Rubber particle drying device

A technology of rubber granules and drying device, which is applied in the directions of drying gas arrangement, drying solid materials, drying chamber/container, etc., can solve the problems of increasing drying time, inability to adjust spacing, and inability to adjust, so as to improve drying efficiency and shorten drying time. , the effect of shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

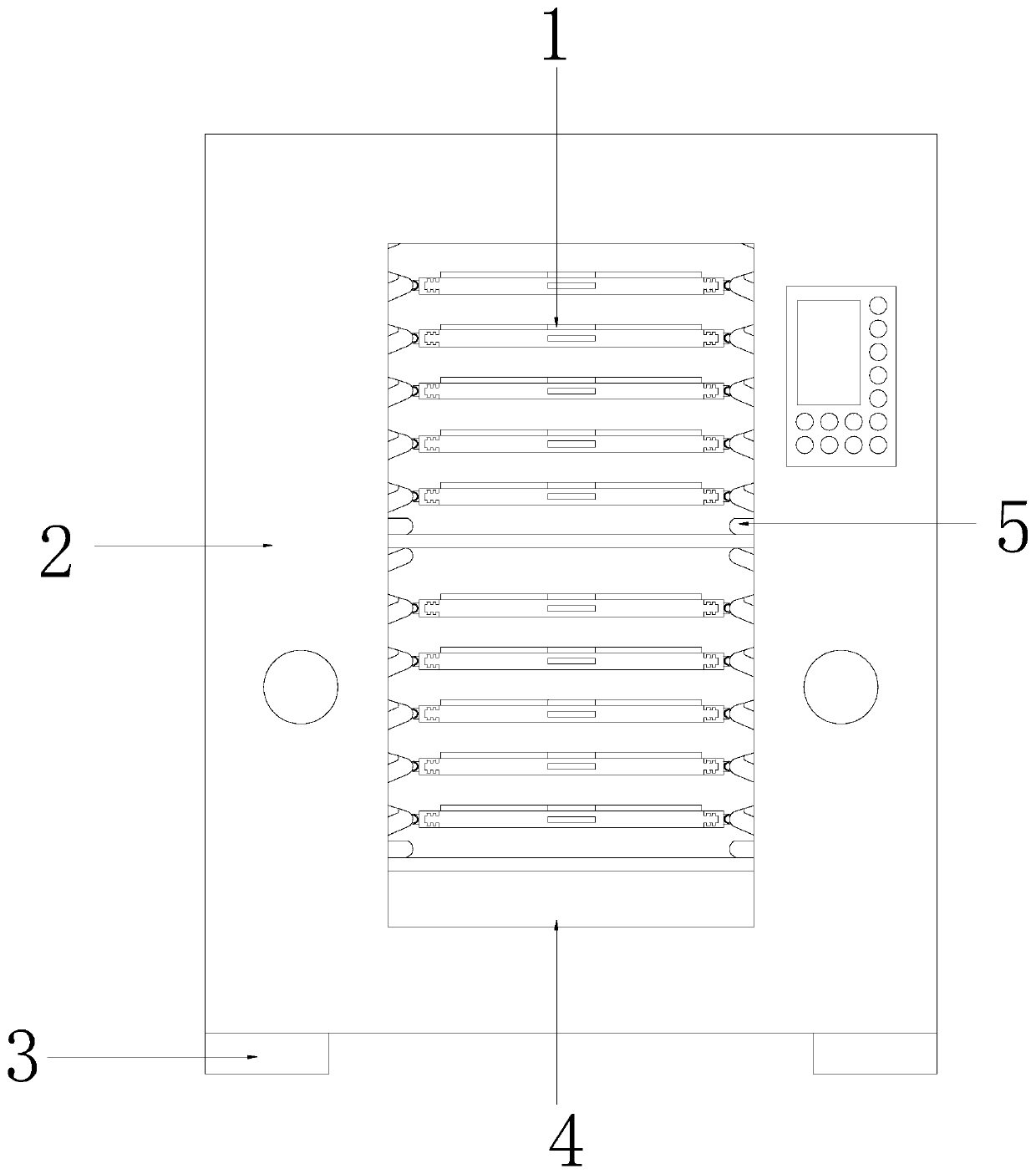

[0036] see Figure 1-7, the present invention provides a technical scheme of a rubber particle drying device: its structure includes a rubber particle drying rack 1, a drying body 2, a supporting foot 3, a rotary table 4, and a glass door 5, and the bottom of the drying body 2 is fixed with a supporting foot 3. The drying body 2 is equipped with a glass door 5, and the drying body 2 has a built-in rotary table 4, and the rotary table 4 is connected with a rubber particle drying rack 1, and the rubber particle drying rack 1 is also built in the drying body 2. The arrangement of the rotating table 4 enables the rubber granule drying rack 1 to rotate, which is beneficial to the uniform drying of the rubber granules and helps to improve the drying efficiency of the rubber granules.

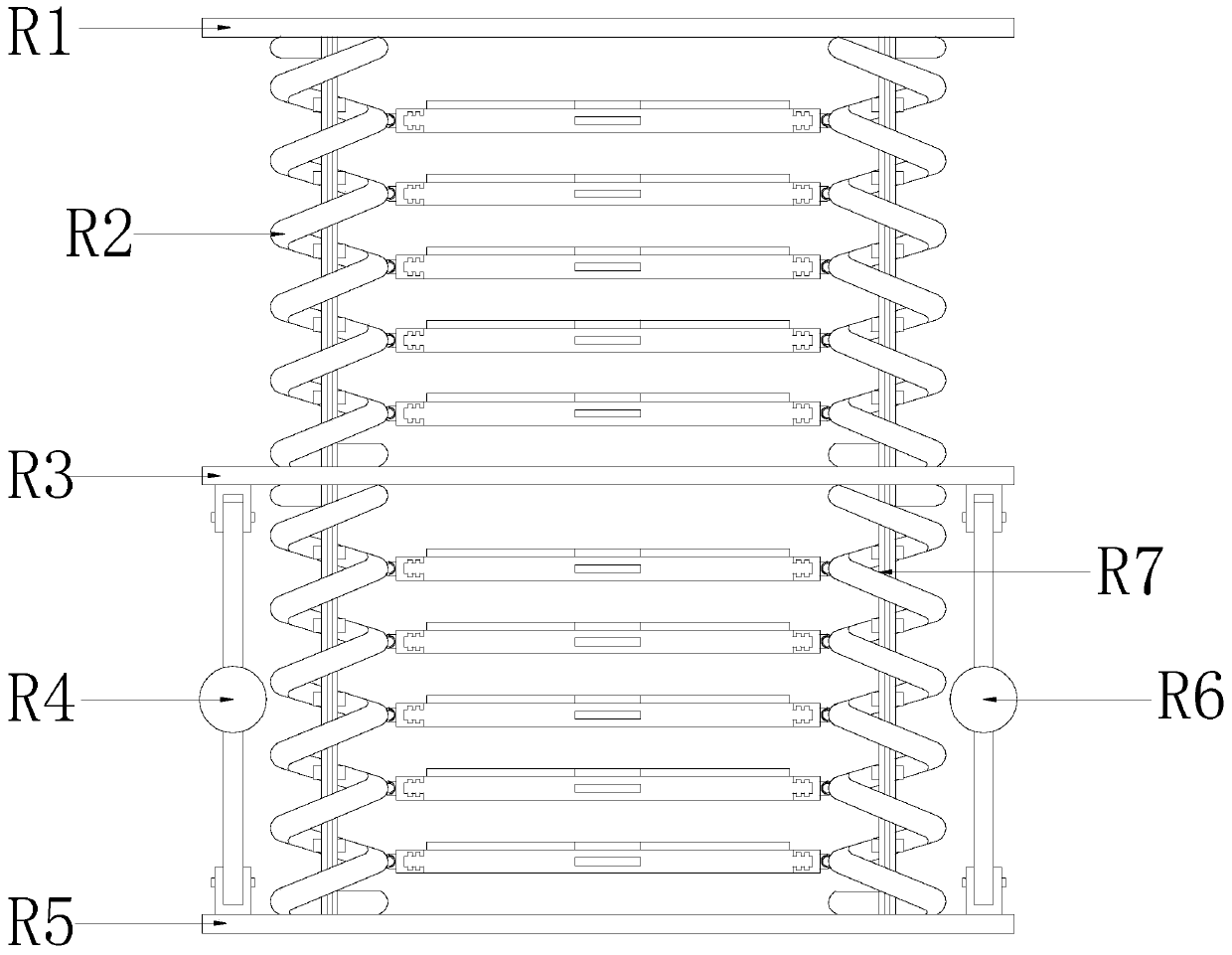

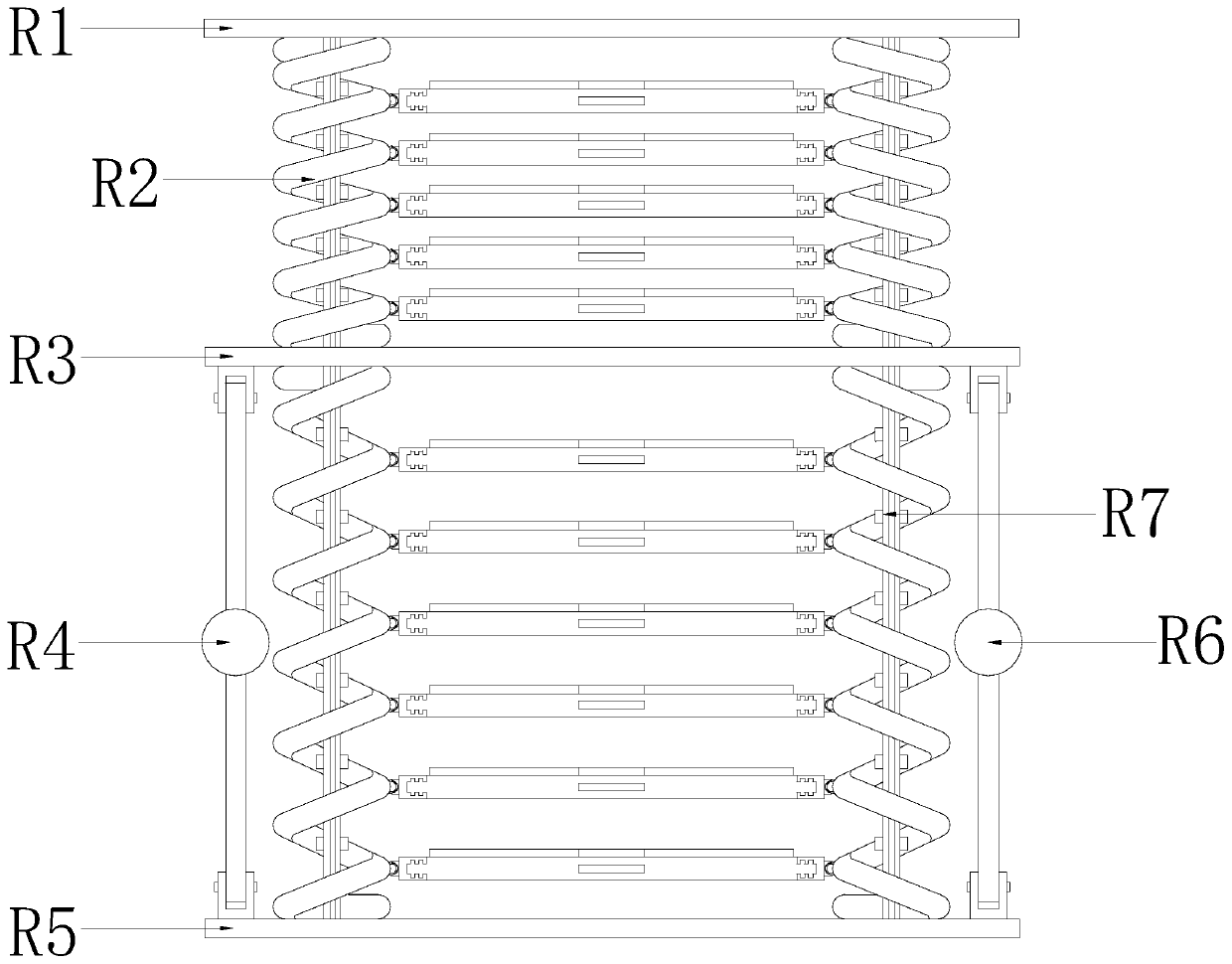

[0037] The rubber granule drying rack 1 includes a top plate R1, an upper rubber granule drying device R2, a partition plate R3, a No. 1 lifting device R4, a bottom plate R5, a No. 2 lifting device R6, a

Embodiment 2

[0041] see figure 1 , the present invention provides a technical scheme of a rubber particle drying device: its structure includes a rubber particle drying rack 1, a drying body 2, a supporting foot 3, a rotary table 4, and a glass door 5, and the bottom of the drying body 2 is fixed with a supporting foot 3. The drying body 2 is equipped with a glass door 5, and the drying body 2 has a built-in rotary table 4, and the rotary table 4 is connected with a rubber particle drying rack 1, and the rubber particle drying rack 1 is also built in the drying body 2. The arrangement of the rotating table 4 enables the rubber granule drying rack 1 to rotate, which is beneficial to the uniform drying of the rubber granules and helps to improve the drying efficiency of the rubber granules.

[0042] see Figure 2-5 , the rubber granule drying rack 1 includes a top plate R1, a drying device R2 on the rubber granules, a partition plate R3, a No. 1 lifting device R4, a bottom plate R5, a No. 2 l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap