Intelligent hot water source incense stick and tobacco drying room system

A hot water source and intelligent technology, applied in the field of drying room system, can solve the problems of long time consumption, easy burn through of radiator tube wall, unsatisfactory low-temperature drying of tobacco leaves, etc., so as to reduce exhaust time and cooling time, cancel The dehumidification process cycle realizes the effect of multiple utilization of one gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

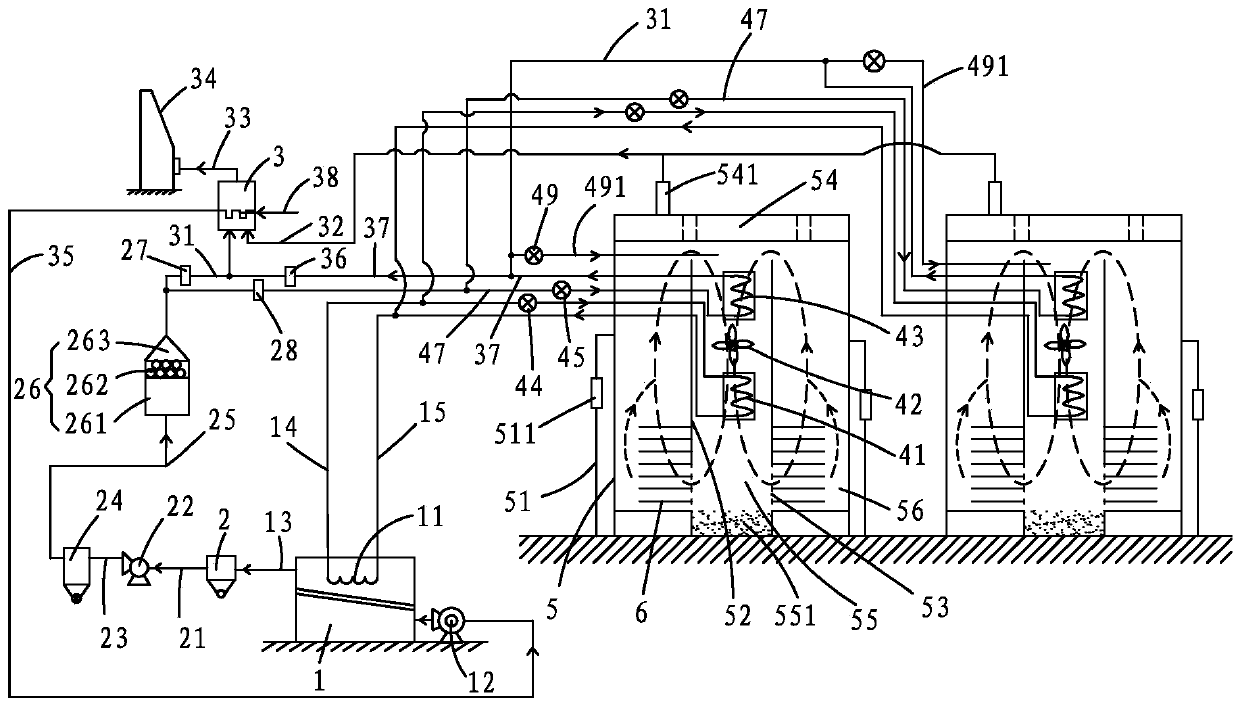

[0031] Such as figure 1 As shown, an intelligent hot water source fragrance core and tobacco leaf drying room system includes a hot water source boiler 1, a furnace gas discharge chimney 34, an electrostatic precipitator 2, a multi-tube dust collector 24, and a boiler induced draft fan 22 , a furnace gas cleaning device 26, a plurality of drying room devices 5, a plurality of drying room temperature and humidity control systems 54, a heat recovery device 3, and a plurality of furnace gas recovery pipes 491;

[0032] The hot water source boiler 1 has a hot water generator 11 and a boiler blower 12; the hot water generator 11 is connected to two heating pipelines 14 and 15, the heating pipeline 14 is connected to a flow regulating valve 44, and the flow regulating valve 44 is connected to each drying The upper end of the room device 5 hot water radiator 41, the heating pipeline 15 is connected to the lower end of each drying room device 5 hot water radiator 41; the boiler blower 12

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap