Stirring impeller and apparatus therewith and method therefor

A technology of stirring blade and stirring device, which is applied in the field of stirring device and stirring blade, can solve the problems of inability to stir treatment, fine particles generated by suspension polymerization, small area, etc., and achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

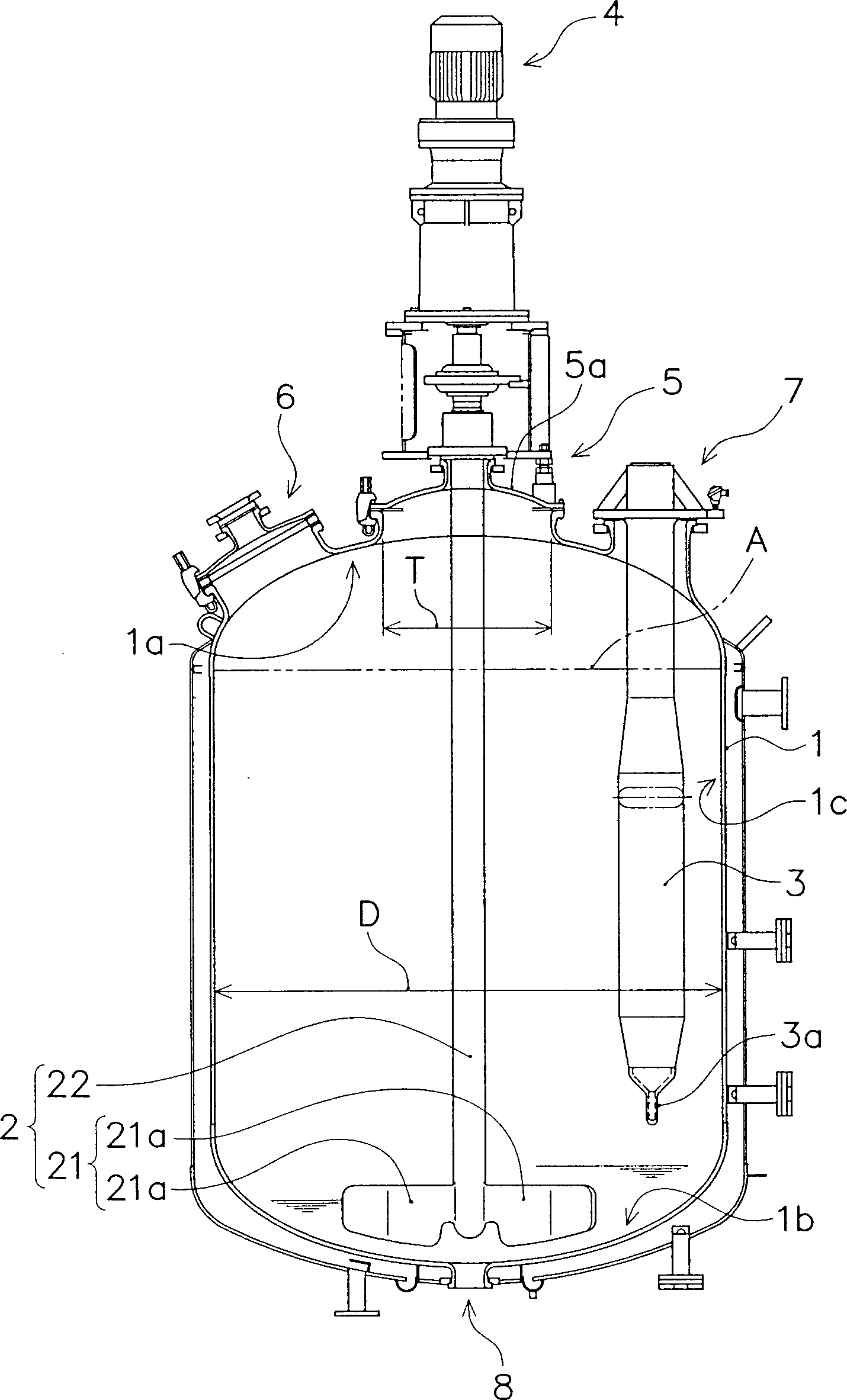

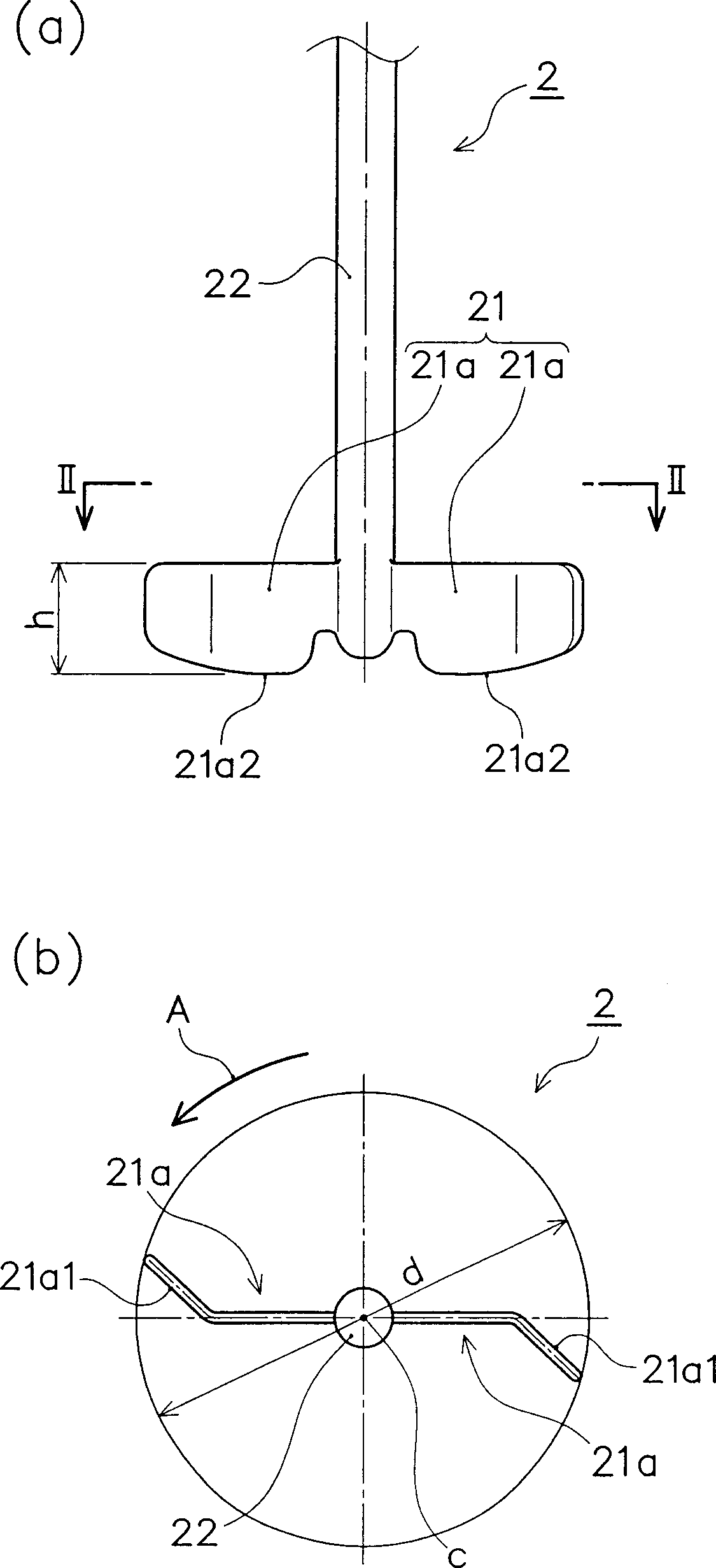

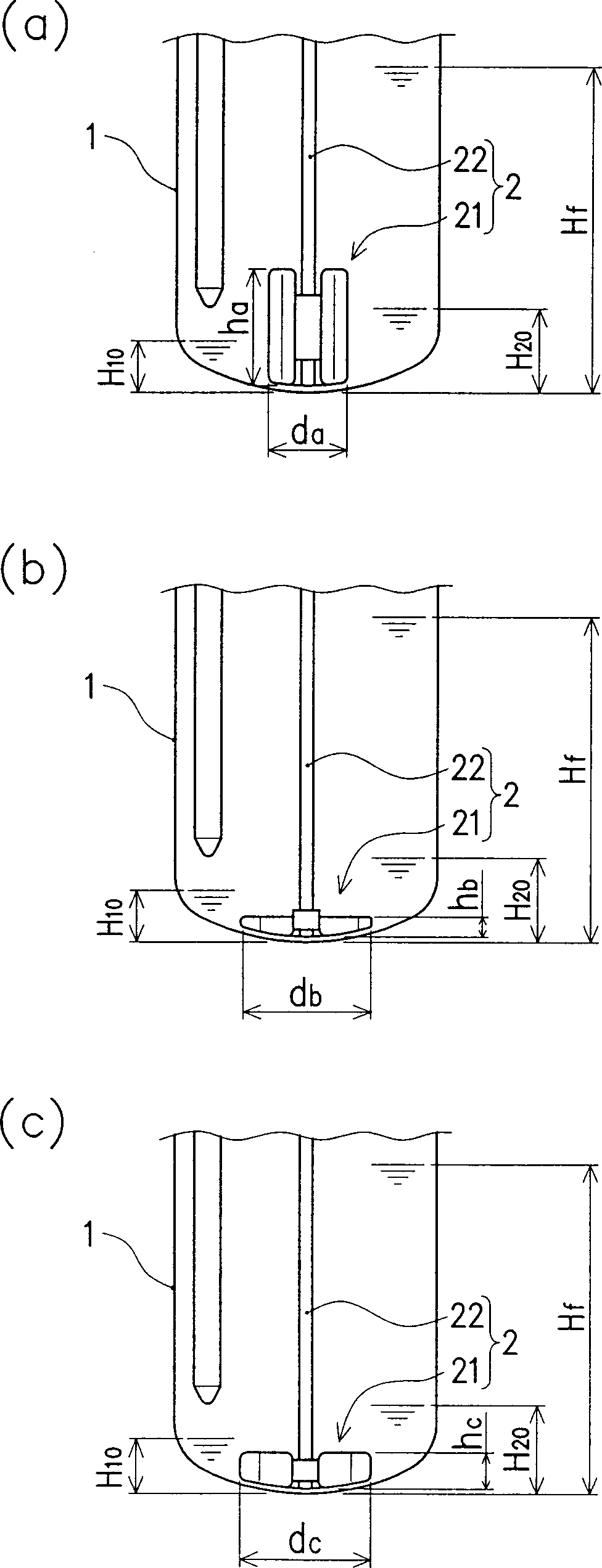

[0043] figure 1 This is a schematic diagram showing a stirring device according to an embodiment of the present invention. The stirring device includes a stirring tank 1 having a vertical cylindrical shape, a stirring blade 2 rotatably installed in the stirring tank 1, a baffle portion 3 fixedly arranged at a predetermined position in the stirring tank 1, and the like. The stirring blade 2 is composed of a blade portion 21 and a stirring shaft 22. The blade portion 21 is composed of two blade configuration portions 21a. The stirring shaft 22 is connected to a driving portion 4 provided at an upper portion outside the stirring tank 1 and driven to rotate.

[0044] The stirring tank 1 has a vertical cylindrical shape as described above, and a stirring blade installation port 5 used to install the stirring blade 2 inside the stirring tank 1 is provided on the top 1a, and used w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap