Collecting material-distributing device

A technology of integrated variable material distributor and material distribution rod, which is applied in the field of integrated variable material distributor, can solve the problems of uneven feeding of the blanking guide column and dead angle of the integrated variable material distributor, so as to solve the problem of uneven feeding , Improve the uniformity characteristics, eliminate the effect of the possibility of dead ends in circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

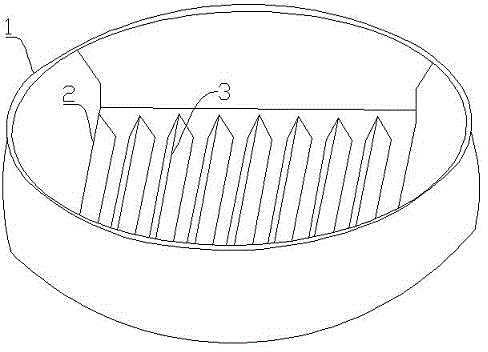

[0010] Such as figure 1 As shown, this embodiment includes an upper circular feed port 1 and a lower square discharge port, the feed port 1 and the discharge port 2 are integrated, and several triangular prism distribution rods are arranged in the discharge port 2 3. Adopt the form of square circle transition to reduce the dead angle of material circulation. The inclined surface of the discharge port 2 is smooth, and the inclined surface flow angle can reach 133 degrees. , in order to increase its supporting strength, the interior is designed with a lined rib plate to increase the strength, and it is truly stable, durable, smooth and has no dead angle vacuum.

[0011] The triangular-shaped material distribution rod 3 is connected with the inner wall of the discharge port 2 through a rotating shaft. In order to prevent the material from being

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap