Condensed water recycling device for textile printing and dyeing dryer

A technology of textile printing, dyeing and drying machine, which is applied in the direction of processing textile material equipment configuration, drying, and drying solid materials, etc., can solve the problems that the cloth fluff cannot be separated, affect the reuse of condensed water, etc., and achieve a reasonable structure of rotary scraping. Effective, clean and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

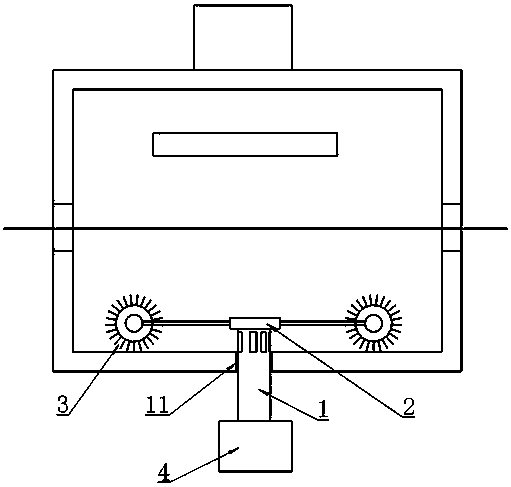

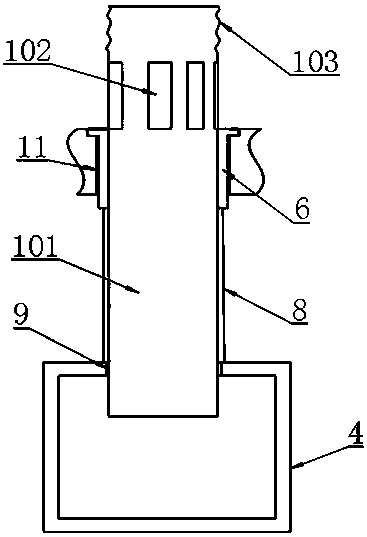

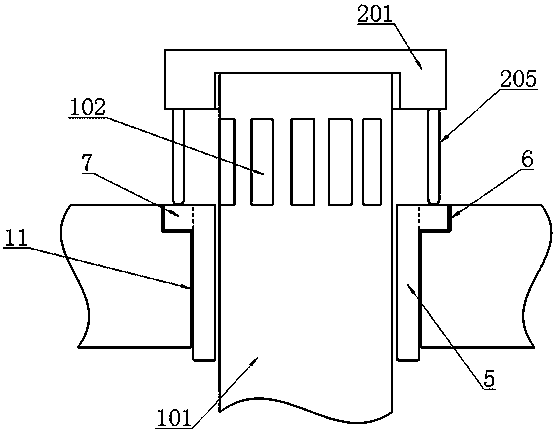

[0024] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Figure 6 As shown, a textile printing and dyeing dryer condensed water recovery and reuse device includes a drain pipe unit 1 that is plugged and arranged on the drain hole 11 of the dryer and is provided with an annular opening, and is arranged on the drain pipe unit 1 The installation cover unit 2 at the upper end of the outer ring and fixed on the inner bottom surface of the dryer is set on the installation cover unit 2 and is used to rotate and remove the lint in the condensed water by driving downward with hot air The rotating brush body unit 3, and the water receiving box 4 arranged at the nozzle position of the lower end of the drain pipe unit 1.

[0025] In this embodiment, the structure of the drying machine is set according to the existing technology, that is, the electric heating wire is energized and heated above the cloth, and the exhaust fan is located in the middle to form the action of blowing hot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap