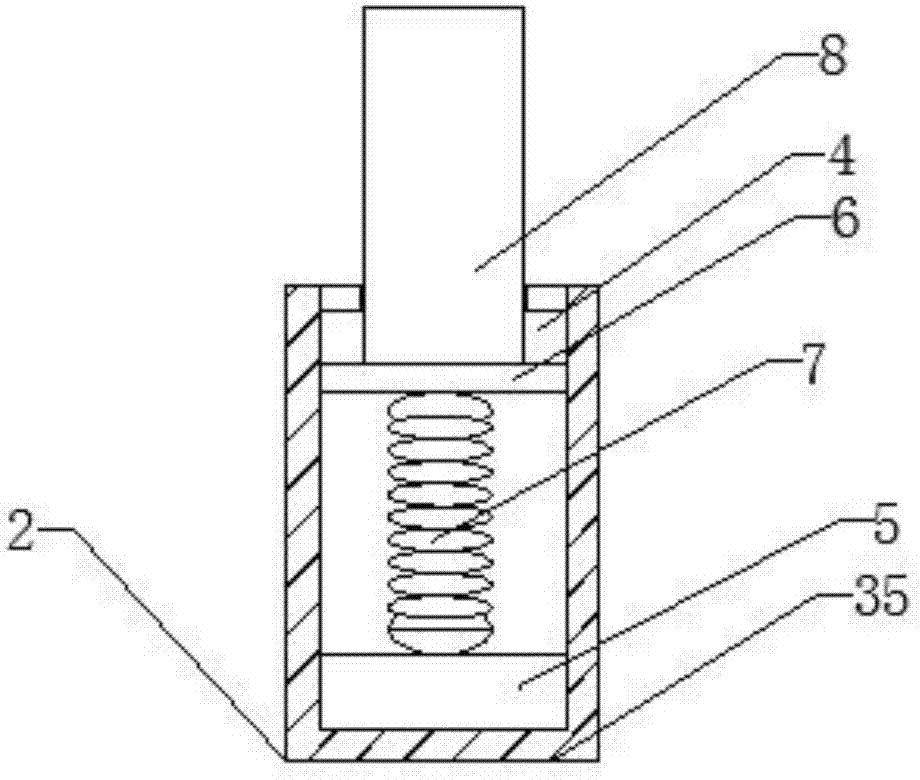

PendingCN113339296AResilientSo as not to damagePump componentsDrying solid materialsThermodynamicsNew energy

The invention discloses a heat dissipation device for a new energy drying machine. The heat dissipation device comprises a heat dissipation device body, the heat dissipation device body internally comprises a first shell, circular grooves, dust removal devices, cylinders and fan blades, the circular grooves are formed in the left end and the right end of the top of the first shell correspondingly, and the dust removal devices are arranged at the ends, away from each other, of the inner walls of the two circular grooves correspondingly; and the cylinders are arranged at the axis positions inside the two circular grooves correspondingly. According to the heat dissipation device, a cleaning mechanism is arranged, and therefore dust on the surfaces of the fan blades can be cleaned; when a fixing plate is hit, part of stress can be reduced through a spring, and rapid rebounding can be achieved; stress can be greatly reduced through a rebounding mechanism; an air bag has certain toughness and is not prone to being damaged through an arc-shaped plate arranged inside; an elastic rope pulls an elastic piece to reset when the rebounding mechanism deforms due to the stress; and the elastic piece is arranged so that the air bag can have the toughness and the rebound reset effect.

Owner:黄亮

Rubber particle drying device

InactiveCN111520990AWith lifting functionEasy to put inDrying gas arrangementsDrying chambers/containersProcess engineeringDrying time

Owner:郑家强

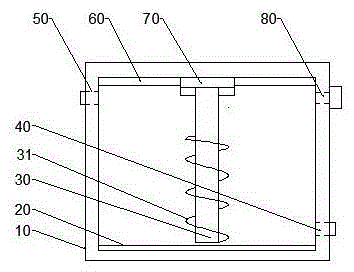

Granulation device

InactiveUS20100058612A1Reduced dimensionDrying gas arrangementsGranulation in stationary drums/troughsEngineeringBiomedical engineering

Owner:ZANCHETTA & C SRL

Spinning gauze lossless drying equipment

InactiveCN106766791AAcceptance balanceAvoid lossDrying gas arrangementsDrying machines with progressive movementsInternal pressureWater vapor

Owner:响水县嘉禾纺织制衣有限公司

Drying device for processing of stone building materials

InactiveCN110849100ADischarge in timeAchieve heat preservationDrying gas arrangementsDrying chambers/containersArchitectural engineeringStructural engineering

Owner:天门市天安建材有限公司

Disinfecting dryer

Owner:CHONGQING UNION MACHINE MFG

Drying device for fluororesin particle production

InactiveCN108534492AEasy to moveImprove drying efficiencyGranular material dryingDrying gas arrangementsEngineeringAir heater

The invention discloses a drying device for fluororesin particle production. The drying device for fluororesin particle production comprises a drying barrel; a base is arranged on the lower side of the drying barrel, and a swinging device is connected between the drying barrel and the base; a feeding port is formed in the top of the end, away from the swinging device, of the drying barrel, and anair inlet is formed in the end, close to the feeding port, of the drying barrel; the end, away from the drying barrel, of the air inlet is connected with a corrugated pipe; the end, away from the airinlet, of the corrugated pipe is connected with an air heater; a stirring device is arranged in the drying barrel, and comprises a stirring rotating shaft, stirring rods and stirring balls; the stirring rotating shaft is rotationally connected in the drying barrel; the uniformly distributed stirring rods are arranged on the outer side of the stirring rotating shaft; each stirring rod is provided with the corresponding stirring balls at equal intervals; and a stirring motor is installed at the end, away from the air inlet, of the drying barrel through a screw. According to the drying device forfluororesin particle production, fluororesin particles are dried through hot air, in the drying process, the stirring device and the swinging device are used for increasing flowing of the fluororesinparticles, and the drying efficiency is improved.

Owner:HUZHOU HEXUANZHU NEW MATERIAL TECH CO LTD

Direct combustion type hot air penetration internal circulation drying device for non-woven fabric production

PendingCN110500865AAchieve cycleEasy drying processDrying gas arrangementsDrying machines with progressive movementsFiberCombustor

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

Condensed water recycling device for textile printing and dyeing dryer

ActiveCN111457713AImprove cleanlinessReasonable and effective rotary scraping structureTextile treatment machine arrangementsDrying solid materialsTextile printerWater use

Owner:福建省新宏港纺织科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap