Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Dry gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drygas is an alcohol-based additive used in automobiles to prevent any water in the fuel from freezing, or to restore combustive power to gasoline spoiled by water. The name Drygas is actually a registered trademarked brand name, owned by Cristy Corporation. It is a liquid that is added into the fuel tank, that absorbs the water and keeps it in solution. Some brands contain methanol and some contain isopropyl alcohol.

Method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas

InactiveCN101691210ALess investmentLow running costSulfur compoundsDispersed particle separationWater vaporTitanium

The invention discloses a method for concentrating titanium white waste acid by utilizing sulfuric-acid production tail gas. The method comprises the following steps: (1) supplying sulfuric-acid production tail gas to titanium white waste acid sprayed to be in a mist state, concentrating the titanium white waste acid and turning the sulfuric-acid production tail gas from dry gas into wet gas containing steam and titanium white waste acid foam; (2) performing gas-liquid separation on the wet gas, treating and then emptying separated gas, mixing separated liquid with the titanium white waste acid concentrated in a step (1) and then repeatedly concentrating the mixture; and (3) performing sampling test on the titanium white waste acid repeatedly concentrated and recovering the titanium white waste acid when the sulfuric acid content of the titanium white waste acid in percentage by mass is detected to reach over 55 percent. The method has the advantages of simple equipment, convenient operation, low investment, low energy consumption, low operation-maintenance cost, capability of avoiding pipeline blockage because of high-temperature scaling and capability of reducing the pressure to treat sulfuric-acid production tail gas.

Owner:WUHAN QINGJIANG CHEM IND

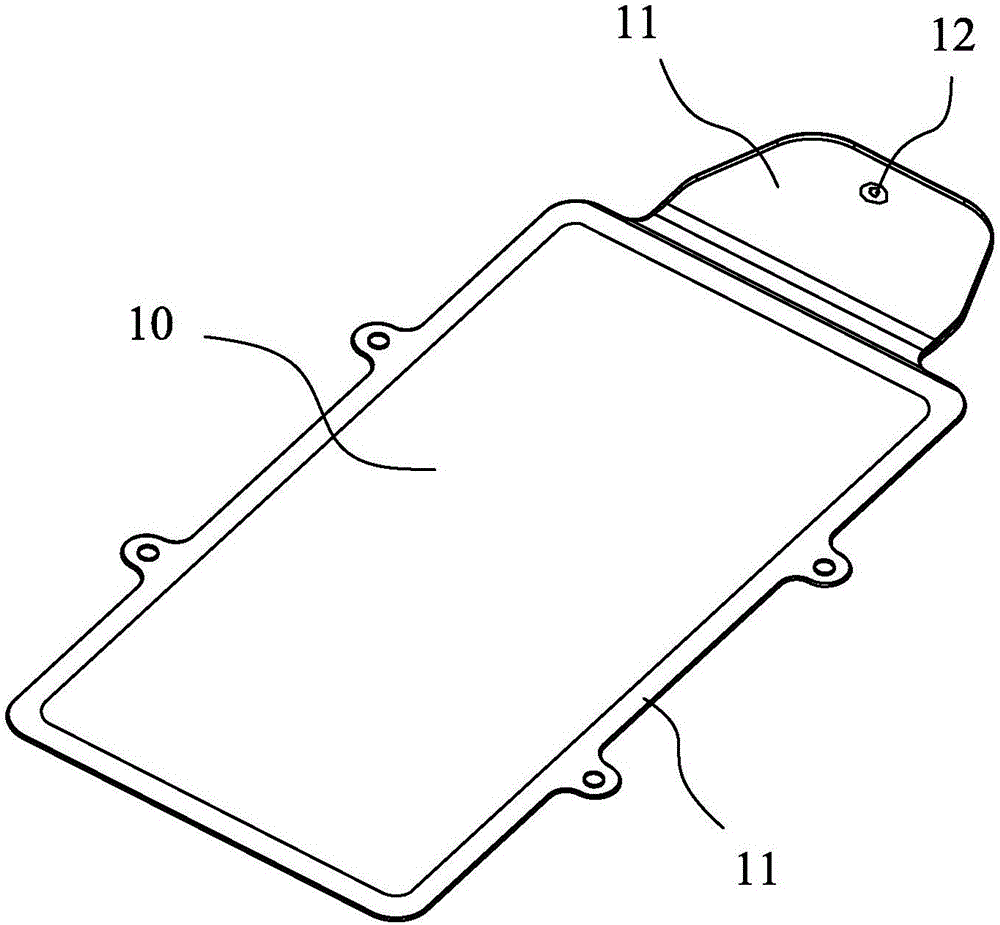

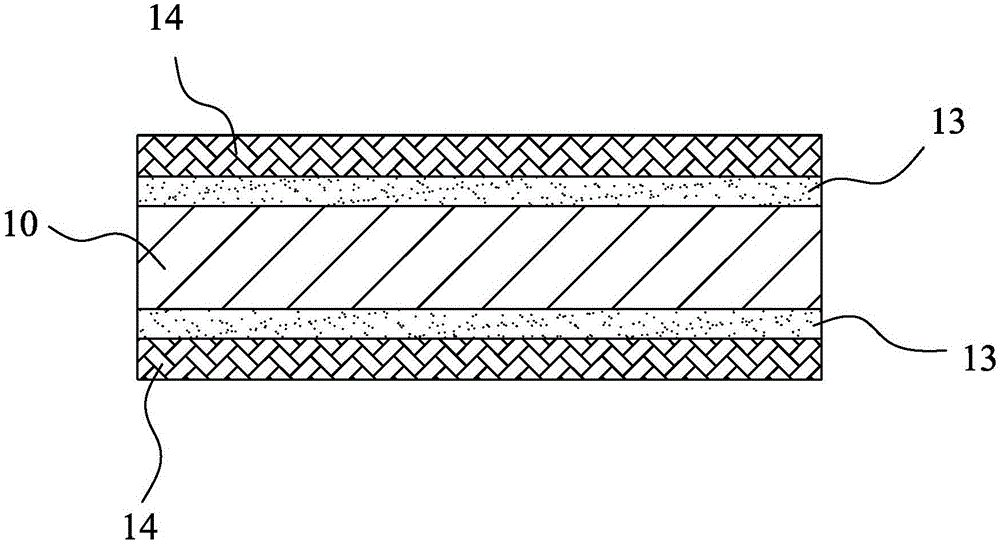

Manufacturing method of high-hardness plastic screen and housing of mobile phone and mobile phone screen and housing manufactured thereby

ActiveCN105922525AHigh hardnessReduce use costSynthetic resin layered productsTelephone set constructionsRainbowAdhesive

Owner:DONGGUAN JIAOJIN ELECTRONICS TECH CO LTD

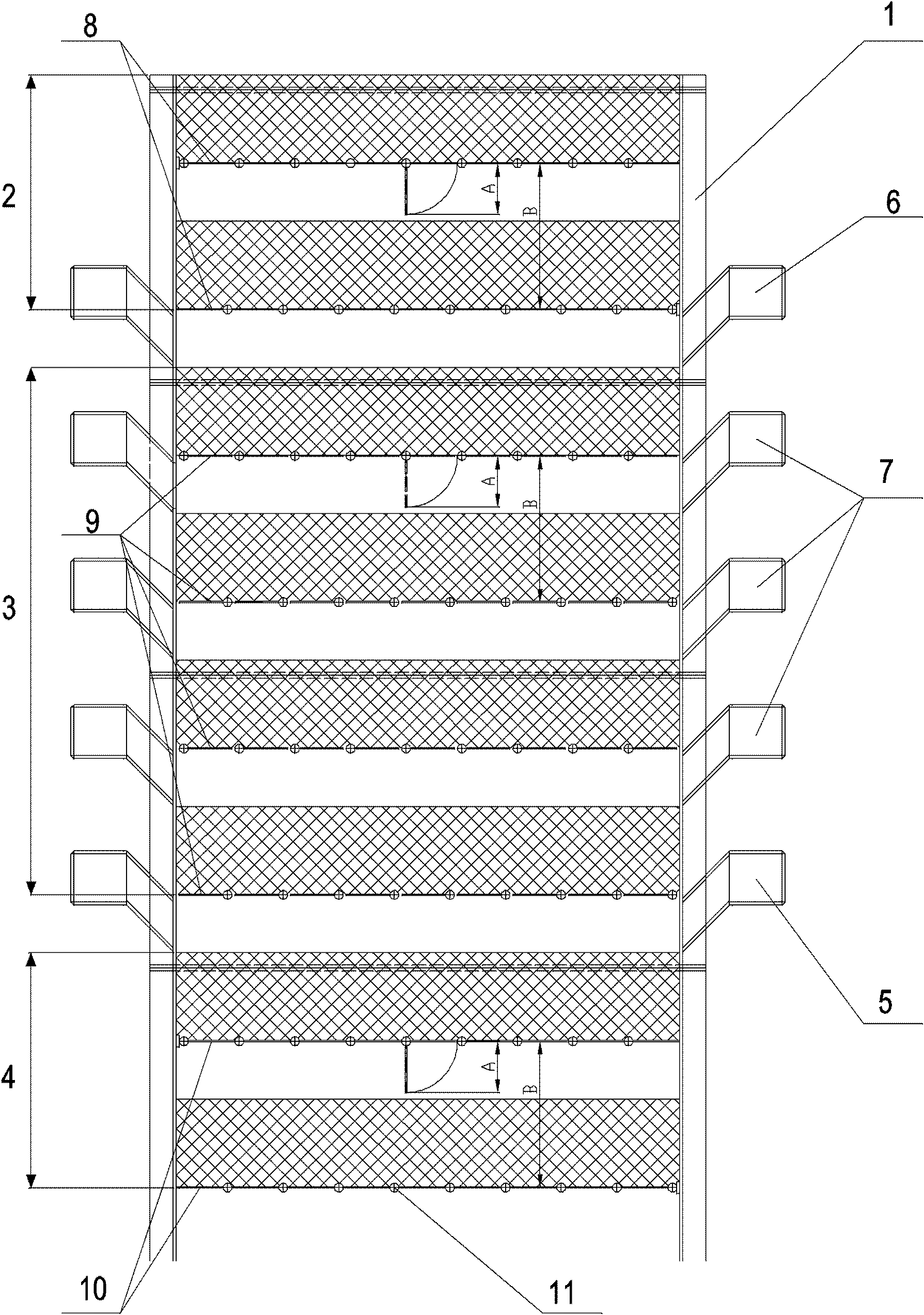

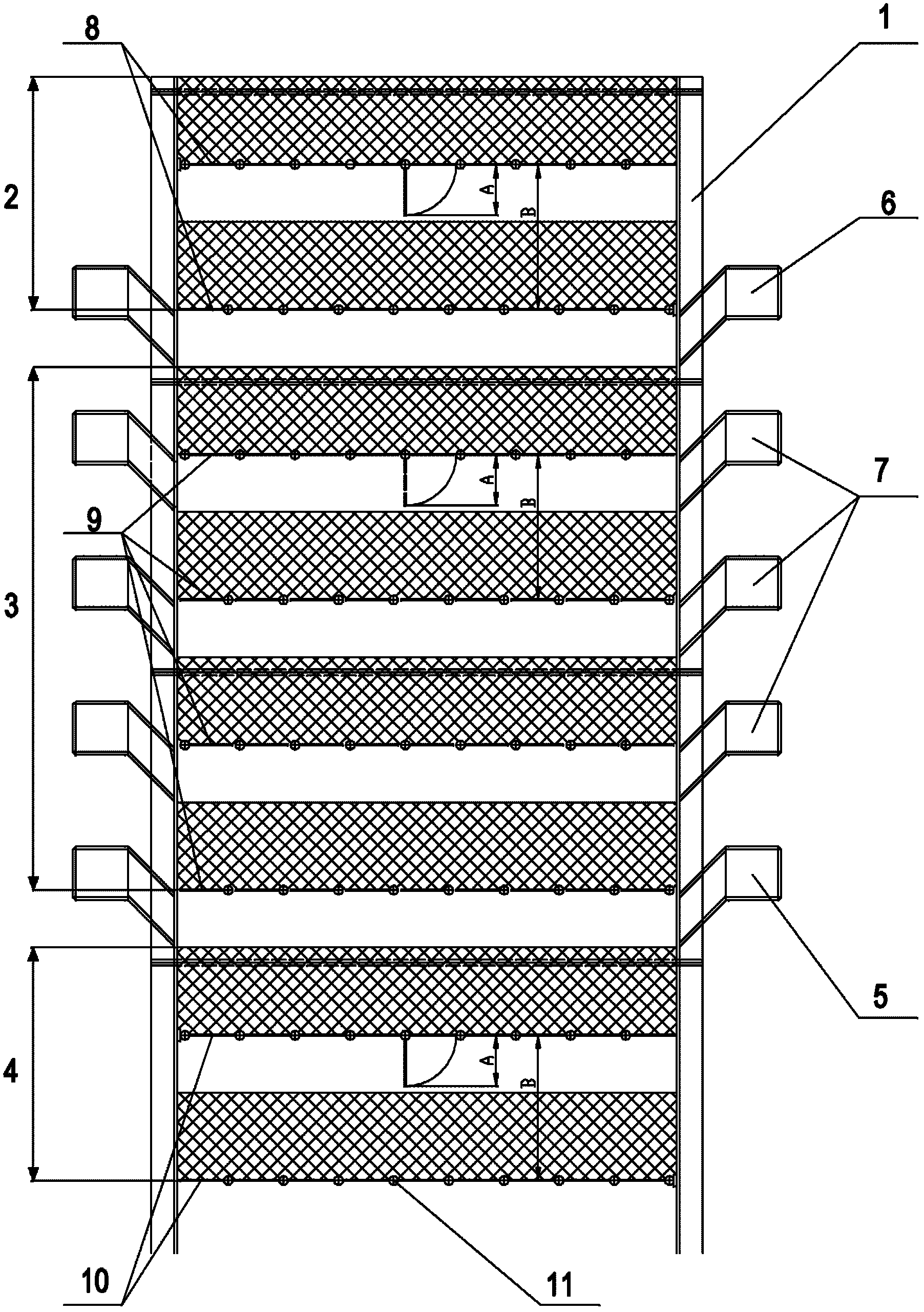

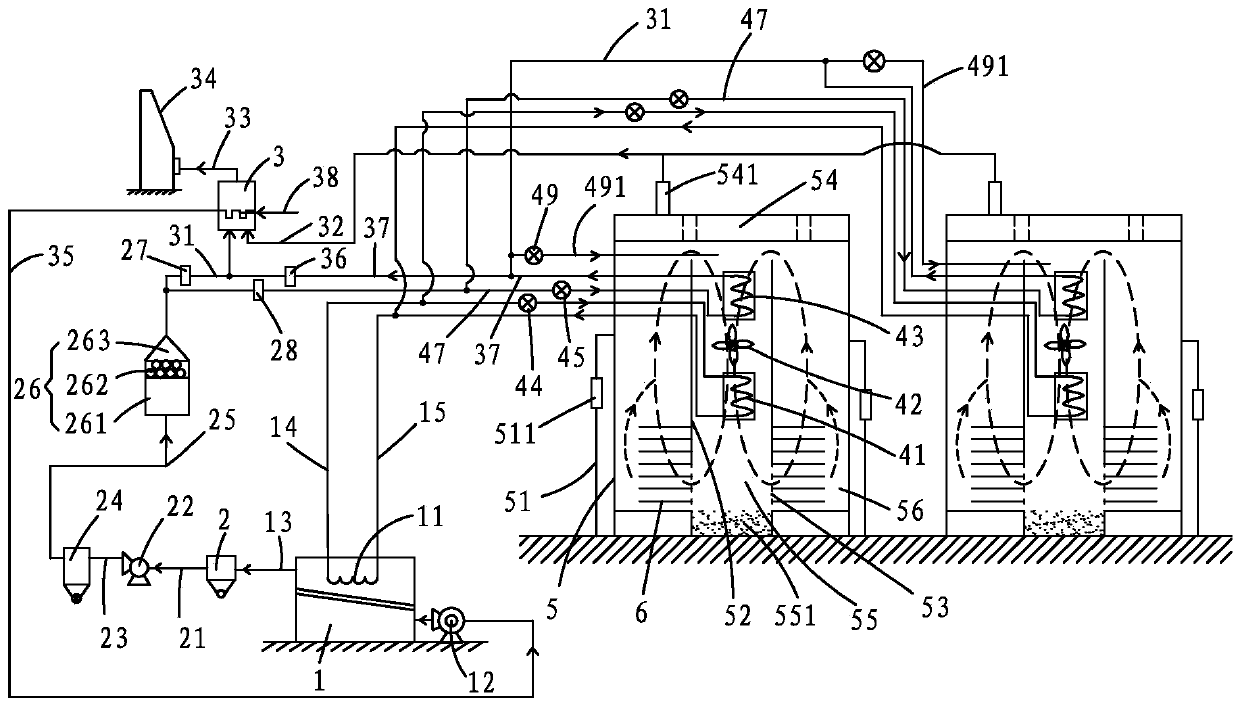

Open type absorption heat pump-MVR technology coupled closed cycle drying system

ActiveCN111947443AReduce trafficReduce the risk of entrainmentEnergy efficient heating/coolingClimate change adaptationThermodynamicsEngineering

The invention discloses an open type absorption heat pump-MVR technology coupled closed cycle drying system which comprises an open type absorption heat pump system and a mechanical compression heat pump cycle system. An outlet of a mechanical heat pump compressor is divided into two paths, one path is in pipeline connection with a hot channel inlet of a heat removal device through a hot channel of a condenser, and the other path is in pipeline connection with the hot channel inlet of the heat removal device through a 2# heat and mass exchanger; and a hot channel outlet of the heat removal device is connected with an expansion valve through a pipeline, an outlet of the expansion valve is divided into two paths, one path is in pipeline connection with an inlet of the mechanical heat pump compressor through a 1# heat and mass exchanger, the other path is in pipeline connection with the inlet of the mechanical heat pump compressor through a cold channel of an evaporator, and a mechanicalcompression type heat pump cycle system is formed. According to the open type absorption heat pump-MVR technology coupled closed cycle drying system, absorbed heat is used for regenerating a dilute solution through the mechanical compression type heat pump cycle system, regenerated steam is used for heating dry gas after the grade of the regenerated steam is improved through an MVR technology; andby means of the open type absorption heat pump-MVR technology coupled closed cycle drying system, a large amount of latent heat in damp and hot gas exhausted by a dryer can be reasonably utilized.

Owner:ZHEJIANG UNIV OF TECH +1

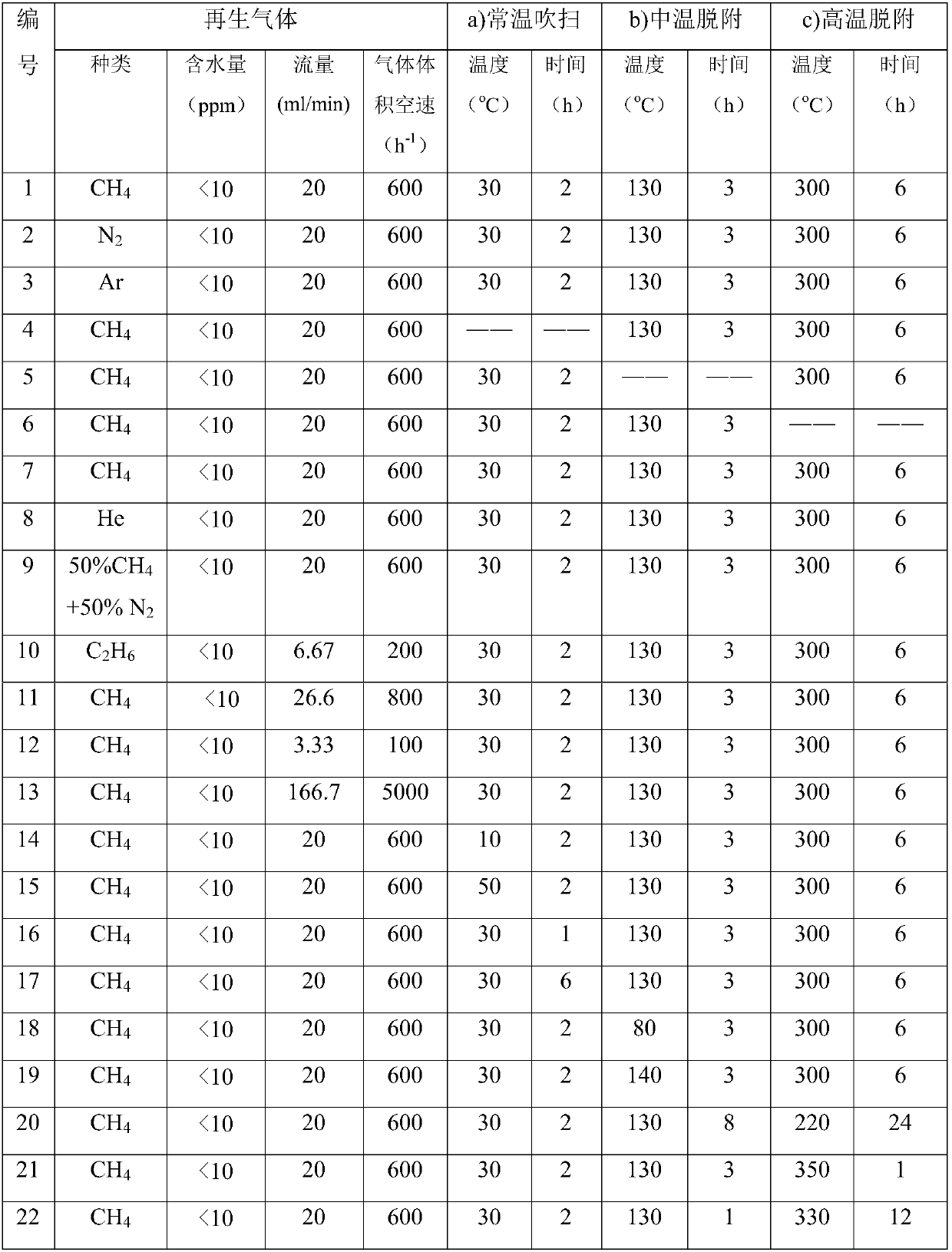

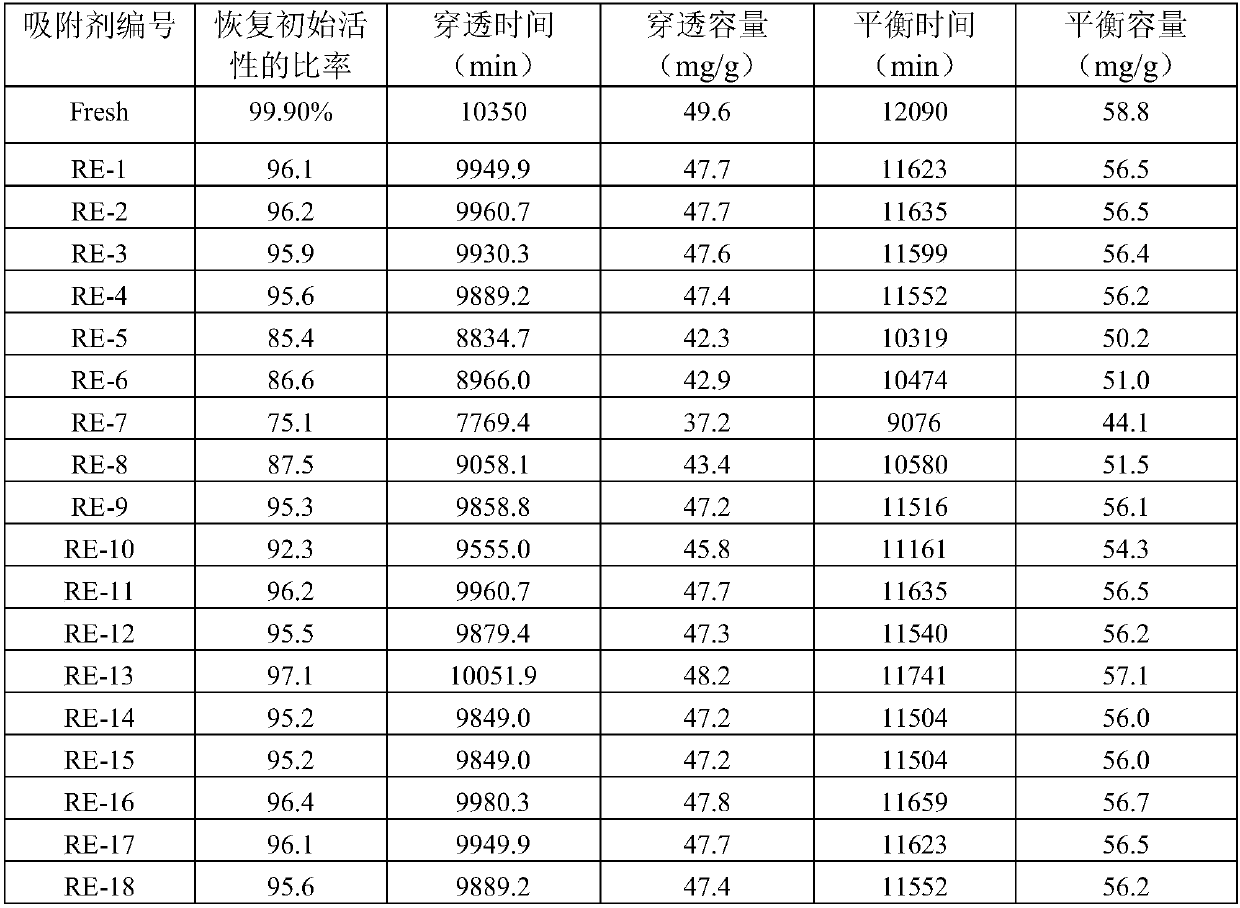

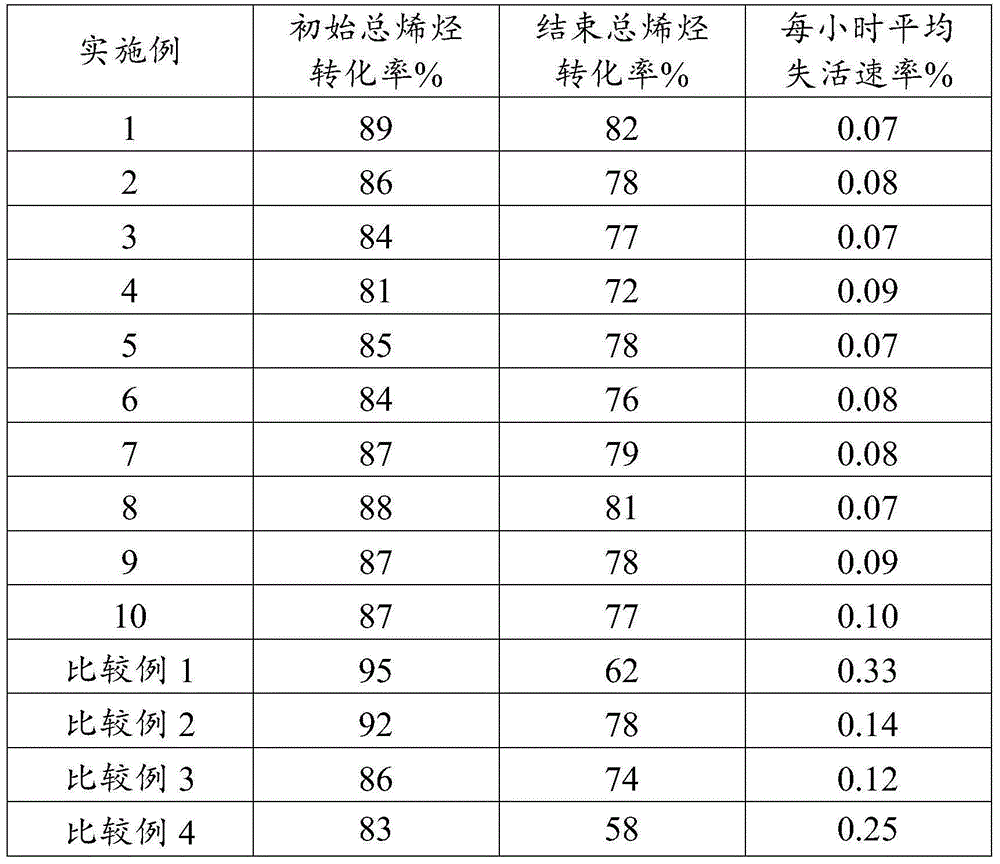

Regeneration method for removing oxygen compound containing adsorbent in low-carbon olefins

ActiveCN107774239ACombustible gas purificationHydrocarbon oils refiningOxygen compoundDry gas

Owner:CHINA PETROLEUM & CHEM CORP +1

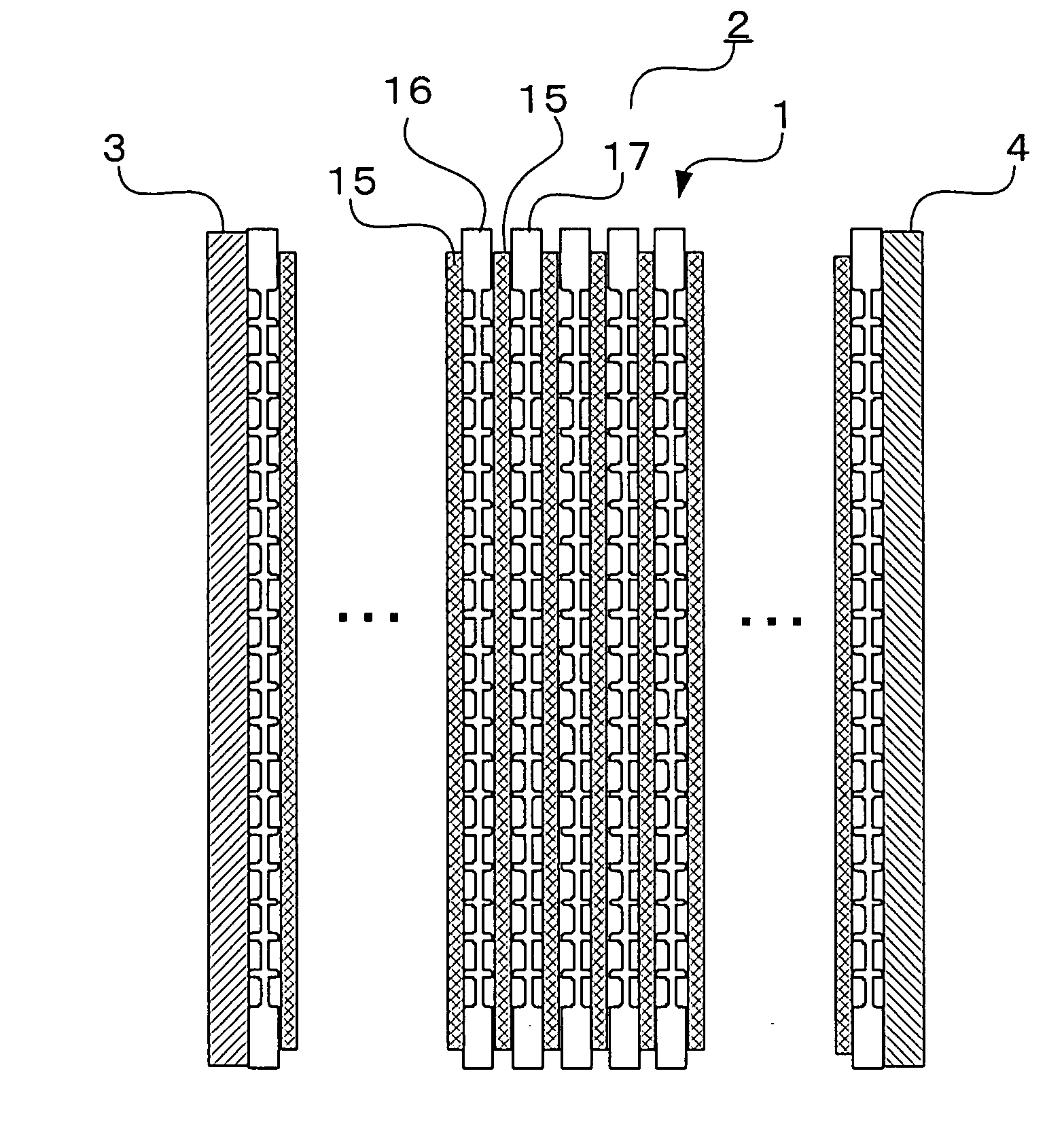

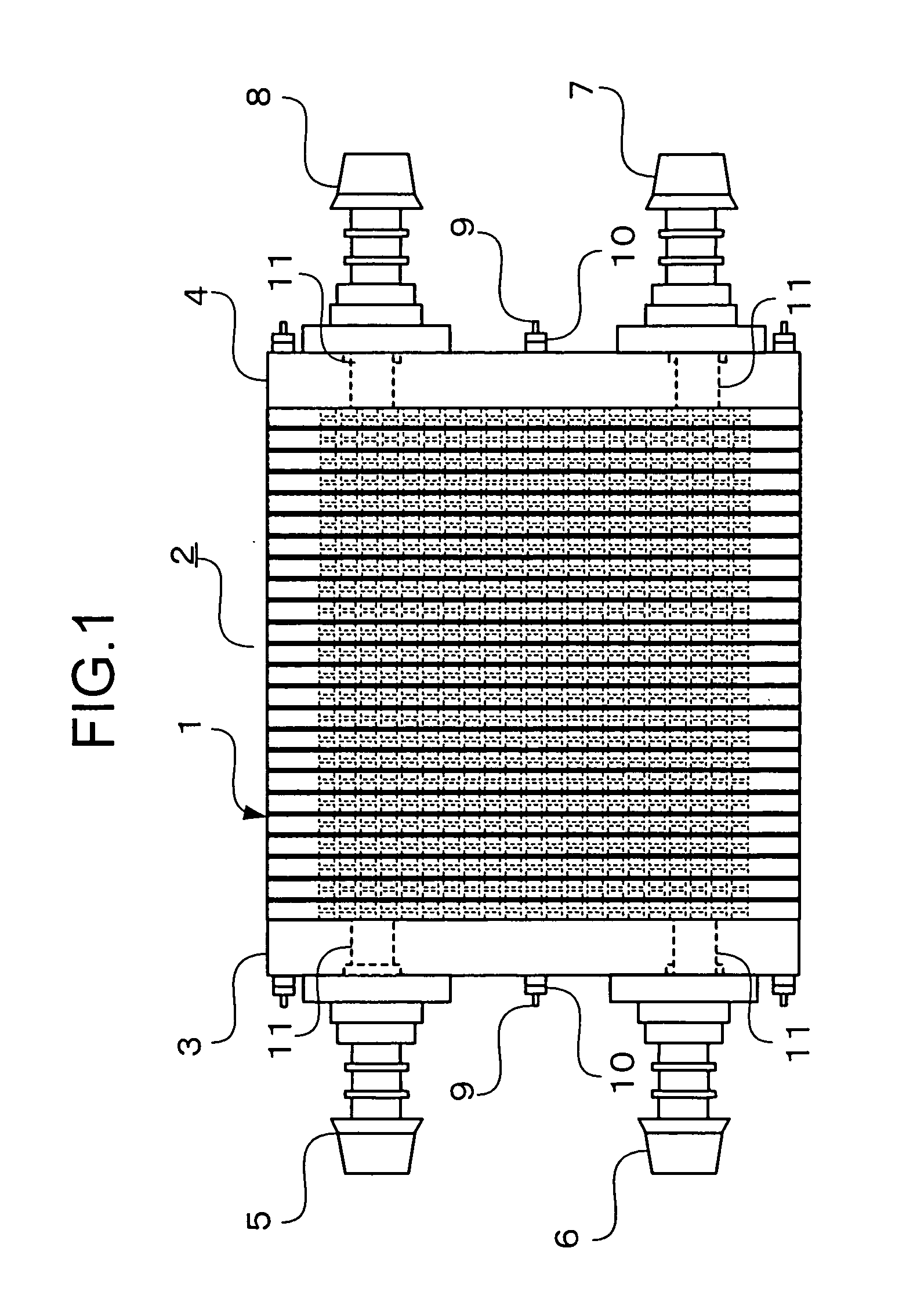

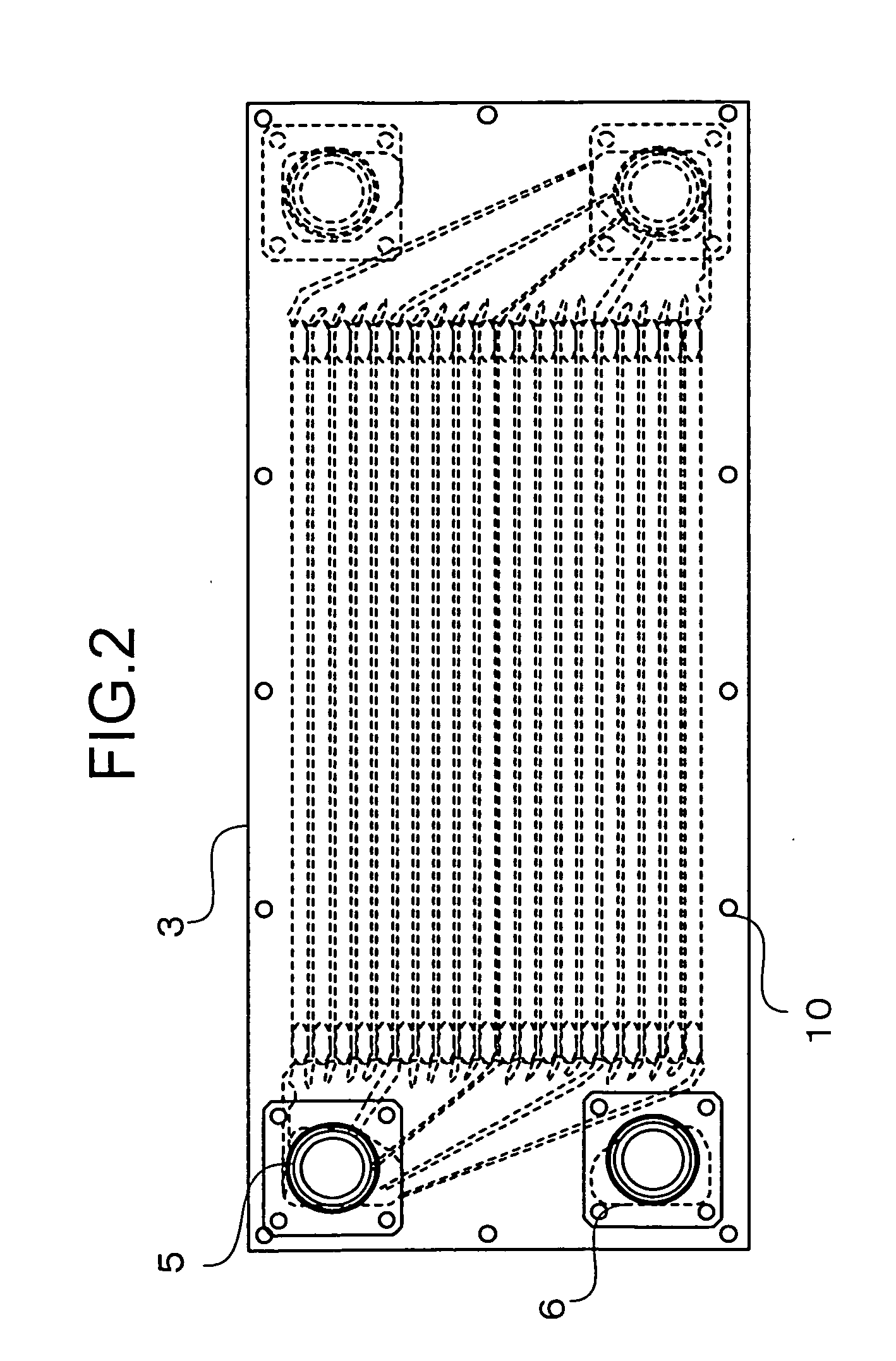

Temperature/humidity exchanger

InactiveUS20070107454A1Raise the dew pointRestrict pressure lossUsing liquid separation agentSolid sorbent liquid separationProduct gasEngineering

Owner:MITSUBISHI ELECTRIC CORP

Fuel cell humidifier device, fuel cell system and humidifying treatment method of fuel cell system

The invention provides a fuel cell humidifier device, a fuel cell system and a humidifying treatment method thereof. The humidifier device comprises a shell, middle-through fiber membrane tubes, a diaphragm and an end cap, a first gas inlet and a first gas outlet for wet gas are formed in the same sides of the two ends of the shell, and the middle-through fiber membrane tubes have different diameters; and the middle-through fiber membrane tubes are located in the shell, the shell is divided into an upper cavity and a lower cavity by the diaphragm, the middle-through fiber membrane tubes suitable for circulation of the dry gas are arranged in the upper cavity, and the middle-through fiber membrane tubes suitable for circulation of the wet gas are arranged in the lower cavity. A plurality of micropores are evenly distributed in the middle of the diaphragm, the wet gas is suitable for entering the upper cavity from the lower cavity through the micropores, and the end cap is provided with a second gas inlet and a second gas outlet for dry gas. According to the novel structure designed in the invention, and the problem that an existing physical humidifier is prone to water accumulation, and operation of a fuel cell is affected is solved.

Owner:HUANGGANG GROVE HYDROGEN AUTOMOBILE CO LTD

Method for producing gasoline blending component from dry gas

InactiveCN106244224AMolecular sieve catalystsLiquid hydrocarbon mixtures productionBenzeneWater vapor

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent hot water source incense stick and tobacco drying room system

Owner:永安市亚林竹类研究所有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap